Abstract

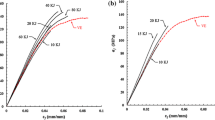

Effects of aspect ratio of multi-wall carbon nanotubes (MWCNTs) on the dispersion of MWCNTs in ethylene-α-octene block copolymer (OBC) and the properties of OBC/MWCNTs nanocomposites were studied, and two series of MWCNTs with different aspect ratios based on the same length and the same diameter were considered. Scanning electron microscope (SEM) and transmission electron microscope (TEM) results show that small and large agglomerates induced by intra- and inter-entanglement of MWCNTs are present for MWCNTs with high aspect ratio having smaller diameter and larger length, respectively. Rheological, electrical and tensile properties of OBC/MWCNTs nanocomposites are related to the aspect ratio and dispersion of MWCNTs. The formation of agglomerates, especially large agglomerates, influence the network perfection, weakening the contribution of MWCNTs to the rheology and electrical properties. The inter-entanglement shows less negative effect on the enhancement for the modulus and strength of OBC nanocomposites, and intra-entanglement of MWCNTs shows discounted enhancing properties. The aspect ratios of MWCNTs related to not only the length but also the diameter play the dominant role on the dispersion in polymers and the properties of polymer nanocomposites.

Graphical abstract

Similar content being viewed by others

References

Iijima S (1991). Nature 354:56–58

Hou PX, Liu C, Cheng HM (2008). Carbon 46:2003–2025

Salvetat JP, Bonard JM, Thomson NH, Kulik AJ, Forro L, Benoit W, Zuppiroli L (1999). Appl Phys A-Mater Sci Process 69:255–260

Qian D, Wagner GJ, Liu WK, Yu MF, Ruoff RS (2002). Appl Mech Rev 55:495–533

Kaneto K, Tsuruta M, Sakai G, Cho W-Y, Ando Y (1999). Synth Met 103:2543–2546

Pop E, Mann D, Wang Q, Goodson K, Dai H (2006). Nano Lett 6:96–100

Sang Z, Ke K, Manas-Zloczower I (2018). ACS Appl Mater Interfaces 10:36483–36492

Kumar S, Li B, Caceres S, Maguire R-G, Zhong W-H (2009). Nanotechnology 20:465708

Andrews R, Weisenberger M-C (2004). Curr Opin Solid State Mater Sci 8:31–37

Ounaies Z (2003). Compos Sci Technol 63:1637–1646

Dang ZM, Shehzad K, Zha JW, Mujahid A, Hussain T, Nie J, Shi CY (2011). Compos Sci Technol 72:28–35

Inukai S, Niihara K, Noguchi T, Ueki H, Magario A, Yamada E, Inagaki S, Endo M (2011). Ind Eng Chem Res 50:8016–8022

Liu Y, Li J, Pan Z (2011). J Polym Res 18:2055–2060

Garg P, Singh BP, Kumar G, Gupta T, Pandey I, Seth RK, Tandon RP, Mathur RB (2010). J Polym Res 18:1397–1407

Yang X, Zhan Y, Yang J, Zhong J, Zhao R, Liu X (2011). J Polym Res 19:9806

Ke K, Pötschke P, Wiegand N, Krause B, Voit B (2016). ACS Appl Mater Interfaces 8:14190–14199

Huang J, Mao C, Zhu Y, Jiang W, Yang X (2014). Carbon 73:267–274

Cui W, Du F, Zhao J, Zhang W, Yang Y, Xie X, Mai YW (2011). Carbon 49:495–500

Liu H, Gao J, Huang W, Dai K, Zheng G, Liu C, Shen C, Yan X, Guo J, Guo Z (2016). Nanoscale 8:12977–12989

Chen Z, Qin Y, Weng D, Xiao Q, Peng Y, Wang X, Li H, Wei F, Lu Y (2009). Adv Funct Mater 19:3420–3426

Yin H, Dittrich B, Farooq M, Kerling S, Wartig K-A, Hofmann D, Huth C, Okolieocha C, Altstädt V, Schönhals A, Schartel B (2015). J Polym Res 22:140

Xu Y, Xu W, Bao J (2014). J Polym Res 21:543

Chi CH, Hsu YC, Tseng LC, Suen SY, Wu JY, Lee RH (2013). J Polym Res 20:269

Krause B, Barbier C, Kunz K, Pötschke P (2018). Polymer 159:75–85

Wu D, Wu L, Zhou W, Sun Y, Zhang M (2010). J Polym Scie Pt B- Polym Phys 48:479–489

Ayatollahi MR, Shadlou S, Shokrieh MM, Chitsazzadeh M (2011). Polym Test 30:548–556

Krause B, Mende M, Pötschke P, Petzold G (2010). Carbon 48:2746–2754

Krause B, Petzold G, Pegel S, Pötschke P (2009). Carbon 47:602–612

Guo J, Liu Y, Prada-Silvy R, Tan Y, Azad S, Krause B, Pötschke P, Grady BP (2014). J Polym Sci B Polym Phys 52:73–83

Castillo FY, Socher R, Krause B, Headrick R, Grady BP, Prada-Silvy R, Pötschke P (2011). Polymer 52:3835–3845

Krause B, Villmow T, Boldt R, Mende M, Petzold G, Pötschke P (2011). Compos Sci Technol 71:1145–1153

Menzer K, Krause B, Boldt R, Kretzschmar B, Weidisch R, Pötschke P (2011). Compos Sci Technol 71:1936–1943

Zhai Y, Zhang R, Yang W, Yang M (2017). Polymer 114:44–53

Li T, Pu JH, Ma LF, Bao RY, Qi GQ, Yang W, Xie BH, Yang MB (2015). Polym Chem 6:7160–7170

Zha XJ, Pu JH, Ma LF, Li T, Bao RY, Bai L, Liu ZY, Yang MB, Yang W (2018). Compos Pt A-Appl Sci Manuf 105:118–125

Zha XJ, Li T, Bao RY, Bai L, Liu ZY, Yang W, Yang MB (2017). Compos Sci Technol 139:17–25

Krause B, Carval J, Pötschke P (2017) AIP Conf Proc 1914:030007–030001–030007-030005

Zhang QH, Fang F, Zhao X, Li YZ, Zhu MF, Chen DJ (2008). J Phys Chem B 112:12606–12611

Huang CL, Wang C (2011). Carbon 49:2334–2344

Seo MK, Park SJ (2004). Chem Phys Lett 395:44–48

Kim JA, Seong DG, Kang TJ, Youn JR (2006). Carbon 44:1898–1905

Song YS (2006). Rheol Acta 46:231–238

Pötschke P, Fornes TD, Paul DR (2002). Polymer 43:3247–3255

Pötschke P, Abdel-Goad M, Alig I, Dudkin S, Lellinger D (2004). Polymer 45:8863–8870

Koerner H, Liu WD, Alexander M, Mirau P, Dowty H, Vaia RA (2005). Polymer 46:4405–4420

Tan Y, Fang L, Xiao J, Song Y, Zheng Q (2013). Polym Chem 4:2939–2944

Bauhofer WG, Kovacs JZ (2009). Compos Sci Technol 69:1486–1498

Zhang J, Mine M, Zhu D, Matsuo M (2009). Carbon 47:1311–1320

Wang Q, Dai J, Li W, Wei Z, Jiang J (2008). Compos Sci Technol 68:1644–1648

Spitalsky Z, Tasis D, Papagelis K, Galiotis C (2010). Prog Polym Sci 35:357–401

Acknowledgements

This work was supported by the National Natural Science Foundation of China (NNSFC grants 51422305 and 51721091).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 1506 kb)

Rights and permissions

About this article

Cite this article

Qian, J., Pu, JH., Zha, XJ. et al. Effect of aspect ratio of multi-wall carbon nanotubes on the dispersion in ethylene-α-octene block copolymer and the properties of the Nanocomposites. J Polym Res 26, 275 (2019). https://doi.org/10.1007/s10965-019-1915-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-019-1915-1