Abstract

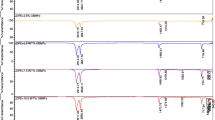

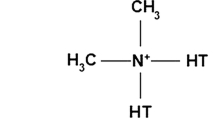

The aim of this study was to investigate the influence of the addition of smectite clay fillers to a polylactide matrix on the physical properties of the nanocomposites thus created, studied during the degradation process. A small amount of nanofiller (3–10 mass %) was used, and the clay was additionally modified with organic ammonium salt for better compatibility with the polymer matrix. Crystallisation, glass transition and melting temperature of the nanocomposites were investigated, and the resulting thermal, structural and mechanical properties were compared to those of a neat polylactide. The degradation process of the materials was examined during immersion in distilled water at 80 °C for 60 days using differential scanning calorimetry (DSC), thermogravimetric analysis (TG), X-ray diffraction (XRD) and scanning electron microscopy (SEM). Macroscopic changes were monitored and mechanical properties tested prior to degradation to evaluate the ability of the modified clay filler to reinforce the polymer and enhance elastic modulus, mechanical strength and Brinell hardness. The influence of the modified smectite filler on the thermal, mechanical and structural properties of the nanocomposites during degradation and its dependence on filler content were discussed and confirmed in the study. It was found that the addition of 3 mass% of the clay filler provides an increase of nearly 20 % in tensile strength, with improved stiffness. It was also found that the addition of organically modified clay to the polymer matrix significantly changes the hydrolytic degradation mechanisms of the polylactide, the crystallinity of the polymer and its degradation rate, depending on the amount of the filler.

Similar content being viewed by others

References

Fomin VA, Guzeev VV. Biodegradable polymers, their present state and future prospects. Prog Rubber Plast Recyc Technol. 2001;17:186–204.

Sorrentino A, Gorrasi G, Vittoria V. Potential perspectives of bionanocomposites for food packaging applications. Trends Food Sci Technol. 2007;18:84–95.

Wu C-J, Gaharwar AK, Schexnailder PJ, Schmidt G. Development of biomedical polymer-silicate nanocomposites: a materials science perspective. Materials. 2010;3:2986–3005.

Auras R, Lim L-T, Selke SEM, Tsuji H. Poly(lactic acid) synthesis, structures, properties, processing, and application. New Jersey: Wiley; 2010.

Lim LT, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–52.

Sharma SK, Nayak SK. Surface modified clay/polypropylene (PP) nanocomposites: effect on physic-mechanical, thermal and morphological properties. Polym Degrad Stab. 2009;94:132–8.

Alexandre M, Dubois P. Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mat Sci Eng. 2000;28:1–63.

Ganguly S, Dana K, Ghatak S. Thermogravimetric study of n-alkylammonium-intercalated montmorillonites of different cation exchange capacity. J Therm Anal Calorim. 2010;100:71–8.

Hussain F, Hojjati M, Okamoto M, Gorga RE. Review article: polymer-matrix nanocomposites, processing, manufacturing, and application: an overview. J Comp Mater. 2006;40:1511–75.

De Azeredo MCH. Nanocomposites for food packaging applications. Food Res Int. 2009;42:1240–53.

Gao F. Clay/polymer composites: the story. Mater Today. 2004;7:50–5.

Pluta M, Galeski A, Alexandra M, Paul MA, Bubois P. Polylactide/montmorillonite nanocomposites and microcomposites prepared by melt blending: structure and some physical properties. J Appl Polym Sci. 2002;86:1497–506.

Choudalakis GA, Kalo H, Breu J, Gotsis AD. CO2 gas barrier properties in polymer nanocomposite coatings containing Li-hectorite clays. J Appl Polym Sci. 2014;131:40805.

Fedullo N, Sorlier E, Sclavons M, Bailly C, Lefebvre JM, Devaux J. Polymer-based nanocomposite: overview, applications and perspectives. Prog Org Coat. 2007;58:87–95.

Koh HC, Park JS, Jeong MA, Hwang HY, Hong YT, Ha SY, Nam SY. Preparation and gas permeation properties of biodegradable polymer/layered silicate nanocomposite membranes. Desalination. 2008;233:201–9.

Xu W, Raychowdhury S, Jiang DD, Retsos H, Giannelis EP. Dramatic improvements in toughness in poly(lactide-co-glycolide) nanocomposites. Small. 2008;4:662–9.

Lu C, Mai Y. Influence of aspect ratio on barrier properties of polymer-clay nanocomposites. Phys Rev Lett. 2005;95:88303–7.

Armentanoo I, Bitinis N, Fortunati E, Mattioli S, Rescignano N, Verdejo R, Lopez-Manchado MA, Kenny JM. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog Polym Sci. 2013;38:1720–47.

Kadi S, Djadoun S. Thermal behavior of poly (etyl methacrylate-co-acrylonitrile) nanocomposites prepared in the presence of an Algerian bentonite via solution intercalation and in situ polymerization. J Therm Anal Calorim. 2015;119:1113–22.

Ray SS, Yamada K, Okamoto M, Ueda K. New polylactidd = e/layered silicate nanocomposite: nanoscale control over multiple properties. Macromol Rapid Commun. 2002;23:943–7.

Chow WS, Lok SK. Thermal properties of poly(lactic acid)/organo-montmorillonite nanocomposites. J Therm Anal Calorim. 2009;95:627–32.

Bergaya F, Theng BKG, Legaly G. Handbook of clay science, development in clay science, vol. 1. Amsterdam: Elsevier Ltd; 2006.

Rapacz-Kmita A, Stodolak-Zych E, Szaraniec B, Gajek M, Dudek P. Effect of clay mineral on the accelerated hydrolytic degradation of polylactide in the polimer/clay nanocomposites. Mater Lett. 2015;146:73–6.

Darder M, Aranda P, Ruiz-Hitzky E. Bionanocomposites: a new concept of ecological, bioinspired, and functional hybrid materials. Adv Mater. 2007;19:1309–19.

Kibbe HA. Handbook of pharmaceutical excipients. 3rd ed. Washington: American Pharmaceutical Association; 2000.

Viseras C, Aguzzi C, Cerezo P, Lopez-Galindo A. Uses of clay minerals in semisolid health care and therapeutic products. Appl Clay Sci. 2007;36:37–50.

Martin O, Avérous L. Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer. 2001;42:6209–19.

Das K, Ray D, Banerjee I, Bandyopadhyay NR, Sengupta S, Mohanty AK, Misra M. Crystalline morphology of PLA/clay nanocomposite films and its correlation with other properties. J Appl Polym Sci. 2010;118:143–51.

Wu T-M, Wu C-Y. Biodegradable poly(lactic acid)/chitosan-modified montmorillonite nanocomposites: preparation and characterization. Polym Degrad Stab. 2006;91:2198–204.

Chapple S, Anandjiwala R, Ray SS. Mechanical, thermal, and fire properties of polylactide/starch blend/clay composites. J Therm Anal Calorim. 2013;113:703–12.

Paul M-A, Delcourt C, Alexandre M, Degee P, Monteverde F, Dubois P. Polylactide/montmorillonite nanocomposites: study of the hydrolytic degradation. Polym Degrad Stab. 2005;87:535–42.

Zhou Q, Xanthos M. Nanoclay and crystallinity effects on the hydrolytic degradation of polylactides. Polym Degrad Stab. 2008;93:1450–9.

Araujo A, Botelho G, Oliveira M, Machado AV. Influence of clay organic modifier on the thermal stability of PLA based nanocomposites. Appl Clay Sci. 2014;88–89:144–50.

Ndazi BS, Karlsson S. Characterization of hydrolytic degradation of polylactic acid/rice hulls composites in water at different temperatures. eXPR Polym Lett. 2011;5:119–31.

Fukushima K, Tabuani D, Abbate C, Arena M, Ferreri L. Effect of sepiolite on the biodegradation of poly(lactic acid)and polycaprolactone. Polym Degrad Stab. 2010;95:2049–56.

Schmidt D, Shah D, Giannelis EP. New advances in polymer/layered silicate nanocomposites. Curr Opin Solid State Mater Sci. 2002;6:205–12.

Acknowledgements

The authors thank PhD Eng. Magdalena Ziąbka for SEM images.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rapacz-Kmita, A., Gajek, M., Dudek, M. et al. Thermal, structural and mechanical analysis of polymer/clay nanocomposites with controlled degradation. J Therm Anal Calorim 127, 389–398 (2017). https://doi.org/10.1007/s10973-016-5771-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-016-5771-5