Abstract

Phosphogypsum (PG) accumulates during wet-phosphoric acid production for fertilizers. In the Philippines, PG is partly (40%) utilized to produce gypsum walls and cement. This work assesses the radiological risks and resource opportunities associated with PG stacks in the Philippines. The conducted in situ radiometric survey measured the activity concentrations of 40K, 238U, and 232Th at 270 locations. Besides, another 120 surface samples were collected. Pure PG exceeds the recommended radiation limits, but simple dilution with conventional materials can make PG available as an inexpensive secondary raw material for construction. PG further contains relevant concentrations of rare earths and Y (195 ppm).

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

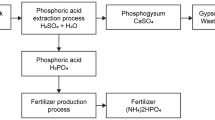

More than three quarters of phosphate fertilizers produced globally are produced from phosphate rock (PR) using phosphoric acid (PA) as an intermediate product, leaving 4–6 t low-radioactive phosphogypsum (PG) per t P2O5 produced, as relevant and potentially hazardous by-product/waste behind [1, 2]. About 85% of the 5.6–7.0 billion t PG produced globally over the lifetime of the phosphate industry are disposed of in stacks in more than 50 countries worldwide. 3–4 billion t are accessible for recovery worldwide [3] while some fresh 100–280 million t PG are added to existing stacks every year [4,5,6]. The relatively low radioactivity concentrations (0.2–3 Bq/g for 226Ra) present in most PG does not allow using the material under most national regulations today [7]. The complete purification of PG from Ra is challenging as the Ra is chemically very similar to Ca making separation from the PG matrix complicated, inefficient, and thus costly, mitigating the direct use of PG as an otherwise inexpensive building material or soil amendment [8]. Besides Ra, PG contains considerable amounts of heavy- and light rare earth elements (REEs) associated with the processed phosphate ores [9].

During PA production nearly 80% of 226Ra and 60–90% of the REEs transfer to the PG [10,11,12,13,14] while nearly 86% of 238U and 70% of 232Th transfer to the PA [5, 15]. The occurrence of radionuclides in PG can be traced to the abundance of Ca in the PR that can substitute radionuclides with similar ionic radius such as U and Th [16, 17]. 226Ra that is a decay product of 238U is the major source of radioactivity among the different radionuclides found in PG [18]. 226Ra further decays to the dense radioactive noble gas 222Rn that is accountable for much of the hazards associated with 226Ra [19, 20]. Numerous studies have also reported elevated concentrations of heavy metals [21, 22] and REEs [23, 24] in PG.

Hakkar et al. [25] estimated that REEs associated with PR production from Morocco alone could substitute some 7–15% of the global REE demand while mitigating adverse environmental effects [26] associated with traditional REE mining. Recovering REEs during PR processing could further provide additional supply security to non-REE mining countries [27, 28]. REEs recovery from PG is an active field of research today [29, 30] and even led to nearly a dozen pilot plant operations that have been reviewed by Al Khaledi et al. [31] and Wu et al. [32]. In addition, Ramirez et al. [33] recently reviewed the economic potential of REEs associated with PG in the Philippines.

There are currently an estimated 10.1 million t PG in tailing ponds in the Philippines that have been accumulated in fertilizer production since 1984. Remarkably, the Philippines do not mine phosphate ores and very different sedimentary PR from China, Egypt, Israel, Jordan, Peru, Tunisia, the USA, and Vietnam as well as igneous PR from Russia and South Africa have been imported and processed over the years. Igneous and sedimentary PR show very different concentrations of accompanying trace elements such as REEs that can reach concentrations of 2% in igneous PR while the concentrations are usually lower in sedimentary PR and uranium that can show concentrations of 0.02% in sedimentary PR but are usually below 0.005% in igneous PR. Nearly 40% of the currently produced PG is already used in cement production and as soil conditioner in the Philippines today. Despite several works detailing the occurrence of radionuclides in Philippine PG [24, 34], knowledge of potential risks associated with the use of the Philippine PG as additives in construction materials is not well-understood yet. This mitigates further unobjectionable utilization of PG as an inexpensive secondary resource.

This study aims to assess the potential risks associated with the radionuclides and heavy metals in Philippine PG through a combination of an in situ ground radiometric survey and chemical analysis. The study is expected to provide important baseline information for the creation of policies related to upcycling and further utilization of PG in the Philippines and elsewhere. Such practice holds the promise of minimizing the environmental and economic risks associated with PG stacking in a region prone to typhoons.

Materials and methods

Description of the PG ponds

There are a total of eight PG ponds with no distinct boundaries at the main fertilizer plant in the Philippines that are shown in Fig. 1. A total of 270 data points in a 25 m × 25 m grid on the surface of the tailing ponds were assessed for 40K, 238U, and 232Th using Bismuth Germanate Oxide (BGO) portable gamma spectroscopy. In addition, 120 surface PG samples were analyzed for heavy metals and REEs using atomic emission spectroscopy. The results of the survey and chemical analysis were compared to literature data of various PG stacks and international regulatory limits.

In situ ground radiometric survey

An in situ radiometric survey of naturally occurring radionuclides 40K, 232U, and 238Th was carried out on the surface of the ponds using portable gamma ray spectrometers (Radiation Solutions RS 230) equipped with 103 cm3 BGO detectors. K was measured through the detection of 1,461 keV gamma rays emitted by its isotope 40K, U was measured through the detection of 1,765 keV gamma rays of 214Bi, a decay product of 238U, and Th was measured through the detection of 2615 keV gamma rays of 208Tl, a decay product of 232Th. The measured concentrations assume radioactive equilibrium in the U and Th decay series. The reliability of the spectrometer was pre-validated using a set of 1 m × 1 m × 30 cm concrete standard calibration pads: one background pad and three pads salted with known concentrations of 40K, 238U, and 232Th, prior to the field measurements. A total of 270 measurements using a 25 m × 25 m grid space on the ponds surface (Fig. 1) were taken for activity concentrations of 40K, 232U, and 238Th using three measurement trials each time.

Surface sample collection, preparation, and analysis

PG samples were also collected from the 270 measurement locations during two fieldtrips in September 2018 and June 2019. Approximately 2 kg of PG were collected per sample from the upper 0.2 m of the ponds and then stored in plastic bags. The collected samples were then dried in an oven at 60 °C for 24 h.

The concentrations of the REEs (La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) and seven heavy metals (As, Cd, Cr, Cu, Ni, Pb, and Zn) in the 120 PG samples were determined using inductively coupled plasma mass spectrometry (ICP-MS) on an Agilent 7700 and inductively coupled plasma optical emission spectrometry (ICP-OES) on an Agilent 5100. The samples were digested using a combination of analytical grade HCl, HNO3, HF and HClO4.The detection limits for REEs ranged from 0.05 to 0.1 mg kg−1 and that of heavy metals from 0.05 to 2 mg kg−1 respectively. A blank solution and certified reference materials (OREAS 501c, 600, 623 90, and 44P) were analyzed for analytical control and validation.

Radiation hazard indices

Around 40% of the PG produced by the fertilizer plant is currently utilized as additives for cement production and as soil conditioner. To assess the risks associated with K, U, and Th in the PG, several radiological risk assessments were performed that are commonly used to assess the potential public exposure and usability of materials with elevated radionuclide concentrations in construction. Specifically, these were the radium equivalent activity (Raeq), the gamma specific activity index (Iγ), the external hazard index (Hex), the internal hazard index (Hin), the absorbed gamma dose rate (Dair), and the annual effective dose equivalent (AEDE).

Radium equivalent activity (Raeq)

The radiological hazards associated with the radionuclides in PG was assessed using the activity concentrations of 40K, 238U, and 232Th and the Raeq (1).

AU, ATh, and AK are the activity concentrations in Bq kg−1 of 238U, 232Th, and 40K. A Raeq of 370 Bq kg−1 is equivalent to the allowable annual dose rate for the general public [35].

Gamma hazard index (Iγ)

The external gamma radiation from the decay of radionuclides is also a major hazard. To assess whether the PG meets the regulatory standards for gamma radiation, we determined the Iγ according to (2).

Iγ values of ≥ 6 correspond to an annual gamma dose rate of 1 mSv y−1 [35].

External (Hex) and Internal (Hin) hazard indices

The estimation of gamma ray exposure of an individual is done using the Hex. An internal hazard through ingestion and inhalation of radon and other radionuclides is also a major concern. The estimation of gamma radiation exposure through the aforementioned exposure pathways is possible using the Hex and Hin that were determined using (3) and (4), respectively.

Hex and Hin should be less than 1 or the unity which is equivalent to an external dose rate of 1.5 mGy y−1 [35].

Absorbed gamma dose rate (Dair)

The Dair is used to measure the amount of radiation from the radionuclides that an individual receives at a given time. It is calculated using (5).

The Dair of the PG ranges from 47.1 to 805.2 nGy h−1 with a mean of 315.3 nGy h−1. The mean Dair exceeds the world average Dair of 59 nGy h−1 [35].

Annual effective dose equivalent (AEDE)

The AEDE is the estimated dose received by an individual over the course of a year. The AEDE of an individual exposed outside to the relevant radionuclides is provided in (6),

where D is the dose rate (Dair), 8760 h is the number of hours in a year, 0.2 is the outdoor occupancy factor, and 0.7 Sv Gy−1 is the conversion coefficient from absorbed dose in air to effective dose received by adults. The mean AEDE of the PG is 386.7 µSv y−1 which exceeds the world average AEDE of 70 µSv y−1 [35].

Heavy metal risk indices

PG contains a number of heavy metals. Due to the absence of heavy metal risk indices for industrial waste by-products existing indices that are frequently used to assess heavy metal pollution in soils and sediments are used in this work. Specifically, the single pollution index (SPI), the pollution load index (PLI), and the potential ecological risk index (PERI) were considered.

Single pollution index (SPI)

The SPI is a direct comparison of the metal concentration to background levels. It is calculated following (7),

where Cn is the metal concentration and Bn is the background or reference concentration of the same metal. The average heavy metal concentrations in the Earth’s upper continental crust was used as reference concentrations [36]. The qualitative ratings of the SPI are as following: ≤ 1 no pollution, 1–2 low level of pollution, 2–3 moderate level of pollution, 3–5 strong level of pollution, and ≥ 5 very strong level of pollution.

Pollution load index (PLI)

To assess the overall degree of heavy metal contamination in the PG, we used the PLI that combines the SPI of the individual heavy metals into a single measure according to (8) [37].

A PLI < 1 signifies no heavy metal pollution, 1 is the baseline of pollution, and > 1 indicates that a material is polluted.

Potential ecological risk index (PERI)

The PERI is the most used index to assess the ecological risks of toxic metals in sediments. It measures the vulnerability of organisms to heavy metal contamination and is expressed through the potential toxicity response index (RI) (9) of various heavy metals in the considered sediments.

Eri is the potential ecological risk factor of the heavy metal, Tri is the biological toxic response factor of the heavy metal (Tri: Cd = 30, As = 10, Cu, Ni, Pb = 5, Cr, V = 2 and Zn = 1), and Cfi is the contamination factor of the individual heavy metal [38]. RI is rated as < 150 low risk, 150–300 moderate risk, 300–600 considerable risk, and > 600 very high risk. The mean RI of the individual heavy metal is classified as < 40 low risk, 40–80 moderate risk, 80–160 considerable risk, 160–320 high risk, and > 320 very high risk.

Results and discussion

Radiometric survey and radiological risk assessment

The in situ radiometric survey determined the activity concentrations of 40K, 232Th, and 238U at 270 locations in the Philippine PG ponds. The results of the activity concentrations of the radionuclides in the ponds is provided in Table 1. The relatively high standard deviation and range of activity concentrations of 40K, 238U, and 232Th in the PG ponds indicate varying radioactive characteristics in each pond which could be attributed to the processing of more than ten different types of PR at the fertilizer plant. It was further found that the mean 40K and 232Th concentrations are within the world average activity concentrations in soil while the concentration of 238U is 18.7 times higher than the world median activity concentration in soil reported by the United Nations Scientific Committee on the Effects of Atomic Radiation (UNSCEAR) [35]. Uranium can be recovered as a by-product during PR processing to PA and ultimately mineral fertilizers [39]. This practice provided nearly 20% of domestically produced uranium in the United States in the late 1980s early 1990s before it became uneconomic [40] and might still be useful to increase supply security at locations that process PR with elevated uranium concentrations [41,42,43]. It is worth noting that if uranium is recovered, it is usually recovered from the PA so that the 238U concentration in the PG remains unchanged. The elevated concentrations of 238U in the Philippine PG show that innovative processes that could not only recover uranium but reduce the uranium concentration in the PG are most desirable, as they would allow the direct use of PG in construction and as soil amendment.

To assess the risks of utilizing PG in industrial applications, several radiological risk assessments commonly used to assess the safety of materials with radionuclides for construction were performed. The statistics of the radiological risk assessments are summarized in Table 2. The Raeq of the PG ranged from 101.9 to 1742.3 Bq kg−1 with a mean of 683.1 Bq kg−1, which exceeded the allowable Raeq of 370 Bq kg−1 equivalent of the allowable annual dose rate for the general public [35]. On the other hand, it was found that the mean Iγ of 2.3 was less than the allowable maximum value of 6. Iγ ≤ 6 corresponds to an annual dose rate of 0.3 mSv y−1. The Iγ of the PG ranged from 0.3 to 5.8 which is within the safe limits for gamma radiation [35]. In addition to Iγ meeting the regulatory standards, it is also important to understand how the gamma radiation affects an individual. The mean (range) of the Hex and the Hin of the PG were 1.8 (0.3–4.7) and 3.6 (0.5–9.3), respectively. These are considerably higher than the unity of 1. The mean values of the Dair and the AEDE of the PG were 315.3 nGy h−1 and 386.7 µSv y−1 and ranged from 47.1–805.2 nGy h−1 and 57.7–987.5 µSv y−1 respectively. Both the Dair and the AEDE exceeded the world median activity concentration in soil reported by the UNSCEAR [35].

The results of the radiological assessments consistently indicate that the 40K, 238U, and 232Th concentrations in Philippine PG exceed the allowable safety limits for industrial use. It is important to note that in the application of PG as raw material in cement production and as replacement for natural gypsum in the Philippines, only a small fraction is being added to significantly lower the radiological hazards, to avoid unreasonable public exposure and to not compromise the mechanical stability of the final product. For instance, in Portland cement production, 5–10% PG can be added to cement clinker producing a mixture that still shows promising results in terms of setting time, flow, and compressive strength behavior [44]. In the manufacturing of fired clay bricks, 30% PG can be added with the resulting material still satisfying the standard requirements [45]. Other remedial measures to limit radiation public exposure in these applications is to simply dilute or mix batches of relatively high and low radioactive PG [46].

Heavy metal risk assessment

A total of 120 surface PG samples were analyzed for heavy metals using ICP-OES. The analysis revealed concentrations of As (2 mg/kg), Cd (0.05 mg/kg), Cr (5 mg/kg), Cu (1 mg/kg), Ni (1 mg/kg), Pb (1 mg/kg), and Zn (1 mg/kg) that were often below the detection limit of 1 mg/kg. A summary of statistics of heavy metals measured within the detection range is shown in Fig. 2a. Among these heavy metals it was found that Pb was the most relevant with mean concentrations of 11 mg/kg and a range from 2–71 mg/kg.

The SPI of the individual heavy metals is shown in Fig. 2b. The mean SPI indicates that there is no heavy metal pollution associated with As (0.76), Cr (0.11), Cu (0.17), Ni (0.08), Pb (0.67), and Zn (0.08) but there is a very strong level of pollution with respect to Cd (5.31). On the other hand, however, the synergistic effects of the heavy metals measured using the PLI with a mean of 0.29 (< < 1) signifies no overall heavy metal contamination in the PG. Moreover, there is an overall low ecological risk associated with the heavy metals in PG as indicated by the mean RI (145.9). The mean Er of the individual heavy metals (Fig. 2c) shows that As (7.6), Cr (0.2), Cu (0.8), Ni (0.4), Pb (3.4) and Zn (0.1) present low risks while Cd (159.4) presents considerable risk. It is worth noting that mobility of these elements, particularly Cd (1%), is very low, thus, preventing significant amount of it leaching from the PG ponds to the groundwater and to the surrounding environment [47].

The results of the heavy metal risk assessments consistently indicate that there is generally a low contamination and ecological risk associated with the heavy metals found in PG in the Philippines.

Critical metal assessment

The 120 PG samples were also analyzed for valuable critical metals, particularly REEs using ICP-MS. Previous studies about REEs in PG reported enriched concentrations [23, 48,49,50,51,52] that may justify REE recovery. Table 3 summarizes the REE concentrations of the surface PG samples along with the previously published REE concentrations from trenches in the ponds recently published by Ramirez et al. (2021). The REE concentrations measured in the Philippines are further compared with REE concentrations of PG stacks in various other countries. Among the major REEs, the compositional abundance is Ce (26.3%) > La (20.9%) > Nd (17.9%) > Y (12.7%). Previous analysis of the economic potential of the REEs in the PG ponds [33] estimated the presence of 2,678 t rare earth oxides (REOs). For reference, the world’s REO mine production is currently 240,000 t per year [53]. Although there are available technologies to extract the REEs from PG, doing so in the Philippines seems to be particularly unpromising as a result of the comparatively low REEs content when compared to other PG stacks as was done in Table 3. The PG taken into account in Table 3 is all derived from processing sedimentary PR that shows much lower average REE concentrations than those found in igneous PR. It is likely that the Philippines will continue processing predominantly sedimentary PR that presently accounts for more than 80% of global phosphate rock production, and all the PR processed in the Philippines in recent years.

Conclusions and recommendations

Heavy metal concentrations in Philippine PG are an exceedingly low risk and REE concentrations will most likely not allow for economic recovery. 40K, 238U, and 232Th associated with PG measured at 270 locations exceeded the recommended safe limits for direct use and simple dilution with non-radioactive material is suggested here to fully utilize the PG stacks in the Philippines and thus eliminate risks associated with PG stacking.

References

Silva LFO, Oliveira MLS, Crissien TJ et al (2021) A review on the environmental impact of phosphogypsum and potential health impacts through the release of nanoparticles. Chemosphere. https://doi.org/10.1016/j.chemosphere.2021.131513

Wang J (2020) Utilization effects and environmental risks of phosphogypsum in agriculture: a review. J Clean Prod 276:123337. https://doi.org/10.1016/j.jclepro.2020.123337

Hermann L, Kraus F, Hermann R (2018) Phosphorus processing-potentials for higher efficiency. Sustain. https://doi.org/10.3390/su10051482

Saadaoui E, Ghazel N, Ben Romdhane C, Massoudi N (2017) Phosphogypsum: potential uses and problems–a review. Int J Environ Stud 74:558–567. https://doi.org/10.1080/00207233.2017.1330582

Tayibi H, Choura M, López FA et al (2009) Environmental impact and management of phosphogypsum. J Environ Manage 90:2377–2386. https://doi.org/10.1016/j.jenvman.2009.03.007

Rashad AM (2017) Phosphogypsum as a construction material. J Clean Prod 166:732–743. https://doi.org/10.1016/j.jclepro.2017.08.049

IAEA (2013) Safety reports series no. 78 radiation protection and management of NORM residues in the phosphate industry

Haneklaus N (2021) Unconventional uranium resources from phosphates. Encycl Nucl Energy. https://doi.org/10.1016/B978-0-12-819725-7.00152-5

Emsbo P, McLaughlin PI, Breit GN et al (2015) Rare earth elements in sedimentary phosphate deposits: solution to the global REE crisis? Gondwana Res 27:776–785. https://doi.org/10.1016/j.gr.2014.10.008

Rychkov VN, Kirillov EV, Kirillov SV et al (2018) Recovery of rare earth elements from phosphogypsum. J Clean Prod 196:674–681. https://doi.org/10.1016/j.jclepro.2018.06.114

Sinha S, Abhilash MP, Pandey BD (2016) Metallurgical processes for the recovery and recycling of lanthanum from various resources: a review. Hydrometallurgy 160:47–59. https://doi.org/10.1016/j.hydromet.2015.12.004

Abdel-Aal EA, Rashad MM, El-Shall H (2004) Crystallization of calcium sulfate dihydrate at different supersaturation ratios and different free sulfate concentrations. Cryst Res Technol 39:313–321. https://doi.org/10.1002/crat.200310188

Rutherford PM, Dudas MJ, Arocena JM (1996) Heterogeneous distribution of radionuclides, barium and strontium in phosphogypsum by-product. Sci Total Environ 180:201–209. https://doi.org/10.1016/0048-9697(95)04939-8

Yahorava V, Bazhko V, Freeman M (2016) Viability of phosphogypsum as a secondary resource of rare earth elements. In: XXVIII International mineral processing congress proceedings

Haneklaus N, Bayok A, Fedchenko V (2017) Phosphate rocks and nuclear proliferation. Sci Glob Secur 25:143–158. https://doi.org/10.1080/08929882.2017.1394061

da Conceição FT, Bonotto DM (2006) Radionuclides, heavy metals and fluorine incidence at Tapira phosphate rocks, Brazil, and their industrial (by) products. Environ Pollut 139:232–243. https://doi.org/10.1016/j.envpol.2005.05.014

Pfister H, Philipp G, Pauly H (1976) Population dose from natural radionuclides in phosphate fertilizers. Radiat Environ Biophys 13:247–261. https://doi.org/10.1007/BF01330769

Rutherford PM, Dudas MJ, Samek RA (1994) Environmental impacts of phosphogypsum. Sci Total Environ 149:1–38. https://doi.org/10.1016/0048-9697(94)90002-7

Lawrie WC, Desmond JA, Spence D et al (2000) Determination of radium-226 in environmental and personal monitoring samples. Appl Radiat Isot 53:133–137. https://doi.org/10.1016/S0969-8043(00)00168-8

Samet JM (1989) Radon and lung cancer. JNCI J Natl Cancer Inst 81:745–758. https://doi.org/10.1093/jnci/81.10.745

Vásconez-Maza MD, Bueso MC, Faz A et al (2021) Assessing the behaviour of heavy metals in abandoned phosphogypsum deposits combining electrical resistivity tomography and multivariate analysis. J Environ Manage. https://doi.org/10.1016/j.jenvman.2020.111517

Martínez J, Hidalgo MC, Rey J et al (2016) A multidisciplinary characterization of a tailings pond in the Linares-La carolina mining district, Spain. J Geochem Explor 162:62–71. https://doi.org/10.1016/j.gexplo.2015.12.013

Walawalkar M, Nichol CK, Azimi G (2016) Process investigation of the acid leaching of rare earth elements from phosphogypsum using HCl, HNO3, and H2SO4. Hydrometallurgy 166:195–204. https://doi.org/10.1016/j.hydromet.2016.06.008

Palattao BL, Ramirez JD, Tabora EU et al (2018) Recovery of Uranium from Philippine wet phosphoric acidusing D2EHPA-TOPO solvent extraction. Philipp J Sci 147:275–284

Hakkar M, Arhouni FE, Mahrou A et al (2021) Enhancing rare earth element transfer from phosphate rock to phosphoric acid using an inexpensive fly ash additive. Miner Eng 172:107166. https://doi.org/10.1016/j.mineng.2021.107166

Balaram V (2019) Rare earth elements: a review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci Front 10:1285–1303. https://doi.org/10.1016/j.gsf.2018.12.005

Golev A, Scott M, Erskine PD et al (2014) Rare earths supply chains: current status, constraints and opportunities. Resour Policy 41:52–59. https://doi.org/10.1016/j.resourpol.2014.03.004

Ganguli R, Cook DR (2018) Rare earths: a review of the landscape. MRS Energy Sustain 5:1–16. https://doi.org/10.1557/mre.2018.7

Chernysh Y, Yakhnenko O, Chubur V, Roubík H (2021) Phosphogypsum recycling: a review of environmental issues, current trends, and prospects. Appl Sci 11:1–22. https://doi.org/10.3390/app11041575

Yang X, Salvador D, Makkonen HT, Pakkanen L (2019) Phosphogypsum processing for rare earths recovery: a review. Nat Resour 10:325–336. https://doi.org/10.4236/nr.2019.109021

Al Khaledi N, Taha M, Hussein A et al (2019) Direct leaching of rare earth elements and uranium from phosphate rocks. IOP Conf Ser Mater Sci Eng. https://doi.org/10.1088/1757-899X/479/1/012065

Wu S, Wang L, Zhao L et al (2018) Recovery of rare earth elements from phosphate rock by hydrometallurgical processes: a critical review. Chem Eng J 335:774–800. https://doi.org/10.1016/j.cej.2017.10.143

Ramirez JD, Diwa RR, Palattao BL, Tabora EU (2021) Economic potential of rare earth elements in the Philippine phosphogypsum. Preprints 2021070342, https://doi.org/10.20944/preprints202107.0342.v1

Haneklaus N, Reyes R, Lim WG et al (2015) Energy neutral phosphate fertilizer production using high temperature reactors: a Philippine case study. Philipp J Sci 144:69–79

UNSCEAR (2000) United nations scientific committee on the effect of atomic radiation. Sources and Effects of Ionizing Radiation, New York

Rudnick R, Gao S (2003) 3.01: composition of the continental crust. Treatise Geochem 3:1–64. https://doi.org/10.1016/B0-08-043751-6/03016-4

Sukri NS, Aspin SA, Kamarulzaman NL et al (2018) Assessment of metal pollution using enrichment factor (EF) and pollution load index (PLI) in sediments of selected Terengganu river, Malaysia. Malays J Fundam Appl Sci 14:235–240. https://doi.org/10.11113/mjfas.v14n2.1065

Hakanson L (1980) An ecological risk index for aquatic pollution control.a sedimentological approach. Water Res 14:975–1001. https://doi.org/10.1016/0043-1354(80)90143-8

Haneklaus N, Sun Y, Bol R et al (2017) To extract, or not to extract uranium from phosphate rock, that is the question. Environ Sci Technol 51:753–754. https://doi.org/10.1021/acs.est.6b05506

Steiner G, Geissler B, Haneklaus N (2020) Making uranium recovery from phosphates great again? Environ Sci Technol 54:1287–1289. https://doi.org/10.1021/acs.est.9b07859

Shang D, Geissler B, Mew M et al (2021) Unconventional uranium in china’s phosphate rock: review and outlook. Renew Sustain Energy Rev. https://doi.org/10.1016/j.rser.2021.110740

Tulsidas H, Gabriel S, Kiegiel K, Haneklaus N (2019) Uranium resources in EU phosphate rock imports. Resour Policy. https://doi.org/10.1016/j.resourpol.2019.02.012

López L, Castro LN, Scasso RA et al (2019) Uranium supply potential from phosphate rocks for Argentina’s nuclear power fleet. Resour Policy. https://doi.org/10.1016/j.resourpol.2019.04.008

Islam GMS, Chowdhury FH, Raihan MT et al (2017) Effect of phosphogypsum on the properties of portland cement. Procedia Eng 171:744–751. https://doi.org/10.1016/j.proeng.2017.01.440

Saadaoui E, Ghazel N, Ben Romdhane C, Massoudi N (2017) Phosphogypsum: potential uses and problems: a review. Int J Environ Stud 74:558–567. https://doi.org/10.1080/00207233.2017.1330582

Duran EB, De Vera C, Dela Cruz F, Garcia T (1996) Remedies to enable the use of phosphogypsum as construction material despite its radon content. Philippine Nuclear Congress, Manila, p 29

Al-Hwaiti MS, Ranville JF, Ross PE (2010) Bioavailability and mobility of trace metals in phosphogypsum from Aqaba and Eshidiya, Jordan. Chem Erde 70:283–291. https://doi.org/10.1016/j.chemer.2010.03.001

Rutherford PM, Dudas MJ, Arocena JM (1995) Radioactivity and elemental composition of phosphogypsum produced from three phosphate rock sources. Waste Manag Res 13:407–423. https://doi.org/10.1016/S0734-242X(05)80021-7

Hammas-Nasri I, Horchani-Naifer K, Férid M, Barca D (2016) Rare earths concentration from phosphogypsum waste by two-step leaching method. Int J Miner Process 149:78–83. https://doi.org/10.1016/j.minpro.2016.02.011

Al-Thyabat S, Zhang P (2015) REE extraction from phosphoric acid, phosphoric acid sludge, and phosphogypsum. Miner Process Extr Metall 124:143–150. https://doi.org/10.1179/1743285515Y.0000000002

Cánovas CR, Chapron S, Arrachart G, Pellet-Rostaing S (2019) Leaching of rare earth elements (REEs) and impurities from phosphogypsum: a preliminary insight for further recovery of critical raw materials. J Clean Prod 219:225–235. https://doi.org/10.1016/j.jclepro.2019.02.104

Liang H, Zhang P, Jin Z, DePaoli D (2017) Rare earths recovery and gypsum upgrade from Florida phosphogypsum. Miner Metall Process 34:201–206. https://doi.org/10.19150/mmp.7860

USGS (2021) Rare earths data sheet 2021

Acknowledgements

This work is funded by the Department of Science and Technology (DOST) of the Philippines, the Philippine Council for Industry, Energy and Emerging Technology Research and Development (PCIEERD) and the Max-Buchner-Forschungsstiftung of DECHEMA e.V (Grant Number 3824). We are thankful to Mr. Dennis Mate and Mr. Antonino Varela, Jr. and his staff for their invaluable contribution to the success of this research project.

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Diwa, R.R., Tabora, E.U., Palattao, B.L. et al. Evaluating radiation risks and resource opportunities associated with phosphogypsum in the Philippines. J Radioanal Nucl Chem 331, 967–974 (2022). https://doi.org/10.1007/s10967-021-08142-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-021-08142-8