Abstract

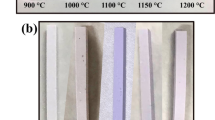

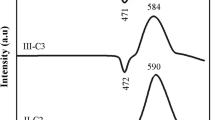

Lithium disilicate (Li2Si2O5) glass-ceramics were fabricated through two sol–gel methods: the nitrate route and the alkoxide route. Thermal analysis revealed different crystallization processing of two gel-derived powders. Li2Si2O5 powders were obtained after heat treatment at 800 °C. These powders were pressed and pressureless sintered under 900–1030 °C. Microstructure of sintered samples revealed the grain size and morphology of Li2Si2O5 ceramics. Although grain size in both samples increased with increasing sintering temperature, samples from the alkoxide route derived powders had more uniform grain size and pore distribution. In addition, open porosity decreased in both samples with increasing sintering temperature. Unlike familiar nucleation that resulted in grain growth mechanism, the Li2Si2O5 particles developed into irregular large size grains at first, and then grew into rod-shaped grains.

Highlights

-

Lithium disilicate glass-ceramics were fabricated through two sol-gel methods.

-

New grain growth mechanism of rodlike Li2Si2O5 grains was illustrated.

-

Sintering property of sol-gel derived Li2Si2O5 is more like that of ceramics.

Similar content being viewed by others

References

Kern M, Knode H, Strubb JR (1991) The all-porcelain, resin-bonded bridge. Quintessence Int 22:257

Andersson M, Odén A (1993) A new all-ceramic crown: A dense-sintered, high-purity alumina coping with porcelain. Acta Odontol Scand 51:59–64

Tinschert J, Natt G, Mautsch W, Augthun M, Spiekermann H (2001) Fracture resistance of lithium disilicate-, alumina-, and zirconia-based three-unit fixed partial dentures: a laboratory study. Int J Prosthodont 14:231

Sundh A, Molin M, Sjögren G (2005) Fracture resistance of yttrium oxide partially-stabilized zirconia all-ceramic bridges after veneering and mechanical fatigue testing. Dent Mater Off Publ Acad Dent Mater 21:476–482

Grey NJ, Piddock V, Wilson MA (1993) In vitro comparison of conventional crowns and a new all-ceramic system. J Dent 21:47–51

Aldegheishem A, Ioannidis G, Att W, Petridis H (2017) Success and survival of various types of all-ceramic single crowns: a critical review and analysis of studies with a mean follow-up of 5 years or longer. Int J Prosthodont 30:168

J Conejo, R Nueesch, M Vonderheide, MB Blatz, Clinical Performance of All-Ceramic Dental Restorations, Current Oral Health Reports, (2017) 4(2):112–113

W Holand, GH Beall, Glass Ceramic Technology, (2012). America: John Wiley & Sons

Quinn JB, Sundar V, Lloyd IK (2003) Influence of microstructure and chemistry on the fracture toughness of dental ceramics. Dent Mater 19:603

Ritter RG (2010) Multifunctional uses of a novel ceramic-lithium disilicate. J Esthet Restor Dent 22:332–341

Heffernan MJ, Aquilino SA, Diaz-Arnold AM, Haselton DR, Stanford CM, Vargas MA (2002) Relative translucency of six all-ceramic systems. Part II: core and veneer materials. J Prosthet Dent 88:10–15

Heffernan MJ, Aquilino SA, Diaz Arnold AM, Haselton DR, Stanford CM, Vargas MA (2002) Relative translucency of six all-ceramic systems. Part I: core materials. J Prosthet Dent 88:4–9

Höland W, Rheinberger V, Apel E, Van THC, Höland M, Dommann A, Obrecht M, Mauth C, Graf-Hausner U (2006) Clinical applications of glass-ceramics in dentistry. J Mater Sci: Mater Med 17:1037–1042

Boiko GG, Sycheva GA, Valjuk LG (1995) Influence of synthesis conditions on the kinetics of crystallization of photosensitive lithium silicate glasses. Glass Phys Chem 21:45–52

Soares PC, Jr. Zanotto ED, Fokin VM, Jain H (2003) TEM and XRD study of early crystallization of lithium disilicate glasses J Non-Cryst. Solids 331:217–227

Zheng X, Wen G, Song L, Huang XX (2008) Effects of P2O5 and heat treatment on crystallization and microstructure in lithium disilicate glass ceramics. Acta Mater 56:549–558

Huang S, Cao P, Wang C, Huang Z, Gao W (2013) Fabrication of a high-strength lithium disilicate glass-ceramic in a complex glass system. J Asian Ceram Soc 1:46–52

Sycheva GA (2011) Sol–gel synthesis of photostructured gold_containing lithium silicate glasses. Glass Phys Chem 37:495–503

Sycheva GA, Kostyreva TG (2014) Nucleation and morphology of crystals in simple and complex silicate glasses R'2O-SiO2, R'2O-R“O-SiO2, (R’ = Li, Na, K; R” = Ca, Mg). Synth Sol-Gel Method 40:513–520

Zhang TB, Easteal AJ, Edmonds NR, Debes B (2007) Sol–gel preparation and characterization of lithium disilicate glass–ceramic. J Am Ceram Soc 90:1592–1596

Yuan K, Wang F, Gao J, Sun X, Deng Z, Wang H, Chen J (2013) Effect of sintering time on the microstructure, flexural strength and translucency of lithium disilicate glass-ceramics. J Non-Cryst Solids 362:7–13

Wen G, Zheng X, Song L (2007) Effects of P2O5 and sintering temperature on microstructure and mechanical properties of lithium disilicate glass-ceramics. Acta Mater 55:3583–3591

Zhao T, Qin Y, Wang B, Yang JF (2015) Improved densification and properties of pressureless-sintered lithium disilicate glass-ceramics. Mater Sci & Eng A 620:399–406

Fernandes HR, Tulyaganov DU, Pascual MJ, Kharton VV, Yaremchenko AA, Ferreira JMF (2012) The role of K2O on sintering and crystallization of glass powder compacts in the Li2O–K2O–Al2O3–SiO2 system. J Eur Ceram Soc 32:2283–2292

Zhao T, Qin Y, Zhang P, Wang B, Yang JF (2014) High-performance, reaction sintered lithium disilicate glass–ceramics. Ceram Int 40:12449–12457

Karpukhina N, Abomosallam HA, Hill RG, Law RV, (2013) Effect of sodium, potassium and zinc substitutions in lithium disilicate glass and glass-ceramics Phys Chem Glasses-B 54:76–83

Knickerbocker SH, Kumar AH, Herron LW (1993) Cordierite glass-ceramics for multilayer ceramic packaging. Am Ceram Soc Bull 72:90–95

Fernandes HR, Tulyaganov DU, Goel IK, Ferreira JMF (2008) Crystallization process and some properties of Li2O–SiO2 glass–ceramics doped with Al2O3 and K2O J Am Ceram Soc 91:3698–3703

Li P, Francis LF (1995) Sol-gel processing of lithium disilicate. J Mater Sci 30:6192–6204

Li P, Ferguson BA, Francis LF (1995) Sol–gel processing lithium disilicate. Part I. Crystalline phase development of gel-derived powders. J Mater Sci 30:4076–4086

Lupulescu A, Glicksman ME (2000) Diffusion-limited crystal growth in silicate systems: similarity with high-pressure liquid-phase sintering. J Cryst Growth 211:49–61

Huang S, Huang Z, Gao W et al. (2013) In situ high-temperature crystallographic evolution of a nonstoichiometric Li2O· 2SiO2 glass. Inorg Chem 52:14188–14195

Acknowledgements

The work was financially supported by Shanghai Committee of Science and Technology, China (17441904100).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Wang, F., Li, K. & Ning, C. Sintering properties of sol–gel derived lithium disilicate glass ceramics. J Sol-Gel Sci Technol 87, 372–379 (2018). https://doi.org/10.1007/s10971-018-4738-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-018-4738-3