Abstract

To overcome the brittleness and the dry shrinkage of silica aerogels, natural attapulgite nanofiber is successfully used as reinforcement for monolithic silica aerogel composites possessing ultralow density and excellent thermal insulation properties. The attapulgite/silica aerogel composites are obtained by dispersing the acid-treated attapulgite fibers in silica sol, followed by aging and ambient pressure drying. The acid treatment of attapulgite fibers obviously improved the adhesion between silica aerogel and attapulgite fibers surface. The microstructure analysis showed that silica particles firmly adhered to the surface of the rod shaped crystal of attapulgite fibers, which played a supporting role as structure skeleton and substantially improved the integrity and mechanical strength of the aerogel composites. No obvious variation of the mesoporous silica structure was observed since the nanosized attapulgite fibers are effectively incorporated into the network, instead of separated into small fragments as pure aerogel shown. As the fiber content increased, the density decreased to 0.163 cm3/g first and then increased, while the thermal conductivity increased slightly with ranging between 0.0198 and 0.0228 W m−1 K−1. The aerogel samples with compression strength varying from 0.8 to 2.5 MPa were obtained. All these promising characteristics indicated that ATP/silica aerogel composites have diverse applications, especially in heat preservation field.

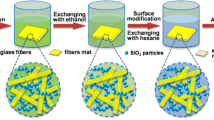

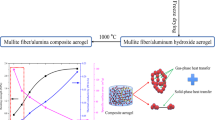

Graphical Abstract

Similar content being viewed by others

References

Hüsing N, Schubert U (1998) Aerogels-airy materials: chemistry, structure, and properties. Angew Chem Int Ed 37(1-2):22–45

Fricke J, Lu X, Wang P, Buttner D, Heinemann U (1992) Optimization of monolithic silica aerogel insulants. J Heat Mass Transfer 35(9):2305–2309

Pierre AC, Pajonk GM (2003) Chemistry of aerogels and their applications. Chem Rev 102(4):4243–4265

Huang Y, Niu J (2015) Application of super-insulating translucent silica aerogel glazing system on commercial building envelope of humid subtropical climates-impact on space cooling load. Energy 83(1):316–325

Koebel M, Rigacci A, Achard P (2012) Aerogel-based thermal superinsulation: an overview. J Sol Gel Sci Technol 63(3):315–339

Amiri TY, Moghaddas J, Khajeh S (2016) Silica aerogel-supported copper catalyst prepared via ambient pressure drying process. J Sol Gel Sci Technol 77(3):627–635

Ma H, Ding E, Wang W (2013) Power reduction with enhanced sensitivity for pellistor methane sensor by improved thermal insulation packaging. Sens Actuators B 187(10):221–226

Stergar J, Maver U (2016) Review of aerogel-based materials in biomedical applications. J Sol Gel Sci Technol 77(3):738–752

Tscheuschner D, Ratke L (2000) Investment casting in silica aerogels. Mater Sci Forum 329-330:479–486

Maleki H, Durães L, García-González C et al. (2016) Synthesis and biomedical applications of aerogels: possibilities and challenges. Adv Colloid Interface Sci 236:1–27

Metzger T, Léonard A, Jomaa W, Tamon H (2011) Understanding and prePlease confirm the book title has been identified correctly in the Reference [11].venting structural changes during drying of gels, modern drying technology, Volume 3. Product quality and formulation. Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, p 155–229

Prakash SS, Hurd HAJ, Rao SM, Brinker CJ (1995) Silica aerogel films prepared at ambient pressure by using surface derivatization to induce reversible drying shrinkage. Nature 374(375):439–443

Leventis N (2007) Three-dimensional core–shell superstructures: mechanically strong aerogels. Chem Res 40(51):874–884

Zou H, Wu S, Shen J (2008) Polymer/silica nanocomposites: preparation, characterization, properties, and applications. Chem Res 108(52):3893–3957

Maleki H, Durães L, Portugal A (2014) An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J Non-Cryst Solids 385(2):55–74

Li Z, Gong L, Cheng X, He S, Li C, Zhang H (2016) Flexible silica aerogel composites strengthened with aramid fibers and their thermal behavior. Mater Des 99:349–355

Meador M, Vivod S, Mccorkle L, Quade D, Sullivan R, Ghosn L (2008) Reinforcing polymer cross-linked aerogels with carbon nanofibers. J Mater Chem 18(16):1843–1852

Yuan B, Ding S, Wang D, Wang G, Li H (2012) Heat insulation properties of silica aerogel/glass fiber composites fabricated by press forming. Mater Lett 75(1):204–206

Tong L, Lou J, Gattass R, He S, Chen X, Liu L (2005) Assembly of silica nanowires on silica aerogels for microphotonic devices. Nano Lett 5(2):259–262

Cai J, Liu S, Feng J, Kimura S, Wada M, Kuga S et al. (2012) Cellulose-silica nanocomposite aerogels by in situ formation of silica in cellulose gel. Angew Chem Int Ed 51(9):2076–2079

Yang X, Sun Y, Shi D, Liu J (2011) Experimental investigation on mechanical properties of a fiber-reinforced silica aerogel composite. Mater Sci Eng A 528(13-14):4830–4836

Li L, Yalcin B, Nguyen B, Meador M, Cakmak M (2009) Flexible nanofiber-reinforced aerogel (xerogel) synthesis, manufacture, and characterization. ACS Appl Mater Interfaces 1(11):2491–2501

Zhang Z, Shen J, Ni X, Wu G, Zhou B, Yang M et al. (2006) Hydrophobic silica aerogels strengthened with nonwoven fibers. J Macromol Sci 43(11):1663–1670

Zeng S, Hunt A, Cao W, Greif R (1994) Pore size distribution and apparent gas thermal conductivity of silica aerogel. J Heat Transf 116(3):756–759

Yang J, Li S, Luo Y, Yan L, Wang F et al. (2011) Compressive properties and fracture behavior of ceramic fiber-reinforced carbon aerogel under quasi-static and dynamic loading. Carbon N Y 49(5):1542–1549

Bradley W (1940) The structural scheme of attapulgite. Am Miner 25:405–410

Meador M, Capadona L, Linda M, Leventis N (2007) Structure–property relationships in porous 3D nanostructures as a function of preparation conditions: isocyanate cross-linked silica aerogels. Chem Mater 19(9):2247–2260

Mendelovici E (1973) Infrared study of attapulgite and HCl treated attapulgite. Clays Clay Miner 21(2):115–119

Cai YF, Xue JY, Polya DA (2007) A Fourier transform infrared spectroscopic study of Mg-rich, Mg-poor and acid leached palygorskites. Spectrochim Acta Part A 66(2):282–288

Malfait W, Zhao S, Verel R, Iswar S, Rentsch D, Fener R et al. (2015) Surface chemistry of hydrophobic silica aerogels. Chem Mater 27(19):6737–6745

Duan Y, Jana S, Lama B, Espe M (2013) Reinforcement of silica aerogels using silane-end-capped polyurethanes. Langmuir 29(20):6156–6165

Scheuerpflug P, Caps R, Büttner D, Fricke J (1985) Apparent thermal conductivity of evacuated SiO2-aerogel tiles under variation of radiative boundary conditions. Int J Heat Mass Transf 28(12):2299–2306

Abe H, Sato K, Naito M et al. (2005) Dry powder processing of fibrous fumed silica compacts for thermal insulation. J Am Ceram Soc 88(5):1359–1361

Kim C, Lee J (2008) Kim B synthesis and pore analysis of aerogel-glass fiber composites by ambient drying method. Coll Surf A 313(1):179–182

Wang J (1995) Monolithic silica aerogel insulation doped with TiO2 powder and ceramic fibers. J Non-Cryst Solids 186(2):296–300

Yang X, Sun Y, Shi D (2012) Experimental investigation and modeling of the creep behavior of ceramic fiber-reinforced SiO2 aerogel. J Non-Cryst Solids 358(3):519–524

Cai J, Liu S, Feng J, Kimura S, Wada M et al. (2012) Cellulose-silica nanocomposite aerogels by In situ formation of silica in cellulose gel. Angew Chem Int Ed 51(9):2076–2079

Acknowledgments

This work was supported by the National Natural Science Foundation of China (grant number 11574331); the Jiangsu and Zhejiang Key R & D program (grant number BE2015104 and 2015C01039); and the Ningbo Science and Technology Bureau (Grant number 2015B11002, 2015A610017 and 2016B10005).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interest.

Rights and permissions

About this article

Cite this article

Li, J., Lei, Y., Xu, D. et al. Improved mechanical and thermal insulation properties of monolithic attapulgite nanofiber/silica aerogel composites dried at ambient pressure. J Sol-Gel Sci Technol 82, 702–711 (2017). https://doi.org/10.1007/s10971-017-4359-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-017-4359-2