Abstract

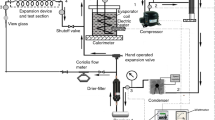

This paper experimentally evaluated the irreversibility in the components (compressor, condenser, capillary tube, and evaporator) of the vapor compression refrigeration system (VCRS) using R134a/LPG refrigerant as a replacement for R134a. For this aim, different tests were conducted for various evaporator and condenser temperatures under controlled surrounding conditions. The results reported that the irreversibilities in the components of VCRS using R134a/LPG blend were found lesser than irreversibilities in the components of VCRS using R134a under similar experimental conditions. Artificial neural network (ANN) models were developed to predict the second law of efficiency and total irreversibility of the refrigeration system. ANN and ANFIS model predictions were also compared with experimental results and an absolute fraction of variance in range of 0.980–0.994 and 0.951–0.977, root-mean-square error in the range of 0.1636–0.2387 and 0.2501–0.4542 and mean absolute percentage error in the range of 0.159–0.572 and 0.308–0.931%, respectively, were estimated. The outcomes suggested that ANN model shows better statistical prediction than ANFIS model.

Similar content being viewed by others

Abbreviations

- e :

-

Specific exergy, kJ kg−1

- S :

-

Entropy, kJ kg−1K−1

- T :

-

Temperature, K

- I :

-

Irreversibility, kW

- P :

-

Pressure, Bar

- h :

-

Enthalpy, kJ kg−1

- W :

-

Compressor power, kW

- Q :

-

Refrigeration capacity, kW

- M R :

-

Refrigerant charge, g

- LPG:

-

Liquefied petroleum gas

- ANN:

-

Artificial neural network

- ANFIS:

-

Adaptive neuro-fuzzy inference system

- ξ :

-

Mass flow rate, kg s−1

- η ex :

-

Second law efficiency, %

- evap:

-

Evaporator

- Cap:

-

Capillary

- Comp:

-

Compressor

- Cond:

-

Condenser

- in:

-

Inlet

- Out:

-

Outlet

- b:

-

Boundary

- o:

-

Dead state

- f:

-

Fluid

References

Buzelin LOS, Amico SC, Vargas JVC, Parise JAR. Experimental development of an intelligent refrigeration system. Int J Refrig. 2005;28:165–75.

Harby K. Hydrocarbons and their mixtures as alternatives to environmental unfriendly halogenated refrigerants: an updated overview. Renew Sustain Energy Rev. 2017;73:1247–64.

Harby K, Gebaly DR, Koura NS, Hassan MS. Performance improvement of vapor compression cooling systems using evaporative condenser: an overview. Renew Sustain Energy Rev. 2016;58:347–60.

Gill J, Singh J. Energetic and exergetic performance analysis of the vapor compression refrigeration system using adaptive neuro-fuzzy inference system approach. Exp Thermal Fluid Sci. 2017;88:246–60.

Hepbasli A. Thermoeconomic analysis of household refrigerators. Int J Energy Res. 2007;31:947–59.

Kabul A, Kizilkan O, Yakut AK. Performance and Energetic analysis of vapor compression refrigeration system with an internal heat exchanger using a hydrocarbon, isobutane (R600a). Int J Energy Res. 2008;32:824–36.

Ahamed JU, Saidur R, Masjuki HH. Thermodynamic performance analysis of R-600 and R-600a as a refrigerant. Eng E-Trans. 2010;5:11–8.

Bolaji BO. Experimental study of R152a and R32 to replace R134a in a domestic refrigerator. Energy. 2010;35:3793–8.

Ozgur AE, Kabul A, Kizilkan O. Exergy analysis of refrigeration systems using an alternative refrigerant (hfo-1234yf) to R-134a. Int J Low-Carbon Technol. 2014;9:56–62.

Saravanakumar R, Selladurai V. Exergy analysis of a domestic refrigerator using eco-friendly R290/R600a refrigerant mixture as an alternative to R134a. J Therm Anal Calorim. 2014;115(1):933–40.

El-Morsi Mohamed. Energy and exergy analysis of LPG (liquefied petroleum gas) as a drop in replacement for R134a in domestic refrigerators. Energy. 2015;86:344–53.

Golzari S, Kasaeian A, Daviran S, Mahian O, Wongwises S, Sahin AZ. Second law analysis of an automotive air conditioning system using HFO-1234yf, an environmentally friendly refrigerant. Int J Refrig. 2017;73:134–43.

Dowlati M, Aghbashlo M, Soufiyan MM. Exergetic performance analysis of an ice-cream manufacturing plant: a comprehensive survey. Energy. 2017;123:445–59.

Raveendran PS, Sekhar SJ. Exergy analysis of a domestic refrigerator with brazed plate heat exchanger as a condenser. J Therm Anal Calorim. 2017;127:2439–46.

Gill J, Singh J. Energy analysis of vapor compression refrigeration system using mixture of R134a and LPG as refrigerant. Int J Refrig. 2017;84:287–99.

Mohanraj M, Jayaraj S, Muraleedharan C. A review on recent developments in new refrigerant mixtures for vapour compression-based refrigeration, air-conditioning and heat pump units. Int J Energy Res. 2011;35:647–69.

Mohanraj M, Jayaraj S, Muraleedharan C, Chandrasekar P. Experimental investigation of R290/R600a mixture as an alternative to R134a in a domestic refrigerator. Int J Therm Sci. 2009;48:1036–42.

Mohanraj M, Jayaraj S, Muraleedharan C. Exergy assessment of a direct expansion solar-assisted heat pump working with R22 and R407C/LPG mixture. Int J Green Energy. 2010;7(1):65–83.

Mohanraj M, Jayaraj S, Muraleedharan C. Applications of artificial neural networks for refrigeration, air-conditioning and heat pump systems—a review. Renew Sustain Energy Rev. 2012;16:1340–58.

Sowparnika GC, Thirumarimurugan M, Sivakumar VM. Performance prediction of refrigeration systems by artificial neural networks. Int J Adv Res Electr Electron Instrum Eng. 2015;4:7673–81.

Esen H, Inalli M, Sengur A, Esen M. Performance prediction of a ground-coupled heat pump system using artificial neural networks. Expert Syst Appl. 2008;35:1940–8.

Onder K. Thermodynamic analysis of a variable speed refrigeration system using artificial neural networks. Expert Syst Appl. 2011;38:11686–92.

Tong L, Yin S, Xie Y, Wang L, Yue X, Wang G. Intelligent simulation on refrigeration system using artificial neural network. In: International conference on natural computation; 2010. p. 1709–11.

Li N, Xia L, Shiming D, Xu X, Chan MY. Steady-state operating performance modelling and prediction for a direct expansion air conditioning system using artificial neural network. Build Serv Eng Res Technol. 2012;33:281–92.

Belman-Flores JM, Ledesma SE, Garcıa MG, Ruiz J, Rodrıguez- Munoz JL. Analysis of a variable speed vapor compression system using artificial neural network. Expert Syst Appl. 2013;40:4362–9.

Ledesma S, Belman-Flores JM. Application of artificial neural networks for generation of energetic maps of a variable speed compression system working with R1234yf. Appl Therm Eng. 2014;69:105–12.

Belman-Flores JM, Ledesma S. Statistical analysis of the energy performance of a refrigeration system working with R1234yf using artificial neural networks. Appl Therm Eng. 2015;82:8–17.

Cao X, Li ZY, Shao LL, Zhang CL. Refrigerant flows through electronic expansion valve: experiment and neural network modeling. Appl Therm Eng. 2016;92:210–8.

Hosoz M, Ertunc HM. Modelling of a cascade refrigeration system using artificial neural network. Int J Energy Res. 2016;30:1200–15.

Rashidi MM, Aghagoli A, Raoofi R. Thermodynamic analysis of the ejector refrigeration cycle using the artificial neural network. Energy. 2017;129:201–15.

Gill J, Singh J. Use of Artificial Neural Network approach for depicting mass flow rate of R134a/LPG refrigerant through straight and helical coiled adiabatic capillary tubes of vapor compression refrigeration system. Int J Refrig. 2018;86:228–38.

Rashidi MM, Ali M, Freidoonimehr N, Nazari F. Parametric analysis and optimization of entropy generation in unsteady MHD flow over a stretching rotating disk using artificial neural network and particle swarm optimization algorithm. Energy. 2013;55(1):497–510.

Rashidi MM, Anwar Bég O, Basiri Parsa A, Nazari F. Analysis and optimization of a transcritical power cycle with regenerator using artificial neural networks and genetic algorithms. Proc Inst Mech Eng Part A J Power Energy. 2011;225(6):701–17.

Padmanabhan VMV, Palanisamy S. The use of TiO2 nanoparticles to reduce refrigerator IR-reversibility. Energy Convers Manag. 2012;59:122–32.

Gill J, Singh J. Energy analysis of vapor compression refrigeration system using mixture of R134a and LPG as refrigerant. Int J Refrig. 2017;84:287–99.

Gill J, Singh J. Performance analysis of vapor compression refrigeration system using an adaptive neuro-fuzzy inference system. Int J Refrig. 2017;82:436–46.

Gill J, Singh J. An applicability of ANFIS approach for depicting energetic performance of VCRS using mixture of R134a and LPG as refrigerant. Int J Refrig. 2018;85:353–75.

ISO, International Standard Organization, International Standard-8187, Household refrigerating appliances (refrigerators/freezers) characteristics and test methods. International Organization for Standardization, Switzerland; 1991.

Moffat RJ. Describing the uncertainties in experimental results. Exp Thermal Fluid Sci. 1988;1:3–17.

Ledesma S, Ibarra-Manzano MA, Garcıa-Hernandez MG, Almanza-Ojeda DL. Neural lab a simulator for artificial neural networks. In: Computing conference IEEE; 2017, p. 716–21.

Masters T. Practical neural network recipes in C ++. San Diego: Academic Press, Inc; 1993.

Gill J, Singh J. Experimental analysis of R134a/LPG as replacement of R134a in a vapor-compression refrigeration system. Int J Air-Cond Refrig. 2017;25:1750015.

Gill J, Singh J. Adaptive neuro-fuzzy inference system approach to predict the mass flow rate of R134a/LPG refrigerant for straight and helical coiled adiabatic capillary tubes in the vapor compression refrigeration system. Int J Refrig. 2017;78:166–75.

Acknowledgements

The authors would like to acknowledge the IKG PTU, Kapurthala, BCET Gurdaspur, and Covenant University, Ogun State, Nigeria, for their excellent support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no competing financial interest.

Rights and permissions

About this article

Cite this article

Gill, J., Singh, J., Ohunakin, O.S. et al. ANN approach for irreversibility analysis of vapor compression refrigeration system using R134a/LPG blend as replacement of R134a. J Therm Anal Calorim 135, 2495–2511 (2019). https://doi.org/10.1007/s10973-018-7437-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7437-y