Abstract

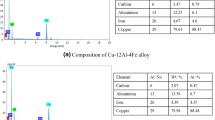

Cu-based quaternary shape memory alloys were extensively investigated alloy in last decade. In this study, Cu–Al–Mn, Cu–Al–Mn–V and Cu–Al–Mn–Cd shape memory alloys were produced by arc melting. We have investigated the effects of the alloying elements on the characteristic transformation temperatures, variations in structure and microstructure. The characterization of the transformation temperatures was studied by the differential scanning calorimetry. It was observed that the addition of the vanadium and cadmium decreases the characteristic transformation temperatures. The structural changes of the samples were studied by X-ray diffraction measurements and optical microscope observations. The crystal structure of the martensite Cu–Al–Mn, Cu–Al–Mn–V and Cu–Al–Mn–Cd shape memory alloys were identified as M18 at room temperature. The crystallite sizes of the alloys were determined. The microstructure of the alloy was studied with the help of optical microscope and V-type martensites with different orientations were detected. Microhardness value of the alloys were found between 194 and 211 Hv.

Similar content being viewed by others

References

Aksu Canbay C, Karagoz Z. The effect of quaternary element on the thermodynamic parameters and structure of CuAlMn shape memory alloys. Appl Phys A. 2013. doi:10.1007/s00339-013-7880-3.

Izadinia M, Dehghani K. Structure and properties of nanostructured Cu–13.2Al–5.1Ni shape memory alloy produced by melt spinning. Trans Nonferr Metals Soc China. 2011;21:2037–43.

Cismasiu C. Shape memory alloys. Croatia: Sciyo; 2010.

Yan L, Lishan C, Yanjun Z, Dazhi Y. DSC study of the reverse martensitic transformation in prestrained TiNi shape memory alloy in different composites. Mater Lett. 2001;51:73–7.

Jiang HJ, Cao S, Ke CB, Ma X, Zhang XP. Nano-sized SiC particle reinforced NiTi alloy matrix shape memory composites. Mater Lett. 2013;100:74–7.

Karagoz Z, Aksu Canbay C. Relationship between transformation temperatures and alloying elements in Cu–Al–Ni shape memory alloys. J Therm Anal Calorim. 2013. doi:10.1007/s10973-013-3145-9.

Aksu Canbay C, Aydogdu A. Thermal analysis of Cu-14.82 wt% Al-0.4 wt% Be shape memory alloy. J Therm Anal Calorim. 2013. doi:10.1007/s10973-012-2792-6.

Meng XL, Zheng YF, Cai W, Zhao LC. Two-way shape memory effect of a TiNiHf high temperature shape memory alloy. J Alloy Compd. 2004;372:180–6.

Chentouf SM, Bouabdallah M, Cheniti H, Eberhardt A, Patoor E. Ageing study of Cu–Al–Be hypoeutectoid shape memory alloy. Mater Charact. 2010;61:1187–93.

Wu MH. Cu-based shape memory alloys. In: Duerig TW, Melton KN, Stockel D, Wayman CM, editors. Engineering aspects of shape memory alloys. New York: Butterworth-Heinemann; 1990. p. 69–88.

Sugimoto K, Kamei K, Nakinawa M. In: Duerig TW, Melton KN, Stockel D, Wayman CM editors. Engineering aspects of shape memory alloys. New York: Butterworth-Heinemann; 1990. p. 89–95.

Lu X, Chen F, Li W, Zheng Y. Effect of Ce addition on the microstructure and damping properties of Cu–Al–Mn shape memory alloy. J Alloy Compd. 2009;480(200):608–11.

Mallik US, Sampath V. Influence of quaternary alloying additions on transformation temperatures and shape memory properties of Cu–Al–Mn shape memory alloy. J Alloy Compd. 2009;469:156–63.

Chen F, Wang HB, Zheng YF, Cai W, Zhao LC. Effect of Fe addition on transformation temperatures and hardness of NiMnGa magnetic shape memory alloys. J Mater Sci. 2005;40:219–21.

Rezvani MR, Shokuhfar A. Synthesis and characterization of nanostructured Cu–Al–Mn shape memory alloy by mechanical alloying. Mater Sci Eng A. 2012;532:282–6.

Sutou Y, Koeda N, Omori T, Kainuma R, Ishida K. Effects of ageing on bainitic and thermally induced martensitic transformations in ductile Cu–Al–Mn based shape memory alloys. Acta Mater. 2009;57:5748–58.

Sutou Y, Omori T, Wang JJ, Kainuma R, Ishida K. Characteristics of Cu–Al–Mn-based shape memory alloys and their applications. Mater Sci Eng A. 2004;378:278–82.

Sutou Y, Omori T, Koeda N, Kainuma R, Ishida K. Effects of grain size and texture on damping properties of Cu–Al–Mn-based shape memory alloys. Mater Sci Eng A. 2006;438–440:74346.

Chentouf SM, Bouabdallah M, Gachon J-I, Proor E, Sari A. Microstructural and thermodynamic study of hypoeutectoidal Cu–Al–Ni shape memory alloys. J Alloy Compd. 2009;470:507–14.

Kainuma R, Satoh N, Liu XJ, Ohnuma I, Ishida K. Phase equilibria and Heusler phase stability in the Cu-rich portion of the Cu–Al–Mn system. J Alloys Compd. 1998;266:191–200.

Xuan Q, Bohong J, Hsu TY. The effect of martensite ordering on shape memory effect in a copper–zinc–aluminium alloy. Mater Sci Eng. 1987;93:205–11.

Meng Q, Yang H, Liu Y, Nam T. Transformation intervals and elastic strain energies of B2–B190 martensitic transformation of NiTi. Intermetallics. 2010;18:2431–4.

Kainuma R, Takahashi S, Ishida K. Thermoelastic martensite and shape memory effect in ductile Cu–Al–Mn alloys. Metall Mater Trans A. 1996;27A:2187–95.

Zheng Y, Li C, Wan F, Long Y. Cu–Al–Mn alloy with shape memory effect at low temperature. J Alloys Compd. 2007;441:317–22.

Prado MO, Decarte PM, Lovey F. Martensitic transformation in Cu–Mn–Al alloys. Scripta Metall Mater. 1995;33(6):878–83.

Aydın C, El-Nasser HM, Yakuphanoglu F, Yahia IS, Aksoy M. Nanopowder synthesis of aluminum doped cadmium oxide via sol–gel calcination processing. J Alloys Compd. 2011;509:854–8.

Rezvani MR, Shokuhfar A. The effect of chemical composition on crystal size and mechanical properties of nanostructured Cu–Al–Mn shape memory alloy prepared by mechanical alloying technique. In: Proceeding of 4th International conference on nanostructure (ICNS4); 2012:1525–1527.

Acknowledgements

This work is financially supported by FÜBAP, Project No. FF.12.35.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Aksu Canbay, C., Keskin, A. Effects of vanadium and cadmium on transformation temperatures of Cu–Al–Mn shape memory alloy. J Therm Anal Calorim 118, 1407–1412 (2014). https://doi.org/10.1007/s10973-014-4034-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4034-6