Abstract

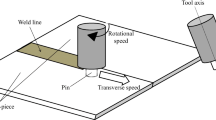

To research the role of mandrel rotation speed on the morphology and mechanical properties of polypropylene (PP) pipes, a self-made rotational shear system (RSS) was applied in this study to manufacture plastic pipes with improved hoop tensile strength through applying hoop shear on the pipes using a rotational mandrel. Morphology study results indicated that different morphologies of the PP pipes were produced when the mandrel rotated at 0 rpm, 2 rpm, 4 rpm, 6 rpm, 8 rpm and 10 rpm. The tensile strength and elongation at break of the pipes were found to increase rapidly with the rotation speed and the properties peaked at 6 rpm. At this speed, the tensile strength and elongation at break increased by 4.1% and 727%, respectively. The high mechanical and thermal performance of the pipe produced at 6 rpm was attributed to the grains begin to refine and the thickness of amorphous region increases throughout the pipe wall.

Similar content being viewed by others

References

Yesil Y, Bhat GS et al (2016) Technology Structure and mechanical properties of polyethylene melt blown nonwovens. INT J CLOTH SCI TECH 28:780–793

Xu H, Zhong GJ, Fu Q, Lei J, Li ZM et al (2012) Interfaces Formation of Shish-Kebabs in Injection-Molded Poly(L-lactic acid) by Application of an Intense Flow Field. Acs Applied Materials & Interfaces, 4(12):6774–6784

Wang K, Chen F, Li Z, Fu Q et al (2014) Control of the hierarchical structure of polymer articles via “structuring” processing. Progress in Polymer ence 39(5):891–920

Ning N, Luo F, Pan B, Zhang Q, Wang K, Fu Q et al (2007) Observation of Shear-Induced Hybrid Shish Kebab in the Injection Molded Bars of Linear Polyethylene Containing Inorganic Whiskers. Macromolecules 40(24):8533–8536

Zhou SY, Niu B, Xie XL et al (2017) Interfacial Shish-Kebabs Lengthened by Coupling Effect of In Situ Flexible Nanofibrils and Intense Shear Flow: Achieving Hierarchy To Conquer the Conflicts between Strength and Toughness of Polylactide. ACS Appl Mater Interfaces 9(11):10148–10159

Gu X, Zhou M, Wang Y et al (2019) Influence of annealing on the morphology and mechanical properties of iPP/HDPE blend with tailored oriented crystalline structures. Journal of Polymer Research 26(8):194

Coates PD, Ward IM et al (1981) Science Die drawing: Solid phase drawing of polymers through a converging die. Polymer Engineering & ence 21:612–618

Pingping, Yang, Qi et al (2018) Structure evolution and orientation mechanism of isotactic polypropylene during the two-stage solid die drawing process. Journal of Applied Polymer Science 135:46581

Ruizhang X, Sheng Z, Jiantao W et al (2018) Impact of different die draw ratio on crystalline and oriented properties of polypropylene cast films and annealed films. J Polym Res 25(6):1–10

An FZ, Gao XQ, Lei J et al (2015) Vibration Assisted Extrusion of Polypropylene. Chinese Journal of Polymer ence 33(5):688–696

Nie M, Wang Q et al (2013) Control of rotation extrusion over shish-kebab crystal alignment in polyethylene pipe and its effect on the pipes crack resistance. Journal of Applied Polymer Science 135:46581.

Nie M, Li X, Hu X et al (2014) Effect of Die Temperature on Morphology and Performance of Polyethylene Pipe Prepared via Mandrel Rotation Extrusion. Journal of Macromolecular ence Part B 53(8):1442–1452

Nie M, Bai SB, Wang Q et al (2010) High-density polyethylene pipe with high resistance to slow crack growth prepared via rotation extrusion. Polym Bull 65(6):609–621

Han R, Nie M, Wang Q et al (2015) Control over β-form hybrid shish-kebab crystals in polypropylene pipe via coupled effect of self-assembly β nucleating agent and rotation extrusion. Journal of the Taiwan Institute of Chemical Engineers 52:158–164

Kalay G, Bevis MJ et al (1997) Processing and physical property relationships in injection olded isotactic polypropylene. 2. Morphology and crystallinity. Journal of Polymer ence Part B: Polymer Physics 35(2):265-291

Kalay G, Bevis MJ et al (2015) The effect of shear controlled orientation in injection moulding on the mechanical properties of an aliphatic polyketone. Journal of Polymer ence Part B Polymer Physics 35(3):415–430

Han R, Nie M, Wang Q et al (2017) Continuously enhanced hoop strength of rotation-extruded polypropylene pipe via self-assembly β nucleating agent with different aspect ratio. J Polym Res 24(11):204

Xie Z, Gao N, Du Z, Yang H, Shen K, Fu Q, Gao X et al (2020) Role of Melt Plasticizing Temperature in Morphology and Properties of PE100 Pipes Prepared by a Rotational Shear System. ACS Omega 5:12660–12671

Na B, Li Z, Lv R et al (2011) Oriented re-crystallization of polypropylene through partial melting and its dramatic influence on mechanical properties. J Polym Res 18(6):2103–2108

Worth RA (1979) The effect of mandrel rotation on power consumption in polypropylene extrusion. Polymer Engineering & ence 19(3):198–202

Deberdeev RY, Zuev BM, Bezruk LI et al (1974) The Properties of Pipes Produced under the Conditions of Spiral Flow. Int J Polym Mater 3(3):177–191

Han R, Nie M, Bai SB et al (2013) Control over crystalline form in polypropylene pipe via mandrel rotation extrusion. Polym Bull 70(7):2083–2096

Nie M, Bai S, Wang Q et al (2010) Effect of the inner wall cooling rate on the structure and properties of a polyethylene pipe extruded at a high rotation speed. Journal of Applied Polymer ence 119(3):1659–1666

Nie M, Wang Q, Bai SB et al (2010) Morphology and property of polyethylene pipe extruded at the low mandrel rotation. Polymer Engineering & ence 50(9):1743–1750

Guo Y, Wang Q, Bai S et al (2010) The Effect of Rotational Extrusion on the Structure and Properties of HDPE Pipes. Polymer-Plastics Technology and Engineering 49(9):908–915

Samuels RJ, Yee RY et al (1972)Characterization of the structure and organization of β-form crystals in type III and type IV isotactic polypropylene spherulites.Journal of Polymer ence Part A-2 Polymer Physics 10, 385–432

Meille V, Stefano Brückner, Sergio et al (1989) Non-parallel chains in crystalline γ-isotactic polypropylene. Nature 340(6233):455–457

Natta G, Corradini P et al (1960) Structure and properties of isotactic polypropylene. Il Nuovo Cimento 15(1):40–51

Wu CM, Chen M, Karger-Kocsis J et al (1999) The role of metastability in the micromorphologic features of sheared isotactic polypropylene melts. Polymer 40(15):4195–4203

Wenig W, Herzog F et al (1993) Injection molding of polypropylene: X-ray investigation of the skin–core morphology. Journal of Applied Polymer ence 50(12):2163–2171

Chu F, Yamaoka T, Kimura Y et al (1995)Crystal transformation and micropore formation during uniaxial drawing of β-form polypropylene film. Polymer 2523-2530

Nie M, Han R, Wang Q et al (2014) Formation and Alignment of Hybrid Shish-Kebab Morphology with Rich Beta Crystals in an Isotactic Polypropylene Pipe. Ind Eng Chem Res 53(10):4142–4146

Leugering VHJ, Kirsch G et al (1973) Beeinflussung der Kristallstruktur von isotaktischem Polypropylen durch Kristallisation aus orientierter Schmelze. Angew Makromol Chem 33(1):17–23

Zebarjad SM, Tahani M, Sajjadi SA et al (2004) Influence of filler particles on deformation and fracture mechanism of isotactic polypropylene. Journal of Materials Processing Tech, 155–156:1459–1464

Acierno S, Coppola S, Grizzuti N et al (2008) Effects of molecular weight distribution on the flow-enhanced crystallization of poly(1-butene). J Rheol 52(2):551–566

Huo H, Meng Y, Li H et al (2004) Influence of shear on polypropylene crystallization kinetics. European Physical Journal E Soft Matter 15(2):167

Yang H, Luo X, Shen K, Yuan Y, Fu Q, Gao X, Jiang L et al (2019) The role of mandrel rotation speed on morphology and mechanical properties of polyethylene pipes produced by rotational shear. Polymer 184:121915

Jiang ZY, Tang YJ, Men YF et al (2007) Structural Evolution of Tensile-Deformed High-Density Polyethylene during Annealing: Scanning Synchrotron Small-Angle X-ray Scattering Study. Macromolecules 40(20):7263–7269

Somani RH, Hsiao BS, Nogales A et al (2013) Structure development during shear flow induced crystallization of i-PP: In situ wide-angle X-ray diffraction study. Macromolecules 33:9385–9394

Larin B, Avila-Orta CA, Somani RH et al (2008) Combined effect of shear and fibrous fillers on orientation-induced crystallization in discontinuous aramid fiber/isotactic polypropylene composites. Polymer 49(1):295–302

Campbell D, Qayyum MM et al (1977) Enhanced fracture strain of polypropylene by incorporation of thermoplastic fibres. J Mater Sci 12(12):2427–2434

Chan CM, Wu J, Li JX et al (2003) Polypropylene/calcium carbonate nanocomposites Polymer 43(10):2981-2992

Pan Y, Gao X, Lei J et al (2016) Effect of different morphologies on the creep behavior of high-density polyethylene. RSC Advances 6(5):3470–3479

Acknowledgment

The work was supported by the National Natural Science Foundation of China (Grant NO.21627804).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Wu, J., Xie, Z., Yang, H. et al. Effect of mandrel rotation speed on morphology and mechanical properties of polypropylene pipes produced by rotational shear. J Polym Res 28, 25 (2021). https://doi.org/10.1007/s10965-020-02366-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02366-0