Abstract

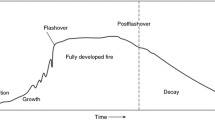

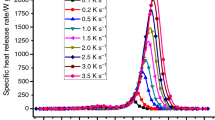

The effects of the heat flux on the thermal decomposition of the commercial flame-retardant ethylene-propylene-diene monomer rubber in a cone calorimeter with a piloted ignition were quantitatively investigated. Correlation analysis of the heat flux and various characteristic parameters, including the ignition time, the thermal thickness, the mass loss rate (MLR), the heat release rate (HRR) and the effective heat of combustion, was conducted. It was found that the transformed ignition time (1/t ig)0.55 and 1/t ig, the peak and average MLR, the first and second peak HRR, the HRR in the quasi-steady stage and the average HRR all increased linearly with the heat flux. The thermal thickness (δ P) decreased with the heat flux and was proportional to \( \rho/\dot{q}^{\prime\prime} \). The specimens under the heat fluxes ≤35 kW m−2 behaved as thermally thin solids, while the thermal decomposition behavior of the specimens under the heat fluxes >35 kW m−2 may be characterized employing the thermally thick heating model. The flammability properties including the critical heat flux, the minimum heat flux, the ignition temperature, the heat of gasification and the heat of combustion, which were calculated theoretically based upon the correlations of the ignition time data, the MLR data and the HRR data with the heat flux, were in accordance with the experimental measured values.

Similar content being viewed by others

References

Duggan G. Usage of ISO 5660 data in UK railway standards and fire safety cases. In: A one-day conference on fire hazards, testing, Materials and products. Shrewsbury: Rapra Technology Ltd; 1997. p. 1–8.

Haack A. Fire protection in traffic tunnels: general aspects and results of the EUREKA project. Tunn Undergr Space Technol. 1998;13(4):377–81.

Hong W. The progress and controlling situation of Daegu Subway fire disaster. In: Sixth Asia-Oceania symposium on fire science and technology. Daegu: International Association for Fire Safety Science; 2004. p. 17–20.

Chiam BH. Numerical simulation of a metro train fire. Master Dissertation, University of Canterbury, New Zealand; 2005.

Dowling V, White N, Webb A, Barnett J. When a passenger train burns, how big is the fire? Invited Lecture. In: Proceedings of the 7th Asia-Oceania symposium on fire science and technology. Hong Kong: International Association for Fire Safety Science; 2007. p. 19–28.

Roh JS, Ryou HS, Park WH, Jang YJ. CFD simulation and assessment of life safety in a subway train fire. Tunn Undergr Space Technol. 2009;24(4):447–53.

White N. Fire development in passenger trains. Master Dissertation, Victoria University, Australia. 2010.

Kumm M. Carried Fire Load in Mass Transport Systems: A study of occurrence, allocation and fire behaviour of bags and luggage in metro and commuter trains in Stockholm. Technical Report: SiST 2010:4, Sweden: Mälardalen University Press; 2010.

Lönnermark A, Lindström J, Li Y. Model-scale metro car fire tests. SP report 2011:33, SP Technical Research Institute of Sweden; 2011.

Schebel K, Meacham BJ, Dembsey NA, Johann M, Tubbs J, Alston J. Fire growth simulation in passenger rail vehicles using a simplified flame spread model for integration with CFD analysis. J Fire Prot Eng. 2012;22(3):197–225.

Ingason H, Kumm M, Nilsson D, Lönnermark A, Claesson A, Li YZ et al. The METRO project, final report. Technical Report: SiST 2012:8, Sweden: Mälardalen University Press; 2012.

Li YZ, Ingason H, Lönnermark A. Correlations between different scales of metro carriage fire tests. In: 11th international symposium on fire safety science. Christchurch, New Zealand: International Association for Fire Safety Science; 2013.

Luche J, Mathis E, Rogaume T, Richard F, Guillaume E. High-density polyethylene thermal degradation and gaseous compound evolution in a cone calorimeter. Fire Saf J. 2012;54:24–35.

Luche J, Rogaume T, Richard F, Guillaume E. Characterization of thermal properties and analysis of combustion behavior of PMMA in a cone calorimeter. Fire Saf J. 2011;46(7):451–61.

An W, Jiang L, Sun J, Liew K. Correlation analysis of sample thickness, heat flux, and cone calorimetry test data of polystyrene foam. J Therm Anal Calorim. 2015;119(1):229–38.

Xu Q, Jin C, Griffin G, Jiang Y. Fire safety evaluation of expanded polystyrene foam by multi-scale methods. J Therm Anal Calorim. 2014;115(2):1651–60.

Xu Q, Jin C, Jiang Y. Analysis of the relationship between MCC and thermal analysis results in evaluating flammability of EPS foam. J Therm Anal Calorim. 2014;118:687–93.

Qu H, Liu C, Wu W, Chen L, Xu J. Using cone calorimeter to study thermal degradation of flexible PVC filled with zinc ferrite and Mg (OH)2. J Therm Anal Calorim. 2014;115(2):1081–7.

Shi L, Chew MYL. Experimental study of woods under external heat flux by autoignition. J Therm Anal Calorim. 2013;111(2):1399–407.

Chen X, Lu S, Li C, Zhang J, Liew KM. Experimental study on ignition and combustion characteristics of typical oils. Fire Mater. 2014;38(3):409–17.

Song L, Zhou S, Wu J, Hu Y. Synergistic effects of lanthanum oxide on magnesium hydroxide flame-retarded ethylene propylene diene terpolymer composite. Polym Plast Technol. 2009;48(10):1088–93.

Du L, Xu G, Zhang Y, Qian J, Chen J. Synthesis and properties of a novel intumescent flame retardant (IFR) and its application in halogen-free flame retardant ethylene propylene diene terpolymer (EPDM). Polym Plast Technol. 2011;50(4):372–8.

Shen ZQ, Chen L, Lin L, Deng CL, Zhao J, Wang YZ. Synergistic effect of layered nanofillers in intumescent flame-retardant EPDM: montmorillonite versus layered double hydroxides. Ind Eng Chem Res. 2013;52(25):8454–63.

Yen YY, Wang HT, Guo WJ. Synergistic effect of aluminum hydroxide and nanoclay on flame retardancy and mechanical properties of EPDM composites. J Appl Polym Sci. 2013;130(3):2042–8.

Quintiere J. A theoretical basis for flammability properties. Fire Mater. 2006;30(3):175–214.

Quang Dao D, Luche J, Richard F, Rogaume T, Bourhy-Weber C, Ruban S. Determination of characteristic parameters for the thermal decomposition of epoxy resin/carbon fibre composites in cone calorimeter. Int J Hydrog Energ. 2013;38(19):8167–78.

Batiot B, Luche J, Rogaume T. Thermal and chemical analysis of flammability and combustibility of fir wood in cone calorimeter coupled to FTIR apparatus. Fire Mater. 2014;38(3):418–31.

ISO 871. Plastics: determination of ignition temperature using a hot air furnace. 3rd ed. Geneva: International Organization for Standardization (ISO); 2006.

ISO 1716. Reaction to fire tests for products-determination of the gross heat of combustion (calorific value). 3rd ed. Geneva: International Organization for Standardization (ISO); 2010.

ISO 5660. Reaction-to-fire tests-heat release, smoke production and mass loss rate-part 1: heat release rate (cone calorimeter method). 2nd ed. Geneva: International Organization for Standardization; 2002.

Babrauskas V. The Cone Calorimeter. In: DiNenno PJ, editor. SFPE handbook of fire protection engineering. 3rd ed. Quincy: National Fire Protection Association; 2002. p. 3.63–81.

Twilley WH, Babrauskas V. User’s guide for the cone calorimeter. SP-745. Gaithersburg: National Institute of Standards and Technology; 1988.

ISO 17554. Reaction to fire-mass loss measurement. Geneva: International Organization for Standardization; 1998.

Babrauskas V. Ignition handbook: principles and applications to fire safety engineering, fire investigation, risk management and forensic science. 2nd ed. Issaquah: Fire Science; 2003.

Mouritz AP, Gibson A. Fire properties of polymer composite materials. Dordrecht: Springer; 2007.

Janssens M. Piloted ignition of wood: a review. Fire Mater. 1991;15(4):151–67.

Janssens M. Improved method of analysis for the LIFT apparatus, part I: ignition. In: Proceedings of the 2nd fire and materials conference. London, England: Interscience Communications; 1993. p. 37–46.

Delichatsios MA. Piloted ignition times, critical heat fluxes and mass loss rates at reduced oxygen atmospheres. Fire Saf J. 2005;40(3):197–212.

Janssens M, Kimble J, Murphy D. Computer tools to determine material properties for fire growth modeling from cone calorimeter data. In: 8th Proceedings of fire and materials. San Francisco, USA: Interscience Communications Limited; 2003. p. 377–87.

Delichatsios M, Panagiotou T, Kiley F. The use of time to ignition data for characterizing the thermal inertia and the minimum (critical) heat flux for ignition or pyrolysis. Combust Flame. 1991;84(3):323–32.

Janssens M. Fundamental thermophysical characteristics of wood and their role in enclosure fire growth. PhD dissertation, Ghent University, Belgium; 1991.

Mikkola E, Wichman IS. On the thermal ignition of combustible materials. Fire Mater. 1989;14(3):87–96.

Shi L, Chew MYL. Fire behaviors of polymers under autoignition conditions in a cone calorimeter. Fire Saf J. 2013;61:243–53.

Karlsson B, Quintiere JG. Enclosure fire dynamics. New York: CRC Press; 2000.

Chen R, Lu S, Zhang B, Li C, Lo S. Correlation of rate of gas temperature rise with mass loss rate in a ceiling vented compartment. Chin Sci Bull. 2014;59(33):4559–67.

Rhodes B, Quintiere J. Burning rate and flame heat flux for PMMA in a cone calorimeter. Fire Saf J. 1996;26(3):221–40.

Rhodes B. Burning rate and flame heat flux for PMMA in the cone calorimeter. NIST-GCR-95-664. Gaithersburg: National Institute of Standards and Technology; 1994.

Quintiere J, Rhodes B. Fire growth models for materials. NIST-GCR-94-647. Gaithersburg: National Institute of Standards and Technology; 1994.

Hopkins D, Quintiere JG. Material fire properties and predictions for thermoplastics. Fire Saf J. 1996;26(3):241–68.

Dillon S, Kim W, Quintiere JG. Determination of properties and the prediction of the energy release rate of materials in the ISO 9705 Room-corner Test. NIST-GCR-98-753. Gaithersburg: National Institute of Standards and Technology; 1998.

Quintiere J, Rangwala A. A theory for flame extinction based on flame temperature. Fire Mater. 2004;28(5):387–402.

Chen R, Lu S, Li C, Li M, Lo S. Characterization of thermal decomposition behavior of commercial flame-retardant ethylene-propylene-diene monomer (EPDM) rubber. J Therm Anal Calorim. 2015;. doi:10.1007/s10973-015-4701-2.

Babrauskas V, Peacock RD. Heat release rate: the single most important variable in fire hazard. Fire Saf J. 1992;18(3):255–72.

Thornton W. The relation of oxygen to the heat of combustion of organic compounds. Lond Edinb Dublin Philos Mag J Sci. 1917;33(194):196–203.

Janssens M. Measuring rate of heat release by oxygen consumption. Fire Technol. 1991;27(3):234–49.

Stoliarov SI, Crowley S, Lyon RE, Linteris GT. Prediction of the burning rates of non-charring polymers. Combust Flame. 2009;156(5):1068–83.

Acknowledgements

This work was sponsored by the Research Fund for the Doctoral Program of Higher Education of China (Grant Nos. 20123402110048 and 20123402120018) and National Natural Science Foundation of China (Grant Nos. 51206157 and 51323010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, R., Lu, S., Li, C. et al. Correlation analysis of heat flux and cone calorimeter test data of commercial flame-retardant ethylene-propylene-diene monomer (EPDM) rubber. J Therm Anal Calorim 123, 545–556 (2016). https://doi.org/10.1007/s10973-015-4900-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4900-x