Abstract

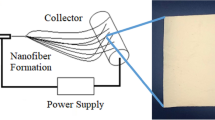

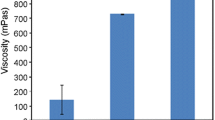

The main objective of the present study is to investigate the effect of diameter on thermal properties of phase change fibers at nanoscale in order to develop a shape-stabilized phase change material (PCM). In this regard, polyethylene glycol/cellulose acetate (PEG/CA) electrospun nanofibers as a model of PCM/polymer structure were electrospun. The electrospinning process was optimized using response surface methodology (RSM) to produce phase change nanofibers (PCNs) with achievable minimum and maximum diameter at nanoscale range. Therefore, PCNs with minimum and maximum diameter (223 nm and 545 nm, respectively) were successfully prepared. According to differential scanning calorimetry (DSC) results, the PCNs sample with maximum diameter exhibited higher efficiency of enthalpy (49.41 %) than the PCNs sample with minimum diameter (46.24 %). On the other hand, a test based on the T-history method revealed that PCNs with maximum diameter enjoy higher thermal insulation effect. Scanning electron microscopy (SEM) as well as DSC results showed that the PCNs samples exposed to thermal cycling test not only preserved their structural durability, but also exhibited about twofold increasing in the efficiency of enthalpy than the non-exposed samples. According to thermogravimetric analysis (TG) results, due to successful entrapping, a fraction of PCMs within the structure of polymer matrix, PCNs sample display greater thermal stability comparing to the pure PCM. The present work emphasises that at nanoscale range, higher diameter of PCNs can present more favorable thermal behavior; suggesting a great potential for advanced applications of thermal energy storage and thermal regulating materials fields.

Similar content being viewed by others

Abbreviations

- PCM:

-

Phase change material

- PCNs:

-

Phase change nanofibers

- PCUFs:

-

Phase change ultrafine fibers

- RSM:

-

Response surface methodology

- TES:

-

Thermal energy storage

- BBD:

-

Box-Behnken design

- DS:

-

Degree of substitution

- EPS:

-

Expanded polystyrene

- MR:

-

Mass ratio

- ANOVA:

-

Analysis of variance

- ∆H m(exp) :

-

Experimental value for heat of fusion

- ∆H m(the) :

-

Theoretical value for heat of fusion

- Mn:

-

Number average molar mass

- R 2 :

-

Correlation coefficient

- V h :

-

Heating rate

- T c :

-

Crystallization temperature

- T m :

-

Melting temperature

- ∆H m :

-

Enthalpy of melting

- ∆H c :

-

Enthalpy of crystallization

- T onset :

-

Onset mass loss temperature

References

Jegadheeswaran S, Pohekar SD. Performance enhancement in latent heat thermal storage system: a review. Renew Sustain Energy Rev. 2009;13:2225–44.

Zalba B, Marín JM, Cabeza LF, Mehling H. Review on thermal energy storage with phase change: materials, heat transfer analysis and applications. Appl Therm Eng. 2003;23:251–83.

Farid MM, Khudhair AM, Razack SAK, Al-Hallaj S. A review on phase change energy storage: materials and applications. Energy Convers Manag. 2004;45:1597–615.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev. 2009;13:318–45.

Nguyen TTT, Lee JG, Park JS. Fabrication and characterization of coaxial electrospun polyethylene glycol/polyvinylidene fluoride (Core/Sheath) composite non-woven mats. Macromol Res. 2011;19:370–8.

Zeng JL, Cao Z, Yang DW, Xu F, Sun LX, Zhang XF, et al. Effects of MWNTs on phase change enthalpy and thermal conductivity of a solid-liquid organic PCM. J Therm Anal Calorim. 2009;95:507–12.

Mondal S. Phase change materials for smart textiles–an overview. Appl Therm Eng. 2008;28:1536–50.

Karaman S, Karaipekli A, Sarı A, Bicer A. Polyethylene glycol (PEG)/diatomite composite as a novel form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells. 2011;95:1647–53.

Tyagi VV, Kaushik SC, Tyagi SK, Akiyama T. Development of phase change materials based microencapsulated technology for buildings: a review. Renew Sustain Energy Rev. 2011;15:1373–91.

Chen C, Wang L, Huang Y. A novel shape-stabilized PCM: electrospun ultrafine fibers based on lauric acid/polyethylene terephthalate composite. Mater Lett. 2008;62:3515–7.

Bhardwaj N, Kundu SC. Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv. 2010;28:325–47.

Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol. 2003;63:2223–53.

Chen C, Wang L, Huang Y. Morphology and thermal properties of electrospun fatty acids/polyethylene terephthalate composite fibers as novel form-stable phase change materials. Sol Energy Mater Sol Cells. 2008;92:1382–7.

McCann JT, Marquez M, Xia Y. Melt coaxial electrospinning: a versatile method for the encapsulation of solid materials and fabrication of phase change nanofibers. Nano Lett. 2006;6:2868–72.

Chen C, Wang L, Huang Y. Ultrafine electrospun fibers based on stearyl stearate/polyethylene terephthalate composite as form stable phase change materials. Chem Eng J. 2009;150:269–74.

Chen C, Wang L, Huang Y. Electrospinning of thermo-regulating ultrafine fibers based on polyethylene glycol/cellulose acetate composite. Polymer. 2007;48:5202–7.

Cai Y, Ke H, Dong J, Wei Q, Lin J, Zhao Y, et al. Effects of nano-SiO2 on morphology, thermal energy storage, thermal stability, and combustion properties of electrospun lauric acid/PET ultrafine composite fibers as form-stable phase change materials. Appl Energy. 2011;88:2106–12.

Ke H, Li D, Wang X, Wang H, Cai Y, Xu Y. Thermal and mechanical properties of nanofibers-based form-stable PCMs consisting of glycerol monostearate and polyethylene terephthalate. J Therm Anal Calorim. 2013;114(1):101–11.

Chen C, Wang L, Huang Y. Electrospun phase change fibers based on polyethylene glycol/cellulose acetate blends. Appl Energy. 2011;88:3133–9.

Chen C, Liu S, Liu W, Zhao Y, Lu Y. Synthesis of novel solid–liquid phase change materials and electrospinning of ultrafine phase change fibers. Sol Energy Mater Sol Cells. 2012;96:202–9.

Cai Y, Zong X, Zhang J, Hu Y, Wei Q, He G, et al. Electrospun nanofibrous mats absorbed with fatty acid eutectics as an innovative type of form-stable phase change materials for storage and retrieval of thermal energy. Sol Energy Mater Sol Cells. 2013;109:160–8.

Coles SR, Jacobs DK, Meredith JO, Barker G, Clark AJ, Kirwan K, et al. A design of experiments (DoE) approach to material properties optimization of electrospun nanofibers. J Appl Polym Sci. 2010;117:2251–7.

Bezerra MA, Santelli RE, Oliveira EP, Villar LS, Escaleira LA. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta. 2008;76:965–77.

Yinping Z, Yi J. A simple method, the-history method, of determining the heat of fusion, specific heat and thermal conductivity of phase-change materials. Meas Sci Technol. 1999;10:201.

Vitchuli N, Shi Q, Nowak J, Nawalakhe R, Sieber M, Bourham M, et al. Plasma-electrospinning hybrid process and plasma pretreatment to improve adhesive properties of nanofibers on fabric surface. Plasma Chem Plasma Process. 2012;32:275–91.

Chen J-P, Ho K-H, Chiang Y-P, Wu K-W. Fabrication of electrospun poly (methyl methacrylate) nanofibrous membranes by statistical approach for application in enzyme immobilization. J Membr Sci. 2009;340:9–15.

Mu G, Luan F, Liu H, Gao Y. Use of experimental design and artificial neural network in optimization of capillary electrophoresis for the determination of nicotinic acid and nicotinamide in food compared with high-performance liquid chromatography. Food Anal Methods. 2013;6:191–200.

Andrady AL. Science and technology of polymer nanofibers. Hoboken: Wiley; 2008.

Greiner A, Wendorff JH. Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew Chem Int Ed. 2007;46:5670–703.

Cho K, Li F, Choi J. Crystallization and melting behavior of polypropylene and maleated polypropylene blends. Polymer. 1999;40:1719–29.

Martuscelli E. Influence of composition, crystallization conditions and melt phase structure on solid morphology, kinetics of crystallization and thermal behavior of binary polymer/polymer blends. Polym Eng Sci. 1984;24:563–86.

van de Witte P, Dijkstra PJ, van den Berg JWA, Feijen J. Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci. 1996;117:1–31.

Morrow NR. Physics and thermodynamics of capillary action in porous media. Ind Eng Chem. 1970;62:32–56.

Han S, Kim C, Kwon D. Thermal/oxidative degradation and stabilization of polyethylene glycol. Polymer. 1997;38:317–23.

Kong Y, Hay J. The measurement of the crystallinity of polymers by DSC. Polymer. 2002;43:3873–8.

Mandžuka Z, Knez Ž. Influence of temperature and pressure during PGSS™ micronization and storage time on degree of crystallinity and crystal forms of monostearate and tristearate. J Supercrit Fluids. 2008;45:102–11.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rezaei, B., Askari, M., Shoushtari, A.M. et al. The effect of diameter on the thermal properties of the modeled shape-stabilized phase change nanofibers (PCNs). J Therm Anal Calorim 118, 1619–1629 (2014). https://doi.org/10.1007/s10973-014-4025-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-4025-7