Abstract

This study is a short communication on progress made in the adaptation of conventional push-rod dilatometry for the measurement of volumetric expansion of liquid salts up to 1300 K. A new crucible design is offered as a practical solution for measurement of liquid salts by this method. Proof-of-concept measurements of the volumetric expansion of sodium chloride (NaCl) are compared to the available data in literature. Measurement of the coefficient of thermal expansion (CTE) of solid NaCl compared favorably to the available data in literature, confirming both magnitude and trend. The average CTE of NaCl (solid) was \(\overline{\alpha }_{{{\text{NaCl}}\;{\text{Solid}}}} = 5.63 \cdot 10^{ - 5} {\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 K}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$K$}}\). The volumetric expansion of liquid NaCl was measured as \(\beta_{{{\text{NaCl}}\;{\text{Liquid}}}} \approx 3.96 \cdot 10^{ - 5} 1/K\) and is essentially constant from the melt point to 1300 K. The volumetric expansion produced by this method is in reasonable agreement with the available published data and previous measurements made by the authors by neutron radiographic technique.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Liquid salts are of research interest for their potential application in heat storage for concentrated thermal solar power plants, pyrochemical processing and separation of actinides, and as the coolant/fuel salt in certain molten salt nuclear reactor (MSR) designs. As an energy storage media, molten salts provide a useful range of material properties, including: a broad liquid temperature range, large heat capacity, and low viscosity [1,2,3,4,5]. Pyrochemical processing relies on the unique redox behavior of the actinides in liquid salt systems and may be coupled with electrolysis to separate fission products [6]. MSRs rely on the fact that liquid salts will remove heat from the core without significant moderation of the average neutron energy, which enables a high rate of transmutation and burning of minor long-lived transuranics. Optimization of a liquid salt for a given application is difficult given the lack of information of thermophysical properties of most compositions and the impact of dilute impurities on overall salt performance. In the case of the single-species salts, where more data is available, there is significant scatter in fundamental properties such as density, melt point, and enthalpy of fusion [7]. A comprehensive understanding of these thermal properties as a function of temperature and composition will be critical towards future development of predictive models that will aid in the design of engineered systems that implement molten salt technology.

There are numerous technical challenges associated with measurement of the thermophysical properties of liquid salts. Chlorides and fluorides can be extremely hydroscopic. Stock materials must be rigorously dried and purified, and subsequent storage and handling must be performed under controlled atmospheric conditions. The melting point of pure unmixed salts is generally high, in excess of 1075 K. Given the elevated vapor pressure at high temperatures (> 1300 K), single-use sealed containers are often required [8]. Conventional methods for measurement of thermal properties generally require non-trivial adaptations. This is highlighted by recent investigations on molten salt heat capacity measurements [9]. Novel methods for liquid salt characterization are required for measurement of small sample sizes or unusually hazardous materials, such as plutonium. Successful adaptation of a commercially available test apparatus enables measurement across a broad range of institutions and promotes cross-validation of data.

This study is a short communication on progress made in the adaptation of conventional push-rod dilatometry for the measurement of volumetric expansion of liquid salts up to 1300 K. Push-rod dilatometry was chosen as it is an essentially ubiquitous tool for measuring material thermal expansion and its applications to molten salts will allow for more rapid screening of candidate salt compositions. This technique also offers some advantages compared to other density measurement techniques, such as pycnometry (ASTM D3505), gas bubble measurement (ISO Standard 18,213), neutron scattering methods, or laser interferometry. With respect to each of these techniques, force controlled push-rod dilatometry would eliminate bubbles in the liquid phase, use a small mass of sample material, is affordable, and has low geometric complexity. A modified liquid cell crucible design is offered as a practical solution for measurement of liquid salts. Preliminary proof-of-concept measurements of the volumetric expansion of NaCl are compared to the available data in literature. The work presented here is a first look into upcoming measurements and will extend to binary/ternary salt mixtures, as well as uranium- and plutonium-bearing salts.

Experimental

Materials

High purity (> 99.99%) NaCl was purchased from Sigma-Aldrich and was subsequently dried by vacuum furnace at 393 K for 24 h and then 493 K for 24 h, similar to such methods described previously in [10,11,12,13]. Phase purity was measured by powder x-ray diffraction (pXRD) (Bruker, D2 Phaser, Bragg–Brentano geometry, Ni-filtered Cu Ka, Bruker AXS, Karlsruhe, Germany), with comparison to available powder diffraction file (PDF-4 +) database. XRD samples were prepared and sealed in a dry inert atmosphere glove box where the oxygen and moisture levels were monitored and maintained between 1 and 5 ppm. The sample container consisted of a low background silicon stage with a plastic dome (Bruker AXS, Karlsruhe, Germany) which sealed the sample material. This x-ray technique was able to detect the presence of oxides or oxychlorides but was limited to the detection of gross impurities in excess of 1–2 wt%. Maximal residual oxychloride/oxide contamination in the dried salts was expected to be equal to or less than the initial water content in the as-received materials, < 0.5 wt%. Moisture content of the as received and dried salt was measured by coulometric Karl Fischer titration (Mettler-Toledo GmbH, Analytical, C30S, Schwerzenbach, Switzerland) using a heating technique to analyze volatile species in the titration solution, hydranal. A moisture content of < 500 ppm in the dried salts was considered suitable for our measurements. These levels of oxide, oxychloride, and water impurities were assumed to be tolerable and would not significantly impact measurements of volumetric expansion, given the larger overall position and temperature uncertainty associated with pushrod dilatometry.

Method

The coefficient of volumetric expansion of liquid NaCl was measured by a force-controlled push rod dilatometer (DIL 402CD, Netzsch Instruments, Germany). A custom graphite cylindrical crucible with a graphite push plate was used; a schematic drawing of this crucible is shown in Fig. 1.

This crucible design was adapted from past dilatometry measurements on molten metals and silicate melts [14,15,16]. The choice of machining technique and crucible diameter was critical to the success of the experiment. The crucible interior was shaped by plunge end milling and then polished with a straight flute reamer. A range of crucible diameters close to the diameter of the push plate were tested. Small diameter mismatch led to binding of the push plate in the crucible while large diameter mismatch allowed fluid to leak from the crucible during the measurement. The crucible diameter was chosen such that no binding occurred, and the mass loss of sample material was minimized. A mass loss of < 1% was a criterion for a successful measurement, as such a variation was within the precision of the mass measurement and will not greatly impact material expansion behavior. Prior to testing, salt was cast in the base of the crucible using a furnace located within an inert atmosphere dry glovebox. During casting the crucible was oriented vertically and the push plate was inserted from the top. Due to the action of the push plate pressing down onto the salt melt during the casting process, the salt solidified into a right cylinder upon cooling. Given the diameter of the crucible, the mass of salt was chosen such that the cast cylinder was 7 mm in height. The casted cylinder of salt was removed from the crucible and the height was measured directly.

Dilatometry measurements were conducted under a flowing inert argon atmosphere up to 1300 K. Reference graphite standards were manufactured of equivalent length, and the length was measured as an average of 10 measurements by a digimatic indicator (543-783BCERT, Mitutoyo, Japan). Standards were turned and polished on a lathe to a length of 7.00 ± 0.02 mm, with a final polishing step of 1200 grit alumina. The height of the as-cast salt block was measured and recorded as Lo. The coefficient of expansion of solid NaCl was determined by the ratio method with the known expansion of graphite as described in ASTM standard E473-11a. The volumetric expansion of the liquid NaCl was calculated from the change in volume between the melt point (Tm = 1074 K) and 1300 K, taking into account the expansion of the graphite crucible and the change in length of the liquid column. Prior to measurement, the dilatometer furnace chamber was purged via vacuum to at least 10−2 mbar and refilled with ultra-high purity (UHP) argon in order to reduce the potential for residual moisture or oxygen contamination. The dilatometer was set to standby for 30 min under flowing UHP argon prior to each measurement. The coefficient of volumetric expansion was measured up to 1300 K using a heating rate of 5 K/min controlled by the sample thermocouple located within 3 mm of the liquid measurement cell. The sample thermocouple was calibrated with a five-point temperature calibration based on high-purity (> 99.99%) melt point standards. Temperature uncertainty at the sample thermocouple was ± 5 K.

Results and discussion

Change in length (represented as dL/Lo) is plotted as a function of temperature in Fig. 2: The plot indicates the expansion of solid and liquid NaCl, separated by a step discontinuity which represents the melt event.

The melt event was shown as a decrease in dL/L0. This was an artifact of the casting process and should not be interpreted as a contraction of the sample material. Because the salt was cast within the graphite crucible prior to the start of the measurement, the diameter of the salt block necessarily contracted while cooling from liquid to solid. Therefore, the diameter of the salt block at the start of the measurement was significantly smaller than the diameter of the interior of the crucible. When the salt liquified it flowed into this residual empty space. The push plate advanced to regain contact with the sample material, and this movement was recorded as an apparent decrease in dL/L0. The average coefficient of thermal expansion (CTE) of solid NaCl was measured as \( \bar{\alpha }_{{{\text{NaCl}}~~{\text{Solid}}}} = 5.63 \cdot 10^{{ - 5}} {\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 K}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$K$}} \), which is consistent with the reported literature [17, 19, 20]. as summarized in Table 1:

At temperatures between 773 and 1073 K an increase in CTE was observed, which was attributed to the defect contribution to α which arises from the formation of Schottky pairs [17, 18]. This trend was confirmed in this study: \(\alpha (T)\) was essentially linear until 773 K, above which the CTE increased significantly. The temperature dependence CTE is given by Eq. (1):

where T is the temperature in Kelvin, and α is in units of 1/K. While the magnitude and trend are in close agreement, the data for \({\alpha }_{\mathrm{NaCl} \mathrm{Solid}}\) at lower temperatures (< 773 K) are 10–20% higher than measured in previous studies [17,18,19,20]. This may be due to entrapped gas within the cast block. In order to mitigate this effect, future measurements will repeatedly cycle the sample between the solid and liquid phase. Solidification in the measurement configuration should minimize any geometric effects. However, measurement of the CTE of the solid salt was not the motivation of this work. Indeed, this work was meant to demonstrate feasibility of molten salt measurements and summarize results of the volumetric changes of liquid NaCl. Thermal expansion measurements on the solid phase was included here to document that the measurement was accurate to the order of magnitude of reference data, with reproduction of the expected trend in CTE. This established confidence in the measurement of the expansion of the liquid. Unlike the case of the solid measurement, confinement of the liquid was taken into account in the calculation of \(\Delta V/{V}_{0}\).

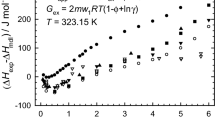

Analysis of the expansion of the liquid was complicated by the fact that the liquid cell would necessarily expand during the measurement and must be corrected in the final analysis [15]. The average coefficient of volumetric expansion, \(\overline{\beta }\), is related to the total change in volume, initial volume of the liquid, and the change in temperature as shown in Eq. (2):

where \({r}_{0}\) is the initial inner radius in the change in volume from the melt point to 1300 K, \({V}_{{T}_{m}}\) is the volume of the liquid at melt, and \(\Delta T\) is the change in temperature from melt to 1300 K. The dependence of \(\beta \) on temperature is shown by Eq. (3):

\(\beta \) is essentially constant. This result was supported by other recent work where the volumetric expansion of molten chlorides was measured by neutron scattering technique; in that work the volumetric expansion was shown to be \(3.98\bullet {10}^{-5}1/K\), which is in close agreement with the result of this study [7]. This was a first of its kind measurement to employ conventional pushrod dilatometry to produce volumetric expansion data of molten NaCl. Future work will expand this effort to include measurements on other solid and liquid chlorides, especially binary and ternary mixtures. This method should be adaptable for the measurement of liquid fluorides and liquid metals.

Conclusions

This short communication summarized progress made in the adaptation of conventional push-rod dilatometry for the measurement of volumetric expansion of NaCl up to 1300 K. An adapted design of graphite liquid cell crucible was employed as a practical solution for measurement of a liquid salt. This method may be generalized to include measurements of any molten salt system. The method for machining and properly sizing the push plate and crucible was described. Measurement of the coefficient of thermal expansion of solid NaCl compared favorably to the available data in literature and confirmed both magnitude and trend. The average CTE of NaCl (solid) was \( \bar{\alpha }_{{{\text{NaCl}}~~{\text{Solid}}}} = 5.63 \cdot 10^{{ - 5}} {\raise0.7ex\hbox{$1$} \!\mathord{\left/ {\vphantom {1 K}}\right.\kern-\nulldelimiterspace} \!\lower0.7ex\hbox{$K$}} \). The volumetric expansion of liquid NaCl was found to be \( \beta _{{{\text{NaCl}}~{\text{Liquid}}}} \approx 3.96 \cdot 10^{{ - 5}} 1/K \) and was essentially constant from the melt point to 1300 K. The data represented here is shown as a first look into upcoming measurements, which will extend to binary/ternary salt mixtures, as well as uranium and plutonium-bearing salts.

References s

Williams DF (2006) ORNL/TM-2006/69, Oak Ridge National Laboratory

Marcus Y (2016) Ionic Liquid Properties. Springer International Publishing AG, Cham

Janz George J (1988) United States. National Bureau of Standards, American Chemical Society, and American Institute of Physics. Thermodynamic and Transport Properties for Molten Salts

Janz GJ (1967) Molten salts handbook. Academic Press, New York

Gaune-Escard M (2002) Molten salts from fundamentals to applications. 1st Ed. 2002. ed. NATO Science Series II: 52

Paget T, McNeese JA, Fife K, Jackson M, Watson R (2019) in Plutonium Handbook, vol 1. American Nuclear Society, La Grange Park, IL

Parker SS, Long A, Lhermitte C, Vogel S, Monreal M, Jackson JM (2022) J Mol Liq 346:118147

Piro MHA, Lipkina K, Hallat D (2021) Thermochim Acta 699:178860

Qualls AL (2018) ORNL/SPR-2018/987

Kraus CA (1943) Phase diagrams of some complex salts of uranium with halides of alkali and alkaline earth metals

Janz GJ, Tomkins RPT, Allen CB, Downey JR, Garner GL, Krebs U, Singer SK (1975) J Phys Chem Ref Data 4:871

Smirnov MV, Stepanov VP (1982) Electrochim Acta 27(11):1551–1563

Vidal JC, Noah K (2019) AIP conference proceedings, 2126, 1. AIP Publishing LLC

Gottsmann J, Dingwell D, Gennaro C (1999) Am Mineral 84:1176–1180

Blumm J, Henderson JB (2000) HTHP 32:109–113

Wang LM, Mei Q (2006) J Mater Sci Technol 22:569–571

Enck FD, Dommel JG (1965) J Applied Phys 36(3):839–844

Merriam MF, Smoluchowski R, Wiegand DA (1962) Phys Rev 125(1):65–67

Walther AK, Haschkowsky WP, Strelkow PG (1937) Physik Z Soviet Union 12:35

Eucken A, Dannohl W (1934) Z Electrochem 40:814

Acknowledgements

The authors thank Alberto Gomez and Shane Mann for their valuable assistance in the setup and operation of the experimental apparatus. Research presented in this article was supported by the Laboratory Directed Research and Development (LDRD) program at Los Alamos National Laboratory, United States (Projects #20190650DI and #20210113DR).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Parker, S.S., Abdul-Jabbar, N.M., Jackson, J.M. et al. Feasibility of volumetric expansion of molten chlorides by conventional pushrod dilatometry. J Radioanal Nucl Chem 331, 5259–5263 (2022). https://doi.org/10.1007/s10967-022-08641-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-022-08641-2