Abstract

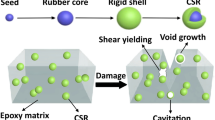

A material with high damping property and based on epoxy/polyacrylate (EP/PA) composite particles was synthesized by two-stage emulsion polymerization. Transmission electron microscopy (TEM) showed that the composite particles have a spherical morphology, a core–shell structure and a diameter of 100 nm–130 nm. Fourier transform infrared spectra (FTIR) indicated the cross-linking between EP groups in the core layer and carboxyl groups in the shell layer of the composite particles during film formation. The cross-linking reaction improved the dynamic mechanical property by the interaction of core and shell polymers. The effects of the cross-linking agent and ratio of the two polymers on the damping capacity were studied by dynamic mechanical analysis (DMA). DMA results revealed that a certain amount of acrylic acid could markedly enhance the loss factor (tan δ) and slightly widen the damping temperature range. When the EP/PA ratio was 1:7, peak values for tan δ of the composite materials could reach 2.10, exceeding the value for most damping materials. The result implies that the EP/PA composites have great potential application in damping steel surface coatings.

Similar content being viewed by others

References

Arumugaprabu V, Uthayakumar M, Manikandan V, Rajini N, Jeyaraj P (2014) Influence of redmud on the mechanical, damping and chemical resistance properties of banana/polyester hybrid composites. Mater Des 64:270–279

Hu J, Wang XF, Liu GY (2010) Effect of SnO2 coating on the damping capacity and tensile property of alumina borate whisker-reinforced aluminum composite at room temperature. Mater Sci Eng A 527:657–662

WW Y, Zhang DZ, Du M, Zheng Q (2013) Role of graded length side chains up to 18 carbons in length on the damping behavior of polyurethane/epoxy interpenetrating polymer networks. Eur Polym J 49:1731–1741

JH G, Zhang XN, MY G, Gu M, Wang XK (2004) Internal friction peak and damping mechanism in high damping 6061Al/SiCp/Gr hybrid metal matrix composite. J Alloys Compd 372:304–308

Wang XQ, Pei YL, Ma Y (2013) The effect of microstructure at interface between coating and substrate on damping capacity of coating systems. Appl Surf Sci 282:60–66

JH G, Zhang XN, MY G (2006) Effect of surface coating of particulate on the overall damping of particulate-reinforced metal matrix composites. Comput Mater Sci 36:338–344

Wang TM, Chen SB, Wang QH, Pei XQ (2010) Damping analysis of polyurethane/epoxy graft interpenetrating polymer network composites filled with short carbon fiber and micro hollow glass bead. Mater Des 31:3810–3815

Buravalla VR, Remillat C, Rongong JA, Tomlinson GR (2001) Advances in damping materials and technology. Smart Mater Bull 8:10–13

Shi XY, Bi WN, Zhao SG (2011) Study on the damping of EVM based blends. J Appl Polym Sci 120:1121–1125

Remillat C (2007) Damping mechanism of polymers filled with elastic particles. Mech Mater 39:525–537

Zhang J, Richards CM (2007) Parameter identification of nalytical and experimental rubber isolators represented by Maxwell models. Mech Syst Signal Process 21:2814–2832

Nagasankar P, Balasivanandha PS, Velmurugan R (2014) The effect of the strand diameter on the damping characteristics of fiber reinforced polymer matrix composites: theoretical and experimental study. Int J Mech Sci 89:279–288

Chu HH, Lee CM, Huang WG (2004) Damping of vinyl acetate–n-butyl acrylate copolymers. J Appl Polym Sci 91:1396–1403

Trakulsujaritchok T, Hourston DJ (2006) Damping characteristics and mechanical properties of silica filled PUR/PEMA simultaneous interpenet rating polymer networks. Eur Polym J 42:2968–2976

El Mahi A, Assarar M, Sefrani Y, Berthelot JM (2008) Damping analysis of orthotropic composite materials and laminates. Composites Part B 39:1069–1076

Cristea M, Ibanescu S, Cascaval CN, Rosu D (2009) Dynamic mechanical analysis of polyurethane-epoxy interpenetrating polymer networks. High Perform Polym 21:608–623

Hang GS, Li Q, Jiang LX (2002) Structure and damping properties of polydimethylsiloxane and polymethacrylate sequential interpenetrating polymer networks. J Appl Polym Sci 85:545–551

Qin CL, Zhao DY, Bai XD, Zhang XG, Zhang B, Jin Z (2006) Vibration damping properties of gradient polyurethane/vinyl ester resin interpenetrating polymer network. Mater Chem Phys 97:517–524

Suhr J, Koratkar N, Keblinski P, Ajayan P (2005) Viscoelasticity in carbon nanotube composites. Nat Mater 4:134–137

Babkina NV, Lipatov YS, Alekseeva TT (2006) Damping properties of composites based on interpenetrating polymer networks formed in the presence of compatibilizing additives. Mech Compos Mater 42:385–392

Treviso A, Genechten BV, Mundo D, Tournour M (2015) Damping in composite materials: properties and models. Composites Part B 78:144–152

Lv XS, Huang ZX, Huang C, Shi MX, Gao GB (2016) Gao QQ (2016) Damping properties and the morphology analysis of the polyurethane/epoxy continuous gradient IPN materials. Composites Part B 88:139–149

Kireitseu MV, Hui D, Tomlinson G (2008) Advanced shockresistant and vibration damping of nanoparticle-reinforced composite material. Composites Part B 39:128–138

Huang GS, Li Q, Jiang LX (2002) Structure and damping properties of polydimethylsiloxane and polymethacrylate sequential interpenetrating polymer networks. J Appl Polym Sci 85:545–551

Qin CL, Cai WM, Cai J, Tang DY, Zhang JS, Qin M (2004) Damping properties and morphology of polyurethane/vinyl ester resin interpenetrating polymer network. Mater Chem Phys 85:402–409

Wang YB, Huang ZX, Zhang LM (2006) Damping properties of silicone rubber/polyacrylate sequential interpenetrating networks. Trans. Nonferrous Met. Soc. China 16:517–520

Li YW, Liu RY, Wang JY, Tang XY (1992) The use of polystyrene/polyacrylate latex interpenetrating networks in coatings for damping noise and vibrations. Prog Org Coat 21:101–107

Xu C, Qiu T, Deng JQ, Meng Y, He LF, Li XY (2012) Dynamic mechanical study on multilayer core–shell latex for damping applications. Prog Org Coat 74:233–239

Zhu YC, Wang B, Gong W, Kong LM, Jia QM (2006) Investigation of the hydrogenbonding structure and miscibility for PU/EP IPN nanocomposites by PALS. Macromolecules 39:9441–9445

Cheng XL, Chen ZX, Shi TS, Wang HY (2007) Synthesis and characterization of core-shell LIPN-fluorine-containing polyacrylate latex. Colloids Surf. A-Physicochem. Eng. Asp. 292:119–124

Finegan IC, Gibson RF (1999) Recent research on enhancement of damping in polymer composites. Compos Struct 44:89–98

Lahelina M, Aaltiob I, Heczkob O, Söderbergb O, Geb Y (2009) DMA testing of Ni–Mn–Ga/polymer composites. Composites Part A 40:125–129

Acknowledgments

The authors are grateful to the financial support by National Natural Science Foundation of China (No.21304030), Hebei Science and Technology planning Project of China (No. 15391201D), Science and Technology Foundation of Colleges and universities in Hebei Province, China (No. ZD2014086) and Scientific research foundation for returned scholars preferred project of Hebei Province, China (No. C201400516).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, E., Yao, M., Du, P. et al. Synthesis and dynamic mechanical study of core–shell structure epoxy/polyacrylate composite particle. J Polym Res 23, 204 (2016). https://doi.org/10.1007/s10965-016-1095-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-016-1095-1