Abstract

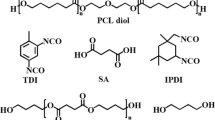

This study describes the results of investigations into the effects of the makeup of aliphatic polyester polyol synthesized by mixing adipic acid with the variable quantities of glycerin (GLY) is a cross-linker upon the mechanical parameters of polyurethane (PU) polymer. Polyurethane (PU) polymer is a thermoplastic polymer that is used to make foams for seats etc. Aliphatic polyester polyols are produced through the esterification of acids, an appropriate catalyst, and glycerin (GLY); whereas a polyurethane polyol is made through the pre-polymerization of (aliphatic polyester) polyol with pure prepolymer, i.e., methylene diphenyl diisocyanate (MDI), and subsequent polymerization of the polyol with prepolymer Shore A hardness and other mechanical attributes of polyurethane are investigated via shore A testing for hardness. Along with this, apparent density was determined using the (American Society for Testing and Materials) ASTM D1622-08 method, as well as resistance against abrasion was determined using a DIN abrasion wear resistance tester. Fourier-transform infrared spectroscopy (FTIR) examination is employed to analyze the structural features of the sample. The findings suggest that the shoreline increased hardness of the PU is associated with an increase in GLY concentrations, which ranges from 4 to 12 g. In spite of this, the PU density shows a decrease with an increase in crosslinker content. The abrasion wears resistance of polyurethane, on the other hand, increases as the concentration of GLY in the polyurethane increases. The presence of specific peaks in the FTIR spectrum supports the creation of polyurethane, according to the results of a structural investigation.

Similar content being viewed by others

Data Availability

Not Applicable.

References

Saunders KJ (1988) Polyurethanes. Organic Polym Chem 358–387

Sawpan MA (2018) Polyurethanes from vegetable oils and applications: a review. J Polym Res 25(8):1–15

Golling FE, Pires R, Hecking A, Weikard J, Richter F, Danielmeier K, Dijkstra D (2019) Polyurethanes for coatings and adhesives–chemistry and applications. Polym Int 68(5):848–855

Rusu LC, Ardelean LC, Jitariu AA, Miu CA, Streian CG (2020) An insight into the structural diversity and clinical applicability of polyurethanes in biomedicine. Polymers 12(5):1197

Eling B, Tomović Ž, Schädler V (2020) Current and future trends in polyurethanes: An industrial perspective. Macromol Chem Phys 221(14):2000114

Dounis DV, Wilkes GL (1997) Structure-property relationships of flexible polyurethane foams. Polymer 38(11):2819–2828

Defonseka C (2019) Flexible Polyurethane Foams. Flexible Polyurethane Foams

König A, Kroke E (2011) Methyl-DOPO—a new flame retardant for flexible polyurethane foam. Polym Adv Technol 22(1):5–13

Dworakowska S, Bogdal D, Prociak A (2012) Microwave-assisted synthesis of polyols from rapeseed oil and properties of flexible polyurethane foams. Polymers 4(3):1462–1477

Santos LMD, Carone CL, Dullius J, Ligabue R, Einloft S (2013) Using different catalysts in the chemical recycling of waste from flexible polyurethane foams. Polímeros 23(5):608–613

Kaushiva BD (1999) Structure-property relationships of flexible polyurethane foams

Casati FM, Herrington RM, Broos R, Miyazaki Y (1998) Tailoring the performance of molded flexible polyurethane foams for car seats. J Cell Plast 34(5):430–466

El-Ratal WH, Mallick PK (1996) Elastic response of flexible polyurethane foams in uniaxial tension

Gómez-Fernández S, Günther M, Schartel B, Corcuera MA, Eceiza A (2018) Impact of the combined use of layered double hydroxides, lignin and phosphorous polyol on the fire behavior of flexible polyurethane foams. Ind Crops Prod 125:346–359

Bote SD, Kiziltas A, Scheper I, Mielewski D, Narayan R (2021) Biobased flexible polyurethane foams manufactured from lactide-based polyester-ether polyols for automotive applications. J Appl Polym Sci 138(29):50690

McKenna ST, Hull TR (2016) The fire toxicity of polyurethane foams. Fire Science Reviews 5(1):1–27

Cinelli P, Anguillesi I, Lazzeri A (2013) Green synthesis of flexible polyurethane foams from liquefied lignin. Eur Polymer J 49(6):1174–1184

Yang H, Yu B, Song P, Maluk C, Wang H (2019) Surface-coating engineering for flame retardant flexible polyurethane foams: A critical review. Compos B Eng 176:107185

Rojek P, Prociak A (2012) Effect of different rapeseed-oil-based polyols on mechanical properties of flexible polyurethane foams. J Appl Polym Sci 125(4):2936–2945

Sonnenschein MF, Wendt BL (2013) Design and formulation of soybean oil derived flexible polyurethane foams and their underlying polymer structure/property relationships. Polymer 54(10):2511–2520

Mahmood N, Yuan Z, Schmidt J, Xu CC (2016) Depolymerization of lignins and their applications for the preparation of polyols and rigid polyurethane foams: A review. Renew Sustain Energy Rev 60:317–329

Lefebvre J, Bastin B, Le Bras M, Duquesne S, Paleja R, Delobel R (2005) Thermal stability and fire properties of conventional flexible polyurethane foam formulations. Polym Degrad Stab 88(1):28–34

Gaan S, Liang S, Mispreuve H, Perler H, Naescher R, Neisius M (2015) Flame retardant flexible polyurethane foams from novel DOPO-phosphonamidate additives. Polym Degrad Stab 113:180–188

Santiago JP, de Campos Silva P, Marques FD, Gomes de Souza Jr F (2018) Glycerin‐Based Polyurethane Obtained by Inverse Emulsion: Comparison Between Magnetic Induction and Conventional Heating. In Macromol Symposia 380(1):1800091

Oprea S, Potolinca VO, Oprea V (2020) Synthesis and characterization of novel polyurethane elastomers that include curcumin with various cross-linked structures. J Polym Res 27(3):1–8

Xia L, Liu J, Li Z, Wang X, Wang P, Wang D, Hu X (2020) Synthesis and flame retardant properties of new boron-containing polyurethane. Journal of Macromolecular Science, Part A 57(8):560–568

Fidan MS, Ertaş M (2020) Optimization of liquefaction parameters of cotton burrs (Gossypium hirsutum L.) for polyurethane-type isolation foams. Kastamonu University J Forestry Faculty 20(1):15–24

Ma M, Wang X, Liu K, Chen S, Shi Y, He H, Wang X (2022) Achieving simultaneously toughening and flame-retardant modification of poly (lactic acid) by in-situ formed cross-linked polyurethane and reactive blending with ammonium polyphosphate. J Maters Sci 1–13

Kerche EF, Delucis RA, MAGALHAES W, Amico SC (2018) Nanocellulose filled biobased polyurethane foams. In Embrapa Florestas-Artigo em anais de congresso (ALICE). In: Brazilian Conference on Composites Materials, 4., 2018, Rio de Janeiro. Proceedings. Rio de Janeiro: PUC-RJ, 2018. 7

Marcos-Fernández ÁA, Navarro R, Benito E, Guzmán J, Garrido L (2021) Properties of polyurethanes derived from poly (diethylene glycol terephthalate). Eur Polymer J 155:110576

Hiroe A, Sakurai T, Mizuno S, Miyahara Y, Goto S, Yamada M, Taguchi S (2021) Microbial oversecretion of (R)-3-hydroxybutyrate oligomer with diethylene glycol terminal as a macromonomer for polyurethane synthesis. Int J Biol Macromol 167:1290–1296

Kurańska M, Leszczyńska M, Malewska E, Prociak A, Ryszkowska J (2020) Implementation of circular economy principles in the synthesis of polyurethane foams. Polymers 12(9):2068

de Oliveira F, Gonçalves LP, Belgacem MN, Frollini E (2020) Polyurethanes from plant-and fossil-sourced polyols: Properties of neat polymers and their sisal composites. Ind Crops Prod 155:112821

Simón D, Borreguero AM, De Lucas A, Rodríguez JF (2018) Recycling of polyurethanes from laboratory to industry, a journey towards the sustainability. Waste Manage 76:147–171

Yu Y, Wang J, Zong J, Zhang S, Deng Q, Liu S (2018) Synthesis of a fluoro-diol and preparation of fluorinated waterborne polyurethanes with high elongation at break. J Macromol Sci Part A 55(2):183–191

Li Q, Xu W, Xi E, Pang Y, Liu X, Mao A (2019) Recovery of Polyols from Polyurethane Foam Wastes by Solvent Decomposition. In IOP Conf Series: Earth and Environ Sci 310(4):042014. IOP Publishing

Prociak A, Malewska E, Kurańska M, Bąk S, Budny P (2018) Flexible polyurethane foams synthesized with palm oil-based bio-polyols obtained with the use of different oxirane ring opener. Ind Crops Prod 115:69–77

Kurańska M, Malewska E, Polaczek K, Prociak A, Kubacka J (2020) A pathway toward a new era of open-cell polyurethane foams—influence of bio-polyols derived from used cooking oil on foams properties. Materials 13(22):5161

Yan Q, Lin Z, Lin X, Fang C (2018) Preparation and characterization of high initial bonding strength reactive hot melt polyurethane adhesive derived from phthalate polyester polyols. J Adhes Sci Technol 32(20):2282–2297

Razavi SMA, Amini AM, Zahedi Y (2015) Characterisation of a new biodegradable edible film based on sage seed gum: Influence of plasticiser type and concentration. Food Hydrocolloids 43:290–298

Jouki M, Khazaei N, Ghasemlou M, HadiNezhad M (2013) Effect of glycerol concentration on edible film production from cress seed carbohydrate gum. Carbohyd Polym 96(1):39–46

Seyedi S, Koocheki A, Mohebbi M, Zahedi Y (2014) Lepidium perfoliatum seed gum: A new source of carbohydrate to make a biodegradable film. Carbohyd Polym 101:349–358

Sanyang ML, Sapuan SM, Jawaid M, Ishak MR, Sahari J (2016) Effect of plasticizer type and concentration on physical properties of biodegradable films based on sugar palm (Arenga pinnata) starch for food packaging. J Food Sci Technol 53(1):326–336

Sahari J, Sapuan SM, Zainudin ES, Maleque MA (2012) A new approach to use Arenga pinnata as sustainable biopolymer: Effects of plasticizers on physical properties. Procedia Chemistry 4:254–259

Nordin N, Othman SH, Rashid SA, Basha RK (2020) Effects of glycerol and thymol on physical, mechanical, and thermal properties of corn starch films. Food Hydrocolloids 106:105884

Kirpluks M, Vanags E, Abolins A, Michalowski S, Fridrihsone A, Cabulis U (2020) High functionality bio-polyols from tall oil and rigid polyurethane foams formulated solely using bio-polyols. Materials 13(8):1985

Mendelovici E, Frost RL, Kloprogge T (2000) Cryogenic Raman spectroscopy of glycerol. J Raman Spectrosc 31:1121–1126

Obeidat SM, Hammoudeh AY, Mahmoud A (2019) Identification and quantification of diethylene glycol contamination in glycerine raw material. Spectrosc Lett 52(1):60–65

Grech L, Mallia B, Camilleri J (2013) Investigation of the physical properties of tricalcium silicate cement-based root-end filling materials. Dent Mater 29(2):e20–e28

Srinivasan TKK, Jose CI, Biswas AB (1969) Infrared spectra and rotational isomerism of mono-, di-, and tri-ethylene glycol monoalkyl ethers. Spectrosc Lett 47(20):3877–3891

Jovanović V, Ristić I, Miletić A, Cakić S, Tanasić J, Budinski-Simendić J (2019) Synthesis of biodegradable polyester based on renewable resources. Bull Nat Sci Res 9(2)

Jiang Z, Yuan KJ, Li SF, Chow WK (2006) Study of FTIR spectra and thermal analysis of polyurethane. Guang pu xue yu guang pu fen xi= Guang pu 26(4):624–628

Hasan KF, Horváth PG, Baş S, Alpár T (2021) Industrial flame retardants for polyurethanes. Materials and Chemistry of Flame-Retardant Polyurethanes Volume 1: A Fundamental Approach 239–264

Çalışıcı M, Gürü M, Çubuk MK, Cansız ÖF (2018) Improving the aging resistance of bitumen by addition of polymer-based diethylene glycol. Constr Bull Mater 169:283–288

Abolins A, Yakushin V, Vilsone D (2018) Properties of polyurethane coatings based on linseed oil phosphate ester polyol. J Renew Mater 6(7):737–745

Worzakowska M (2014) TG/FTIR/QMS studies of long chain esters of geraniol. J Anal Appl Pyrolysis 110:181–193

Ranjbar Z, Montazeri S, Nayini MMR, Jannesari A (2010) Synthesis and characterization of diethylene glycol monobutyl ether—Blocked diisocyanate crosslinkers. Prog Org Coat 69(4):426–431

Wang J, Chen D, Zhang Q (2007) Analysis of glycolysis products of polyurethane fiber waste with diethylene glycol. Fibers Polym 8(1):13–18

Hill DJT, O’Donnell JH, Perera MCS, Pomery PJ (1997) Polymerisation of diethylene glycol bis-allyl carbonate up to high degrees of conversion. Eur Polym J 33(5):649–658

Funding

This research received no external funding.

Author information

Authors and Affiliations

Contributions

Conceptualization, Muhammad Shafiq and Shahzad Maqsood Khan; methodology, Muhammad Shafiq; software, Muhammad Shafiq; validation, Muhammad Shafiq and Shahzad Maqsood Khan.; formal analysis, Muhammad Taqi Zahid Butt.; investigation, Muhammad Shafiq.; writing—original draft preparation, Muhammad Shafiq.; writing—review and editing, Shahzad Maqsood Khan.; supervision, Shahzad Maqsood Khan and Muhammad Taqi Zahid Butt.; project administration, Shahzad Maqsood Khan.; All authors have read and agreed to the published version of the manuscript.”

Corresponding authors

Ethics declarations

Conflicts of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shafiq, M., Butt, M.T.Z. & Khan, S.M. Synthesis of diethylene glycol-based aliphatic polyester polyol and effect of glycerin crosslinker on its properties. J Polym Res 29, 401 (2022). https://doi.org/10.1007/s10965-022-03199-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03199-9