Abstract

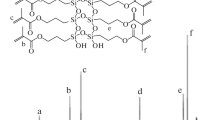

Compatibility of polymeric dispersant with other components in a coating is an important criterion to formulate coating with desirable optical properties, particularly surface gloss. This study detailed the synthesis of polymeric dispersant incorporated with fatty acid pigment anchoring group, PD-1, and its subsequent application in various types of organic coating binder systems. 1H-NMR analysis indicated about 98% of monomer conversion has taken place during the synthesis. Incorporation of oleic acid in the dispersant was highly strategic, resulting with long alky side chain along the dispersant chain for better steric stabilization effect, long hydrocarbon chain terminated with -COOH to serve as flexible and efficient pigment anchoring group, as well as improved the compatibility of the dispersants in wide range of organic coating binder systems. The synthesized fatty acid-based polymeric dispersant adsorbed well on the titania pigment surface and could effectively disperse and stabilize them. Titania paste prepared with PD-1 recorded the lowest viscosity close to 180 cps and the value remained approximately constant after 2 weeks of aging. The good compatibility of the PD-1 with other components in a coating mixture enabled the formation of relatively small particle size that correlates well with the surface gloss of the coatings. From benchmarking exercise, the synthesized dispersant performed equally well, if not better than the commercial dispersants. The color stability of coatings formulated with PD-1 remained the highest (dE = 0.1 to 0.3), recorded lowest rub out values (dE = 0.5 to 0.6), and highest contrast ratio in various coating systems.

Similar content being viewed by others

Data availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Hamidi NASM, Kamaruzzaman WMIWM, Nasir NAM, Shaifudin MS, Ghazali MSM (2022) Potential application of plant-based derivatives as green components in functional coatings: A review.Clean Mater100097

Madhavi G, Kishan N, Raghavendra CR (2022) A review on recent approaches in the field of surface coating. Mater Today Proc 52:403–406

Acaralı N, Demir S (2021) Physical and chemical effects of quartet structure (bamboo/zinc borate/shellac/surfactant) on organic coatings. J Indian Chem Soc 98(3)

Jhamb S, Liang X, Dam-Johansen K, Kontogeorgis GM (2020) A model-based solvent selection and design framework for organic coating formulations. Prog Org Coat 140

Kraśkiewicz A, Kowalczyk A, Kowalczyk K, Schmidt B (2023) Novel solvent-free UV-photocurable varnish coatings based on acrylic telomers–Synthesis and properties. Prog Org Coat 175

Thapliyal D, Verros GD, Arya RK (2022) A study on residual solvent, crystallinity and thermal properties of poly (styrene)-poly (methyl methacrylate)-toluene coatings. Prog Org Coat 173

Pandian B, Ramalingam S, Sreeram KJ, Rao JR (2021) Natural pigment: Preparation of brown pigment from lignin biomass for coloring application. Dyes Pigm 195

Yang YJ, Kelkar AV, Zhu X, Bai G, Ng HT, Corti DS, Franses EI (2015) Effect of sodium dodecylsulfate monomers and micelles on the stability of aqueous dispersions of titanium dioxide pigment nanoparticles against agglomeration and sedimentation. J Colloid Interface Sci 450:434–445

.Wu, W., Zhou, Q., Xu, B., Zhong, Y., Xu, H., Zhang, L., & Mao, Z. (2022) Study on the dispersion mechanism of the polycarboxylic acid dispersant for disperse dyes. J Mol Liq 349

Deng D, Boyko V, Pancera SM, Tadros T (2011) Rheological investigations on the influence of addition of sodium polyacrylate to titanium dioxide suspensions. Colloids Surf, A 389(1–3):149–157

Nagose S, Rose E, Joshi A (2019) Study on wetting and dispersion of the Pigment Yellow 110. Prog Org Coat 133:55–60

Shang X, Zhu Y, Li Z (2016) Dispersion of silicon carbide in poly alpha olefins-6 and trimethylopropane trioleate. Colloids Surf, A 509:244–251

Notley SM, Craig VS, Fogden A, Evans DR (2011) Adsorption of dispersants at a polyester resin–alkane interface. Colloids Surf, A 377(1–3):318–324

Tsai HY, Chang SJ, Yang TY, Li CC (2018) Distinct dispersion stability of various TiO2 nanopowders using ammonium polyacrylate as dispersant. Ceram Int 44(5):5131–5138

Pérez JP, Martínez-Boza FJ, Partal P (2016) Stability assessment of non-aqueous polymer dispersions through viscous flow and linear viscoelastic rheological tests. Polym Testing 50:164–171

Rezende TC, Silvestre JC, Mendonça PV, Moniz J, Serra AC, Coelho JF (2022) Efficient dispersion of TiO2 in water-based paint formulation using well-defined poly [oligo (ethylene oxide) methyl ether acrylate] synthesized by ICAR ATRP. Prog Org Coat 165

Abdelaziz MA, Ibrahim MA, Abdel-Messih MF, Mekewi MA (2020) Vivid application of polyurethane as dispersants for solvent based inkjet ink. Prog Org Coat 148

Afcona <Dispersing-Technology.pdf> (2005). Accessible at https://www.afcona.com.my/pdf/Dispersing-Technology.pdf. Accessed 28 Sept 2023

Opdam J, Govers SP, Melio J, van der Ven LG, de With G, Tuinier R, Esteves ACC (2022) Distribution of block copolymers in drying polymer films. J Colloid Interface Sci 612:617–627

Liu F, Han EH, Ke W (2013) Adsorption and stabilization of nano-TiO2 particles in a concentrated dispersion. Prog Nat Sci Mater Int 23(5):464–468

Wiącek AE et al (2014) The electrokinetic and rheological behavior of phosphatidylcholine-treated TiO2 suspensions. Colloids Surf, A 440:110–115

Monteiro S, Dias A, Mendes AM, Mendes JP, Serra AC, Rocha N, Magalhães FD (2014) Stabilization of nano-TiO2 aqueous dispersions with poly (ethylene glycol)-b-poly (4-vinyl pyridine) block copolymer and their incorporation in photocatalytic acrylic varnishes. Prog Org Coat 77(11):1741–1749

Sangli PM, Chaudhary S, Rose E, Bhavsar R (2020) Effect of molecular weight of polcarboxylate surfactant on properties of concentrated aqueous titanium dioxide dispersions. J Coat Technol Res 17:393–400

Elrebii M, Mabrouk AB, Boufi S (2014) Synthesis and properties of hybrid alkyd–acrylic dispersions and their use in VOC-free waterborne coatings. Prog Org Coat 77(4):757–764

Fragata F, Salai RP, Amorim C, Almeida E (2006) Compatibility and incompatibility in anticorrosive painting: The particular case of maintenance painting. Prog Org Coat 56(4):257–268

Kim TK, Kim BK, Lee SY, Cho YL, Kim MS, Jeong HM (2010) Thermoplastic polyurethane elastomer/thermoplastic polyolefin elastomer blends compatibilized with a polyolefinic segment in TPU. Macromol Res 18:177–184

Afcona <AFCONA - 4071 TDS eng.pdf> (2020). Accessible at https://www.afcona.com.my/entAttchDL.php?iID=698. Accessed 10 Mar 2023

Abd El-Wahab H, Nasser AM, Abd ElBary HM, Abd Elrahman M, Hassanein M (2021) Effect of the modified dispersing agent and milling time on the properties and particle size distribution of inkjet ink formulation for textile printing. Pigm Resin Technol 50(4):356–366

Chen YM, Hsu RS, Lin HC, Chang SJ, Chen SC, Lin JJ (2009) Synthesis of acrylic copolymers consisting of multiple amine pendants for dispersing pigment. J Colloid Interface Sci 334(1):42–49

Elbasuney S (2017) Sustainable steric stabilization of colloidal titania nanoparticles. Appl Surf Sci 409:438–447

Namgoong JW, Chung SW, Jang H, Kim YH, Kwak MS, Kim JP (2018) Improving nanoparticle dispersions of pigment and its application to a color filter: New phthalocyanine derivatives as synergist. J Ind Eng Chem 58:266–277

Ohenoja K, Saari J, Illikainen M, Niinimäki J (2014) Effect of molecular weight of sodium polyacrylates on the particle size distribution and stability of a TiO2 suspension in aqueous stirred media milling. Powder Technol 262:188–193

Foinard A, Décaudin B, Barthélémy C, Debaene B, Odou P (2012) Impact of physical incompatibility on drug mass flow rates: example of furosemide-midazolam incompatibility. Ann Intensive Care 2:1–4

Elbasuney S (2014) Dispersion characteristics of dry and colloidal nano-titania into epoxy resin. Powder Technol 268:158–164

Yang X, Ren T, Zhang B (2021) Dispersion performance of polycarboxylate terpolymers with different alkyl side-chain lengths in pesticide suspension concentrate. Int J Chem Eng 2021:1–7

Lim BL, Ang DTC (2022) Development of poly (butyl acrylate-co-oleic acid) as biobased polymeric dispersant and its application in preparation of pigment concentrate. J Appl Polym Sci 139(42)

Sun Z, Fan H, Chen Y, Huang J (2018) Synthesis of self-matting waterborne polyurethane coatings with excellent transmittance. Polym Int 67(1):78–84

Chang J, Wang X, Shao J, Li X, Xin W, Luo Y (2020) Synthesis and characterization of environmentally-friendly self-matting waterborne polyurethane coatings. Coatings 10(5):494

Tyagi S, Ray AK, Sood YV (2010) Surface characteristics of coating layers formed by coating pigments with different particle sizes and size distribution. J Coat Technol Res 7:747–756

Calvez I, Szczepanski CR, Landry V (2021) Preparation and characterization of low gloss UV-curable coatings based on silica surface modification using an acrylate monomer. Prog Org Coat 158

Järnström J, Ihalainen P, Backfolk K, Peltonen J (2008) Roughness of pigment coatings and its influence on gloss. Appl Surf Sci 254(18):5741–5749

Gueli AM, Bonfiglio G, Pasquale S, Troja SO (2017) Effect of particle size on pigments colour. Color Res Appl 42(2):236–243

Funding

We would like to acknowledge the financial support from Ministry of Higher Education Malaysia through Fundamental Research Grant Scheme (Project number: FRGS/1/2021/STG04/UM/02/4).

Author information

Authors and Affiliations

Contributions

Mr. Boon-Leong Lim: Conceptualization, Methodology, Validation, Visualization, Formal analysis, Investigation, Data Curation, Writing – Original Draft. Dr. Desmond Teck-Chye Ang: Conceptualization, Methodology, Funding acquisition, Resources, Writing – Review & Editing, Supervision, Project administration.

Corresponding author

Ethics declarations

Competing interests

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lim, BL., Ang, D.TC. Polymeric dispersant incorporated with fatty acid as TiO2 anchoring group for surface coating applications. J Polym Res 30, 446 (2023). https://doi.org/10.1007/s10965-023-03830-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-023-03830-3