Abstract

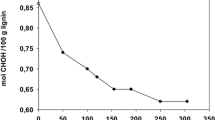

This paper aims to study certain aspects of the preparation of tannin–lignin adhesives. Mimosa tannins and lignosulfonates were used in wood adhesives formulation to substitute resins based on formaldehyde. Two ammonium lignosulfonates and two sodium lignosulfonates were glyoxalated to be more reactive. The thermal stability of the lignosulfonates before and after glyoxalation was analysed by thermogravimetric analysis (TG) and differential scanning calorimetry (DSC). The proportion of mimosa tannins and sodium lignosulfonates varied from 20 % tannins to 60 % tannins. 40 % of mimosa tannins were mixed with either glyoxalated sodium lignosulfonates or glyoxalated ammonium lignosulfonates. The thermal properties of the resins were studied by TG, DSC and thermomechanical analysis (TMA). The results showed that after glyoxalation, the degradation of lignosulfonates started at 125 °C instead of 171 °C for the non-glyoxalated lignosulfonates. The results obtained showed that the 40 mass% tannins resin was the most efficient. The TMA results showed that the curing of the resins started at 100–110 °C. The TG and DSC results of the cured resins showed a thermal stability of the adhesives up to approximately 200 °C.

Similar content being viewed by others

References

Sellers T. Wood adhesive innovations and applications in North America. For Prod J. 2001;51:12–22.

Gomez-Bueso J, Haupt R. Chapter 8: wood composite adhesives. In: Pilato L, editor. Phenolic resins a century progress. Berlin, Heidelberg: Springer Berlin Heidelberg; 2010. p. 155–87.

Cheng S, Yuan Z, Leitch M, Anderson M, Xu C. Highly efficient de-polymerization of organosolv lignin using a catalytic hydrothermal process and production of phenolic resins/adhesives with the depolymerized lignin as a substitute for phenol at a high substitution ratio. Ind Crop Prod. 2013;44:315–22.

El Mansouri N-E, Yuan Q, Huang F. Characterization of alkaline lignins for use in phenol-formaldehyde and epoxy resins. BioResources. 2011;6:2647–62.

Khan MA, Ashraf SM, Malhotra VP. Development and characterization of a wood adhesive using bagasse lignin. Int J Adhes Adhes. 2004;24:485–93.

Khan MA, Ashraf SM, Malhotra VP. Eucalyptus bark lignin substituted phenol formaldehyde adhesives: a study on optimization of reaction parameters and characterization. J Appl Polym Sci. 2004;92:3514–23.

Khan MA, Ashraf SM. Studies on thermal characterization of lignin: substituted phenol formaldehyde resin as wood adhesives. J Therm Anal Calorim. 2007;89:993–1000.

Matuana LM, Riedl B, Barry AO. Caractérisation cinétique par analyse enthalpique différentielle des résines phenol-formaldehyde à base de lignosulfonates. Eur Polym J. 1993;29:483–90.

Moubarik A, Grimi N, Boussetta N, Pizzi A. Isolation and characterization of lignin from Moroccan sugar cane bagasse: production of lignin–phenol-formaldehyde wood adhesive. Ind Crop Prod. 2013;45:296–302.

El Mansouri N, Pizzi A, Salvadó J. Lignin-based wood panel adhesives without formaldehyde. Holz als Roh- und Werkst. 2007;65:65–70.

El Mansouri N-E, Pizzi A, Salvadó J. Lignin-based polycondensation resins for wood adhesives. J Appl Polym Sci. 2007;103:1690–9.

Kielhorn J, Pohlenz-Michel C, Schmidt S, Mangelsdorf I. Glyoxal (concise international chemical assessment document 57) World Health Organization. 2004

Navarrete P, Mansouri HR, Pizzi A, Tapin-Lingua S, Benjelloun-Mlayah B, Pasch H, et al. Wood panel adhesives from low molecular mass lignin and tannin without synthetic resins. J Adhes Sci Technol. 2010;24:1597–610.

Ballerini A, Despres A, Pizzi A. Non-toxic, zero emission tannin-glyoxal adhesives for wood panels. Holz als Roh- und Werkst. 2005;63:477–8.

El Mansouri N-E, Yuan Q, Huang F. Synthesis and characterization of kraft lignin-based epoxy resins. BioResources. 2011;6:2492–503.

Lei H, Pizzi A, Du G. Environmentally friendly mixed tannin/lignin wood resins. J Appl Polym Sci. 2008;107:203–9.

Ping L, Pizzi A, Guo ZD, Brosse N. Condensed tannins from grape pomace: characterization by FTIR and MALDI TOF and production of environment friendly wood adhesive. Ind Crop Prod. 2012;40:13–20.

Vázquez G, González-Alvarez J, Santos J, Freire MS, Antorrena G. Evaluation of potential applications for chestnut (Castanea sativa) shell and eucalyptus (Eucalyptus globulus) bark extracts. Ind Crop Prod. 2009;29:364–70.

Gornik D, Hemingway RW, Tisler V. Tannin-based cold-setting adhesives for face lamination of wood. Holz als Roh- und Werkst. 2000;58:23–30.

Kim S. Environment-friendly adhesives for surface bonding of wood-based flooring using natural tannin to reduce formaldehyde and TVOC emission. Bioresour Technol. 2009;100:744–8.

Navarrete P, Pizzi A, Tapin-Lingua S, Benjelloun-Mlayah B, Pasch H, Rode K, et al. Low formaldehyde emitting biobased wood adhesives manufactured from mixtures of tannin and glyoxylated lignin. J Adhes Sci Technol. 2012;26:1667–84.

Jorge FC, Pascoal Neto C, Irle MA, Gil MH, Pedrosa de Jesus J. Wood adhesives derived from alkaline extracts of maritime pine bark: preparation, physical characteristics and bonding efficacy. Holz als Roh- und Werkst. 2002;60:303–10.

Lu Y, Shi Q, Gao Z. Thermal analysis and application of larch tannin-based adhesive for plywood and hardboard. Holz als Roh- und Werkst. 1995;53:205–8.

Özacar M, Soykan C, ŞengiL İA. Studies on synthesis, characterization, and metal adsorption of mimosa and valonia tannin resins. J Appl Polym Sci. 2006;102:786–97.

Vázquez G, González-Alvarez J, Lopez-Suevos F, Freire S, Antorrena G. Curing kinetics of tannin–phenol-formaldehyde adhesives as determined by DSC. J Therm Anal Calorim. 2002;70:19–28.

Vázquez G, González-Alvarez J, Antorrena G. Curing of a phenol-formaldehyde–tannin adhesive in the presence of wood: analysis by differential scanning calorimetry. J Therm Anal Calorim. 2006;84:651–4.

Pichelin F, Kamoun C, Pizzi A. Hexamine hardener behaviour: effects on wood glueing, tannin and other wood adhesives. Holz als Roh- und Werkst. 1999;57:305–17.

Moubarik A, Mansouri HR, Pizzi A, Charrier F, Allal A, Charrier B. Corn flour-mimosa tannin-based adhesives without formaldehyde for interior particleboard production. Wood Sci Technol. 2013;47:675–83.

Pichelin F, Nakatani M, Pizzi A, Wieland S, Despres A, Rigolet S. Structural beams from thick wood panels bonded industrially with formaldehyde-free tannin adhesives. For Prod J. 2006;56:31–6.

El Hage R, Brosse N, Navarrete P, Pizzi A. Extraction, characterisation and utilization of organosolv Miscanthus lignin for the conception of resin for wood adhesives. J Adhes Sci Technol. 2011;25:1549–60.

El Mansouri N-E, Yuan Q, Huang F. Study of chemical modification of alkaline lignin by the glyoxalation reaction. BioResources. 2011;6:4523–36.

Tejado A, Peña C, Labidi J, Echeverria JM, Mondragon I. Physico-chemical characterization of lignins from different sources for use in phenol-formaldehyde resin synthesis. Bioresour Technol. 2007;98:1655–63.

Boeriu CG, Bravo D, Gosselink RJA, van Dam JEG. Characterisation of structure-dependent functional properties of lignin with infrared spectroscopy. Ind Crop Prod. 2004;20:205–18.

Ping L, Brosse N, Chrusciel L, Navarrete P, Pizzi A. Extraction of condensed tannins from grape pomace for use as wood adhesives. Ind Crop Prod. 2011;33:253–7.

Peña C, de la Caba K, Retegi A, Ocando C, Labidi J, Echeverria JM, et al. Mimosa and chestnut tannin extracts reacted with hexamine in solution. J Therm Anal Calorim. 2009;96:515–21.

Garro Galvez JM, Riedl B, Conner AH. Analytical studies on tara tannins. Holzforschung. 1997;51:235–43.

Acknowledgements

We gratefully acknowledge the financial support of the “Conseil Général des Landes” and of ANR-10-EQPX-16 Xyloforest. We also thank Tembec Company (Tartas 40 - France) for providing lignosulfonate samples.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chupin, L., Charrier, B., Pizzi, A. et al. Study of thermal durability properties of tannin–lignosulfonate adhesives. J Therm Anal Calorim 119, 1577–1585 (2015). https://doi.org/10.1007/s10973-014-4331-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4331-0