Abstract

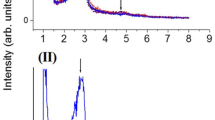

Ti containing mesoporous MCM-41 materials have been synthesized through two methods: heating and non-heating [room temperature (RT)]. The synthesized materials have been characterized using X-ray diffraction, Fourier transform infrared, nitrogen sorption, and X-ray fluorescence methods and their thermal stabilities evaluated using thermogravimetric methods in inert atmosphere. The thermal stabilities have been analyzed based on the synthesis method, as well as on the amount of titanium in the MCM-41 materials. The thermal stability results suggest that uncalcined MCM-41 materials generally show higher mass loss than their calcined counterparts. Also, the RT-synthesized materials showed lower stability than the high-temperature synthesized samples for the uncalcined samples. It is also been found that MCM-41 materials show improved thermal stabilities as the amount of titanium is increased.

Similar content being viewed by others

References

Kresge CT, Leonowicz ME, Roth WJ, Vartuli JC, Beck JS. Ordered mesoporous molecular sieves synthesized by a liquid-crystal template mechanism. Nature. 1992;359:710–2.

Beck JS, Vartuli JC, Roth WJ, Leonowicz ME, Kresge CT, Schmitt KD, Chu CTW, Olson DH, Sheppard EW. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J Am Chem Soc. 1992;114:10834–43.

Beck JS, Inventor Mobil Oil Corporation, Assignee. Method for synthesizing mesoporous crystalline material. United States Patent 5057296, 15 Oct 1991; 1991.

Huh S, Wiench JW, Trewyn BG, Song S, Pruski M, Lin VSY. Tuning of particle morphology and pore properties in mesoporous silicas with multiple organic functional groups. Chem Commun. 2003;18:2364–5.

Hu X, Foo ML, Chuah GK, Jaenicke S. Pore size engineering on MCM-41: selectivity tuning of heterogenized AlCl3 for the synthesis of linear alkyl benzenes. J Catal. 2000;195:412–5.

Wang A, Kabe T. Fine-tuning of pore size of MCM-41 by adjusting the initial pH of the synthesis mixture. Chem Commun. 1999;20:2067–8.

Zhao SX, Lu GQ, Hu X. A novel method for tailoring the pore-opening size of MCM-41 materials. Chem Commun. 1999;15:1391–2.

Liou T-H. A green route to preparation of MCM-41 silicas with well-ordered mesostructure controlled in acidic and alkaline environments. Chem Eng J. 2011;171:1458–68.

Zhang K, Chen H-L, Albela B, Jiang J-G, Wang Y-M, He M-Y, Bonneviot L. High-temperature synthesis and formation mechanism of stable, ordered MCM-41 silicas by using surfactant cetyltrimethylammonium tosylate as template. Eur J Inorg Chem. 2011;2011:59–67.

Selvaraj M, Sinha PK, Park DW, Kim I, Kawi S, Ha CS. Selective synthesis of 6,8-di-t-butylated flavan over Zn–Al containing mesoporous silica catalysts. Dalton Trans. 2012;41:14197–203.

Wang S, Shi Y, Ma X, Gong J. Tuning porosity of Ti–MCM-41: implication for shape selective catalysis. ACS Appl Mater Interfaces. 2011;3:2154–60.

Ravikovitch PI, Wei D, Chueh WT, Haller GL, Neimark AV. Evaluation of pore structure parameters of MCM-41 catalyst supports and catalysts by means of nitrogen and argon adsorption. J Phys Chem B. 1997;101:3671–9.

Liepold A, Roos K, Reschetilowski W. Mesoporous MCM-41 materials—effect of acidity and porosity on catalytic properties. Chem Eng Sci. 1996;51:3007–12.

Galarneau A, Desplantier-Giscard D, Di Renzo F, Fajula F. Thermal and mechanical stability of micelle-templated silica supports for catalysis. Catal Today. 2001;68:191–200.

Yuan Q, Zhang Y, Chen T, Lu D, Zhao Z, Zhang X, Li Z, Yan C-H, Tan W. Photon-manipulated drug release from a mesoporous nanocontainer controlled by azobenzene-modified nucleic acid. ACS Nano. 2012;6:6337–44.

Jang HR, Oh H-J, Kim J-H, Jung KY. Synthesis of mesoporous spherical silica via spray pyrolysis: pore size control and evaluation of performance in paclitaxel pre-purification. Microporous Mesoporous Mater. 2013;165:219–27.

Luan Z, Cheng C-F, Zhou W, Klinowski J. Mesopore molecular sieve MCM-41 containing framework aluminum. J Phys Chem. 1995;99:1018–24.

Tanev PT, Chibwe M, Pinnavaia TJ. Titanium-containing mesoporous molecular sieves for catalytic oxidation of aromatic compounds. Nature. 1994;368:321–3.

Kumar N, Kubicka D, Garay AL, Mäki-Arvela P, Heikkilä T, Salmi T, Murzin DY. Synthesis of Ru-modified MCM-41 mesoporous material, Y and beta zeolite catalysts for ring opening of decalin. Top Catal. 2009;52:380–6.

Busuioc AM, Meynen V, Beyers E, Mertens M, Cool P, Bilba N, Vansant EF. Structural features and photocatalytic behaviour of titania deposited within the pores of SBA-15. Appl Catal A. 2006;312:153–64.

Hagen A, Schueler K, Roessner F. The performance of Ti–MCM-41 in aqueous media and after mechanical treatment studied by in situ XANES, UV/Vis and test reactions. Microporous Mesoporous Mater. 2002;51:23–33.

Reddy EP, Sun B, Smirniotis PG. Transition metal modified TiO2-loaded MCM-41 catalysts for visible- and UV-light driven photodegradation of aqueous organic pollutants. J Phys Chem B. 2004;108:17198–205.

Li B, Wang J, Fu J, Wang J, Zou C. Selective liquid phase oxidation of benzoin to benzil over transition metals doped MCM-41 with air. Catal Commun. 2008;9:2000–2.

Karthik M, Lin L-Y, Bai H. Bifunctional mesoporous Cu–Al–MCM-41 materials for the simultaneous catalytic abatement of NO x and VOCs. Microporous Mesoporous Mater. 2009;117:153–60.

Shanmugapriya K, Palanichamy M, Balasubramanian VV, Murugesan V. Vapour phase reaction of m-cresol and ethyl acetate over MCM-41 molecular sieves: one-pot synthesis of coumarin derivatives. Microporous Mesoporous Mater. 2006;95:272–8.

Pârvulescu V, Anastasescu C, Su BL. Bimetallic Ru–(Cr, Ni, or Cu) and La–(Co or Mn) incorporated MCM-41 molecular sieves as catalysts for oxidation of aromatic hydrocarbons. J Mol Catal A. 2004;211:143–8.

Pârvulescu V, Tablet C, Anastasescu C, Su BL. Activity and stability of bimetallic Co (V, Nb, La)-modified MCM-41 catalysts. Catal Today. 2004;93–95:307–13.

Occelli ML, Biz S, Auroux A. Effects of isomorphous substitution of Si with Ti and Zr in mesoporous silicates with the MCM-41 structure. Appl Catal A. 1999;183:231–9.

Szegedi Á, Popova M. Toluene hydrogenation over nickel-containing MCM-41 and Ti–MCM-41 materials. J Porous Mater. 2010;17:663–8.

Yanishpolskii VV, Pavlenko AN, Tertykh VA, Il’in VG, Leboda R, Skubiszewska-Zieba J. Mesoporous titanium-containing silicas. Synthesis and geometrical characteristics. J Therm Anal Calorim. 2000;62:569–73.

Jomekian A, Mansoori S, Bazooyar B, Moradian A. Enhancement in thermal and hydrothermal stabilities of novel mesoporous MCM-41. J Porous Mater. 2012;19:979–88.

Araujo SA, Ionashiro M, Fernandes VJ Jr, Araujo AS. Thermogravimetric investigations during the synthesis of silica-based MCM-41. J Therm Anal Calorim. 2001;64:801–5.

Goworek J, Kierys A, Gac W, Borwka A, Kusak R. Thermal degradation of CTAB in as-synthesized MCM-41. J Therm Anal Calorim. 1999;96:375–82.

Kusak R. Template transformations in preparation of MCM-41 silica. J Therm Anal Calorim. 2005;79:555–60.

Souza LCK, Pardauil JJR, Zamian JR, Filho GNR, Costa CEF. Influence of the incorporated metal on template removal from MCM-41 type mesoporous materials. J Therm Anal Calorim. 2011;106:355–61.

Wan K, Liu Q, Zhang C. Thermal stability of Si–MCM-41 in gaseous atmosphere. Mater Lett. 2003;57:3839–42.

He N, Lu Z, Yuan C, Hong J, Yang C, Bao S, Xu Q. Effect of trivalent elements on the thermal and hydrothermal stability of MCM-41 mesoporous molecular materials. Supramol Sci. 1998;5:553–8.

He N, Yang C, Dai Q, Wang J, Yuan C, Lu Z. Studies on the state of Fe and La in MCM-41 mesoporous molecular sieve materials by TG analysis and other techniques. J Therm Anal Calorim. 2000;61:827–37.

Kuang YP, He NY, Wang J, Xiao PF, Yuan CW, Lu ZH. Investigating the state of Fe and La in MCM-41 mesoporous molecular sieve materials. Colloids Surf A. 2001;179:177–84.

Schacht P, Norena-Franco L, Ancheyta J, Ramirez S, Hernandez-Perez I, Garcia LA. Characterization of hydrothermally treated MCM-41 and Ti–MCM-41 molecular sieves. Catal Today. 2004;98:115–21.

Vunain E, Opembe NN, Jalama K, Mishra AK, Meijboom R. Thermal stability of amine-functionalized MCM-41 in different atmospheres. J Therm Anal Calorim. 2014;115(2):1487–96. doi:10.1007/s10973-013-3350-6.

Sadjadi MS, Farhadyar N, Zare K. Synthesis of nanosize MCM-41 loaded with TiO2 and study of its photocatalytic activity. Superlattices Microstruct. 2009;46:266–71.

Lihitkar NB, Abyaneh MK, Samuel V, Pasricha R, Gosavi SW, Kulkarni SK. Titania nanoparticles synthesis in mesoporous molecular sieve MCM-41. J Colloid Interface Sci. 2007;314:310–6.

Shao GN, Elineema G, Quang DV, Kim YN, Shim YH, Hilonga A, Kim J-K, Kim HT. Two step synthesis of a mesoporous titania–silica composite from titanium oxychloride and sodium silicate. Powder Technol. 2012;217:489–96.

Wang S, Shi Y, Ma X. Microwave synthesis, characterization and transesterification activities of Ti–MCM-41. Microporous Mesoporous Mater. 2012;156:22–8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Opembe, N.N., Vunain, E., Mishra, A.K. et al. Thermal stability of Ti–MCM-41. J Therm Anal Calorim 117, 701–710 (2014). https://doi.org/10.1007/s10973-014-3750-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-3750-2