Abstract

This study presents a comprehensive investigation into the structural, morphological, and electrical properties of sol-gel synthesized Ba0.75Ni0.25Tc0.88Mn0.12O3 perovskite ceramic (BNTMO). The meticulous preparation protocol, involving solvating various precursors, was followed by an extensive characterization employing X-ray diffraction, scanning electron microscopy, and dielectric studies. XRD analysis affirmed the single-phase single-phase cubic structure with Pm-3m space, while SEM revealed a well-defined morphology with an average particle size of 243 nm. The electrical conductivity exploration, elucidated through Jonscher’s universal power law, provided insights into charge carrier dynamics, exhibiting semiconductor behavior. Impedance spectroscopy unraveled a distinctive relaxation peak, corroborated by Cole-Cole plots, unveiling a unique charge carrier mechanism. Dielectric studies showcased intriguing polarization dynamics, indicating promising applications in energy storage. The convergence of activation energy values from various analyses underscores the coherence in the charge carrier relaxation process. Overall, our findings contribute to a nuanced understanding of the electrical intricacies of BNTMO, presenting avenues for its utilization in advanced technological applications.

Graphical Abstract

Highlight

-

X-ray diffraction (XRD) confirmed that Ba0.75Ni0.25Tc0.88Mn0.12O3 (BNTMO) has a cubic structure (Pm-3m).

-

Scanning electron microscopy (SEM) showed BNTMO has a well-defined morphology with 243 nm average particle size.

-

BNTMO exhibited semiconductor behavior, with electrical conductivity following Jonscher’s universal power law.

-

Impedance spectroscopy showed a relaxation peak and Cole-Cole plots indicated a unique charge carrier mechanism.

-

Dielectric studies suggested potential energy storage applications with consistent activation energy values.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

ABO3 perovskites, classified as oxide materials, find application in diverse areas, including solid oxide fuel cells, piezo- and ferro-electricity, and water splitting. Their exceptional stability when subjected to cation substitution suggests the potential discovery of novel compounds suitable for various applications. Notably, when A represents a large cation like Ba and Bi is a small cation from the d-transition series, these perovskites are recognized for their polytypic nature. These ceramic materials play a crucial role in scientific industries due to their captivating properties, encompassing dielectric, magnetic, optical, and transport characteristics. They contribute significantly to essential fields such as material science, solid-state chemistry, condensed matter physics, and advanced materials like high-temperature (Tc) superconductivity, colossal magnetoresistance, and multiferosity [1]. Furthermore, they find utility in microelectronics, memories, resonators, and energy storage devices [2,3,4,5]. Within perovskites, the influence of A-site atoms on physical properties is attributed to steric effects, while B-site atoms, characterized by their size, valence, and spin, play a crucial role in shaping magnetic, electric, and multiferroic properties [6]. Notably, rare-earth transition metal oxides exhibit exchange mechanisms, leading to competition between ferromagnetic and antiferromagnetic phases, coupled with distinctive dielectric properties.

Furthermore, materials with substantial dielectric constants and low dielectric loss play a crucial role in the electronic industry by facilitating device miniaturization. Ferroelectric and relaxor ferroelectrics are known for their high dielectric constants, and a recent surge of interest has emerged in materials exhibiting such properties [7]. Among these, BiBaO3 has garnered significant attention [8,9,10,11,12]. Initially, it was thought that the material’s notable dielectric effects were linked to intrinsic polarization mechanisms related to either electric charge ordering or the unique crystal structure. However, subsequent studies revealed that the giant dielectric constant effects were associated with Maxwell-Wagner (MW) polarization [13]. MW polarization is commonly observed in heterogeneous systems where dielectric components possess varying conductivities, forming interfaces and barrier layers [14,15,16,17,18]. Researchers have employed impedance spectroscopy to characterize these compounds, a non-destructive technique offering simultaneous electrical and dielectric characterization of ceramic materials.

Impedance plots serve as valuable tools for measuring conductivities and characterizing interfacial, grain boundary, and bulk grain effects. The Arrhenius activation energy can be extracted from impedance data. Complex impedance (Z) formalism aids in eliminating stray frequency effects, allowing for comparative conductivity assessments. This electrical impedance formalism is instrumental in investigating the relaxations of defect species and dielectric behavior. The technique has been successfully applied to study various ferroelectric materials, including LiNbO3 ceramic [19], europium-modified lead titanate ceramics [20], LiTaO3 ceramic [21], and several other compounds. Moreover, electrical properties of ceramic BaTiO3 were explored using ac impedance spectroscopy across the temperature range of 25 °C to 330 °C and frequencies from 1 Hz to 1 MHz. Fixed-frequency Curie-Weiss plots indicated deviations from linearity at temperatures well above Tc. The ac measurements revealed that grain boundary impedances impact Curie-Weiss plots in two ways: at high temperatures, they increasingly dominate fixed-frequency permittivity, while at lower temperatures closer to Tc, the high-frequency permittivity contains a contribution from grain boundary effects [22,23,24,25,26,27,28,29].

Besides, Furthermore, the material BaTcO3 underwent a comprehensive study, with its structural, electronic, and magnetic properties thoroughly examined using density functional theory (DFT). The electronic properties exhibited a semi-metallic behavior, and the partial density of states analysis revealed that oxygen and technetium atoms played a significant role in contributing to the Fermi level. Remarkably, BaTcO3 demonstrated pronounced ferroelectric behavior, showcasing a spontaneous polarization value of 1.21 C/m2. This characteristic suggests its potential suitability for electronic applications such as electromechanical devices, dynamic random-access memory, and field-effect transistors [30,31,32]. The significance of our work lies in addressing the conspicuous gap in detailed studies concerning the temperature and frequency dependence of Ba0.75Ni0.25Tc0.88Mn0.12O3 (BNTMO) materials. By conducting a comprehensive investigation into the frequency and temperature dependencies of the dielectric and impedance properties of these ceramic nanoparticles, we aim to provide crucial insights into their electrical behavior. Such understanding is fundamental for advancing applications in various technological domains, including energy storage, electronics, and telecommunications. Moreover, elucidating the electrical properties of BNTMO materials not only contributes to the fundamental understanding of their behavior but also paves the way for optimizing their performance in practical applications, thus fostering advancements in materials science and engineering.

2 Experimental procedure

2.1 Materials chemistry

2.1.1 Preparation protocol

The synthesis of the polycrystalline perovskite ceramic sample Ba0.75Ni0.25Tc0.88Mn0.12O3 (BNTMO) was achieved through the sol-gel method, employing high-purity chemicals for the preparation of the compound. Various precursors including BaCO3 (purity ≥99%, Supplier: ABC Chemicals, Country: USA), NiO (purity ≥99.9%, Supplier: XYZ Materials, Country: Germany), Tc2O7 (purity ≥99.5%, Supplier: PQR Corporation, Country: Japan), and MnO2 (purity ≥99.8%, Supplier: LMN Industries, Country: China) were solvated in a citric acid solution, supplemented with ethylene glycol, and diluted nitric acid. The proportions of the precursors were meticulously calculated, weighed using a precision balance, and combined in an Erlenmeyer flask equipped with a magnetic stirrer. A solution of 50 ml nitric acid and 25 ml distilled water was added to dissolve the mixture, followed by a 5-h dissolution at 65 °C on a hot plate.

Subsequently, citric acid and ethylene glycol were introduced to homogenize the reaction medium. The resulting mixture was then elevated to a temperature of 150 °C. Following this, a heat treatment at 500 °C for 5 h was conducted, and the resulting powder was crushed and compressed in a mold using a force of 4 tons/cm2, yielding circular pellets with dimensions of 1.78 mm thickness and 12 mm diameter. These pellets underwent an annealing cycle, ranging from 500 °C to 1000 °C, with each cycle lasting 12 h, to produce a dense material.

2.1.2 Characterization

The structural, phase purity, and homogeneity assessments of the prepared sample were conducted via X-ray powder diffraction (XRD) using a PHILIPS diffractometer, X’PERT PRO MPD. XRD spectra were acquired at room temperature within the Bragg angle range of 2θ = 20° to 100°, employing anticathode copper radiation (λCuKα = 1.54060 Å) and a step size of ∆θ = 0.02°. Furthermore, in the pursuit of comprehensive validation, it’s important to inquire whether the authors considered incorporating a standard measurement technique, such as utilizing LaB6. Employing a standard material like LaB6 facilitates the calibration of the XRD instrument and validates its performance, enhancing the reliability and reproducibility of the obtained results.

We employed Match, an advanced software tool for XRD analysis. It facilitates phase identification by comparing experimental data with a database of crystalline structures, conducts quantitative analysis to determine phase abundances, and offers detailed structural insights including lattice parameters and atomic coordinates [33]. Rietveld refinement was performed using FullProf (Version 2018) software [34]. High-quality powder diffraction data were initially prepared, followed by the input of structural models into the software. Iterative refinement cycles were then conducted to minimize discrepancies between observed and calculated diffraction patterns, with adjustments made to refinement parameters as necessary [35].

For the examination of particle microstructure and elemental composition, Scanning Electron Microscopy (SEM) coupled with Energy Dispersive X-ray Spectroscopy (EDS) was employed. SEM analysis was carried out with a FEI Quanta 650 FEG scanning electron microscope at 15 kV. The EDS system facilitated the identification and mapping of elements present in the sample, offering insights into the chemical composition and spatial distribution of various elements.

Dielectric measurements were executed using a precision impedance analyzer, Agilent 4294 A, configured in the Cp-Rp setup. The frequency range spanned from 100 Hz to 1 MHz, while the temperature varied from 200 K to 360 K, facilitated by a bath-cryostat. To enhance heat transfer and prevent moisture interference, the sample was placed in a helium atmosphere. Additionally, the compounds, in disk form, featured opposite surfaces coated with conductive silver paste to ensure electrode conductivity.

3 Results and discussion

3.1 Density of the BNTMO sample

The relative density of the Ba0.75Ni0.25Tc0.88Mn0.12O3 ceramic, indicative of its densification level and structural integrity, was determined by dividing its measured mass of 4 grammes by its volume of approximately 0.67 cm³. This computation yielded a value of approximately 5.97 g/cm³. Further analysis involved calculating the theoretical density, which involved intricate calculations considering the composition and crystal structure of the material. Utilizing the lattice parameters and molar masses of the constituent elements, the theoretical density was derived to be approximately 4.372 × 10−22 g/cm³.

3.2 XRD-sample characterization

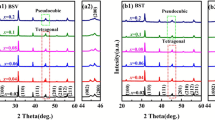

Figure 1a displays the X-ray diffraction pattern for BNTMO ceramic at room temperature. The diffraction intensities align closely with calculated values, affirming the material’s robust crystallization. All peaks are identified within the cubic system with space group Pm-3m, establishing the compound’s monophasic nature via Rietveld refinement. The XRD diffractograms yield lattice parameters (a = b = c = 3.8943 Å ± 0.0012 Å) and a volume (V) of 59.1258 Å3 ± 0.882 Å3. Reliability factors, including a goodness factor (χ2) of 1.46, RF (Rietveld factor) of 1.36, Bragg factor (RB) of 1.69, and Rwp (weighted profile R-factor) of 5.66, were determined. The parameters obtained from the refinement process serve as indicators of the fitting quality between the experimental and calculated diffraction patterns. Typically, lower values of χ², RF, RB, and Rwp indicate a better fit, suggesting that the refined crystal structure accurately represents the experimental data. Therefore, the values obtained in this study indicate a good agreement between the observed and calculated diffraction patterns, affirming the reliability of the derived physical parameters [36]. The crystallographic characteristics and parameter values of the BNTMO sample were presented in Table 1.

To validate the perovskite-like structure and distortion level, the Goldschmidt tolerance factor (t) was calculated using ionic radii (r) for Ba2+ (1.61 Å), Ni2+ (0.63 Å), Tc4+ (0.64 Å), Mn4+ (0.53 Å), Mn3+ (0.58 Å), and O2- (1.4 Å) [37, 38]. The calculated t value exceeding 1 indicates a cubic structure for the material. In our microstructural analysis, we employed two methods to determine the crystallite size. Firstly, we utilized the Debye-Scherrer method, which calculates crystallite size from the broadening of X-ray diffraction peaks, using the formula DDS = (K.λ)/(β.cos θ) [39]. Here, K is a constant, λ is the wavelength of the X-rays, β is the full width at half maximum (FWHM) of the diffraction peak, and θ is the Bragg angle. This calculation yielded a crystallite size of 19 nm. Additionally, we employed the Williamson Hall approach, a technique that takes into account both the crystallite size and the strain within the material. The formula used is [40]:

Here, DWH represents the crystallite size determined through the Williamson Hall method, and ε is the strain induced by deformation. By plotting β Cos (θ) against sin (θ) and performing a linear regression, we determined the intercept, which provided us with a DWH crystallite size of 35 nm. Importantly, the DWH crystallite size exceeded the DDS crystallite size obtained without considering deformation effects (ε = 0). This difference indicates a widening effect attributed to a 0.12% deformation in the material. In other words, the material’s crystallites appear larger when deformation effects are taken into account, highlighting the impact of deformation-induced widening on crystallite size determination.

The Miller indices along with the corresponding Bragg positions and interplanar spacing (d) are detailed in Table 2.

Additionally, the atomic positions within the cubic crystal structure of Ba0.75Ni0.25Tc0.88Mn0.12O3 were determined through XRD Rietveld refinement using the FullProf software and presented in Table 3. In the refined structure, fractional coordinates relative to the unit cell parameters were assigned to Ba, Ni, Tc, Mn, and O ions, with corresponding occupation factors reflecting the composition of the ceramic material. Furthermore, thermal parameters such as atomic displacement parameters (ADPs) were determined for each element, indicating the extent of atomic vibrations within the crystal lattice.

3.3 Morphological and chemical characterization of the prepared ceramic

The SEM was employed to investigate the morphology of the sintered powder. The objective of this morphological study was to assess the crystallinity of the material and observe the growth of grains, as depicted in Fig. 2a, b, featuring images at different scales. Additionally, Fig. 2b presents Field Emission Scanning Electron Microscopy (FESEM) images processed using ImageJ software [41]. This software was utilized for calculating the average size of particles. The method involved measuring the sizes of the clearest particles in SEM images, which varied in size. Subsequently, a frequency diagram, illustrating particle size distribution, was generated. The average nanoparticle size was then estimated using a lognormal fit of this diagram (Fig. 2c).

The observed morphology was characterized by its density and uniformity, with particle sizes averaging around 243 nm. Figure 2d showcases a semi-quantitative analysis conducted through energy dispersive spectroscopy (EDS). This technique enabled the determination of the chemical composition of the prepared material, confirming that the samples’ compositions align with the basic stoichiometric compositions, free from impurities.

Each peak in the EDS spectrum was precisely identified with O, Ba, Ni, Mn, and Tc, affirming the absence of any unexpected elements. This comprehensive elemental analysis provides crucial insights into the composition of the sample under study. The presence of Ba indicates the involvement of barium-based compounds, while Ni and Mn suggest the presence of nickel and manganese, respectively, which are commonly found in perovskite structures. Additionally, the detection of Tc signifies the presence of technetium, which may have been incorporated into the sample during synthesis or as a result of environmental contamination. The peak energies correspond to specific X-ray emissions associated with each element’s characteristic transitions, such as Lα and Kα lines, presented in Table 4 reported from the ref. [42]. For instance, the Ba peak at 4.46 keV corresponds to the Lα emission, while the Ni peak exhibits both Lα (0.85 keV) and Kα (7.47 keV) emissions. Similarly, Mn displays Lα (0.63 keV) and Kα (5.89 keV) emissions. These energy values serve as distinctive fingerprints for each element, aiding in their identification and quantification.

3.4 Electrical conductivity behaviors of BNTMO ceramic

The exploration of electrical conductivity is crucial for understanding the properties of dielectric materials, providing valuable insights into the underlying conduction mechanisms. Electrical conduction involves the movement of charged particles through a transmission medium, generating an electric current in response to an applied electric field. In dielectrics, two primary conduction mechanisms exist: electrode-limited and bulk-limited conduction mechanisms [43, 44].

The electrode-limited mechanism hinges on the electrical characteristics at the electrode-dielectric interface. This mechanism allows us to extract physical features such as the barrier height at the electrode-dielectric interface and the effective mass of the conduction carriers in the dielectric material. On the other hand, the bulk-limited mechanism relies on the electrical properties intrinsic to the dielectric itself. Analysis of this mechanism yields essential physical parameters within the dielectric, including trap level, trap spacing, trap density, carrier drift mobility, dielectric relaxation time, and density of states in the conduction band [45].

Figure 3a illustrates the frequency dependence of the alternating current (ac) conductivity at various temperature values. The observed increase in ac conductivity with frequency and temperature affirms the semiconductor behavior of the compound. Notably, a dispersion of conductivity towards higher frequencies, characteristic of ω, was observed. This dispersion aligns with Jonscher’s law, where σ(ω) = σdc + A.ωs, defining the dc-conductivity (σdc), the pre-exponential factor (A), angular frequency (ω), and the exponent (s) [46, 47].

The temperature dependence of the dc-conductivity, presented in the Fig. 3b and analyzed through the Arrhenius law, provided an activation energy (Ea) value of 0.242 eV, setting it apart from similar research, such as BaMn1−xNixO3, which typically falls within the range of 0.21–0.33 eV [48]. Utilizing the Origin softwere (Version 2022. OriginLab Corporation, Northampton, MA, USA), the values of “s” were determined using Jonscher’s law. We have extracted the fitted parameters at each temperature of Jonscher’s power law tabulated in Table 5.

The temperature variation of the exponent (s) presented in Fig. 3c reveals an increase with temperature, suggesting that the non-overlapping small-polaron tunneling (NSPT) model best characterizes the conduction phenomenon in the synthesized compound. This choice is supported by the observed trend of s increasing with temperature, consistent with NSPT behavior [49].

3.5 Impedance spectroscopy analysis

The application of complex impedance spectroscopy stands out as an effective, straightforward, and versatile method for scrutinizing the frequency-dependent characteristics of various electrical parameters and phenomena within a sample. This encompasses the analysis of effects such as grain behavior, grain boundaries, and electrode effects. The simplicity of impedance formulation enhances its utility in this context. In the literature, the electrical conduction observed in oxide materials primarily originates from processes like ion hopping involving Mn3+, Mn4+, and Ni3+, or the overlapping of d orbitals of cations [50]. When an electric field is applied, electrons undergo migration from one site to another, eliciting an electrical response. The real part (Z’) and imaginary part (-Z”) of the complex impedance are computed using the following formulas:

Each parameter in the given formulas represents a distinct aspect of the electrical circuit’s behavior. Resistance (R) quantifies the opposition to current flow, while the Quality Factor (Q) reflects the circuit’s efficiency and selectivity. Angular Frequency (ω) governs the rate of change of alternating current, with the parameter (α) indicating the power law behavior of the circuit. Capacitance (C) measures the ability to store charge, influencing the circuit’s response to voltage variations. Figure 4a illustrates the fluctuation of the real part of impedance (Z’) for the BNTMO ceramic across a broad spectrum of frequencies and temperatures. Our observations reveal a stable Z’ value at lower frequencies, indicating a decline as the frequency increases, thereby leading to enhanced material conductivity. Z’ also exhibits temperature-dependent variations, converging in the high-frequency region, showcasing semiconductor behavior.

The decreasing trend of Z’ with temperature suggests the semiconductor nature of the composition. At higher frequencies, the Z’ values merge, potentially due to the release of space charge and reduced barrier properties of the material. This aligns with findings in literature for various materials. Figure 4b presents Z″ plotted against frequency. The Z″ spectrum shows peaks at lower temperatures that flatten at higher temperatures, implying a broadening of peaks with temperature rise. As temperature rises, the maximum Z″ steadily shifts to higher frequencies, signaling an amplifying loss tangent and confirming the existence of temperature-sensitive electrical relaxation phenomena. This observation aligns with findings from related studies investigating perovskites and double perovskites materials, such as Ba0.75Bi0.25Ni0.7Mn0.3O3 [13], BiBa0.5Ag0.5Ni2O6 [16], and BiBaNiNbO6 [17], further substantiating the broader implications of our research.

The compound’s relaxing nature and polarization, characterized as space charges, are evident as the relaxation frequency (Fmax) increases and relaxation time (τ) decreases with rising temperature. The temperature dependence of the relaxation frequency (Fmax) can be modeled using the Arrhenius relation, expressed as follows [51, 52]:

The symbols f0, Ea, and KB represent the pre-exponential term, activation energy, and Boltzmann constant, respectively. In Fig. 4c, the variation of Ln (Fmax) is depicted as a function of 1000/T, revealing an activation energy (Ea) value of 0.244 eV obtained from the linear fit of the curve. Moving on to the Nyquist plot in Fig. 5, it illustrates the relationship between Z’ and Z″ across a frequency range of 1 K Hz to 1 MHz at temperatures ranging from 200 K to 360 K. The impedance spectra exhibit semicircle arcs at all temperatures, indicating that grain boundary conduction predominantly governs the conduction process in the samples.

With increasing temperature, the semicircular arc’s radius decreases, and its center point shifts towards the axis center, implying the existence of a relaxation time distribution and a non-Debye type relaxation in the studied structure. The experimentally obtained impedance data are validated by comparing them to theoretical predictions using the Z-View software. This software fits the experimental data to equivalent circuit configurations, representing the material’s electrical components and processes. By selecting the most suitable configuration and adjusting its parameters, researchers confirm the validity of their observations, enhancing understanding of the material’s electrical behavior [53, 54]. The chosen circuit model is of the type (R2 + CPE1//R1), where R1 and R2 represent the resistances of the grain and grain boundary, respectively, and CPE1 is the constant phase element associated with the grain boundary. The impedance response of a constant phase element (CPE) can be expressed as follows [55, 56]:

The CPE parameters, Q and α, remain frequency independent. Table 6 provides the evaluated values for R1, R2, CPE2, and α at each temperature. Notably, the R1 values are more significant than the R2 values, reinforcing the assertion that the conduction mechanism in the sample is primarily associated with grain boundary contributions, consistent with previous citations. As temperature increases, there is a noticeable decrease in the grain resistance, R1, as indicated in the table. This trend can be elucidated by considering the incorporation of charge carrier mobility into the conduction process [43]. Furthermore, this decline in R1 affirms the semiconductor nature of the substance.

3.6 Dielectric studies

The intricate permittivity of a non-Debye model for a dielectric material is delineated by the following relationship [57]:

Here, ε∞ represents the high-frequency permittivity, εS is the static permittivity, ε0 is the permittivity of free space, τ is the relaxation time, ω is the angular frequency, α is a parameter between 0 and 1 (with a value of 0 indicating non-Debye relaxation), and σdc represents the ohmic conductivity [58, 59].

As illustrated in Fig. 6a, the disparity in the real part ε′ of the complex permittivity exhibits an increase with temperature but diminishes with higher frequencies. This behavior is likely attributed to the material’s dielectric polarization mechanism. The ε′ values exhibit notable elevation at lower frequencies, primarily ascribed to the accumulation of charge carriers between the sample and the electrodes, a phenomenon known as interfacial polarization [60]. Similar studies conducted on perovskite materials such as (Bi0.5Ba0.5Ag)0.5(NiMn)0.5O3 [61], and Ba0.67Ni0.33Mn1-xFexO3 [62], as well as metallic oxides like gamma iron oxide (γ-Fe2O3) [63], and Cu-doped ZnO [64], have reported analogous behavior.

Examining Fig. 6b, it unveils the variation of dielectric loss as a function of frequency at different temperatures. Notably, a reduction in the tangent (δ) with increasing frequency is evident. This decrease can be attributed not only to the presence of a relaxation time distribution but also to the contribution of charge carrier density [65]. Consequently, the prepared sample exhibits a higher dielectric permittivity, which holds promise for technological applications such as energy storage.

3.7 Electrical modulus studies

In delving into the dielectric characteristics and polarization of our sample, a thorough examination of dielectric characterization was conducted. The comprehensive understanding of both conduction and relaxation is facilitated through the electric modulus formalism, as articulated in the mathematical framework available at [66]:

Where M’ and M” represent the real and imaginary parts of the electric modulus, respectively. This formalism provides a robust foundation for assessing the intricate interplay between conduction and relaxation phenomena in the dielectric behaviors of our material. They are expressed using the relationships shown below:

Figure 7a illustrates the variation in the real part of the electrical modulus at different temperature values as a function of frequency. Despite the initially low values of M’ at low frequencies, they exhibit a notable increase at higher frequencies across all temperatures. This phenomenon, coupled with significant permittivity values, is attributed to the accumulation of charges between the electrode and the material, substantiating the dielectric characterizations.

Examining the frequency-dependent behavior of the modulus imaginary part M′′ in Fig. 7b unveils a discernible relaxation process. Commencing at a low level, M′′ experiences an augmentation with frequency at specific temperatures until reaching a maximum, indicating a relaxation peak. With an increase in temperature, the modulus values shift towards achieving the maximum at a higher frequency. These observed relaxation peaks provide compelling evidence of the sample’s ionic conductor nature. Particularly noteworthy is that the imaginary part of the modulus attains its maximum at ωτ = 1, underscoring a distinctive feature of the relaxation phenomenon [67].

4 Conclusions

In summary, a polycrystalline sample of Ba0.75Ni0.25Tc0.88Mn0.12O3 was successfully synthesized through the sol-gel method, revealing a single-phase structure with a cubic arrangement (space group Pm-3m) as confirmed by X-ray diffraction analysis. The comprehensive investigation of complex impedance within the temperature range of 200–360 K and the frequency range of 100 Hz–1 MHz uncovered a singular relaxation peak in the frequency dependence of the imaginary part of the complex impedance (Z′′). The Cole-Cole plots demonstrated a semi-circular arc, aptly described by an electrical equivalent circuit of R1 + (R2//CPE2). The exploration of electrical conductivity spectra through the Jonscher universal power law provided valuable insights. Notably, the activation energy, derived from both conductance and time relaxation analyses, exhibited remarkable similarity. This convergence in activation energy values suggests that the relaxation process can be attributed to the same type of charge carriers. The findings underscore the intricate electrical properties of the synthesized material, shedding light on its potential applications and contributing to the broader understanding of charge carrier dynamics in similar compositions.

References

Du Y, Cheng ZX, Wang X-L, Dou SX (2010) J Appl Phys 108(9):093914

Ahemad MJ, Akhtar J, Younas M, Siddique M, Hasan MM (2012) J Appl Phys 112(7):074105

Prasad BV, Rao GN, Chen JW, Babu DS (2011) Mater Res Bull 46:1670–1673

Ho TG, Ha TD, Pham QN, Gang HT, Do TAT, Nguyen NT (2011) Adv Nat Sci Nanosci Nanotechnol 2:015012

Shanker J, Buchi Suresh M, Narsinga Rao G, & Suresh Babu D (2019) Colossal dielectric, relaxor ferroelectric, diamagnetic and weak ferromagnetic properties of NdCrO3 perovskite nanoparticles. J Mater Sci 54(7):5595–5604

Saha S, Chanda S, Dutta A, Sinha TP (2014) J Sol-Gel Sci Technol 69:553–563

Aravind G, Raghasudha M, Ravinder D (2015) J Materiomics 1:348–356

Yadav A, Khasa S, Hooda A, Dahiya MS, Agarwal A, Chand P (2016) Spectrochim Acta A Mol Biomol 157:129–137

Khorasani-Motlagh M, Noroozifar M, Yousefi M, Jahani SH (2013) Int J Nanosci Nanotechnol 9(1):7–14

Megha U, Shijina K, Varghese G (2014) Process Appl Ceram 8(2):87–92

Khetrea SM, Chopadea AU, Khilarea CJ, Bamane SR (2011) J Porous Mater 1(1):1–5

Prakash BJ, Rudramadevi BH, Buddhudu S (2014) Ferroelectr Lett Sect 41:110–122

Nassar KI, Tayari F, Benamara M, Teixeira SS, Graça MPF (2023) RSC Adv 13:24023–24030

Mohamed M, Iben Nassar M, Iben Nassar K, Rammeh N, Graça MPF (2023) Indian J Phys 97:1717–1725

Iben Nassar K, Rammeh N (2023) Indian J Phys 97:1749–1757

Iben Nassar K, Tayari F, Slimi M et al. (2023) J Mater Sci Mater Electron 34:216

Iben Nassar K, Tayari F, Slimi M et al. (2022) J Mater Sci Mater Electron 33:27147–27157

Iben Nassar K, Slimi M, Rammeh N et al. (2022) J Mater Sci Mater Electron 33:20134–20143

Mohamed M, Iben Nassar K, Mohamed M, Rammeh N, Graça MPF (2022) J Mol Struct 1258:132658

Nassar KI, Rammeh N, Teixeira SS et al. (2022) Appl Phys A 128:373

Nassar KI, Rammeh N, Teixeira SS et al. (2022) J Electron Mater 51:370–377

Iben Nassar K, Slimi M, Rammeh N (2021) Appl Phys A 127:940

Nassar KI, Slimi M, Rammeh N (2021) J Mater Sci Mater Electron 32:24050–24057

Siemons M, Koplin TJ, Simon U (2007) Appl Surf Sci 254:669–676

Uzair M et al. (2023) J Mater Sci Mater Electron 34(7):631

Kumar A et al. (2023) Appl Phys A 129(10):722

Arora M et al. (2023) Rapid adaptation to CDK2 inhibition exposes intrinsic cell-cycle plasticity. Cell 186(12):2628–2643

Dhak P et al. (2009) Mater Sci Eng B 164(3):165–171

Moritomo Y, Tomioka Y, Asamitsu A, Tokura Y (1995) Phys Re B 51:3297

Wang H, Che JG (2011) Europhys Lett 96(6):67012

Reynolds E et al. (2017) Phys Rev B 95(5):054430

Borisov VS et al. (2012) Phys Rev B 85(13):134410

Rodríguez-Carvajal J (1993) Phys B Condens Matter 192:55–69

McCusker LB, Von Dreele RB, Cox DE, Louër D, Scardi P (1999) J Appl Crystallogr 32(1):36–50

Rodríquez-Carvajal J, Roisnel T (2004) Mater Sci Forum 443:123–126

Goldschmidt, V. M., & Holmsen, D. (1927). Geochemische verteilungsgesetze der elemente (No. 1). In Kommission bei J. Dybwad.

Benamara M et al. (2021) Appl Phys A 128(1):1–18

Benamara M, Rivero-Antúnez P, Dahman H, Essid M, Bouzidi S, Debliquy M, El Mir L (2023) Selective and rapid detection of acetone using aluminum-doped ZnO-based sensors. J Sol-Gel Sci Technol 108(1):13–27

Ramezanipour F et al. (2009) J Solid State Chem 182:153

Schneider CA, Rasband WS, Eliceiri KW (2012) Nat Methods 9(7):671–675

Jonscher K, Husain A (1996) J Phys B Condens Matter 217:29–34

Graça MPF, Prezas PR, Costa MM, Valente MA (2010) J Sol-Gel Sci Technol 64:78–85

Mohanty HS, Kumar A, Sahoo B, Kurliya PK, Pradhan DK (2018) J Mater Sci Mater Electron 29:6966–6977

Ghozza MH, Yahia IS (2021) Impact of gadolinium doping on structure, electrical and magnetic properties of Gd x Cd1− x MnO3 manganite nanoparticles. J Mater Sci: Mater Electron 32(9):11628–11639

Gao J, Hu FX (2005) Appl Phys Lett 86(9):092504

Benamara M et al. (2023) J Magn Magn Mater 569:170479

Nassar KI, Tayari F, Benamara M et al. (2023) RSC Adv 13:24023–24030

Costa MM, Pires J´unior GFM, Sombra ASB (2010) Mater Chem Phys 123:35–39

Mohanty HS, Jena M, Jena K, Dey T, Nayak RK, Kata T, Tripathy N (2022) J Mater Sci Mater Electron 33:15232–15253

Mohanty HS, Puhan TS, Padhi S, Panda S, Samantaray SS, Rana G, Karmakar S (2023) ECS J Solid State Sci Technol 12(9):093001

Cordoba-Torres P et al. (2012) Electrochim Acta 72:172–178

Hirschorn B et al. (2010) Electrochim Acta 55:6218–6216

Lily K, Kumari K, Choudhary RNP (2008) J Alloy Compd 453:325–331

Graça MPF, da Silva MF, Valente MA (2008) Influence of thermal and thermoelectric treatments on structure and electric properties of B2O3–Li2O–Nb2O5 glasses. J Non-Cryst Solids 354(10–11):901–908

Cole KS, Krishna PM, Prasad DM, Lee JH, Kim JS (2008) J Alloy Compd 464:497

Kolodziej H, Sobczyk L (1971) Acta Phys Pol A 39:59

Tayari F, Nassar KI, Benamara M et al. (2024) Ceram Int 50(7):11207–11215

Tayari F, Nassar KI, Algessair S, Hjiri M, Benamara M et al. (2024) RSC Adv 14:12561–12573

Benamara M, Zahmouli N, Teixeira SS et al. (2022) J Electron Mater 51:2698–2707

Benamara M, Nassar KI, Rivero-Antúnez P, Essid M, Teixeira SS, Zhao S, Esquivias L (2024) Nanomaterials 14(5):402

Qian X, Gu N, Cheng Z, Yang X, Wang E, Dong S (2001) Electrochim Acta 46:1829

Dutta TP, Sinha (2010) Phys B 405:1475

Benamara M, Bouzidi S, Zahmouli N, Teixeira SS, Graça MPF, El Mir L, Valente MA (2022) Appl Phys A 128:1

Zhang Y, Chen Y, Yan M, Chen F (2015) Reconstruction of relaxation time distribution from linear electrochemical impedance spectroscopy. J Power Sources 283:464–477

Macdonald J. R (2009) Comments on the electric modulus formalism model and superior alternatives to it for the analysis of the frequency response of ionic conductors. J Phys Chem Solids 70(3–4):546–554

Rekik H, Ghallabi Z, Royaud I, Arous M, Seytre G, Boiteux G, Kallel A (2013) Dielectric relaxation behaviour in semi-crystalline polyvinylidene fluoride (PVDF)/TiO2 nanocomposites. Compos B Eng 45(1):1199–1206

Acknowledgements

The authors extend their appreciation to the Deanship of Research and Graduate Studies at King Khalid University for funding this work through large Research Project under grant number RGP2/68/45.

Funding

Open access funding provided by FCT|FCCN (b-on).

Author information

Authors and Affiliations

Contributions

FT: methodology, writing—review, editing, and investigation; KIN: conceptualization, investigation, writing—original draft; MB: methodology, investigation; SBM: conceptualization, resources; AYAA: Visualization, supervision, Resources; SST: review and editing, Validation, supervision; MPFG: review and editing, Validation, supervision. All authors have read and agreed to the published version of the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tayari, F., Nassar, K.I., Benamara, M. et al. Insights into dielectric and electrical conductivity dynamics in sol-gel synthesized Ba0.75Ni0.25Tc0.88Mn0.12O3 perovskite ceramic. J Sol-Gel Sci Technol (2024). https://doi.org/10.1007/s10971-024-06425-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10971-024-06425-6