Abstract

Positron Annihilation Spectroscopy (PAS) is a non-destructive technique used mostly in material science for studying open spaces/free volumes in materials. In this work, several different nuclear materials originating from the nuclear fuel cycle or round-robin exercises are analyzed by PAS. Our goal was, as for a first test of applicability, to check whether the technique is potentially suitable in a nuclear forensic examination for origin assessment of nuclear materials in order to support investigation. The results, presented below are promising and can certainly be further improved by analyzing larger sets of samples.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nuclear or other radioactive materials are present in every step of the nuclear fuel cycle. Moreover, the peaceful use of these materials can be found in the industry or in scientific research, during medical diagnostics or therapy, and in numerous other fields of science and technology [1]. However, nuclear or other radioactive materials associated with these applications, if fallen into wrong hands, might be used for terrorist or other criminal acts. Therefore, the International Atomic Energy Agency in its recommendations and guidance is encouraging to establish State’s nuclear security regimes, however, nuclear security is the State’s responsibility. “The responsibility for nuclear security within a State rests entirely with the State, which has to ensure the security of nuclear material, other radioactive material, associated facilities, and associated activities under its jurisdiction. Each State aims to achieve nuclear security by creating its own nuclear security regime which is appropriate to that State” [2]. Nuclear Security means the prevention of, detection of, and response to criminal or intentional unauthorized acts involving or directed at nuclear materials, other radioactive materials, associated facilities, or associated activities. The nuclear security infrastructure is an integrated set of nuclear security measures. In response to a nuclear security event, nuclear security measures should be initiated, i.e. assessment, notification of competent authorities, interdict(ion), activation of National Response Framework, criminal investigation, radiological crime scene management (collection of evidence), analysis of evidence (conducting nuclear forensic and traditional forensic examinations), prosecution and returning of the material under control [2, 3]. A key element of this system and response measures is nuclear forensics, that means “the examination of nuclear or other radioactive material, or of evidence contaminated with radionuclides, in the context of legal proceedings under international or national law related to nuclear security” [4]. During the nuclear forensic examination, in addition to the exact identification and characterization of the materials involved, the applied scientific methods should be, preferably, suitable for the determination of the origin (method of production/manufacturing and or age since last separation.) of the nuclear material. This requires not only destructive techniques e.g. using chemical analysis, but sometimes it is already very informative to apply detailed structural or morphological characterization, i.e. lattice structure, grain size, surface morphology, even visual outlook, and many others. To meet these requirements, Positron Annihilation Spectroscopy (PAS) may provide a useful tool at the lattice structure level, as positrons are sensitive to indicate changes in the electron density distribution, lattice defect structure and even secondary phase transitions can be explored. Moreover, the techniques of PAS use well filtered specific gamma energies (mostly the 511 keV annihilation radiation and a characteristic gamma radiation of the positron source nuclide in lifetime measurements) that is usually negligible in relevant nuclear materials (some high energy gammas may generate the 511 keV photons due to positrons born in pair production), therefore the background radiation of the radioactive sample causes no interferences. In the positron lifetime measurements the measurement of the coincidence makes the foreign positrons negligible, in the case of Doppler broadening measurements the source of positrons does not matter.

PAS is a non-destructive method that has been used in materials science for decades. It is an important and unique method in the study of the microstructure and the defect distribution in metals [5,6,7,8,9,10]. Moreover, positrons provide direct and exclusive information on free volumes in polymers [11,12,13,14,15], semi-conductors [16,17,18,19], and other non-metallic materials [20,21,22,23,24]. Sometimes, PAS offers a valuable opportunity to study rather complex materials (chemical complexes, mixtures), as well [25,26,27,28,29,30,31,32].

The positron, entering the sample material, loses its energy in a few picoseconds and reacts as a low energy particle in (thermal) equilibrium with its surroundings. As the antiparticle of the electron, sooner or later, the positron will annihilate with a surrounding electron. However, before the annihilation, positrons get involved in various interactions. A positron might participate in chemical reactions or be trapped in a neutral or negatively charged open volume defects. In non-metal materials, some of the positrons are able to form even bound states with electrons. This bound state is called positronium (Ps) and it resembles a hydrogen atom in which the proton is replaced by the positron. The most important physico-chemical reaction of a positron or a positronium in solid materials is the process of getting trapped in free volumes where the free volume means atomic scale voids, lattice defects. This trapping is due to the local fluctuations of the Coulomb potential [5].

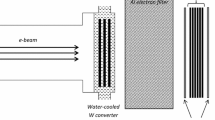

At the end of its lifetime, a positron usually annihilates into two 511 keV gamma-photons with an electron. The local electronic structure (mostly electron density) modifies the lifespan of positrons and changes the momentum distribution of the annihilating electron positron pairs in the matter [5, 33, 35]. The two most commonly used techniques in PAS studies are Positron Annihilation Lifetime Spectroscopy (PALS) and Doppler Broadening Spectroscopy (DBS). If fast positrons are used, the source of which is a radioactive nuclide, positrons penetrate the material up to a few tens of microns. However, if a slow positron beam is used, only the topmost few microns of the sample surface is scanned [33]. In this study, we have applied fast positrons, so, the results are characterizing the bulk of the sample materials.

Radionuclide containing materials have been measured many times by PAS technique. Upadhyay et al. studied UO2 powders finding that positrons are suitable tools to determine defect structures in ceramic powders [35]. Roudil et al. studied material exchange mechanism in actinide doped UO2 [36]. Lund et al. measured impurities and their effect on the enthalpy change of vacancies in depleted uranium [37]. Macchi et al. identified oxygen related defects and vacancies by PAS in UOx thin films [38]. As the above examples show, PAS might be a powerful technique in the field of structural studies of nuclear materials. Nevertheless, PAS has not ever been used to identify the structure and the origin of nuclear materials in forensic examinations.

The aim of this study was to show that the PAS technique might be a tool that is able to provide structural information about nuclear materials and, in some special cases, it might even help track the origin of the material in a cost effective and fast way. During the work, we compared nuclear materials of different but known origin and of certified structure.

Experimental

Fourteen different nuclear samples were analyzed in this study by PAS. Most of the selected samples were certified reference materials. These samples were nuclear materials with known analytical data determined by other techniques, i.e., reference materials from the International Atomic Energy Agency, samples from nuclear forensic round robin exercises e.g. Collaborating Material Exercise (CMX) organized by the Nuclear Forensic International Technical Working Group (ITWG), samples analyzed in international partnerships and even some real confiscated materials. The materials selected for the study are described in Table 1.

Most of the samples were, even in their ‘as received’ states, fine powders. However, some of them had to be pulverized to cover the positron source with the sample adequately. This process was performed on Samples No. 2, 3, 4, and 13. Prior to the measurement, each sample was homogenized and 300 to 500 mg was taken for the measurement depending on the density and the amount of the particular sample. The sample thickness was large enough so that all the positrons emitted from the source were absorbed in the sample.

The samples were mostly uranium oxides of different chemical composition. Thus, every sample contained all the isotopes being normally present in an uranium decay chain. However, this background radioactivity did not disturb PAS measurements. First, the activity of the positron source was well over the activity of the samples and even that was well below the undistorted detection limits of the detectors. Moreover, in the case of PALS, the coincidence technique applied eliminates the background almost totally. In the case of Doppler-distribution measurements, none of the isotopes in the samples had a characteristic line around the annihilation energy. So, only a Compton-background of these isotopes was expected around the annihilation line. This background was more or less flat, leaving the Doppler-parameters unaffected.

After covering the positron source, all the samples were wrapped in aluminum foil together with the positron source, ensuring that the sample covered both side of the source adequately.

The positron source for PAS measurements was made of carrier free 22NaCl sealed between thin (2 mg·cm−2) Kapton foils. The activity of the source was approximately 5·105 Bq.

PALS measurements were performed by a fast–fast coincidence system with two BaF2 crystal detectors. The photomultipliers were Philips XP2020Q tubes. The electronics was built from ORTEC CF-DDs and TAC, and a Tennelec/Nucleus PCA-3 card (AD-converter + memory). The Spectra were collected in 4096 memory channels till reaching about 1.5 million counts overall. The channel time was 12.9 ps while the time-resolution of the system was about 220 ps.

The Doppler Broadening Spectroscopy (DBS) measurements were performed with a High Purity Germanium (HPGe) detector manufactured by DSG (Detector System GmbH). The electronics contained a Canberra 2026 amplifier and a Tennelec/Nucleus PCA-3 card (AD-converter + memory). The resolution of the system was about 1.1 keV for the annihilation photo-peak (511 keV). For the characterization of the samples, we used both of the usual Doppler-parameters, S- and W-parameters.

Results and discussion

Results of the DBS measurements are shown in Fig. 1 arranged in an S–W diagram.

Fuel pellets (Samples 1–6, full symbols) provide S–W pairs scattered widely on a more or less straight line. Even if the dominant phase is UO2 in these cases (as confirmed by powder XRD measurements), the characteristic Doppler-parameters distinguish samples of different manufacturing processes. This phenomenon gives a chance to find a way to identify the origin of the fuel pellets. The points are well-separated indicating different electronic structures for the various pellets. Even if further details of the defect structure created in the manufacturing process cannot be read from these data, the wide separation of S–W pair values are promising from the point of view of forensic research. However, in irradiated materials, highly enriched uranium, and in Pu, defects can be created due radiation damage in addition to those produced by the manufacturing process. These may include F-centers, colloids, and He bubbles.

Obviously, this limited study only provides a hint and further research is needed to decide whether the observed differences are random or they are characteristic to the manufacturing processes of the pellets.

On the other hand, ore concentrates (open symbols) provide S–W pairs scattered in a small area in Fig. 1. Despite the fact that sometimes even the chemical composition of the samples differ, the S–W points are very close to each other. This steadiness of S–W data can well suggest that, in all the ores, positrons annihilate at similar surroundings, regardless even of the chemical composition of the ore. This latter assumption is supported by lifetime data (see below) suggesting similar annihilation surroundings, as well. This might help localize the place of annihilation.

In comparison to DBS measurements, the positron lifetimes distinguish the fuel pellet and ore concentrate samples in a different way: they show significant differences dividing the samples into two groups (Fig. 2). The fuel pellets (Samples No. 1–6, closed symbols) and the uranium ore concentrates (Samples No. 7–14, open symbols) can easily be separated by the average positron lifetimes having average lifetimes of 267 ± 5 ps and 317 ± 7 ps respectively. The ore concentrates provide always a significantly longer lifetime than any of the manufactured pellets. The longer value indicates a ‘looser’ structure (probably with more defects). The average electron density is much lower in the ores than in the fuel pellets providing a longer average lifetime.

A closer look at the lifetime spectra can probably clarify some of the dim aspects of the connection between PAS and the structure of a uranium oxide sample. Every spectrum was evaluated into three lifetime components, all indicating a separate positron state in the sample.

The longest lifetime was, in every case, a low intensity (< 2%) long-living (1600–1800 ps) component. This can be identified as the sign of positronium (Ps) formation on the surface of the uranium oxide grains. This kind of Ps-formation is well-known for fine grained materials [34]. In our cases, the intensity of this component was always too low and lifetime differences were irrelevant. Therefore, we ignore this component for further discussions.

The medium lifetime component was around 381 ± 5 ps in every studied sample and proved to be surprisingly stable, regardless of the type of the sample. The length of the lifetime indicates a positron trapped in a relatively large free volume hole (interstitial, U-vacancy, vacancy cluster, etc.) with low electron density in the hole. Due to the stability of the lifetime, we should look for a crystal position that is present in both types of materials, ores and fuel pellets. Unfortunately, this limited study does not allow us to identify the defect.

The relative intensity of the medium component varies with the type of the material (Fig. 3). It is significantly higher in the uranium ore concentrates (55 ± 4%) than in the manufactured pellets (33 ± 4%). This result suggests that the concentration of the corresponding crystal defects vary while the ore is processed. Although they are still present in fuel pellets, the manufacturing process removes a lot of them.

The shortest positron lifetime suggests a ‘denser’ structure in pellets (Fig. 4) than in ores. The lifetime is shorter in pellets (173 ± 6 ps) than in ores (204 ± 9 ps). Consequently, as this lifetime component is usually connected with free annihilation (or shallow traps in certain cases), the average electron density is higher in fuel pellets than in ores.

Summarizing the lifetime details, we should conclude that the manufacturing process removes a lot of free volume type crystal defects from the ores and leads to a structure with higher electron density in every case. According to positron lifetime data, the structures of processed pellets of different origins are close to each other. On the other hand, the studied ore concentrates differ remarkably from each other and from the pellets.

The marked difference between the ore concentrate samples must be due to two different effects. The origin of the ore (the mine) obviously determines what kind of impurities as dopants may be present in the uranium mineral lattice (pitchblende, uraninite, etc.) and what kind of other minerals may form mixed phases with the uranium compounds. On the other hand, the oxide type uranium minerals are often denoted as U3O8, indicating a UVI/UIV mixed oxide. The lattice of such an oxide readily contains defects, thus offering trapping sites for positrons.

Chemical and thermal processing of the ore concentrate (fuel pellet production) partially removes these defects just like the chemical impurities, and this can sensitively be observed in the positron lifetime data.

Conclusions

According to our results, PAS can be used to differentiate between nuclear materials based on microstructure. PALS can definitely separate ore concentrates from fuel pellets. The average positron lifetime measurements can be helpful to identify enriched pellets according to their origin. Moreover, remarkable indications were found that the method is able to differentiate uranium ore concentrates by their geographical origin. DBS provided well separated S–W values for the pellets, suggesting a possibility to identify the nuclear forensic signature (e.g. manufacturing technology) of fuel pellets. To establish a useful forensic tool, further studies are required to collect more data to gain higher statistical significance for the observed differences in spectral parameters. A database with PAS analytical data on nuclear materials would be useful for origin assessment of the samples.

Additional measurements are needed on model compounds to determine the mechanism of the formation and annihilation of positron states in the different types of nuclear materials.

Our measurements showed that the PAS is a cost effective, low-maintenance, easily accessible and easy-to-maintain technique that can be used to perform rapid nuclear forensic analysis in case of some special type of nuclear materials as uranium ore concentrates.

References

IAEA Nuclear Security Series No. 6 (2007) Combating illicit trafficking in nuclear and other radioactive material. IAEA, Vienna

IAEA Nuclear Security Series No. 20 (2013) Objective and essential elements of a state’s nuclear security regime. IAEA, Vienna

IAEA Nuclear Security Series No. 15 (2011) Nuclear security recommendations on nuclear and other radioactive material out of regulatory control. IAEA, Vienna

IAEA Nuclear Security Series No. 2-G (2015) Nuclear forensics in support of investigation. IAEA, Vienna

Mogensen OE (1995) Positron annihilation in chemistry. Springer, Berlin, Heidelberg

Gigl T, Beddrich L, Dickmann M, Rienäcker B, Thalmayr M, Vohburger S, Hugenschmidt C (2017) Defect imaging and detection of precipitates using a new scanning positron microbeam. New J Phys 19:123007. https://doi.org/10.1088/1367-2630/aa915b

Cizek J (2018) Characterization of lattice defects in metallic materials by positron annihilation spectroscopy: a review. J Mater Sci Technol 34:577–598. https://doi.org/10.1016/j.jmst.2017.11.050

Michalcová A, Vojtech D, Cizek J, Procházka I, Drahokoupil J, Novák P (2011) Microstructure characterization of rapidly solidified Al–Fe–Cr–Ce alloy by positron annihilation spectroscopy. J Alloy Compd 509:3211–3218. https://doi.org/10.1016/j.jallcom.2010.12.049

Toyama T, Matsukawa Y, Saito K, Satoh Y, Abe H, Shinohara Y, Nagai Y (2015) Microstructural analysis of impurity segregation around β-Nb precipitates in Zr–Nb alloy using positron annihilation spectroscopy and atom probe tomography. Scripta Mater 108:156–159. https://doi.org/10.1016/j.scriptamat.2015.07.005

Hamilton C, Dymek S, Dryzek E, Kopyscianski M, Pietras A, Weglowska A, Wrobel M (2017) Application of positron lifetime annihilation spectroscopy for characterization of friction stir welded dissimilar aluminum alloys. Mater Charact 132:431–436. https://doi.org/10.1016/j.matchar.2017.09.017

Biganeh A, Kakuee O, Rafi-Kheiri H, Lamehi-Rachti M, Sheikh N, Yahaghi E (2020) Positron annihilation lifetime and doppler broadening spectroscopy of polymers. Radiat. Phys. Chem. 166:108461. https://doi.org/10.1016/j.radphyschem.2019.108461

Hu M, Liu J, Kong J, Qi N, Wu Y, Chen Z, Xu S, Li N (2022) Free volume and gas transport properties of hydrolyzed polymer of intrinsic microporosity (PIM-1) membrane studied by positron annihilation spectroscopy. Microp Mesoporous Mater 335:111770. https://doi.org/10.1016/j.micromeso.2022.111770

Chavan C, Bhajantri RF, Bulla S, Ravikumar HB, Raghavendra M, Sakthipandi K, Yogesh Kumar K, Prasanna BP (2022) Ion dynamics and positron annihilation studies on polymer ceramic composite electrolyte system (PVA/NaClO4/Y2O3): application in electrochemical devices. Ceram Int 48:17864–17884. https://doi.org/10.1016/j.ceramint.2022.03.058

Shpotyuk O, Ingram A, Shpotyuk Y, Filipecki J, Shpotyuk O (2020) Volumetric effects in the degradation of dimethacrylate-based polymer/filler nanocomposites: a positron annihilation study. Polym Degrad Stabil 176:109150. https://doi.org/10.1016/j.polymdegradstab.2020.109150

Szabó B, Süvegh K, Zelkó R (2011) Effect of storage on microstructural changes of Carbopol polymers tracked by the combination of positron annihilation lifetime spectroscopy and FT-IR spectroscopy. Int J Pharm 416:160–163. https://doi.org/10.1016/j.ijpharm.2011.06.028

Tuomisto F, Makkonen I (2013) Defect identification in semiconductors with positron annihilation: experiment and theory. Rev Moderns Phys 85:1583. https://doi.org/10.1103/RevModPhys.85.1583

Alatalo M, Puska MJ, Nieminen RM (1993) Positron annihilation at paramagnetic defects in semiconductors. J Phys Condens Matter 5:307–314. https://doi.org/10.1088/0953-8984/5/22/002

Uedono A, Iguchi H, Narita T, Kataoka K, Egger W, Koschine T (2019) Annealing behavior of vacancy-type defects in Mg- and H-implanted GaN studied using monoenergetic positron beams. Phys Status Solidi B 256:1900104. https://doi.org/10.1002/pssb.201900104

Hautojärvi P, Corbel C (1995) Positron spectroscopy of defects in metals and semiconductors. In: Duqasquier A, Mills AP (Eds) Proceedings of international school of physics “enrico fermi”, vol 125, pp 491–532. https://doi.org/10.3254/978-1-61499-211-0-491.

Oshtrakh MI, Semionkin VA, Kopelyan EA, Milder OB (1999) Mössbauer and positron life-time study of oxyhemoglobin solution irradiated by electrons. Radiat Phys Chem 55:549–554. https://doi.org/10.1016/S0969-806X(99)00300-X

Vajda B, Szabó K, Süvegh R, Zelkó GÚ (2012) Tracking of the viability of Stenotrophomonas maltophilia bacteria population in polyvinylalcohol nanofiber webs by positron annihilation lifetime spectroscopy. Int J Pharm 429:135–137. https://doi.org/10.1016/j.ijpharm.2012.03.018

Quarles CA, Jobando V, Arpin P (2007) Positron annihilation lifetime and Doppler broadening correlations for a variety of polymers, cross linked rubbers and organic liquids. Nucl Instrum Methods Phys Res Sect B 261:875–878. https://doi.org/10.1016/j.nimb.2007.03.048

Djourelov N, Suzuki T, Misheva M, Margaca FMA, Salvado IMM (2005) Positron annihilation lifetime study of organic-inorganic hybrid materials prepared by irradiation. J Non-Cryst Solids 351:340–345. https://doi.org/10.1016/j.jnoncrysol.2004.11.015

Palcsó B, Zs M, Süvegh K, Herczegh A, Zelkó R (2019) Chlorine dioxide-loaded poly(acrylic acid) gels for prolonged antimicrobial effect. Mater Sci Eng C 98:782–788. https://doi.org/10.1016/j.msec.2019.01.043

Abraham AR, Nambissan PMG (2022) Positron annihilation spectroscopy for defect characterization in nanomaterials. Design, fabrication, and characterization of multifunctional nanomaterials. Elsevier, pp 123–146. https://doi.org/10.1016/B978-0-12-820558-7.00016-9

Bartos J, Sausa O, Svajdlenkova H, Matko I, Cechová K (2019) Bulk and confined n - alkanes: n - undecane in unmodified vs. modified silica gels by positron annihilation lifetime spectroscopy and electron spin resonance techniques. J Non-Cryst Solids 511:1–9. https://doi.org/10.1016/j.jnoncrysol.2019.01.036

Dong W, Fong C, Hill AJ, Boyd BJ, Drummond CJ (2013) Probing the amphiphile micellar to hexagonal phase transition using Positron Annihilation Lifetime Spectroscopy. J Colloid Interface Sci 402:173–179. https://doi.org/10.1016/j.jcis.2013.03.039

Oliveira FC, Denadai AML, Fulgencio F, Olivieira AM, Andrade ACA, Melo ACA, Yoshida MI, Windmöller D, Magalhaes WF (2017) Supramolecular interactions between triphenylphosphine oxide and benzamide evaluated by positron annihilation lifetime spectroscopy. J Mol Struct 1134:298–306. https://doi.org/10.1016/j.molstruc.2016.12.062

Zelkó R, Orbán Á, Süvegh K (2006) Tracking of the physical ageing of amorphous pharmaceutical polymeric excipients by positron annihilation spectroscopy. J Pharm Biomed Anal 40:249–254. https://doi.org/10.1016/j.jpba.2005.07.014

Zelkó R, Süvegh K (2004) Comparison of the enthalpy recovery and free volume of polyvinylpyrrolidone during anomalous glassy to rubbery transition. Eur J Pharm Sci 21:519–523. https://doi.org/10.1016/j.ejps.2003.11.013

Stadlbauer M, Hugenschmidt C, Schreckenbach K, Böni P (2007) Investigation of the chemical vicinity of crystal defects in ion-irradiated Mg and a Mg–Al–Zn alloy with coincident Doppler broadening spectroscopy. Phys Rev B 76:174104. https://doi.org/10.1088/1742-6596/505/1/012032

Gilles R, Hofmann M, Johnson F, Gao Y, Mukherji D, Hugenschmidt C, Pikart P (2011) Analysis of antiphase domain growth in ternary FeCo alloys after different cooling rates and annealing treatments using neutron diffraction and positron annihilation. J Alloy Compd 509:195–199. https://doi.org/10.1016/j.jallcom.2010.09.075

Asgarian SM, Kargar Z, Hatami F (2021) Irradiation of Ni-Cu ferrite nanoparticles by 241Am-9Be source and investigation of their structural and magnetic properties using positron annihilation spectroscopy. Nucl Instrum Methods Phys Res Sect B 503:37–44. https://doi.org/10.1016/j.nimb.2021.07.009

Brusa RS, Deng W, Karwasz GP, Zecca A (2002) Doppler-broadening measurements of positron annihilation with high-momentum electrons in pure elements. Nucl Instrum Methods Phys Res Sect B Beam Interact Mater Atoms 194:519–531. https://doi.org/10.1016/S0168-583X(02)00953-9

Upadhyaya DD, Muraleedharan RV, Sharma BD (1982) Study of positron lifetime spectra in UO2 powders. J Nucl Mater 105:219–222. https://doi.org/10.1016/0022-3115(82)90377-4

Roudil D, Barthe MF, Jégou C, Gavazzi A, Vella F (2012) Investigation of defects in actinide-doped UO2 by positron annihilation spectroscopy. J Nucl Mater 420:63–68. https://doi.org/10.1016/j.jnucmat.2011.08.011

Lund KR, Lynn KG, Weber MH, Macchi C, Somoza A, Juan A, Okuniewski MA (2015) Impurity migration and effects on vacancy formation enthalpy in polycrystalline depleted uranium. J Nucl Mater 466:343–350. https://doi.org/10.1016/j.jnucmat.2015.08.014

Macchi C, Somoza A, Guimpel J, Suárez S, Egger W, Hugenschmidt C, Mariazzi S, Brusa RS (2021) Oxygen related defects and vacancy clusters identified in sputtering grown UOx thin films by positron annihilation techniques. Results in Physics 27:104513. https://doi.org/10.1016/j.rinp.2021.104513

Acknowledgements

The authors would like to thank to Dr. Mihály Óvári, from Nuclear Security Department, Centre for Energy Research, Budapest, Hungary for his review of this article and for providing useful comments. The work was performed in the framework of the Hevesy György Ph.D. School for Chemistry, Eötvös Loránd University, Budapest, Hungary.

Funding

Open access funding provided by Centre for Energy Research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Tóbi, C., Homonnay, Z. & Süvegh, K. A possible novel method in nuclear forensics: positron annihilation spectroscopy. J Radioanal Nucl Chem 332, 2741–2747 (2023). https://doi.org/10.1007/s10967-023-08926-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-023-08926-0