Abstract

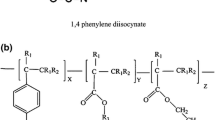

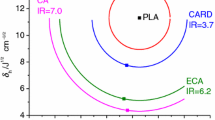

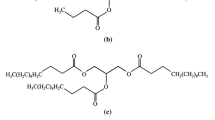

This study addresses the synthesis of three esters from 2,5-furandicarboxylic acid with different alcohols to a one-pot reaction through acid catalysis to evaluate them as biobased plasticizers for poly(lactic acid) (PLA). The 1H-NMR and FTIR analysis revealed the chemical structure of the synthesized plasticizers: dibutyl furan-2,5-dicarboxylate (DBF), di(2-methylbutyl) furan-2,5-dicarboxylate (DMBF) and didodecyl furan-2,5-dicarboxylate (DDF). The films of PLA and plasticized PLA, with contents up to 20 wt.% of plasticizer, were investigated by differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA) and mechanical analysis. The results highlight that the plasticizer’s chemical structure and molecular weight affect the thermal and mechanical properties of the blends. In detail, DBF and DMBF were more effective in reducing the glass transition temperature (Tg), cold crystallization temperature (Tcc), and melting temperature (Tm) due to the ease of these low weight plasticizers to blend with PLA leading to the increase in chain mobility, which consequently increased the degree of crystallization. DDF was only effective in low concentrations (2.5 and 5 wt %); as concentration increases, the more pronounced phase separation becomes. The DMA results showed that all the plasticizers investigated decreased the Tg of PLA, with greater reduction for plasticizers having the lowest molecular weight. The elongation at break and tensile strength increased by incorporating 15 and 20 wt.% of DMBF, indicating a good compromise between flexibility and strength. Thus, DMBF showed more attractive potential as a "green" plasticizer for PLA, followed by DBF to produce packaging films.

Similar content being viewed by others

Availability of data and material

Not applicable.

Code availability

Not applicable.

References

Moreno A, Lligadas G, Ronda JC, Galià M, Cádiz V (2018) Linear and branched acetal polymers from castor oil via acetal metathesis polymerization. Eur Polym J 108:348–356

Mangaraj S, Mohanty S, Swain S, Yadav A (2019) Development and characterization of commercial biodegradable film from PLA and corn starch for fresh produce packaging. J Packag Technol Res 3:127–140

Sanyang M, Sapuan S, Jawaid M, Ishak M, Sahari J (2016) Development and characterization of sugar palm starch and poly (lactic acid) bilayer films. Carbohydr Polym 146:36–45

Zhou Y, Lei L, Yang B, Li J, Ren J (2018) Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym Test 68:34–38

Xue Y, Ma Z, Xu X, Shen M, Huang G, Bourbigot S, Liu X, Song P (2021) Mechanically robust and flame-retardant polylactide composites based on molecularly-engineered polyphosphoramides. Compos Part A Appl Sci Manuf 144:106317–106332

Lemmouchi Y, Murariu M, Dos Santos AM, Amass AJ, Schacht E, Dubois P (2009) Plasticization of poly (lactide) with blends of tributyl citrate and low molecular weight poly (d, l-lactide)-b-poly (ethylene glycol) copolymers. Eur Polym J 45:2839–2848

Zhang Y, Jing J, Liu T, Xi L, Sai T, Ran S, Fang Z, Huo S, Song P (2021) A molecularly engineered bioderived polyphosphate for enhanced flame retardant, UV-blocking and mechanical properties of poly (lactic acid). Chem Eng J 411:128493–128506

Kulinki Z, Piorkowska E (2005) Crystallization, structure and properties of plasticized poly (L-lactide). Polymer 46:10290–10300

Singh S, Maspoch ML, Oksman K (2019) Crystallization of triethyl-citrate-plasticized poly (lactic acid) induced by chitin nanocrystals. J Appl Polym Sci 136:47936–47948

Xu X, Dai J, Ma Z, Liu L, Zhang X, Liu H, Tang L-C, Huang G, Wang H, Song P (2020) Manipulating interphase reactions for mechanically robust, flame-retardant and sustainable polylactide biocomposites. Compos B Eng 190:107930–107945

Zhou J, Yao Z, Zhou C, Wei D, Li S (2014) Mechanical properties of PLA/PBS foamed composites reinforced by organophilic montmorillonite. J Appl Polym Sci 131:40773–40781

Mohapatra AK, Mohanty S, Nayak S (2014) Study of thermo-mechanical and morphological behaviour of biodegradable PLA/PBAT/layered silicate blend nanocomposites. J Polym Environ 22:398–408

Bocqué M, Voirin C, Lapinte V, Caillol S, Robin JJ (2016) Petro-based and bio-based plasticizers: chemical structures to plasticizing properties. J Polym Sci Part A: Polym Chem 54:11–33

Erythropel HC, Brown T, Maric M, Nicell JA, Cooper DG, Leask RL (2015) Designing greener plasticizers: Effects of alkyl chain length and branching on the biodegradation of maleate based plasticizers. Chemosphere 134:106–112

Greco A, Maffezzoli A (2016) Cardanol derivatives as innovative bio-plasticizers for poly-(lactic acid). Polym Degrad Stab 132:213–219

Maiza M, Benaniba MT, Massardier-Nageotte V (2016) Plasticizing effects of citrate esters on properties of poly (lactic acid). J Polym Eng 36:371–380

Ljungberg N, Wesslén B (2005) Preparation and properties of plasticized poly (lactic acid) films. Biomacromol 6:1789–1796

Ljungberg N, Wesslen B (2003) Tributyl citrate oligomers as plasticizers for poly (lactic acid): thermo-mechanical film properties and aging. Polymer 44:7679–7688

de Jong E, Dam M, Sipos L, Gruter G-J (2012) Furandicarboxylic acid (FDCA), a versatile building block for a very interesting class of polyesters. In: series As, editor. Biobased Monomers, Polymers, and Materials. Washington, DC: ACS Publications p 1–13

Gomes M, Gandini A, Silvestre AJ, Reis B (2011) Synthesis and characterization of poly (2, 5-furan dicarboxylate) s based on a variety of diols. J Polym Sci Part A: Polym Chem 49:3759–3768

Yu Z, Zhou J, Zhang J, Huang K, Cao F, Wei P (2014) Evaluating effects of biobased 2, 5-furandicarboxylate esters as plasticizers on the thermal and mechanical properties of poly (vinyl chloride). J Appl Polym Sci 131:40938–40948

Nguyen T, Kim YJ, Park S-K, Lee K-Y, Park J-w, Cho JK, Shin S (2019) Furan-2, 5-and Furan-2, 3-dicarboxylate Esters Derived from Marine Biomass as Plasticizers for Poly (vinyl chloride). ACS Omega 5:197–206

Matos M, Cordeiro RA, Faneca H, Coelho JF, Silvestre AJ, Sousa AF (2019) Replacing Di (2-ethylhexyl) Terephthalate by Di (2-ethylhexyl) 2, 5-Furandicarboxylate for PVC Plasticization: Synthesis, Materials Preparation and Characterization. Materials 12:2336–2352

Bischoff E, Simon DA, Schrekker HS, Lavorgna M, Ambrosio L, Liberman SA, Mauler RS (2016) Ionic liquid tailored interfaces in halloysite nanotube/heterophasic ethylene–propylene copolymer nanocomposites with enhanced mechanical properties. Eur Polym J 82:82–92

Bischoff E, Daitx T, Simon DA, Schrekker HS, Liberman SA, Mauler RS (2015) Organosilane-functionalized halloysite for high performance halloysite/heterophasic ethylene–propylene copolymer nanocomposites. Appl Clay Sci 112:68–74

Chaudhary BI, Nguyen BD, Zamanskiy A (2015) Dialkyl furan-2, 5-dicarboxylates, epoxidized fatty acid esters and their mixtures as bio-based plasticizers for poly (VInylchloride). J Appl Polym Sci 132:42382–42388

Muller J, Jiménez A, González-Martínez C, Chiralt A (2016) Influence of plasticizers on thermal properties and crystallization behaviour of poly (lactic acid) films obtained by compression moulding. Polym Int 65:970–978

Li H, Huneault AM (2007) Effect of nucleation and plasticization on the crystallization of poly (lactic acid). Polymer 48:6855–6866

Kodal M, Sirin H, Ozkoc G (2019) Long-and short-term stability of plasticized poly (lactic acid): effects of plasticizers type on thermal, mechanical and morphological properties. Polym Bull 76:423–445

Xiao H, Lu W, Yeh JT (2009) Effect of plasticizer on the crystallization behavior of poly (lactic acid). J Appl Polym Sci 113:112–121

Greco A, Ferrari F, Maffezzoli A (2018) Thermal analysis of poly (lactic acid) plasticized by cardanol derivatives. J Therm Anal Calorim 134:559–565

Yu H-Y, Zhang H, Abdalkarim SYH, Yang L, Zhu J, Gu J, Yao J (2019) Interfacial compatible poly (ethylene glycol) chains modified cellulose nanosphere as bifunctional reinforcements in green polylatic acid for food packagings. J Taiwan Inst Chem Eng 95:583–593

Santos EF, Oliveira RV, Reiznautt QB, Samios D, Nachtigall SM (2014) Sunflower-oil biodiesel-oligoesters/polylactide blends: Plasticizing effect and ageing. Polym Test 39:23–29

Zaldua N, Mugica A, Zubitur M, Iturrospe A, Arbe A, Re GL, Raquez J-M, Dubois P, Müller AJ (2016) The role of PLLA-g-montmorillonite nanohybrids in the acceleration of the crystallization rate of a commercial PLA. CrystEngComm 18:9334–9344

Quero E, Müller AJ, Signori F, Coltelli MB, Bronco S (2012) Isothermal Cold-Crystallization of PLA/PBAT Blends With and Without the Addition of Acetyl Tributyl Citrate. Macromol Chem Phys 213:36–48

Lai W-C, Liau W-B, Lin T-T (2004) The effect of end groups of PEG on the crystallization behaviors of binary crystalline polymer blends PEG/PLLA. Polymer 45:3073–3080

Hassouna F, Raquez J-M, Addiego F, Dubois P, Toniazzo V, Ruch D (2011) New approach on the development of plasticized polylactide (PLA): Grafting of poly (ethylene glycol)(PEG) via reactive extrusion. Eur Polym J 47:2134–2144

Mosnáčková K, Šlosár M, Kollár J, Janigová I, Šišková A, Chmela Š, Sikorska W, Perďochová D, Gálisová I, Alexy P (2019) Ageing of plasticized poly (lactic acid)/poly (3-hydroxybutyrate)/carbon black mulching films during one season of sweet pepper production. Eur Polym J 114:81–89

Llanes LC, Clasen SH, Pires AT, Gross IP (2021) Mechanical and thermal properties of poly (lactic acid) plasticized with dibutyl maleate and fumarate isomers: Promising alternatives as biodegradable plasticizers. Eur Polym J 142:110112–110123

Yang Y, Xiong Z, Zhang L, Tang Z, Zhang R, Zhu J (2016) Isosorbide dioctoate as a “green” plasticizer for poly (lactic acid). Mater Des 91:262–268

Boyacioglu S, Kodal M, Ozkoc G (2020) A comprehensive study on shape memory behavior of PEG plasticized PLA/TPU bio-blends. Eur Polym J 122:109372–109383

Ferri J, Samper M, García-Sanoguera D, Reig M, Fenollar O, Balart R (2016) Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly (lactic acid). J Mater Sci 51:5356–5366

Carbonell-Verdu A, Garcia-Garcia D, Dominici F, Torre L, Sanchez-Nacher L, Balart R (2017) PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur Polym J 91:248–259

Chieng BW, Ibrahim NA, Then YY, Loo YY (2014) Epoxidized vegetable oils plasticized poly (lactic acid) biocomposites: mechanical, thermal and morphology properties. Molecules 19:16024–16038

Acknowledgements

The authors are grateful to CAPES, CNPq and FAPERGS/PRONEX for their financial support.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Talita Portes dos Santos contributed to writing–original draft, writing–review and editing, conceptualization, methodology, investigation. Kim Blume Dias contributed to formal analysis, methodology and investigation. Eveline Bischoff contributed to writing–review and editing, conceptualization. Raquel Santos Mauler contributed to supervision, writing, conceptualization and funding acquisition.

Corresponding authors

Ethics declarations

Conflicts of interest

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

dos Santos, T.P., Dias, K.B., Bischoff, E. et al. Synthesis of esters derived from 2,5-furandicarboxylic acid and study of its plasticizing effects on poly(lactic acid). J Polym Res 29, 58 (2022). https://doi.org/10.1007/s10965-022-02914-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-02914-w