Abstract

Between 2016 and 2021, Germany’s first total diet study was performed to assess the variety of substances humans are exposed to by dietary intake. On a global scale rather unique, the natural radionuclides lead-210, uranium-234, uranium-238, radium-226, and radium-228 should be investigated in over 200 different food samples within that study. This paper serves as a guide how to successfully determine these natural radionuclides in very low concentrations in a variety of samples. Two independent laboratories were involved for comparison to assure the quality of the presented sample pretreatment and analyzing techniques.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Both, natural and human-made radionuclides ubiquitously present in the environment, may enter the food chain to a certain extent. The order of magnitude of their transfer and accumulation in crops and animal products vary widely and depend mainly on the respective physicochemical properties of the radionuclide in conjunction with natural and anthropogenic factors such as soil properties, climatic conditions or agricultural practices [1,2,3].

Until recently, the public exposure to radiation from radionuclides caused, among other things, by the consumption of food, was only considered in the event of a nuclear or radiological emergency by the International Atomic Energy Agency (IAEA) [4]. Accordingly, most of the national environmental monitoring programs solely focus on human-made radionuclides. However, with the establishment of the IAEA Safety Standard Series No. GSR Part 3 [5] complemented by the IAEA-TECDOC-2011 [6] and Safety Reports Series No. 114 [7], the general dietary public exposure to radionuclides in non-emergency situations was brought to attention. This includes human-made radionuclides present in the environment due to past nuclear or radiological emergencies and activities, but also natural radionuclides [5]. Evaluating 127 dietary dose studies covering 46 countries worldwide [7], approximately 90% of the annual effective dose from dietary intake can be related to natural radionuclides of the uranium (U) and thorium (Th) decay chain. The four main contributors in order of priority are polonium-210 (Po-210), lead-210 (Pb-210), radium-228 (Ra-228), and radium-226 (Ra-226). This is in good agreement with the generic dose assessment carried out by the United Nations Scientific Committee on the Effects of Atomic Radiation (UNSCEAR) for the ingestion of U and Th series radionuclides [1]. Potassium-40 (K-40) as naturally occurring part of the stable potassium (K) was excluded from this dose assessment because it is not amenable to control. Caesium-134 (Cs-134), caesium-137 (Cs-137), and strontium-90 (Sr-90) as human-made radionuclides together with the carbon-14 (C-14), originating both from natural sources and human activities, accounted only for 8% of the annual effective dose by dietary intake.

To assess the dietary intake and potential exposure to radionuclides, it is mandatory to investigate their levels in foods and link them with food consumption data. Different study designs of dietary surveys exist, such as canteen meal studies, duplicate diet studies, market basket studies and total diet studies [6, 7]. The most efficient study design to examine contents of substances in foods for risk assessment is a total diet study (TDS) [8]. Essential characteristics of a TDS are the selection of representative foods of a population´s diet, preparation of foods as typically consumed and combining of similar food items to one pool sample. Conducted by several countries like Australia, Japan and USA since decades [9], the field phase of the first German TDS started in 2016 by the German Federal Institute for Risk Assessment (BfR) [10]. With the investigation of more than 300 beneficial or potentially harmful substances in 356 foods [11,12,13,14,15,16,17], the BfR MEAL Study (‘meals for exposure assessment and analysis of foods’) is one of the broadest TDSs worldwide. The determination of radionuclides within this study was performed by the radiochemical laboratory of the Federal Office for Radiation Protection (BfS). The focus was on the analyses of natural radionuclides since the radiation exposure to human-made radionuclides is well known and reported annually in Germany [18]. Typically, radionuclides in dietary surveys are analyzed utilizing gamma spectrometry due to the simultaneous identification and quantification of a number of gamma-emitting radionuclides and a less extensive sample preparation [19,20,21,22,23,24,25,26]. However, the content of the radionuclides of interest may vary widely between as well as within food groups, such as in vegetables, fruit, meat or fish and their respective associated products. Since the natural radionuclides Po-210, Pb-210, Ra-228, and Ra-226, which contribute the most to the annual dose [7], are primarily alpha and beta emitters, their detection via gamma spectrometry might be challenging or not possible at all. Brief descriptions of a number of radioanalytical techniques for the determination of these natural radionuclides can be found in the literature [27,28,29,30,31] including a previous BfS study [32]. The aim of the present study was to establish reliable and optimized methods for the determination of the naturally occurring radionuclides Pb-210, Ra-226, Ra-228, and additionally the U isotopes uranium-234 (U-234) and uranium-238 (U-238) in more than 200 food samples provided by the BfR MEAL Study. Since numerous food samples were unique and had not been investigated before, sample pretreatment procedures, measurement setups and their optimization will be described in detail by the BfS laboratory and the external quality assurance laboratories VKTA—Radiation Protection, Analytics & Disposal Rossendorf e.V. and IAF—Radioökologie GmbH. This paper will also address the aspects of radioactive decay and ingrowth as an essential issue that needs to be considered when analyzing natural radionuclides within a TDS study where in some cases long storage times of food sample material are unavoidable.

Material and methods

Selection, purchasing and preparation of foods

The design of the BfR MEAL Study is described elsewhere [10, 33] and followed international recommendations for TDSs. To establish the MEAL food list, representative consumption data for the population in Germany were used from the National Nutrition Survey II for female and male participants aged between 14 and 80 years [34]. Additionally, a consumption survey for children between a half and six years (VELS) [35] was used. The MEAL food list includes 356 MEAL foods, which were assigned to 19 main food groups according to the FoodEx 2 classification. The MEAL food list covers 90% of the German diet for different age groups and genders [33]. Rarely consumed foods (< 10%) containing potentially high amounts of undesired substances were also included in the MEAL food list. Due to capacity and analytical reasons, the BfS selected a sub-group of 202 food samples from the MEAL food list for the analysis of natural radionuclides (Table S1, Supplementary Information), which were potentially relevant for dose contribution due to ingestion. This sub-group of foods covered all food groups that are important to represent general dietary habits of the German population. Food products intended for the BfS analyses were purchased by the BfR between 2016 and 2019 as described previously [12, 14]. After sampling, MEAL foods were prepared in the BfR study kitchen according to typically used recipes, described elsewhere in detail [11, 12, 14]. Followed by subsequent pooling and homogenization steps, between 730 g and 3013 g fresh weight of the pool samples were stored for the BfS in VWR® twist-seal LDPE bags (4000 ml) at -20 °C (Table 1). To facilitate sample preparation up to 1630 g of deionized water was added to 47 out of the 202 BfS pool samples. From 12/2016 to 11/2019 the frozen, pool samples were delivered to the BfS on a monthly basis for further treatment and analyses.

Sample pretreatment

The received pool sample material from the BfR was dried to a constant weight at 105 °C in evaporation dishes in a Heraeus Instruments (NTU 75/125) oven at the BfS. Afterwards, up to four muffle furnaces from Linn High Therm (LK 312.11 and LK 112.11) with manual temperature control were used for dry-ashing the sample material at a target temperature of 400 °C for 24 h. To avoid a temperature increase due to exothermic processes, for example due to high fat contents in certain food samples, dry-ashing was only carried out with small amounts (30 g and 100 g) of the dried sample material (Table S1, Supplementary Information). Thus, depending on the total dry weight (61 g to 2288 g), the process of dry-ashing was performed in several rounds for each pool sample. The amount of ash material obtained for each pool sample ranged from 5 g to 119 g (Table 1). For each radionuclide analysis, 2 g to 10 g of pool sample ash material was dissolved by microwave digestion with an ETHOS-Lab System® device. For this purpose, up to 1 g of ash material was added in each of the ten 90 ml polytetrafluoroethylene (PTFE) vessels of the microwave digestion system together with 2.5 ml of deionized water, 5 ml of nitric acid (HNO3, 14 mol/l), 1.5 ml of hydrochloric acid (HCl, 12 mol/l) and 1.5 ml of hydrogen peroxide (H2O2, 10 mol/l). For the subsequent determination of the chemical yield of the respective radioanalytical technique, 0.5 ml of a 16 mg/ml solution of lead(II) nitrate (Pb(NO3)2) as a stable carrier for the Pb-210 analysis, 0.06 Bq U-232 as a yield tracer for the determination of U isotopes and 2 ml of a 53 mg/l solution of barium chloride (BaCl2 · 2H2O) as a stable carrier for the analyses of Ra-226 and Ra-228 were added. After prereaction of up to three hours, the vessels were closed. Then, the applied standard program for microwave digestion was run for a total of 40 min including several temperature steps between 100 °C and 210 °C and a power maximum of 1300 W. After ventilation and cooling the vessels down, their contents were transferred into a glass beaker and placed on a sand bath. With a watch glass on top of the beaker as a lid, the solution was carefully evaporated to dryness. Further processing on the sand bath of the dry residue proved to be beneficial. For Pb-210 analyses, 20 ml to 100 ml of deionized water, 5 ml of HNO3 (14 mol/l) and 1 ml of H2O2 (10 mol/l) were added. All other samples were treated with 20 ml of HNO3 (14 mol/l) and 2 ml of H2O2 (10 mol/l).

Radioanalytical techniques and measurements

Pb-210

The concept of Pb-210 determination in this study was based on coprecipitation of Pb with iron hydroxide, followed by extraction chromatography with subsequent direct measurement of Pb-210 via liquid scintillation counting (LSC) as outlined in ISO 13163 [36]. Therefore, the pretreated dry residue was dissolved in 100 ml of warm deionized water and HNO3 (14 mol/l). The necessary amount of HNO3 ranged from 1 ml to 5 ml and was strongly dependent on the food matrices. After complete dissolution, further deionized water was added to a volume of 400 ml. To preconcentrate Pb, a coprecipitation with iron hydroxide was performed by adding 2 ml of a 48.4 mg/ml solution of iron(III) chloride (FeCl3 · 6H2O). Homogenization of the sample solution was performed on a hot plate between 70 °C and 80 °C. After approximately one hour, a potassium hydroxide (KOH) solution (2 mol/l) was added until a pH between 8 and 9 was reached. The sample was continuously stirred for another 30 min on a hot plate. The solution was cooled down to room temperature for at least three hours or overnight to allow complete precipitation. The supernatant was decanted and the precipitate was centrifuged and washed with deionized water once between 30 °C and 40 °C and several times at 25 °C. The precipitate was subsequently dissolved in 8.3 ml of HCl (12 mol/l). Deionized water was added to a volume of 50 ml. For the following sequential extraction, a strontium resin (Sr Resin SR5 C20-A TrisKem) was used to separate Pb-210 from most of the other radionuclides like its progeny bismuth-210 (Bi-210) and Po-210. Potentially other present Pb isotopes, however, will still remain. The column was conditioned with 2 ml of HCl (2 mol/l), then the sample (50 ml) was loaded onto the column and washed with 15 ml of HCl (2 mol/l) to elute Bi and Fe. Polonium was then eluted successively with 15 ml of 1 mol/l and 0.1 mol/l HNO3 each. For the purpose of this study these fractions were of no further interest and therefore discarded. Eventually Pb was eluted with 20 ml of a di-ammonium hydrogen citrate solution ((NH4)2C6H8O7, 0.05 mol/l). After homogenization and subsampling for the chemical yield determination via inductively coupled plasma optical emission spectrometry (ICP-OES), the eluate volume was reduced to 8 ml on a sand bath. For LSC measurement, the eluate (8 ml), 12 ml of Ultima Gold™ AB (scintillant optimized for alpha and beta discrimination) and 70 µl of HNO3 (14 mol/l) were added to a polyethylene LSC vial. Measurements were performed with a Wallac 1220 Quantulus™ (Perkin Elmer, Inc.) within an energy window ranging of 5.3 keV to 21 keV.

U isotopes

In this study, the activity concentrations of U-234 and U-238 were determined using sequential extraction and alpha spectrometric measurement of the electrodeposited U. Before starting with the sequential extraction step, the dry residue from the pretreatment was re-dissolved in 40 ml of HNO3 (3 mol/l). This dissolved sample solution was loaded onto an UTEVA® column (UT-C50-A TrisKem) which was preconditioned with 5 ml of HNO3 (3 mol/l). The sample beaker was rinsed twice with 5 ml of HNO3 (3 mol/l) to ensure quantitative transfer onto the column. This washing solution was also loaded onto the column. To remove Fe, Ra and Th from the adsorbed U, the column was first washed with 5 ml of HCl (9 mol/l), then 10 ml of HCl (5 mol/l) and thirdly with 20 ml of a solution of HCl (5 mol/l) and oxalic acid (C2H2O4, 0.05 mol/l). These eluates were discarded. In the last step, U was eluted with 20 ml of HCl (0.01 mol/l) for counting source preparation. For this, the eluate was evaporated until dryness on a sand bath and the dry residue treated with 5 ml of HNO3 (14 mol/l) and 2.5 ml of sulfuric acid (H2SO4, 18 mol/l) to decompose any organic material that might have been washed of the column. The dry residue was re-dissolved in 10 ml of H2SO4 (1.5 mol/l) and transferred into the prepared electrolytic cells. The beaker was rinsed twice with 2 ml of deionized water each time. The rinses were added to the electrodeposition cell as well. After adding a drop of methyl red solution, several drops of concentrated ammonia solution (NH4OH, 14 mol/l) were added until the color of the solution turned to yellow. Then, the solution was titrated with H2SO4 (1.5 mol/l) until the color changes to red. A pH between 2.4 and 2.5 was achieved with a further addition of three drops of H2SO4. Electrodeposition was carried out at 300 mA for four hours. Approximately one minute before turning the power off, 0.5 ml of NH4OH solution (14 mol/l) was added. Afterwards the cell was dismantled and the stainless-steel disk rinsed with deionized water and dried by rinsing with acetone. After electrodeposition, the counting source was measured using an Alpha-Ensemble-8 system from ORTEC/AMETEK®.

Ra isotopes

In order to reduce the amount of ash material needed for all radionuclide analyses of each pool sample, the methodologies of the Ra-228 and Ra-226 determination were combined in this study. Radium-228 (half-life 5.75 years) was indirectly determined using its progeny actinium-228 (Ac-228) with a half-life of 6.15 h and a much higher beta energy than Ra-228 itself. The principle of the method is in accordance with Burnett and Cable [37] and comprised a preconcentration step of Ra by coprecipitation with barium sulfate (BaSO4), followed by conversion into the carbonate, the separation of Ac after ingrowth via extraction chromatography, its microprecipitation with cerium(III) fluoride (CeF3) and the immediate measurement of the beta activity of Ac-228. The eluate from the extraction chromatography containing Ra was used for Ra-226 determination via the radon-222-emanation technique according to ISO 13165-2 [38]. For the combined procedure the pretreated dry residue was dissolved in 300 ml of deionized water while stirring on a hot plate until boiling. A few drops of methyl red solution as well as 5 ml of a citric acid solution (C6H8O7, 1 mol/l) as masking agent were added to the solution. Adjustment to a pH of 6.2 was achieved by adding concentrated NH4OH solution (14 mol/l) until the color of the solution changed from pink to yellow. The solution was heated until boiling on a hot plate. Using 3 ml of sulfuric acid solution (H2SO4, 9 mol/l), BaSO4 was precipitated and left overnight to achieve complete settlement of the precipitate. Discarding the supernatant, the precipitate was vacuum-filtered using a 0.45 µm cellulose acetate membrane filter (OE67 Whatman™) and washed thoroughly with deionized water. The filter and the precipitate were poured into a 250 ml beaker and covered by 75 ml deionized water. After addition of 5 g of potassium carbonate (K2CO3), the beaker was covered with a watch glass as a lid. The solution was boiled and stirred on a hot plate for approximately 30 min. The filter was rinsed with deionized water and discarded, while the remaining precipitate and solution were vacuum-filtered using an 589/3 ashless, cellulose filter from Whatman™ (blue ribbon filter). The carbonate precipitate was dissolved in 5 ml of HNO3 (1 mol/l) and the date and time were noted. To achieve secular equilibrium between Ra-228 and Ac-228 the sample was left aside for at least 30 h. For the following extraction chromatography, a RE-C50-A column (Eichrom) with a column bed volume of 2 ml was used to separate Ra, Pb and Ba from Ac. The column was conditioned with 5 ml of HNO3 (1 mol/l).

After discarding this eluate, the sample was loaded onto the column and a 25 ml volumetric flask was placed under the column to collect the following solutions. The sample beaker was rinsed with 5 ml of HNO3 (1 mol/l) and loaded onto the column as well. Date and time were noted. After washing the column with an additional 15 ml of HNO3 (1 mol/l), the volumetric flask was filled with deionized water to the calibration mark. For the chemical yield determination of the Ra separation, 200 µl of the solution were used to analyze the carrier element Ba via ICP-OES. The remaining solution was used for the Ra-226-analysis. To elute Ac from the column, 15 ml of HNO3 (0.1 mol/l) were added. The eluate was collected in a 50 ml beaker made of polyethylene (PE). 0.2 ml of a cerium nitrate solution (Ce(NO3)3, 3.6 mmol/l) and 1 ml of hydrofluoric acid (HF, 23 mol/l) were added and the solution stirred for 30 min at room temperature. The solution was then vacuum-filtered using a 0.1 µm polyvinylidene fluoride (PVDF) membrane filter from Durapore™. The precipitate was washed with deionized water and dried by rinsing with acetone. The filter was fixed on a steel disk and measured using a LB 770 alpha–beta low-level measuring device from Berthold Technologies. Date and time were noted, allowing the calculation of the Ra-228 activity concentration from the ingrowth period and decay interval of Ac-228 and the counting rate as outlined in Burnett and Cable [37].

To determine Ra-226, the eluate (approx. 25 ml) from the extraction chromatography was transferred into a radon bubbler. The sample was purged with air for about ten minutes to remove Rn-222 and then both valves of the bubbler were closed. This allowed for a defined and documented onset of Rn-222 ingrowth, which typically lasted at least two weeks. After this ingrowth period, a suitable pumping device was applied to flush Rn-222 out of the bubbler solution into a previously evacuated scintillation chamber (Lucas cell). The date and time were documented. After three hours, the radioactive equilibrium between Rn-222 and its progenies (polonium-214, polonium-218) was reached. The alpha radiation was detected using a photomultiplier with an amplifier from ORTEC® supplemented by a counting and registration device. The Ra-226 activity concentration was calculated considering the ingrowth period and decay interval of Rn-222 during progeny ingrowth as well as measurement and the counting rate according to ISO 13165-2 [38].

Results and discussion

The matrices of the 202 pool samples analyzed within this study varied widely, demanding in some cases further methodological steps to ensure the quality of the results with regard to detection limit and chemical yield. Therefore, sample repetitions were necessary mostly starting from the dry-ashed material again, unless otherwise stated. Emphasizes to these optimizations will be given for the pretreatment procedures and each radionuclide analysis in the following.

Improvements in sample pretreatment

In the course of the study, the time needed for sample pretreatment was optimized by increasing the drying temperature to 130 °C for pool samples with high water or fat content (e.g. fruits, milk and dairy products). This was done in a separate oven from Heraeus Instruments (UT 6200). For samples with high fat content, the leaking fat was adsorbed by ash-free paper. The amount of fat was in most cases negligible with respect to the fresh weight. Only the fat of the cream and codfish liver pool sample was decanted because it accounted for 22% and 33% of the total fresh weight, respectively. To ensure that both decanted fat samples did not contain any of the radionuclides of interest, solvent extraction was conducted twice for each sample. For this, 100 ml of HNO3 (0.1 mol/l) and 100 ml of the separated fat were added to a separating funnel, two times letting it settle for approximately 15 min each time. The HNO3 solutions were combined in a beaker, ready for the radioanalytical techniques. The fat of both samples did not contain any of the radionuclides of interest and was therefore discarded.

In general, samples with a very high fat content remained a residual moisture of about 5% after drying and had to be treated carefully in the subsequent dry-ashing step.

For 17 pool samples, particularly fruits, the amount of material received after dry-ashing was below 10 g in total. This is not enough material to apply all methods to those samples (Table 2). Therefore, it was not possible to determine all radionuclides of interest for all pool samples. This results in a difference in the total number of pool samples analyzed for the individual radionuclides (Table 1). Some samples returned deep black ashes, which indicated high amounts of organic material left in the sample. To facilitate the further sample processing for the analyses of the U and Ra isotopes, subsamples were therefore additionally dry-ashed at temperatures above 500 °C for 24 h to 72 h (Table S1, Supplementary Information). Lead-210 could be determined up to 400 °C treated samples. At higher temperatures it was not investigated, as Pb-210 becomes volatile. For instance, Magno et al. [39] noted a significant loss of Pb-212 tracer during the dry-ashing of food samples above 600 °C. The dry-ashing of the sugar and honey pool samples was not successful because of the very high content of organic material, that resulted in almost no sample material left. These samples were processed using wet sample preparation methods as discussed in the following sections.

After microwave digestion, particularly samples with a high content of fat or protein remained very cloudy, leading to a notable decrease in chemical yield. To facilitate handling of the samples during radiochemical separation and to prevent a considerable loss in chemical yield, a further wet digestion step was enclosed using HNO3 and H2O2. Depending on the food material this procedure was repeated up to 15 times until the remaining dry residue was preferably colorless or did not change its color notably (yellow, blue, purple or magenta). Typically, fruits, potatoes and root vegetables and their related products needed several repetitions, while milk and dairy products were usually ready after one treatment. In some cases, an aqua regia digestion was additionally required. This was especially the case for vegetable and meat samples and their related products.

Improvements in radioanalytical techniques and measurements

Pb-210

The method used for Pb-210 determination led to an average chemical yield of 74% and a detection limit of 16 mBq/kg referred to fresh weight (FW) for all verified results. This is in line with the typical detection limits for Pb-210 in food and drinking water samples given by the IAEA of 3 mBq/kg FW to 30 mBq/kg FW [7]. Since the time between the earliest sample production date as reference date and final results obtained in this study ranged from 135 days to over four years, both the ingrowth of Ra-226 (half-life 1,600 years) and radioactive decay of Pb-210 (half-life 22.3 years) was taken into account in the decay correction. Complete sample repetitions starting from the dry-ashed material had to be made for 15 out of 183 samples due to low values in chemical yield (≤ 24%), results between decision threshold and detection limit or the initial results needed to be verified. In this course, slight modifications in sample pretreatment and radiochemical separation steps were made for method improvement. For example, in the first separation step, the coprecipitate of Pb and iron hydroxide could not always be completely dissolved in HCl. Hence, before starting with sequential extraction, over 80% of all analyzed Pb-210 samples had to be vacuum-filtered using a MN 640 d ashless cellulose filter by Macherey–Nagel™ (blue ribbon filter). The filter was washed with deionized water until reaching a final sample volume of 50 ml. The remaining residue was discarded. Furthermore, some of the samples (e.g. grain and potato samples and their related products as well as nuts) contained high amounts of Ra-228 (> 10 Bq/kg relative to ash weight). This caused difficulties in the correct determination of the Pb-210 activity concentration as the Ra-228 progeny Pb-212 and its daughter nuclides bismuth-212 (Bi-212), polonium-212 (Po-212) and thallium-208 (Tl-208) strongly interferes in the subsequent LSC measurements. Therefore, the sequential extraction procedure was generally modified by waiting at least 60 h between the last two elution steps, to ensure that potentially available short-lived Pb-212 (half-life 10.64 h) has decayed. For the honey and sugar pool samples, various wet sample preparation techniques using potassium permanganate (KMnO4) as outlined in the results and discussion section for the Ra isotopes or the procedure described in [40] were tested. For seven fruit and vegetable pool samples with very low amounts of ash material available, a combination of the Ra isotopes and Pb-210 radioanalytical techniques was tried. After the combined addition of stable Pb and Ba carrier at the beginning, the steps of the Ra isotopes, analysis were routinely proceeded. After the Ra-226 determination, 25 ml to 30 ml of the remaining Ra eluate were loaded onto a Sr resin column previously conditioned with 20 ml of HNO3 (1 mol/l). The eluate of the subsequently added 15 ml of 1 mol/l and 15 ml of 0.1 mol/l of HNO3 was discarded, while the following eluate of Pb, eluted by adding 20 ml of a (NH4)2C6H8O7 solution (0.05 mol/l), was further processed as described in the material and methods section for Pb-210. Valid results with a chemical yield between 26% and 42% were received for four of these pool samples. However, the described methods for the honey, sugar and some of the fruit and vegetable pool samples did not always lead to reproducible results. Since the available amount of sample material was also limited, no Pb-210 results are available for five out of 183 pool samples including the honey and sugar pool samples and two fruit pool samples of the combined procedure. In contrast, due to sufficient ash material available, it was possible to repeat the complete analytical procedure two to four times for six out of the 183 pool samples, until valid results were received. For nine selected pool samples, the complete procedure was performed twice for internal quality assurance. Nevertheless, for 21 food samples Pb-210 activity concentrations either between decision threshold and detection limit or below the decision threshold were obtained.

U isotopes

With regard to the variety of food pools processed, the method for the determination of the U isotopes was the most robust and sensitive one compared to the others presented. On average, a chemical yield of 63% and a detection limit of 0.91 mBq/kg FW were reached for all verified results, which is more than one order of magnitude below the typical detection limit given by the IAEA [7]. From the overall amount of 202 processed pool samples in this study, for 201 samples sufficient ash material was initially available to perform the U isotope analyses. Sample repetitions were only necessary for the verification of the initial results for ten pool samples. Some pool samples were also repetitively measured from dry-ashed material, as they could not be entirely dissolved in HNO3 before the beginning of the sequential extraction, resulting in very low chemical yields (1% to 10%). Therefore, in the course of the study a further treatment step was established, where these respective samples had to be evaporated to dryness again and then at least 3 g of sodium carbonate (Na2CO3) were added together with 50 ml of deionized water. The sample solutions were boiled for 30 min and then cooled to room temperature. Vacuum filtration was applied using a 0.45 µm cellulose acetate membrane filter. The filtrate was discarded and the residue on the filter dissolved with 40 ml of hot HNO3 (3 mol/l). After a second filtration step using the same setup, the filtrate was used for the next step. Including this additional step, the chemical yields improved and ranged between 20% and 71%. To determine the U isotopes in the honey and sugar pool samples, a different wet digestion procedure than the one described for Pb-210 and the Ra isotopes was applied prior to the sequential extraction and alpha spectrometry routine. Here, each pool sample was assigned to four beakers, weighing in 25 g sample material and adding 0.06 Bq U-232 as a yield tracer, respectively. Samples were combusted by carefully increasing the temperature on a hot plate. The cooled residue in each beaker was then dissolved in 30 ml of HNO3 (14 mol/l) in the warmth of a hot plate, and evaporated to dryness after adding 2 ml of H2O2 (10 mol/l). This wet digestion step was repeated ten times till almost no residue was left in the beakers. After adding 40 ml of HNO3 (3 mol/l) to each beaker, the dissolved residue was consecutively loaded onto the column. The further procedure was carried out as described in the material and methods section. The chemical yield was 83% for the sugar and 74% for the honey pool sample. Even though this described procedure worked successfully, it required the use of a lot of HNO3 and H2O2 as well as process time. Therefore, other methods were tested for the determination of Pb-210 and the Ra isotopes in the honey and sugar pool samples. For three out of 201 pool samples no results can be presented due to the lack of ash material available for necessary repetitions. For only 2% of all processed 201 samples results either between decision threshold and detection limit or below the decision threshold were received for either U-234 or U-238.

Ra isotopes

In total, 200 food pool samples were prepared for the combined Ra-226 and Ra-228 methodology, based on the ash material available. The decay of Ra-228 was considered using the earliest sample production date as reference date and assuming that the ingrowth of Ra-228 caused by Th-232 decay can be neglected due to the typically extremely low activity concentrations of Th-232 [1, 32]. Repetitions in Ra-228 and/or Ra-226 analyses were made either from ash material still available or from the Ra eluate kept after the Ra-226 determination. Since both Ra isotopes were determined indirectly via its progenies, it was possible to repeatedly use the eluate for Ra analyses again with respect to a slight decrease in chemical yield (2% to 16%). For internal plausibility checks, the Ra ratios within the food groups were compared with each other and additionally with data from Wichterey et al. [32] and the UNSCEAR 2000 report [1]. In general, the number of repetitions for both radionuclides in this study was the highest for several reasons. Even though the average chemical yield of 90% was very high, particularly grain product samples caused very low chemical yields (0% to 20%) in the first run and were therefore repeated starting from the dry-ashed material. The average detection limit of Ra-228 at 20 mBq/kg FW was one order of magnitude higher than that of Ra-226 at 5 mBq/kg FW. Even though these average Ra detection limits were closer together than those reported by the IAEA at 100 mBq/kg FW for Ra-228 and 0.1 mBq/kg FW to 1 mBq/kg FW for Ra-226 [7], this difference sometimes led to results for Ra-228 between decision threshold and detection limit or below the decision threshold, but not for Ra-226 in this study. Therefore, several repetitions for Ra-228 were carried out, using slightly increased amounts of ash material (1 g to 2 g) where possible, whereas Ra-226 was only repeatedly determined for internal quality control reasons. Still, for 14 pool samples only results between decision threshold and detection limit or below decision threshold were achieved for Ra-228. The analysis did not work for two out of the 200 pool samples (one vegetable pool sample and one grain-based product), so no results were obtained for either radionuclide. Furthermore, particularly milk and dairy products with high contents of Ca, as well as grain product samples produced enormous amounts of BaSO4 coprecipitate that needed to be minimized in volume prior to vacuum-filtration. Therefore, before starting the conversion into a carbonate, 100 ml of HCl (1.5 mol/l) were added to the precipitate and the mixture was stirred for 30 min in the heat on a hot plate followed by vacuum-filtration using a 0.45 µm cellulose acetate membrane filter (OE67 Whatman™). Since the honey and sugar pool sample could not be regularly processed, approximately 280 g each of the fresh weight material were diluted in 220 g of deionized water. Subsequently, 2 ml of H2SO4 (9 mol/l) were added followed by homogenization and stirring in the heat of a hot plate. As strong oxidizing agent up to 10 g KMnO4 dissolved in a sufficient volume of deionized water was added to the sample solution, causing a change in color from purple to brown to colorless. The stable Ba carrier was added and the next steps proceeded analogous to all other samples.

External quality assurance

In order to validate the results of the radiochemical analyses within the study, two leading radiochemical institutions in Germany—VKTA—Radiation Protection, Analytics & Disposal e.V. and IAF—Radioökologie GmbH—were assigned to analyze 15 selected pool samples with different methodological approaches. The choice of samples for this external comparison was based on the dry-ashed sample material left and the detection limits the laboratories were able to reach. Taking this into account and trying to cover the range of food groups, four nut, three grain, three milk and diary, three vegetable and two fish pool samples were selected (Table S1, Supplementary Information). Between 43 g and 118 g ash material were sent to the two external laboratories. Details regarding the applied methods can be found in Table 3 and in the Supplementary Information. All results for these 15 selected pool samples received from the various applied methods of all three laboratories are given in Table S2 (Supplementary Information).

To compare the external values (cext) with the internal BfS values (cint) the overlap of the respective uncertainties (u) of each value pair was examined. In order to quantify this, the following formula was used to calculate the decision criterion z*:

An overlap of the 95% confidence intervals was deemed to be sufficient for the decision that the two values of each pair can be considered to be as equal within the possibilities of the applied pretreatment steps and radiochemical procedures. This leads to the conclusion, that z* should be between −2 and 2. Because of the very low contents of radionuclides in a wide variety of the samples, it was decided to use a linear propagation of uncertainties. The term z* has been chosen to signify, that the formula is based in principle on known z- and ζ-scores used in proficiency tests and intercomparisons [41].

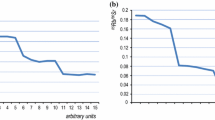

As indicated in Fig. 1 the match between internal and external results was best for U-234, where 93% of the absolute values of z* (|z*|) were below one and 7% between one and two. For U-238, 87% of the samples gave |z*|-values below one, one sample a |z*|-value between one and two and one sample a |z*|-value of 2.1. The results for Pb-210 showed |z*|-values below one for 80% and between one and two for 20% of the samples. For Ra-226, 67% of the |z*|-values lie below one and 23% between one and two, and for Ra-228, 80% of the samples gave values below one and 20% values between one and two. Overall the results of the external analyses and their evaluation show that the applied methodology to determine the activity concentrations of Pb-210, U-234, U-238, Ra-228, and Ra-226 in the 202 food pool samples within this study is reliable.

Conclusion

In this study, procedures to determine the natural radionuclides Pb-210, U-234, U-238, Ra-228, and Ra-226 in a wide variety of food samples were developed. Approaches to analytical problems were addressed, allowing to successfully achieve reliable results for almost every type of food sample at very low levels with a reasonable amount of ash material deployed. In some cases, combinations of radioanalytical techniques can be a reasonable solution to ensure the determination of all radionuclides of interest. Still, the limited amount of ash material available was the mean reason causing a deficiency in results in some food groups. Therefore, for upcoming studies, a doubling in fresh weight material for some food groups like fruits is advisable. A general increasement in fresh weight material for all food pool samples especially those foods with high fat content, however, cannot be recommended since it would tremendously raise the time and costs needed for sample pretreatment. On the other hand, in some food groups (e.g. nuts or meat and their associated products) the available fresh weight material was sufficient for several repetitions or external quality assurance. The analysis of natural and/or human-made radionuclides is typically challenging due to the low activity concentrations combined with the certain amount of sample material needed, but also due to the aspects of radioactive decay. Being part of a total diet study allowed the BfS access to a very concise set of samples representing the diet of the German population. The purchase and preparation of the food pool samples within the scope of the total diet study by the BfR, however, followed a strict time plan due to the accessibility of foods (e.g. origin, season). Thus, the number and type of food pool samples delivered to the BfS each month varied highly. Furthermore, it was difficult to estimate the time needed for sample pretreatment for the variety of food samples in advance before starting with the radioanalytical techniques and measurements by the BfS laboratory. Even though, these outlined time-dependent issues seem mostly hard to control, appropriate time management when setting up a similar study should be discussed considering the findings of this study. In addition, it should be clarified beforehand whether a proper consideration of the decay of the radionuclides of interest and the potential ingrowth of other radionuclides is possible in the process of data evaluation afterwards. If this cannot be guaranteed, certain kinds of radionuclides should be excluded from the beginning as was done for Po-210 with its comparably short half-life (138 days) in this study.

References

UNSCEAR (2000) Sources and effects of ionizing radiation. United Nations scientific committee on the effects of atomic radiation. UNSCEAR 2000 Report to the General Assembly, with Scientific Annexes. United Nations, New York

Linsalata P (1994) Uranium and thorium decay series radionuclides in human and animal foodchains—a review. J Environ Qual 23:633–642

Cinelli G, De Cort M, Tollefsen T (2019) European atlas of natural radiation. Publication Office of the European Union, Luxembourg

IAEA (2018) Regulatory control of radioactive discharges to the environment. IAEA Safety Standards Series No. GSG-9. International Atomic Energy Agency, Vienna

IAEA (2014) Radiation protection and safety of radiation sources: International Basic Safety Standards. IAEA Safety Standards Series No. GSR Part 3. International Atomic Energy Agency, Vienna

IAEA (2022) Exposure due to radionuclides in food other than during a nuclear or radiological emergency. Part 2: Considerations in implementing requirement 51 of IAEA General Safety Requirements Part 3 (International Basic Safety Standards). IAEA-TECDOC-2011. International Atomic Energy Agency, Vienna

IAEA (2023) Exposure due to radionuclides in food other than during a nuclear or radiological emergency Part 1: Technical Material. Safety Reports Series No. 114. International Atomic Energy Agency, Vienna

EFSA, FAO, WHO (2011) Towards a harmonised Total Diet Study approach: a guidance document. EFSA J 9:24509

Moy GG, Vannoort RW (2013) Total diet studies. Springer, New York

Kolbaum AE, Jaeger A, Ptok S, Sarvan I, Greiner M, Lindtner O (2022) Collection of occurrence data in foods—the value of the BfR MEAL study in addition to the national monitoring for dietary exposure assessment. Food Chem X 13:100240

Fechner C, Hackethal C, Höpfner T, Dietrich J, Bloch D, Lindtner O, Sarvan I (2022) Results of the BfR MEAL Study: Germany, mercury is mostly contained in fish and seafood while cadmium, lead, and nickel are present in a broad spectrum of foods. Food Chem X 14:100326

Hackethal C, Kopp JF, Sarvan I, Schwerdtle T, Lindtner O (2021) Total arsenic and water-soluble arsenic species in foods of the first German total diet study (BfR MEAL Study). Food Chem 346:128913

Stadion M, Hackethal C, Blume K, Wobst B, Abraham K, Fechner C, Lindtner O, Sarvan I (2022) The first German total diet study (BfR MEAL Study) confirms highest levels of dioxins and dioxin-like polychlorinated biphenyls in foods of animal origin. Food Chem X 16:100459

Sarvan I, Kolbaum AE, Pabel U, Buhrke T, Greiner M, Lindtner O (2021) Exposure assessment of methylmercury in samples of the BfR MEAL Study. Food Chem Toxicol 149:112005

Kolbaum AE, Sarvan I, Bakhiya N, Spolders M, Pieper R, Schubert J, Jung C, Hackethal C, Sieke C, Grünewald K-H, Lindtner O (2023) Long-term dietary exposure to copper in the population in Germany—results from the BfR MEAL study. Food Chem Toxicol 176:113759

Schendel S, Berg T, Scherfling M, Drößer C, Ptok S, Weißenborn A, Lindtner O, Sarvan I (2022) Results of the BfR MEAL Study: highest levels of retinol found in animal livers and of β-carotene in yellow-orange and green leafy vegetables. Food Chem X 16:100458

Hackethal C, Pabel U, Jung C, Schwerdtle T, Lindtner O (2023) Chronic dietary exposure to total arsenic, inorganic arsenic and water-soluble organic arsenic species based on results of the first German total diet study. Sci Total Environ 859:160261

Sangiorgi M, Hernández Ceballos MA, Iurlaro G, Cinelli G, de Cort M (2019) 30 years of European Commission Radioactivity Environmental Monitoring data bank (REMdb)—an open door to boost environmental radioactivity research. Earth Syst Sci Data 11:589–601

FDA (2015) Total Diet Study radionuclide results summary statistics market baskets 2006 through 2014. U.S. Food and Drug Administration, Washington

Health Canada (2020) Canadian total diet study—radionuclides 2000-2020. Health Canada. https://open.canada.ca/data/en/dataset/062c769f-57d7-432e-9d33-1e333a87d6d0

Yang B, Tuo F, Zhou Q, Zhang J, Li Z, Pang C (2022) Dietary exposure of radionuclides and heavy metals in adult residents in a high background natural radiation area using duplicate diet method. Sci Rep UK 12:16676

Hernández F, Hernández-Armas J, Catalán A, Fernández-Aldecoa JC, Landeras MI (2004) Activity concentrations and mean annual effective dose of foodstuffs on the island of Tenerife, Spain. Radiat Prot Dosimetry 111:205–210

Renaud P, Roussel-Debet S, Pourcelot L, Gurriaran R (2015) 226Ra and 228Ra activities in French foodstuffs. Radioprotection 50:111–115

Renaud P, Roussel-Debet S, Pourcelot L, Thebault H, Loyen J, Gurriaran R (2015) 210Pb and 210Po activities in French foodstuffs. Radioprotection 50:123–128

Desideri D, Meli M, Roselli C, Forini N, Rongoni A, Feduzi L (2013) Natural radionuclides in Italian diet and their annual intake. J Radioanal Nucl Chem 299:1461–1467

Van TT, Bat LT, Nhan DD, Quang NH, Cam BD, Hung LV (2019) Estimation of radionuclide concentrations and average annual committed effective dose due to ingestion for the population in the Red River Delta, Vietnam. Environ Manag 63:444–454

Rosa M, Taddei M, Cheberle L, Ferreira M, Santos S, Avegliano R, Bergamini G, Maihara V (2015) Determination of 234U, 235U, 238U, 228Th, 230Th, 232Th, 226Ra, 228Ra, and 210Pb in foods from Brazilian Total Diet. J Radioanal Nucl Chem 306:695–700

Pietrzak-Flis Z, Suplinska MM, Rosiak L (1997) The dietary intake of 238U, 234U, 230Th, 232Th, 228Th and 226Ra from food and drinking water by inhabitants of the Walbrzych region. J Radioanal Nucl Chem 222:189–193

Sdraulig S, Orr B, Urban D, Tinker R (2019) Radiation doses from the average Australian diet. Technical Report 181. Australian Radiation Protection and Nuclear Safety Agency (ARPANSA), Miranda

Smith-Briggs JL, Bradley EJ (1984) Measurement of natural radionuclides in U.K. diet. Sci Total Environ 35:431–440

Fisenne IM, Perry PM, Decker KM, Keller HW (1987) The daily intake of 234, 235, 238U, 228, 230, 232Th and 226, 228Ra by New York City residents. Health Phys 53:357–363

Wichterey K, Beyermann M, Kümmel M (2004) Results of the investigation on natural radiation exposure due to ingestion. Kerntechnik 69:5–6

Sarvan I, Bürgelt M, Lindtner O, Greiner M (2017) Expositionsschätzung von Stoffen in Lebensmitteln. Die BfR-MEAL-Studie—die erste Total-Diet-Studie in Deutschland. Bundesgesundheitsbl 60:689–696

Krems C, Bauch A, Götz A, Heuer T, Hild A, Möseneder J, Brombach C (2006) Methoden der nationalen Verzehrsstudie II. Ernaehr Umsch 53:44–50

Banasiak U, Heseker H, Sieke C, Sommerfeld C, Vohmann C (2005) Abschätzung der Aufnahme von Pflanzenschutzmittel-Rückständen in der Nahrung mit neuenVerzehrsmengen für Kinder. Bundesgesundheitsbl 1:84–98

ISO (2021) Water quality-Lead-210-Test method using liquid scintillation counting. ISO 13163

Burnett W, Cable P, Moser R (1995) Determination of radium-228 in natural waters using extraction chromatographic resins. Radioact Radiochem 6:36–44

ISO (2022) Water quality-Radium-226-Part 2: test method using emanometry. ISO 13165-2

Magno PJ, Groulx P, Apidianakis JC (1970) Lead-210 in air and total diets in the United States during 1966. Health Phys 18:383–388

Borylo A, Romanczyk G, Wieczorek J, Struminska-Parulska D, Kaczor M (2019) Radioactivity of honey from northern Poland. J Radioanal Nucl Chem 319:289–296

ISO (2022) Statistical methods for use in proficiency testing by interlaboartory comparison. ISO-13528

Acknowledgements

The BfR MEAL Study is supported by funds of the Federal Ministry of Food and Agriculture (BMEL) based on a decision of the Parliament of the Federal Republic of Germany via the Federal Office for Agriculture and Food (BLE) under the innovation support program. For the external quality assurance laboratory services, a public call for tenders following the rules of procedure for the award of public supply and service contracts below EU thresholds was conducted by the BfS. VKTA—Radiation Protection, Analytics & Disposal e.V. and IAF—Radioökologie GmbH as a group consortium awarded the public contract.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Peggy Hofmann, Michaela Achatz, Kerstin Behrend, Tanja Berg, Christel Busse, Annett Guttmann, Holger Hummrich, Oliver Lindtner, Christian Lucks, Laura Manteufel, Maximilian Rast, Irmela Sarvan, Beate Schmidt, Klaus Schmidt, Clemens Scholtysik, and Diana Walther. The first draft of the manuscript was written by Peggy Hofmann and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

All authors declare to have no competing or financial interest that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hofmann, P., Achatz, M., Behrend, K. et al. The first German total diet study: Analytical techniques to identify natural radionuclides in food samples. J Radioanal Nucl Chem 333, 2449–2460 (2024). https://doi.org/10.1007/s10967-024-09481-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-024-09481-y