Abstract

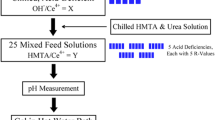

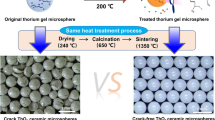

Pressurized water treatments were investigated as a means to prevent cracking of internal gelation sol-gel microspheres upon drying and heating. A batch of gelled cerium oxide microspheres was prepared, split into two samples that were processed with and without a pressurized water treatment, and dried in air at room temperature. Thermogravimetric analysis was used to compare the mass loss profiles between the two samples and to understand volatile emissions from cerium oxide microspheres during heat treatments up to 600 °C. Microspheres that were processed without a pressurized water treatment lost ~4.6 times more mass upon heating than microspheres that were subjected to a pressurized water treatment. Comparison of the cracking behavior of microspheres prepared with and without a pressurized water treatment indicated that microspheres subjected to a pressurized water treatment were virtually crack-free after heat treatments. Conversely, microspheres processed without a pressurized water treatment, which is typical of traditional washing processes, exhibited extensive cracking. Analysis of residues dried from pressurized water treatment effluents indicated that hexamethylenetetramine and urea, which are excess reactants from the internal gelation process, were removed from gelled microspheres during the pressurized water treatment step. Traditional processing methods for preparing internal gelation microspheres use specific feed solution and gelation parameters to reduce subsequent cracking upon drying and heating. Results from this study indicate that more aggressive gel-forming conditions may be used to produce crack-free microspheres, if a pressurized water treatment step is included after washing and before air-drying.

A hydrothermal treatment on gelled microspheres removes species that otherwise cause cracking upon drying the heating.

Highlights

-

High-quality, crack-free microspheres of CeO2 were produced

-

Pressurized water treatments prevented cracking of sol-gel microspheres

-

Pressurized water treatments removed hexamine and urea prior to drying

-

Cracking was attributed to the release of volatile species while drying and heating

Similar content being viewed by others

References

Brugghen FW v. d., Noothout AJ, Hermans MEA et al. (1970) A U(VI)-process for microsphere production. In: Sol-gel processes and reactor fuel cycles. Oak Ridge National Laboratory, Gatlinburg, Tennessee

Kanij JBW, Noothout AJ, Votocek O (1973) The KEMA U(VI)-process for the production of UO2 microspheres. In: Proceedings of a panel on sol-gel process for fuel fabrication. International Atomic Energy Agency, Vienna

Collins JL, Chi A (2009) Determination of ideal broth formulations needed to prepare hydrous cerium oxide microspheres via the internal gelation process. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Ye B, Miao J-L, Li J-L et al. (2012) Fabrication of sze-controlled CeO2 microparticles by a microfluidic sol–gel process as an analog preparation of ceramic nuclear fuel particles. J Nucl Sci Technol 50:774–780. https://doi.org/10.1080/00223131.2013.796897

Gangar BV, Nagarajan K, Krishnan RV, Pandit AB(2012) Preparation of alumina and alumina-ceria microspheres using an internal gelation process and their characterization. Trans Indian Ceram Soc 71:101–109

Gao Y, Ma JT, Zhao XY et al. (2015) The formation of alumina ceramic microspheres by internal gelation process Key Eng Mater 655:103–107. https://doi.org/10.4028/www.scientific.net/KEM.655.103

Collins JL, Pye SL (2008) Determination of ideal broth formulations needed to prepare hydrous aluminum oxide microspheres by the internal gelation process. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Idemitsu K, Arima T, Inagaki Y et al. (2003) Manufacturing of zirconia microspheres doped with erbia, yttria and ceria by internal gelation process as a part of a cermet fuel. J Nucl Mater 319:31–36. https://doi.org/10.1016/S0022-3115(03)00130-2

Benay G, Hubert F, Modolo G (2008) Preparation of yttria-stabilized zirconia-ceria kernels as fuel precursors using internal gelation. Radiochim Acta 96:285–291. https://doi.org/10.1524/ract.2008.1489

Collins JL, Watson JS (2000) Economic evaluation for the production of sorbents and catalysts derived from hydrous titanium oxide microspheres prepared by the HMTA internal gelation process. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Kumar N, Pai RV, Joshi JK et al. (2006) Preparation of (U,Pu)O2 pellets through Sol–Gel microsphere pelletization technique. J Nucl Mater 359:69–79. https://doi.org/10.1016/j.jnucmat.2006.07.018

Pai RV, Dehadraya JV, Bhattacharya S et al. (2008) Fabrication of dense (Th,U)O2 pellets through microspheres impregnation technique. J Nucl Mater 381:249–258. https://doi.org/10.1016/j.jnucmat.2008.07.044

Pai RV, Mukerjee SK, Vaidya VN (2004) Fabrication of (Th,U)O2 pellets containing 3 mol% of uranium by gel pelletisation technique. J Nucl Mater 325:159–168. https://doi.org/10.1016/j.jnucmat.2003.11.010

Kumar N, Sharma RK, Ganatra VR et al. (1991) Studies of the preparation of thoria and thoria-urania microspheres using an internal gelation process. Nucl Technol 96:169–177. https://doi.org/10.13182/NT91-A34602

Kumar A, Radhakrishna J, Kumar N et al. (2013) Studies on preparation of (U0.47,Pu0.53)O2 microspheres by internal gelation process. J Nucl Mater 434:162–169. https://doi.org/10.1016/j.jnucmat.2012.11.009

Ledergerber G, Ingold F, Stratton RW et al. (1996) Preparation of transuranium fuel and target materials for the transmutation of actinides by gel coconversion. Nucl Technol 114:194–204. https://doi.org/10.13182/NT96-A35249

Katalenich JA, Hartman MR, O’Brien RC, Howe, Steven D (2013) Fabrication of cerium oxide and uranium oxide microspheres for space nuclear power applications. In: Nuclear and Emerging Technologies for Space (NETS 2013). American Nuclear Society, Albuquerque, NM

Borland M, Frank S, Lessing P et al. (2008) Evaluation of aqueous and powder processing techniques for production of Pu-238 fueled general purpose heat sources. Idaho National Laboratory, Idaho Falls, Idaho

United States (1991) Report of an Investigation into Deterioration of the Plutonium Fuel Form Fabrication Facility (PuFF) at the DOE Savannah River Site. In: U.S. Dept. of Energy, Office of Nuclear Safety; Available to the public from the National Technical Information Service. Springfield, VA, Washington, DC

Office of Oversight, Rollow T (2000) Type A accident investigation of the March 16, 2000 Plutonium-238 multiple intake event at the plutonium facility Los Alamos National Laboratory. U.S. Department of Energy, Office of Environment, Safety, and Health, Washington, DC

Department of Energy, National Nuclear Security Administration (2003) Type B accident investigation of the August 5, 2003 Plutonium-238 multiple uptake event at the plutonium facility, Los Alamos National Laboratory, New Mexico. Technical Information Center, Oak Ridge Tennessee

Katalenich JA (2014) Production of Monodisperse, Crack-Free Cerium Oxide Microspheres by Internal Gelation Sol-Gel Methods. University of Michigan, Ann Arbor, Michigan

Katalenich JA (2017) Production of cerium dioxide microspheres by an internal gelation sol–gel method. J Sol-Gel Sci Technol 82:654–663. https://doi.org/10.1007/s10971-017-4345-8

Katalenich JA, Pierson BD, Kitchen BB (2018) Production of monodisperse cerium oxide microspheres with diameters near 100 µm by internal-gelation sol–gel methods. J Sol-Gel Sci Technol 86:329–342. https://doi.org/10.1007/s10971-018-4641-y

Katalenich JA (2019) Impurity levels in cerium oxide microspheres prepared by internal gelation sol-gel methods. J Sol-Gel Sci Technol. https://doi.org/10.1007/s10971-019-05165-2

Hunt RD, Collins JL (2004) Uranium Kernel Formation via Internal Gelation. Radiochim Acta 92:909–915. https://doi.org/10.1524/ract.92.12.909.55110

Collins JL (2004) Production of depleted UO2 kernels for the advanced gas-cooled reactor program for use in TRISO coating development. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Haas PA, Begovich JM, Ryon AD, Vavruska JS (1980) Chemical flowsheet conditions for preparing urania spheres by internal gelation. Ind Eng Chem Prod Res Dev 19:459–467. https://doi.org/10.1021/i360075a033

Hunt RD, Montgomery FC, Collins JL (2010) Treatment techniques to prevent cracking of amorphous microspheres made by the internal gelation process. J Nucl Mater 405:160–164. https://doi.org/10.1016/j.jnucmat.2010.08.007

Hunt RD, Collins JL, Johnson JA, Cowell BS (2017) Production of 75–150 µm and <75µm of cerium dioxide microspheres in high yield and throughput using the internal gelation process. Ann Nucl Energy 105:116–120. https://doi.org/10.1016/j.anucene.2017.03.010

Haas PA (1975) Formation of liquid drops with uniform and controlled diameters at rates of 10^3 to 10^5 drops per minute. Am Inst Chem Eng 21:383–385

Haas PA, Lackey WJ (1973) Improved size uniformity of sol-gel spheres by imposing a vibration on the sol in dispersion nozzles. Oak Ridge National Laboratory, Oak Ridge, Tennessee

King CM, King RB, Garber RA et al. (1990) Magnetic Resonance as a Structural Probe of a Uranium (VI) Sol-Gel Process. In: MRS Online Proceedings Library. Materials Research Society, San Francisco, CA

Collins JL, Lloyd MH, Fellows RL (1984) Effects of process variables on reaction mechanisms responsible for ADUN hydrolysis, precipitation, and gelation in the internal gelation gel-sphere process. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Collins MHL JL, Fellows RL (1987) The basic chemistry involved in the internal-gelation method of precipitating uranium as determined by pH measurements. Radiochim Acta 42:121–134

Vaidya VN, Mukherjee SK, Joshi JK et al. (1987) A study of chemical parameters of the internal gelation based sol-gel process for uranium dioxide. J Nucl Mater 148:324–331

Collins JL, Lloyd MH, Shell SE (2005) Control of urania crystallite size by HMTA-Urea reactions in the internal gelation process for preparing (U,Pu)O2 fuel kernels. Oak Ridge National Laboratory, Oak Ridge, Tennessee

Lloyd MH, Bischoff K, Peng K et al. (1976) Crystal habit and phase attribution of U (VI) oxides in a gelation process. J Inorg Nucl Chem 38:1141–1147

Baran V, Štamberg K, Tympl M, Kinzelová J (1975) Uranyl prepared by the internal gelation. Part I. The determination of the gelation regions in uranyl nitrate systems. J Nucl Mater 58:59–66. https://doi.org/10.1016/0022-3115(75)90167-1

Robisson AC, Dauby J, Grandjean S et al. (2008) Microspheres prepared by internal gelation – Understanding of HMTA and urea reactions. In: ATALANTE 2008. Commissariat à l'énergie atomique, Montpellier, France

Ng H, Teoh S, Moris N, Yang Yap S (2004) Structural, infrared spectral and thermogravimetric analysis of a hydrogen-bonded assembly of cobalt(II) and nickel(II) mixed complex cations with hexamethylenetetraamine and aqua ligands: {[M(hmt)2(H2O)4][M(H2O)6]}(SO4)2·6H2O. J Coord Chem 57:1037–1046. https://doi.org/10.1080/00958970412331281791

Yufanyi DM, Ondoh AM, Foba-Tendo J, Mbadcam KJ (2015) Effect of decomposition temperature on the crystallinity of α-Fe2O3 (Hematite) obtained from an Iron(III)-Hexamethylenetetramine precursor. Am J Chem 5:1–9

Stranski IN, Klipping G, Bogenschuetz AF et al. (1957) 43 Thermal Decomposition of Hexamethylenetetramine. In: Farkas A (ed) Advances in catalysis. Academic Press, Berlin-Dahlem, Germany, p 406–414

Chen JP, Isa K (1998) Thermal decomposition of urea and urea derivatives by simultaneous TG/(DTA)/MS. J Mass Spectrom Soc Jpn 46:299–303. https://doi.org/10.1016/j.tca.2013.04.034

Schaber P, Colson J, Higgins S et al. (1999) Study of the urea thermal decomposition (pyrolysis) reaction and importance to cyanuric acid production. Am Lab 31:13–21

Tischer S, Börnhorst M, Amsler J et al. (2019) Thermodynamics and reaction mechanism of urea decomposition. Phys Chem Chem Phys 21:16785–16797. https://doi.org/10.1039/C9CP01529A

Huthmacher K, Most D (2000) Cyanuric acid and cyanuric chloride. In: Ullmann’s encyclopedia of industrial chemistry. American Cancer Society, Hanau-Wolfgang, Federal Republic of Germany

Stein SE Mass Spectra. NIST Mass Spec Data Center, National Institute of Standards and Technology

Warner RC (1942) The kinetics of the hydrolysis of urea and of arginine. J Biol Chem 142:705–723

Dirnhuber P, Schütz F (1948) The isomeric transformation of urea into ammonium cyanate in aqueous solutions. Biochem J 42:628–632

Hirano M, Kato E (1999) Hydrothermal synthesis of nanocrystalline cerium(IV) oxide powders. J Am Ceram Soc 82:786–788. https://doi.org/10.1111/j.1151-2916.1999.tb01838.x

Wang F, Zhu J, Liu H (2018) Urea controlled hydrothermal synthesis of ammonium aluminum carbonate hydroxide rods. AIP Adv 8:035103. https://doi.org/10.1063/1.5018826

Shaw WHR, Bordeaux JJ (1955) The decomposition of urea in aqueous media. J Am Chem Soc 77:4729–4733. https://doi.org/10.1021/ja01623a011

Acknowledgements

Brian Kitchen, Bruce Pierson, Dr Michael Hartman, Dr Gary Was, and Dr John Foster of the University of Michigan Nuclear Engineering and Radiological Sciences Department provided useful ideas and input during the course of this work. The author would like to acknowledge and thank Ted Huston, W. M. Keck Elemental Geochemistry Laboratory, in the University of Michigan Department of Earth and Environmental Sciences, for ICP-HRMS analyses. In addition, the author would like to acknowledge and thank James Windak of the University of Michigan Chemistry Department for operating an electron impact mass spectrometer for experiments and Ian Schwerdt of the Pacific Northwest National Laboratory for paper review. This research was conducted with government support under and awarded by DoD, Air Force Office of Scientific Research, National Defense Science and Engineering Graduate (NDSEG) Fellowship, 32 CFR 168a. This material is based on work supported by the National Science Foundation Graduate Research Fellowship under Grant No. DGE 1256260. Any opinion, findings, and conclusions or recommendations expressed in this material is that of the author and does not necessarily reflect the views of the National Science Foundation. This material is based on work supported by the Center for Space Nuclear Research (CSNR) under the Universities Space Research Association (USRA) Subcontract 06711–003. The USRA operates the CSNR for the Idaho National Laboratory. This research was supported by a research seed grant received from the Michigan Space Grant Consortium with matching funds from the University of Michigan Department of Nuclear Engineering and Radiological Sciences. Pacific Northwest National Laboratory is operated for the United States Department of Energy by Battelle Memorial Institute under contract DE-AC05-76RL01830.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

JAK declares that he has no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Katalenich, J.A. Use of a pressurized water treatment to prevent cracking of internal gelation sol-gel microspheres. J Sol-Gel Sci Technol 94, 298–309 (2020). https://doi.org/10.1007/s10971-020-05230-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-020-05230-1