Abstract

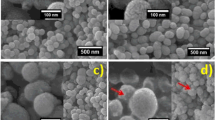

In this study, bioactive glass-ceramic (BGC) particles were synthesized following the original composition of Bioglass 45S5 consisting of SiO2, CaO, Na2O, and P2O5 with an acid catalyzed sol-gel derived route (Acid-BGC) and with an N-cetyl trimethylammonium bromide (CTAB) assisted modified Stöber process under basic conditions (Basic-BGC). XRD study of Acid-BGC confirms the complete conversion of bioglass to its glass-ceramic form (crystalline phase), while Basic-BGC indicates a reduced crystalline ceramic conversion with mixed phases. Scanning electron microscopy and Transmission electron microscopy images of Basic-BGC revealed the nanometric particle size distribution. It has been observed that enhancing the CTAB concentration reduces the particle size of Basic-BGC. However, with the reduction in particle size, the mesoporous nature of Basic-BGC particles gets reduced. Hence, 6 mM CTAB concentration was selected as the optimized concentration, which provides particle size within the nanoscale range without losing mesoporous structure. The mesoporous nature of the nanoparticles was also estimated with BET and BJH studies. The Basic-BGC particles were further functionalized with dopamine hydrochloride, glutamic acid, and cystamine dihydrochloride, and their effect on bioactivity and dispersion stability was studied. The bioactivity under exposure to simulated body fluid (SBF) for 10 days was evaluated for Basic-BGC and functionalized Basic-BGCs with XRD, attenuated total reflectance-Fourier transform infrared spectroscopy (ATR-FTIR), and energy dispersive spectroscopy (EDS). The formation of apatite crystals on BG surfaces could be established from these characterizations. The surface zeta potential of the particles was measured using the DLS method. Further, a series of in vitro studies were carried out to assess the cytocompatibility of Basic-BGC and functionalized Basic-BGCs, which includes the antimicrobial activity using disk-diffusion method, cytocompatibility utilizing MTT assay, antioxidant property through DPPH radical scavenging activity, DAPI staining of nuclei for identification of viable cells after cell culture on the particles. Finally, the dispersion stability of the particles was studied in different polymer solutions. Overall, the glutamic acid functionalized Basic-BGCs offer significant antibacterial, antioxidant, and bioactivity with good dispersion stability in dilute polymer solutions, ensuring their potential use in electrospinning and bioprinting applications.

Graphical Abstract

The quaternary composition of BGC containing SiO2-CaO-Na2O- P2O5 oxides has been synthesized in the CTAB template assisted modified Stöber process under basic conditions (Basic-BGC) while optimizing CTAB concentration ensured nanoparticles with mesoporous structure. The nano Basic-BGCs were further functionalized with glutamic acid, and functionalization provides enhanced antimicrobial and antioxidant properties with superior bioactivity. The dispersion stability of functionalized Basic-BGCs in dilute polycationic and polyanionic solutions enables their potential use in bioprinting and electrospinning.

Similar content being viewed by others

References

Li F, Jiang Y, Chen M, Yu B, Wang J, Wang F (2022) Effect of ZrO2 addition on in-vitro bioactivity and mechanical properties of SiO2-Na2O-CaO-P2O5 bioactive glass-ceramic. Ceram Int 48:18541–18550

Hench LL, Splinter RJ, Allen WC, Greenlee TK (1971) Bonding mechanisms at the interface of ceramic prosthetic materials. J Biomed Mater Res 5:117–141

Nawaz Q, de Pablos‐Martín A, Martins de Souza e Silva J et al. (2020) New insights into the crystallization process of sol‐gel–derived 45S5 bioactive glass. J Am Ceram Soc 103:4234–4247

Balasubramanian P, Buettner T, Pacheco VM, Boccaccini AR (2018) Boron-containing bioactive glasses in bone and soft tissue engineering. J Eur Ceram Soc 38:855–869

Marikani A, Maheswaran A, Premanathan M, Amalraj L (2008) Synthesis and characterization of calcium phosphate based bioactive quaternary P2O5–CaO–Na2O–K2O glasses. J Non Cryst Solids 354:3929–3934

Chakraborty PK, Adhikari J, Saha P (2021) Variation of the properties of sol–gel synthesized bioactive glass 45S5 in organic and inorganic acid catalysts. Mater Adv 2:413–425

Xynos ID, Edgar AJ, Buttery LDK et al. (2001) Gene‐expression profiling of human osteoblasts following treatment with the ionic products of Bioglass® 45S5 dissolution. J Biomed Mater Res J Soc Biomater Jpn Soc Biomater Aust Soc Biomater Korean Soc Biomater 55:151–157

Nawaz Q, Rehman MAU, Burkovski A et al. (2018) Synthesis and characterization of manganese containing mesoporous bioactive glass nanoparticles for biomedical applications. J Mater Sci Mater Med 29:1–13

Siqueira RL, Costa LC, Schiavon MA et al. (2017) Bioglass® and resulting crystalline materials synthesized via an acetic acid-assisted sol–gel route. J Sol Gel Sci Technol 83:165–173

El-Rashidy AA, Waly G, Gad A et al. (2018) Preparation and in vitro characterization of silver-doped bioactive glass nanoparticles fabricated using a sol-gel process and modified Stöber method. J Non Cryst Solids 483:26–36

Li Y, Chen X, Ning C et al. (2015) Facile synthesis of mesoporous bioactive glasses with controlled shapes. Mater Lett 161:605–608

Mao Y, Liao J, Wu M et al. (2020) Preparation of nano spherical bioglass by alkali-catalyzed mixed template. Mater Res Express 7:105202

Stöber W, Fink A, Bohn E (1968) Controlled growth of monodisperse silica spheres in the micron size range. J Colloid Interface Sci 26:62–69

Kesse X, Vichery C, Nedelec J-M (2019) Deeper insights into a bioactive glass nanoparticle synthesis protocol to control its morphology, dispersibility, and composition. Acs Omega 4:5768–5775

Zheng K, Taccardi N, Beltrán AM et al. (2016) Timing of calcium nitrate addition affects morphology, dispersity and composition of bioactive glass nanoparticles. RSC Adv 6:95101–95111

Zhang X, Zeng D, Li N et al. (2016) Functionalized mesoporous bioactive glass scaffolds for enhanced bone tissue regeneration. Sci Rep. 6:1–12

Wang H, Gao X, Wang Y et al. (2012) Bio-templated synthesis of mesoporous bioactive glass with a hierarchical pore structure. Mater Lett 76:237–239

Veres R, Vanea E, Gruian C et al. (2014) The effects of PEG assisted synthesis and zinc addition on gamma irradiated bioactive glasses. Compos Part B Eng 66:83–88

Duan H, Diao J, Zhao N, Ma Y (2016) Synthesis of hollow mesoporous bioactive glass microspheres with tunable shell thickness by hydrothermal-assisted self-transformation method. Mater Lett 167:201–204

Hu Q, Chen X, Zhao N, Li Y (2013) Facile synthesis and in vitro bioactivity of monodispersed mesoporous bioactive glass sub-micron spheres. Mater Lett 106:452–455

Santhiya D, kumari Alajangi H, Anjum F et al. (2013) Bio-inspired synthesis of microporous bioactive glass-ceramic using CT-DNA as a template. J Mater Chem B 1:6329–6338

Luo H, Xiao J, Peng M et al. (2020) One-pot synthesis of copper-doped mesoporous bioglass towards multifunctional 3D nanofibrous scaffolds for bone regeneration. J Non Cryst Solids 532:119856

Chen Q-Z, Rezwan K, Françon V et al. (2007) Surface functionalization of Bioglass®-derived porous scaffolds. Acta Biomater 3:551–562

Xue Y, Zhang Z, Niu W et al. (2019) Enhanced physiological stability and long‐term toxicity/biodegradation in vitro/in vivo of monodispersed glycerolphosphate‐functionalized bioactive glass nanoparticles. Part Part Syst Charact 36:1800507

Eqtesadi S, Motealleh A, Miranda P et al. (2013) A simple recipe for direct writing complex 45S5 Bioglass® 3D scaffolds. Mater Lett 93:68–71

Kleinfehn AP, Lammel Lindemann JA, Razvi A et al. (2019) Modulating bioglass concentration in 3D printed poly (propylene fumarate) scaffolds for post-printing functionalization with bioactive functional groups. Biomacromolecules 20:4345–4352

Larranaga A, Ramos D, Amestoy H et al. (2015) Coating of bioactive glass particles with mussel-inspired polydopamine as a strategy to improve the thermal stability of poly (l-lactide)/bioactive glass composites. RSC Adv 5:65618–65626

Tejido-Rastrilla R, Baldi G, Boccaccini AR (2018) Ag containing polydopamine coating on a melt-derived bioactive glass-ceramic: effect on surface reactivity. Ceram Int 44:16083–16087

Das MP, Pandey G, Neppolian B, Das J (2021) Design of poly-l-glutamic acid embedded mesoporous bioactive glass nanospheres for pH-stimulated chemotherapeutic drug delivery and antibacterial susceptibility. Colloids Surf B Biointerfaces 202:111700

Słota D, Florkiewicz W, Sobczak-Kupiec A (2020) Ceramic-polymer coatings on Ti-6Al-4V alloy modified with l-cysteine in biomedical applications. Mater Today Commun 25:101301

Zhao Y, Gao S, Zhao S et al. (2012) Synthesis and characterization of disulfide-crosslinked alginate hydrogel scaffolds. Mater Sci Eng C 32:2153–2162

Kokubo T, Takadama H (2006) How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 27:2907–2915

Hu Q, Li Y, Zhao N et al. (2014) Facile synthesis of hollow mesoporous bioactive glass sub-micron spheres with a tunable cavity size. Mater Lett 134:130–133

Xu Y, Wu P, Feng P et al. (2018) Interfacial reinforcement in a poly-l-lactic acid/mesoporous bioactive glass scaffold via polydopamine. Colloids Surf B Biointerfaces 170:45–53

Khan M, Shaik MR, Khan ST et al. (2020) Enhanced antimicrobial activity of biofunctionalized zirconia nanoparticles. ACS omega 5:1987–1996

Wang J, Fei G, Pan Y et al. (2019) Simultaneous reduction and surface functionalization of graphene oxide by cystamine dihydrochloride for rubber composites. Compos Part A Appl Sci Manuf 122:18–26

Sharifiaghdam M, Shaabani E, Asghari F, Faridi‐Majidi R (2022) Chitosan coated metallic nanoparticles with stability, antioxidant, and antibacterial properties: potential for wound healing application. J Appl Polym Sci 139:51766

Karimi‐Soflou R, Mohseni‐Vadeghani E, Karkhaneh A (2022) Controlled release of resveratrol from a composite nanofibrous scaffold: Effect of resveratrol on antioxidant activity and osteogenic differentiation. J Biomed Mater Res Part A 110:21–30

Prabhu M, Kavitha K, Suriyaprabha R et al. (2013) Preparation and characterization of silver-doped nanobioactive glass particles and their in vitro behaviour for biomedical applications. J Nanosci Nanotechnol 13:5327–5339

Bano S, Akhtar M, Yasir M et al. (2021) Synthesis and characterization of silver–strontium (Ag-Sr)-doped mesoporous bioactive glass nanoparticles. Gels 7:34

Sing KSW (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl Chem 57:603–619

Huang K, Cai S, Xu G et al. (2013) Preparation and characterization of mesoporous 45S5 bioactive glass–ceramic coatings on magnesium alloy for corrosion protection. J Alloy Compd 580:290–297

Anand A, Lalzawmliana V, Kumar V et al. (2019) Preparation and in vivo biocompatibility studies of different mesoporous bioactive glasses. J Mech Behav Biomed Mater 89:89–98

Liang Q, Hu Q, Miao G et al. (2015) A facile synthesis of novel mesoporous bioactive glass nanoparticles with various morphologies and tunable mesostructure by sacrificial liquid template method. Mater Lett 148:45–49

Taghvaei AH, Danaeifar F, Gammer C et al. (2020) Synthesis and characterization of novel mesoporous strontium-modified bioactive glass nanospheres for bone tissue engineering applications. Microporous Mesoporous Mater 294:109889

Toncón-Leal CF, Villarroel-Rocha J, Silva MTPda et al. (2021) Characterization of mesoporous region by the scanning of the hysteresis loop in adsorption–desorption isotherms. Adsorption 27:1109–1122

Zheng K, Torre E, Bari A et al. (2020) Antioxidant mesoporous Ce-doped bioactive glass nanoparticles with anti-inflammatory and pro-osteogenic activities. Mater Today Bio 5:100041

Tian T, Xie W, Gao W et al. (2019) Micro-nano bioactive glass particles incorporated porous scaffold for promoting osteogenesis and angiogenesis in vitro. Front Chem 7:186

Dang TH, Bui TH, Guseva EV et al. (2020) Characterization of bioactive glass synthesized by sol-gel process in hot water. Crystals 10:529

Ou S-F, Tsao Y-L, Lin W-C et al. (2020) Novel epigallocatechin-3-gallate (Egcg)-loaded mesoporous bioglass scaffolds for bone recruitment applications. Appl Sci 11:243

Lai W, Yang S, Jiang Y et al. (2020) Artefact peaks of pore size distributions caused by unclosed sorption isotherm and tensile strength effect. Adsorption 26:633–644

Thielemann JP, Girgsdies F, Schlögl R, Hess C (2011) Pore structure and surface area of silica SBA-15: influence of washing and scale-up. Beilstein J Nanotechnol 2:110–118

Erasmus EP, Johnson OT, Sigalas I, Massera J (2017) Effects of sintering temperature on crystallization and fabrication of porous bioactive glass scaffolds for bone regeneration. Sci Rep. 7:1–12

Lusvardi G, Malavasi G, Tarsitano F et al. (2009) Quantitative structure− property relationships of potentially bioactive fluoro phospho-silicate glasses. J Phys Chem B 113:10331–10338

Arstila H, Hupa L, Karlsson KH, Hupa M (2008) Influence of heat treatment on crystallization of bioactive glasses. J Non Cryst Solids 354:722–728

O’Donnell MD (2011) Predicting bioactive glass properties from the molecular chemical composition: glass transition temperature. Acta Biomater 7:2264–2269

Tabia Z, El Mabrouk K, Bricha M, Nouneh K (2019) Mesoporous bioactive glass nanoparticles doped with magnesium: drug delivery and acellular in vitro bioactivity. RSC Adv 9:12232–12246

Shah AT, Ain Q, Chaudhry AA et al. (2015) A study of the effect of precursors on physical and biological properties of mesoporous bioactive glass. J Mater Sci 50:1794–1804

Faure J, Drevet R, Lemelle A et al. (2015) A new sol–gel synthesis of 45S5 bioactive glass using an organic acid as catalyst. Mater Sci Eng C 47:407–412

Heng C, Liu M, Wang K et al. (2015) Biomimic preparation of highly dispersible silica nanoparticles based polymer nanocomposites. Ceram Int 41:15075–15082

Bai L, Duan S, Jiang W et al. (2017) High performance polydopamine-functionalized mesoporous silica nanospheres for U (VI) removal. Appl Surf Sci 426:1121–1132

Yan P, Wang J, Wang L et al. (2011) The in vitro biomineralization and cytocompatibility of polydopamine coated carbon nanotubes. Appl Surf Sci 257:4849–4855

Sousa MH, Rubim JC, Sobrinho PG, Tourinho FA (2001) Biocompatible magnetic fluid precursors based on aspartic and glutamic acid modified maghemite nanostructures. J Magn Magn Mater 225:67–72

Kumar R, Inbaraj BS, Chen BH (2010) Surface modification of superparamagnetic iron nanoparticles with calcium salt of poly (γ-glutamic acid) as coating material. Mater Res Bull 45:1603–1607

Dutta B, Nema A, Shetake NG et al. (2020) Glutamic acid-coated Fe3O4 nanoparticles for tumor-targeted imaging and therapeutics. Mater Sci Eng C 112:110915

Park K, Park SS, Yun YH, Ha C-S (2017) Mesoporous silica nanoparticles functionalized with a redox-responsive biopolymer. J Porous Mater 24:1215–1225

Ylänen H, Karlsson KH, Itälä A, Aro HT (2000) Effect of immersion in SBF on porous bioactive bodies made by sintering bioactive glass microspheres. J Non Cryst Solids 275:107–115

Lei B, Chen X, Wang Y, Zhao N (2009) Synthesis and in vitro bioactivity of novel mesoporous hollow bioactive glass microspheres. Mater Lett 63:1719–1721

Wu S, Liu X, Yeung KWK et al. (2014) Biomimetic porous scaffolds for bone tissue engineering. Mater Sci Eng R Rep. 80:1–36

Quintero Sierra LA, Escobar Sierra DM (2019) Synthesis and bioactivity evaluation of a rice husk-derived bioactive glass. JOM 71:302–307

Mariappan CR, Ranga N (2017) Influence of silver on the structure, dielectric and antibacterial effect of silver doped bioglass-ceramic nanoparticles. Ceram Int 43:2196–2201

Gorriti MF, López JMP, Boccaccini AR et al. (2009) In vitro study of the antibacterial activity of bioactive glass‐ceramic scaffolds. Adv Eng Mater 11:B67–B70

Gupta N, Santhiya D, Murugavel S et al. (2018) Effects of transition metal ion dopants (Ag, Cu and Fe) on the structural, mechanical and antibacterial properties of bioactive glass. Colloids Surf A Physicochem Eng Asp 538:393–403

Akhtach S, Tabia Z, Bricha M, El Mabrouk K (2021) Structural characterization, in vitro bioactivity, and antibacterial evaluation of low silver-doped bioactive glasses. Ceram Int 47:29036–29046

Wang Y, Pan H, Chen X (2019) The preparation of hollow mesoporous bioglass nanoparticles with excellent drug delivery capacity for bone tissue regeneration. Front Chem 7:283

Kumar A, Murugavel S, Aditya A, Boccaccini AR (2017) Mesoporous 45S5 bioactive glass: synthesis, in vitro dissolution and biomineralization behavior. J Mater Chem B 5:8786–8798

Acknowledgements

PS would like to acknowledge DST Inspire Faculty Scheme (DST/INSPIRE/04/2015/000742). JA would like to recognize the fellowship assistance (Institute Ph.D. fellowship) kindly supported by IIEST Shibpur for the Ph.D. program. The authors would also like to acknowledge Prof. Amitava Basu Mallick, Professor, Department of Metallurgy and Materials Engineering-IIEST Shibpur, for the support of DSC characterization and Dr. Partha Bhattacharyya, Department of Electronics and Telecommunication Engineering, for the help of BET characterization. The Central Research Facility, IIT Kharagpur, facilitated the EDS characterization slot.

Funding

The functionalization part was partially supported by SERB Core Research Grant, Govt. of India, Grant No. CRG/2021/005113.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Adhikari, J., Dasgupta, S., Barui, A. et al. Functionalized mesoporous SiO2-CaO-Na2O-P2O5 based nanometric glass-ceramic particles with enhanced dispersibility and bioactivity. J Sol-Gel Sci Technol 106, 757–774 (2023). https://doi.org/10.1007/s10971-023-06074-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06074-1