Abstract

Cellulose nanofibrils with a substantial aspect ratio (100–150) were isolated from an abundant agricultural waste, arecanut husk. These cellulose nanofibrils were incorporated into natural rubber (NR) latex and the resulting composites were investigated for rheological, dynamic mechanical, physical and thermal properties. Rheological and dynamic mechanical analysis of the composites were carried out as a function of fibre content, frequency and temperature using Rubber Process Analyser (RPA) and Dynamic Mechanical Analyser (DMA). All the systems registered rise in elastic response with increase in frequency. RPA studies showed that the nanocellulose fibrils had a profound influence on the rheological behaviour of the composites. The rheological percolation threshold of the composites was obtained to be between 2 to 4 phr. The dispersion of nanofibrils in the composites was investigated using Scanning electron microscopy (SEM) and Transmission electron microscopy (TEM). An extensive network formation in the NR matrix, credited to the higher aspect ratio of nanofibrils, imparted the composites with improved mechanical properties. Cellulose nanofibrils do not inflict any detrimental effect on the thermal profiles of the composites.

Graphical abstract

Similar content being viewed by others

Availability of data and material

The authors confirm that the data supporting the findings of this study are available in this article. Raw data that support the findings of this study are available from the corresponding author, upon reasonable request.

References

Darder M, Aranda P, Ruiz-Hitzky E (2007) Bionanocomposites: A new concept of ecological, bioinspired, and functional hybrid materials. Adv Mater 19:1309–1319. https://doi.org/10.1002/adma.200602328

Oksman K, Mathew AP, Bondeson D, Kvien I (2006) Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos Sci Technol 66:2776–2784. https://doi.org/10.1016/j.compscitech.2006.03.002

Siqueira G, Bras J, Dufresne A (2010) Cellulosic bionanocomposites: A review of preparation, properties and applications. Polymers (Basel) 2:728–765. https://doi.org/10.3390/polym2040728

Lau K-T, Gu C, Hui D (2006) A critical review on nanotube and nanotube/nanoclay related polymer composite materials. Compos B Eng 37:425–436. https://doi.org/10.1016/j.compositesb.2006.02.020

Roy N, Sengupta R, Bhowmick AK (2012) Modifications of carbon for polymer composites and nanocomposites. Prog Polym Sci 37:781–819. https://doi.org/10.1016/j.progpolymsci.2012.02.002

Flauzino Neto WP, Silvério HA, Dantas NO, Pasquini D (2013) Extraction and characterization of cellulose nanocrystals from agro-industrial residue – Soy hulls. Ind Crops Prod 42:480–488. https://doi.org/10.1016/j.indcrop.2012.06.041

Costa LMM, de Olyveira GM, Cherian BM et al (2013) Bionanocomposites from electrospun PVA/pineapple nanofibers/Stryphnodendron adstringens bark extract for medical applications. Ind Crops Prod 41:198–202. https://doi.org/10.1016/j.indcrop.2012.04.025

Pasquini D, Teixeira EDM, Curvelo AADS, Belgacem MN, Dufresne A (2010) Extraction of cellulose whiskers from cassava bagasse and their applications as reinforcing agent in natural rubber. Ind Crop Prod 32:486–490. https://doi.org/10.1016/j.indcrop.2010.06.022

Johar N, Ahmad I, Dufresne A (2012) Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crop Prod 37:93–99. https://doi.org/10.1016/j.indcrop.2011.12.016

Bendahou A, Kaddami H, Dufresne A (2010) Investigation on the effect of cellulosic nanoparticles’ morphology on the properties of natural rubber based nanocomposites. Eur Polym J 46:609–620. https://doi.org/10.1016/j.eurpolymj.2009.12.025

Siqueira G, Tapin-Lingua S, Bras J, da Silva Perez D, Dufresne A (2011) Dufresne Mechanical properties of natural rubber nanocomposites reinforced with cellulosic nanoparticles obtained from combined mechanical shearing, and enzymatic and acid hydrolysis of sisal fibers. Cellulose 18(1):57–65

Visakh PM, Thomas S, Oksman K, Mathew AP (2012) Crosslinked natural rubber nanocomposites reinforced with cellulose whiskers isolated from bamboo waste: Processing and mechanical/thermal properties. Compos Part A: Appl Sci Manuf 43(4):735–741

Abraham E, Deepa B, Pothan LA, John M, Narine SS, Thomas S, Anandjiwala R (2013) Physicomechanical properties of nanocomposites based on cellulose nanofibre and natural rubber latex. Cellulose 20:417–427. https://doi.org/10.1007/s10570-012-9830-1

Amash A, Zugenmaier P (1998) Study on cellulose and xylan filled polypropylene composites. Polym.bull 258:251–258

Bras J, Hassan ML, Bruzesse C, Hassan EA, El-Wakil NA, Dufresne A (2010) Mechanical, barrier, and biodegradability properties of bagasse cellulose whiskers reinforced natural rubber nanocomposites. Ind Crop Prod 32:627–633. https://doi.org/10.1016/j.indcrop.2010.07.018

Silva MJ, Sanches AO, Medeiros ES, Mattoso LH, McMahan CM, Malmonge JA (2014) Nanocomposites of natural rubber and polyaniline-modified cellulose nanofibrils. J Therm Anal Calorim 117:387–392. https://doi.org/10.1007/s10973-014-3719-1

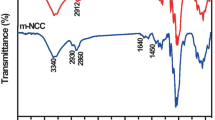

Chandra J, George N, Narayanankutty SK (2016) Isolation and characterization of cellulose nanofibrils from arecanut husk fibre. Carbohydr Polym 142:158–166. https://doi.org/10.1016/j.carbpol.2016.01.015

Abraham E, Thomas MS, John C, Pothen LA, Shoseyov O, Thomas S (2013) Green nanocomposites of natural rubber/nanocellulose: Membrane transport, rheological and thermal degradation characterisations. Ind Crop Prod 51:415–424. https://doi.org/10.1016/j.indcrop.2013.09.022

Larson RG (1999) The structure and rheology of complex fluids ;. New York: Oxford university press. Vol 150

Yang J, Han CR (2013) Dynamics of silica-nanoparticle-filled hybrid hydrogels: Nonlinear viscoelastic behavior and chain entanglement network. J Phys Chem C 117:20236–20243. https://doi.org/10.1021/jp404616

Giannelis EP, Krishnamoorti R, Manias E (1999) Polymer-silicate nanocomposites: model systems for confined polymers and polymer brushes. Polym in conf envir 107–147

Hui S, Chaki TK, Chattopadhyay S (2010) Dynamic and Capillary Rheology of LDPE-EVA – Based Thermoplastic Elastomer : Effect of Silica Nanofiller. Polym Compos 31(3):377–391

Barick AK, Tripathy DK (2011) Preparation, characterization and properties of acid functionalized multi-walled carbon nanotube reinforced thermoplastic polyurethane nanocomposites. Mater Sci Eng B 176:1435–1447. https://doi.org/10.1016/j.mseb.2011.08.001.[24]

Bogoslovov R, Roland C, Ellis A (2008) Effect of silica nanoparticles on the local segmental dynamics in poly (vinyl acetate). Macromolecules 41(4):1289–1296

Dutta NK, Choudhury NR, Haidar B, Vidal A, Donnet JB, Delmotte L, Chezeau JM (1994) High resolution solid-state nmr investigation of the filler-rubber interaction: 1. High speed 1H magic-angle spinning nmr spectroscopy in carbon black filled styrene. Polymer 35(20):4293–4299

Merabia S, Sotta P, Long DR (2008) A microscopic model for the reinforcement and the nonlinear behavior of filled elastomers and thermoplastic elastomers (Payne and Mullins effects). Macromolecules 8252–8266

Du F, Scogna RC, Zhou W, Brand S, Fischer JE, Winey KI (2004) Nanotube networks in polymer nanocomposites: Rheology and electrical conductivity. Macromolecules 37:9048–9055

Wang Y, Xu J, Bechtel S, Koelling K (2006) Melt shear rheology of carbon nanofiber/polystyrene composites. Rheol Acta 45(6):919–941

Solomon M, Almusallam A, Seefeldt K (2001) Rheology of polypropylene/clay hybrid materials. Macromolecules 34(6):1864–1872

Mahi H, Rodrigue D (2012) Linear and non-linear viscoelastic properties of ethylene vinyl acetate/nano-crystalline cellulose composites. Rheol Acta 51(2):127–142

Akcora P, Kumar SK, Moll J, Lewis S, Schadler LS, Li Y, Benicewicz BC, Sandy A, Narayanan S, Ilavsky J, Thiyagarajan P (2010) “Gel-like” mechanical reinforcement in polymer nanocomposite melts 1003–10. https://doi.org/10.1021/ma902072d

Kim H, Macosko C (2008) Morphology and properties of polyester/exfoliated graphite nanocomposites. Macromolecules 41:3317–3327

Favier V, Chanzy H, Cavaille JY (1995) Polymer Nanocomposites Reinforced by Cellulose Whiskers. Macromolecules 28:6365–6367. https://doi.org/10.1021/ma00122a053

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose Nanocrystals : Chemistry , Self-Assembly , and Applications. Chem Rev 3479–3500

Morin A, Dufresne A (2002) Nanocomposites of chitin whiskers from Riftia tubes and poly (caprolactone). Macromolecules 35:2190–2199

Dalmas F, Cavaillé JY, Gauthier C, Chazeau L, Dendievel R (2007) Viscoelastic behavior and electrical properties of flexible nanofiber filled polymer nanocomposites. Influence of processing conditions. Compos Sci Technol 67:829–839. https://doi.org/10.1016/j.compscitech.2006.01.030

Basuli U, Chaki TK, Chattopadhyay S (2011) Thermomechanical and rheological behaviour of polymer nanocomposites based on ethylene-methyl acrylate (EMA) and multiwalled carbon nanotube (MWNT). Plast Rubber Compos 40:213–222

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63:283–293

Osswald TA (2015) Understanding polymer processing: processes and governing equations, Carl Hanser Verlag GmbH Co KG

Einstein A (1956) Investigations on the theory of the brownian movement. Cour Corp

Guth E, Gold O (1938) On the hydrodynamical theory of the viscosity of suspensions. Phys Rev 53(322):2–15

Guth E (1945) Theory of filler reinforcement. J Appl Phys 16:20–25. https://doi.org/10.1063/1.1707495

Martins JN, Bassani TS, Barra GMO, Oliveira RVB (2011) Electrical and rheological percolation in poly(vinylidene fluoride)/multi-walled carbon nanotube nanocomposites. Polym Int 60:430–435. https://doi.org/10.1002/pi.2965

Marcovich N, Auad M, Bellesi N (2006) Cellulose micro/nanocrystals reinforced polyurethane. J Mater Res 21:870–881

Azizi Samir MA, Alloin F, Dufresne A (2005) Review of recent research into cellulosic whiskers, their properties and their application in nanocomposite field. Biomacromolecules. 6:612–626. https://doi.org/10.1021/Bm0493685

Medeiros ES, Galiani PD, Moreno RMB, Mattoso LHC, Malmonge JA (2010) A comparative study of the non-isothermal degradation of natural rubber from Mangabeira (Hancornia speciosa Gomes) and Seringueira (Hevea brasiliensis). J Therm Anal Calorim 100:1045–1050. https://doi.org/10.1007/s10973-009-0477-6

Acknowledgements

We would like to thank SAIF-STIC CUSAT, Department of Physics, Maharaja’s College, Ernakulam and Centre for nanoscience and nanotechnology, MG university, Kottayam for characterization.

Funding

This work was not supported by any funding agencies.

Author information

Authors and Affiliations

Contributions

Julie Chandra C.S.: Conceptualization, methodology, visualization, investigation and writing, Bipinbal P.K.: Conceptualization, writing, reviewing and editing, Renju V.S.: Data curation and resources, Vidya Raman.: Data curation, resources and reviewing. Bindu Sharmila T.K.: Data curation, writing, Sreesha Sasi: Writing, reviewing and editing. Jolly V.Antony.: writing, reviewing and editing.

Corresponding author

Ethics declarations

Consent to participate

Not Applicable.

Consent for publication

Not Applicable.

Research involving human and animal participants

This article does not contain any studies involving animals or human participants performed by any of the authors.

Conflict of interest

The authors have no conflict of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

C.S., J.C., P.K., B., V.S, R. et al. Bionanocomposites based on natural rubber and cellulose nanofibrils from arecanut husk: Rheological, mechanical and thermal characterizations. J Polym Res 29, 217 (2022). https://doi.org/10.1007/s10965-022-03069-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03069-4