Abstract

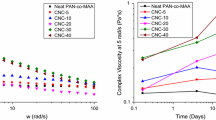

A novel, hybrid polymer composite wherein hydrophilic nanocrystalline cellulose (NCC) and hydrophobic lignin particles are reinforced into hydrophobic acrylic fiber based polyacrylonitrile (PAN) matrix is fabricated by the spin-casting technique. The discrete and synergetic influence of NCC and lignin on the PAN matrix was compared and studied on the basis of the assessment of the tensile properties of the composite films. It was observed that incorporation of NCC and lignin in the ratio of 50:50 into the PAN matrix enhanced its tensile strength and Young’s modulus by 55% and 223% respectively. Individual comparison of FTIR spectra was performed to understand the structural aspects of neat PAN and PAN composite films incorporated with NCC, lignin, and blends of NCC and lignin. Further, the composite films were assessed for physical properties such as density, viscosity, and contact angle. The impact of NCC and lignin loading on the surface morphology of the PAN matrix has been evaluated using SEM imaging tool. The thermal stability behaviour of the neat PAN film and PAN composite film was comprehended using TG analysis.

Similar content being viewed by others

References

Nabi Saheb D, Jog JP (1999) Natural fiber polymer composites: A review. Adv Polym Technol. https://doi.org/10.1002/(SICI)1098-2329(199924)18:4%3c351::AID-ADV6%3e3.0.CO;2-X

Loginova EV, Mikheev IV, Volkov DS, Proskurnin MA (2016) Quantification of copolymer composition (methyl acrylate and itaconic acid) in polyacrylonitrile carbon-fiber precursors by FTIR-spectroscopy. Anal Methods. https://doi.org/10.1039/c5ay02264a

Khalid MY, Al Rashid A, Arif ZU, Ahmed W, Arshad H (2021) Recent advances in nanocellulose-based different biomaterials: types, properties, and emerging applications. J Mater Res Technol. https://doi.org/10.1016/j.jmrt.2021.07.128

Abdul Rashid ES, Muhd Julkapli N, Yehye WA (2018) Nanocellulose reinforced as green agent in polymer matrix composites applications. Polym. Adv. Technol. https://doi.org/10.1002/pat.4264

Gan PG, Sam ST, Abdullah MF, Omar MF (2020) Thermal properties of nanocellulose-reinforced composites: A review. J Appl Polym Sci. https://doi.org/10.1002/app.48544

Kim JH, Shim BS, Kim HS, Lee YJ, Min SK, Jang D, Abas Z, Kim J (2015) Review of nanocellulose for sustainable future materials. J Precis Eng Manuf - Green Technol. https://doi.org/10.1007/s40684-015-0024-9

Ilyas RA, Sapuan SM, Sanyang ML, Ishak MR, Zainudin ES (2018) Nanocrystalline cellulose as reinforcement for polymeric matrix nanocomposites and its potential applications: a review. Curr Anal Chem. https://doi.org/10.2174/1573411013666171003155624

Geng S, Wei J, Aitomäki Y, Noël M, Oksman K (2018) Well-dispersed cellulose nanocrystals in hydrophobic polymers by in situ polymerization for synthesizing highly reinforced bio-nanocomposites. Nanoscale. https://doi.org/10.1039/c7nr09080c

Wang X, Jia Y, Liu Z, Miao J (2018) Influence of the lignin content on the properties of poly (lactic acid)/lignin-containing cellulose nanofibrils composite films. Polymers. https://doi.org/10.3390/polym10091013

Yang J, Ching YC, Chuah CH (2019) Applications of lignocellulosic fibers and lignin in bioplastics: A review. Polymers. https://doi.org/10.3390/polym11050751

Wang J, Chen W, Dong T, Wang H, Si S, Li X (2021) Enabled cellulose nanopaper with outstanding water stability and wet strength via activated residual lignin as a reinforcement. Green Chem. https://doi.org/10.1039/d1gc03906g

Wei L, Agarwal UP, Matuana L, Sabo RC, Stark NM (2018) Performance of high lignin content cellulose nanocrystals in poly (lactic acid). Polymer. https://doi.org/10.1016/j.polymer.2017.12.039

Xiong R, Zhang X, Tian D, Zhou Z, Lu C (2012) Comparing microcrystalline with spherical nanocrystalline cellulose from waste cotton fabrics. Cellulose. https://doi.org/10.1007/s10570-012-9730-4

Panamgama LA, Peramune PR (2018) Coconut coir pith lignin: A physicochemical and thermal characterization. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2018.03.012

Júnior MA, Borsoi C, Hansen B, Catto AL (2019) Evaluation of different methods for extraction of nanocellulose from yerba mate residues. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2019.04.064

Hemmati F, Jafari SM, Taheri RA (2019) Optimization of homogenization-sonication technique for the production of cellulose nanocrystals from cotton linter. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.06.241

Altaner CM, Horikawa Y, Sugiyama J, Jarvis MC (2014) Cellulose Iβ investigated by IR-spectroscopy at low temperatures. Cellulose. https://doi.org/10.1007/s10570-014-0360-x

Maekawa E, Ichizawa T, Koshijima T (1989) An evaluation of the acid-soluble lignin determination in analyses of lignin by the sulfuric acid method. J Wood Chem Technol. https://doi.org/10.1080/02773818908050315

Jiang E, Maghe M, Zohdi N, Amiralian N, Naebe M, Laycock B, Fox BL, Martin DJ, Annamalai PK (2019) Influence of different nanocellulose additives on processing and performance of PAN-based carbon fibers. ACS Omega. https://doi.org/10.1021/acsomega.9b00266

Liu HC, Tuan CC, Davijani AA, Wang PH, Chang H, Wong CP, Kumar S (2017) Rheological behavior of polyacrylonitrile and polyacrylonitrile/lignin blends. Polymer. https://doi.org/10.1016/j.polymer.2017.01.043

Liang W, Chenyang Y, Bin Z, Xiaona W, Zijun Y, Lixiang Z, Hongwei Z, Nanwen L (2019) Hydrophobic polyacrylonitrile membrane preparation and its use in membrane contactor for CO2 absorption. J Memb Sci. https://doi.org/10.1016/j.memsci.2018.09.066

Redondo A, Mortensen N, Djeghdi K, Jang D, Ortuso RD, Weder C, Korley LT, Steiner U, Gunkel I (2022) Comparing percolation and alignment of cellulose nanocrystals for the reinforcement of polyurethane nanocomposites. ACS Appl Mater Interfaces. https://doi.org/10.1021/acsami.1c21656

Liu HC, Chien AT, Newcomb BA, Liu Y, Kumar S (2015) Processing, structure, and properties of lignin-and CNT-incorporated polyacrylonitrile-based carbon fibers. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.5b00562

Rashid ES, Gul A, Yehya WA, Julkapli NM (2021) Physico-chemical characteristics of nanocellulose at the variation of catalytic hydrolysis process. Heliyon. https://doi.org/10.1016/j.heliyon.2021.e07267

Luo J, Chang H, Bakhtiary Davijani AA, Liu HC, Wang PH, Moon RJ, Kumar S (2017) Influence of high loading of cellulose nanocrystals in polyacrylonitrile composite films. Cellulose. https://doi.org/10.1007/s10570-017-1219-8

Guo Y, Cheng C, Huo T, Ren Y, Liu X (2020) Highly effective flame retardant lignin/polyacrylonitrile composite prepared via solution blending and phosphorylation. Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2020.109362

Wang Z, Yao Z, Zhou J, Zhang Y (2017) Reuse of waste cotton cloth for the extraction of cellulose nanocrystals. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2016.10.044

Joseph J, Jemmis ED (2007) Red-, blue-, or no-shift in hydrogen bonds: a unified explanation. J Am Chem Soc. https://doi.org/10.1021/ja067545z

Altaner CM, Thomas LH, Fernandes AN, Jarvis MC (2014) How cellulose stretches: synergism between covalent and hydrogen bonding. Biomacromol. https://doi.org/10.1021/bm401616n

Mishra SB, Mishra AK, Kaushik NK, Khan MA (2007) Study of performance properties of lignin-based polyblends with polyvinyl chloride. J Mater Process Technol. https://doi.org/10.1016/j.jmatprotec.2006.10.016

Mustafov SD, Mohanty AK, Misra M, Seydibeyoğlu MÖ (2019) Fabrication of conductive Lignin/PAN carbon nanofibers with enhanced graphene for the modified electrodes. Carbon. https://doi.org/10.1016/j.carbon.2019.02.058

Funding

This work was financially supported by the Department of science of Technology (DST), New Delhi, India, under the Woman Scientist Scheme – A (WoS-A).File No- SR/WOS-A/ET-90/2017.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Muthusamy, V.P., Krishnakumar, V. Tensile performance of NCC and lignin reinforcements in PAN matrix. J Polym Res 29, 462 (2022). https://doi.org/10.1007/s10965-022-03300-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03300-2