Abstract

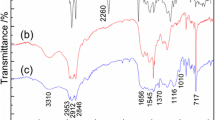

Thermo-expandable microcapsules (TEMs) with polyurethane as the shell and n-hexane as the blowing agent were synthesized by interfacial reaction between isocyanate-terminated polyurethane prepolymer aqueous dispersion and polyamine chain extender. The synthetic process for the thermo-expandable PU-shelled microcapsules was established. The factors which affected the efficiency for blowing agent encapsulation were investigated by fourier transform infrared spectroscopy (FT-IR), laser particle size analyzer and thermo-gravimetric analysis (TGA). The foaming performances of the microcapsules were characterized by polarizing optical microscope with hot platform (POM) and thermo-mechanical analyzer (TMA). The results showed that PU-shelled thermo-expandable microcapsules were successfully synthesized and had good foaming performance. The NCO/OH ratio was found to have a significant effect on the encapsulation of n-hexane and the appropriate ratio was found to be 3:1. Diethylenetriamine (DETA), which is a polyamine chain extender, was found to be a more suitable chain-extender than other polyamine chain extenders in encapsulation the hexane. PU-shelled thermo-expandable microcapsules containing 25.8% blowing agent was fabricated. The onset expand temperature of TEMs was found to be 206 °C, and the maximum foaming temperature was at 235 °C, according to thermo-mechanical analysis. The volume expansion ratio of TEMs reached 27 times according to the measurement by polarizing optical microscope. The PU shelled TEMs showed good foaming performance in vinyl acetate-ethylene copolymer matrix.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings can be shared upon request.

References

Banea MD, da Silva LFM, Campilho RDSG, Sato CK (2014) Smart adhesive joints: an overview of recent developments. J Adhes 90:16–40

Jiao SZ, Sun ZC, Li FR, Yan MJ, Cao MJ, Li DS, Liu Y, Li LH (2019) Preparation and application of conductive polyaniline-coated thermally expandable microspheres. Polymers 11:22

Park JW, Lee SJ, Ji SH, You HN, Kim JH, Ryu KJ (2019) Effects of shell thickness of thermally expandable microspheres on the application of underbody coating for vehicles. https://doi.org/10.20944/preprints201906.0284.v1

Lee B, Son I, Kim JH, Kim C, Yoo JY, Ahn BW, Hwang J, Lee J, Lee JH (2018) Polymeric nanocapsules containing methylcyclohexane for improving thermally induced debonding of thin adhesive films. J Appl Polym Sci 135:46586

Jeoung SK, Han JS, Jung YJ, Hong S, Shim SE, Hwang YJ, Lee PC, Ha JU (2016) Fabrication of thermally expandable core-shell microcapsules using organic and inorganic stabilizers and their application. J Appl Polym Sci 133:44247

Zheng ZH, Qiang LH, Yang T, Wang BN, Cui XJ, Wang HY (2014) Preparation of microencapsulated ammonium polyphosphate with carbon source- and blowing agent-containing shell and its flame retardance in polypropylene. J Polym Res 21:443

Chen SY, Sun ZC, Li LH, Xiao YH, Yu YM (2017) Preparation and characterization of conducting polymer-coated thermally expandable microspheres. Chin Chem Lett 28:658–662

Banea MD, Campilho R (2014) Mechanical and thermal characterization of a structural polyurethane adhesive modified with thermally expandable particles. Int J Adhes Adhes 54:191–199

Fujino M, Taniguchi T, Kawaguchi Y, Ohshima M (2013) Mathematical models and numerical simulations of a thermally expandable microballoon for plastic foaming. Chem Eng Sci 104:220–227

Loomis J, Xu P, Panchapakesan B (2013) Stimuli-responsive transformation in carbon nanotube/expanding microsphere-polymer composites. Nanotechnology 24:185703

Rheem MJ, Jung H, Ha J, Baeck SH, Shim SE (2017) Suspension polymerization of thermally expandable microspheres using low-temperature initiators. Colloid Polym Sci 295:171–180

Lebedeva NV, Sanders SN, Ina M, Zhushma AP, Olson SD, Rubinstein M, Sheiko SS (2016) Multicore expandable microbubbles: controlling density and expansion temperature. Polymer 90:45–52

Azimi HR, Rezaei M, Abbasi F (2011) The effect of expansion conditions on the batch foaming dynamics of St–MMA copolymer. J Cell Plast 48:125–140

Yasuhiro K, Daichi I (2010) Thermally expandable microcapsules for polymer foaming-relationship between expandability and viscoelasticity. Polym Eng Sci 50:835–842

Hou Z, Xia Y, Qu W, Kan CY (2015) Preparation and properties of thermoplastic expandable microspheres with P(VDC-AN-MMA) shell by suspension polymerization. Int J Polym Mater 64:427–431

Hou ZS, Zhang H, Ji CX, Zhang DM, Qu WQ, Sun B (2015) Preparation and properties of thermal-expandable microspheres with P(VDC-AN-St) shell by suspension polymerization. Polym Mater Sci Eng 31:49–52

Vamvounis G, Jonsson M, Malmström E, Hult A (2013) Synthesis and properties of poly(3-n-dodecylthiophene) modified thermally expandable microspheres. Eur Polym J 49:1503–1509

Koh E, Lee SJ, Shin J, Kim YW (2013) Renewable polyurethane microcapsules with isosorbide derivatives for self-healing anticorrosion coatings. Ind Eng Chem Res 52:15541–15548

Koh E, Kim NK, Shin J, Kim YW (2014) Polyurethane microcapsules for self-healing paint coatings. RSC Advance 4:16214–16223

Hu JF, Zhang XT, Qu JQ, WenYL SWF (2018) Synthesis, characterizations and mechanical properties of microcapsules with dual shell of polyurethane(PU)/melamine formaldehyde(MF): effect of different chain extenders. Ind Eng Chem Res 57:3591–3601

Patil DK, Agrawal DS, Mahire RR, More DH (2015) Synthesis, characterization, and controlled release study of polyurea microcapsules containing metribuzin herbicide. Russ J Appl Chem 88:1692–1700

Chen L, Xu LL, Shang HB (2009) Microencapsulation of butyl stearate as a phase change material by interfacial polycondensation in a polyurea system. Energy Convers Manag 50:723–729

Lu SF, Shen TW, Xing JW, Song QW, Shao JF, Zhang J, Xin C (2018) Preparation and characterization of cross-linked polyurethane shell microencapsulated phase change materials by interfacial polymerization. Mater Lett 211:36–39

He Y, Zhang XY, Runt J (2014) The role of diisocyanate structure on microphase separation of solution polymerized polyureas. Polymer 55:906–913

Ham YR, Lee DH, Kim SH, Shin YJ, Yang MH, Shin JS (2010) Microencapsulation of imidazole curing agent for epoxy resin. Ind Eng Chem 16:728–733

Acknowledgments

The work was supported by the Postgraduate Practice Innovation Program of Jiangsu (SJCX17_0718).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

This work complies with ethical standard.

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bai, X., Li, J., Wang, C. et al. Thermo-expandable microcapsules with polyurethane as the shell. J Polym Res 27, 185 (2020). https://doi.org/10.1007/s10965-020-02160-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-02160-y