Abstract

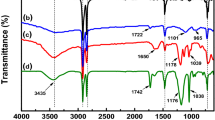

Osteolysis which is triggered by inflammatory responses to PE wear particles in the artificial hip joints is a serious issue. In order to prolonging the service life of artificial joints and endow the low tribological properties of the bearing surface of ultra-high molecular weight polyethylene (UHMWPE), hydrophilic acrylamide (AM) was grafted onto the surface of UHMWPE powders with the method of ultraviolet irradiation (UV) and then the modified UHMWPE powders were hot pressed as the bulk materials. The tribological properties of modified UHMWPE were investigated under distilled water, saline, calf serum by sliding against stainless steel ball. The measurement of Fourier-transform infrared (FT-IR) spectroscopy, Energy different spectrometry (EDS) and X-ray photoelectron spectroscopy (XPS) indicate that AM was successfully grafted onto the surface of UHMWPE powders by UV irradiation. The contact angle of UHMWPE is 95° which is higher than that of modified UHMWPE and the wettability of UHMWPE-g-AM is effectively improved. The tensile strength of modified sample decreases. The friction coefficient of modified sample is lower than that of untreated UHMWPE in aqueous lubricants during a long-term friction. The modified UHMWPE with the diameter of 58–75 μm has the lowest friction coefficient in calf serum which is about 0.075. The wear tests of knee joint moving simulator show that the pure UHMWPE has the highest wear rate, about 8 × 10−7 mm3(N · m)−1 and the wear rate of grafted UHMWPE decreases gradually water with the decrease of powder diameter. The sample with the 58–75 μm powder diameter has the lowest wear rate which is about 4.8 × 10−7mm3(N · m)−1 . The tribological properties of UHMWPE grafted with AM has been improved and the grafting hydrophilic PAM polymer brushes are helpful to form a lubricating film of water, which leads to the improvement of the lubricity.

Similar content being viewed by others

References

Kurtz SM, Muratoglu OK, Evans M, Edidin AA (1999) Advances in the processing, sterilization, and crosslinking of ultra-high molecular weight polyethylene for total joint arthroplasty. Biomaterials 20:1659–1688

Gupta SK, Chu A, Ranawat AS, Slamin J, Ranawat CS (2007) Review article: osteolysis after total knee arthroplasty. J Arthroplast 22:787–799

Jacobs JJ, Roebuck KA, Archibeck M, Hallab NJ, Glant TT (2001) Osteolysis: basic science. Clin Orthop Relat Res 393:71–77

Muratoglu OK, Wannomae K, Christensen S, Rubash HE, Harris WH (2005) Ex vivo wear of conventional and cross-linked polyethylene acetabular liners. Clin Orthop Relat Res 438:158–164

Glant TT, Jacobs JJ, Molnár G, Shanbhag AS, Valyon M, Galante JO (1993) Bone resorption activity of particulate‐stimulated macrophages. J Bone Miner Res 8:1071–1079

Morita Y, Nakata K, Ikeuchi K (2003) Wear properties of zirconia/alumina combination for joint prostheses. Wear 254:147–153

Xiong D-S (2004) Study on tribological properties of ion-implanted ultra-high-molecular-weight polyethylene. Mocaxue Xuebao(Tribology)(China) 24:244–248

Yao J, Laurent M, Johnson T, Blanchard C, Crowninshield R (2003) The influences of lubricant and material on polymer/CoCr sliding friction. Wear 255:780–784

Suresh B, Maruthamuthu S, Khare A, Palanisamy N, Muralidharan VS, Ragunathan R et al (2011) Influence of thermal oxidation on surface and thermo-mechanical properties of polyethylene. J Polym Res 18:2175–2184

Khan M, Al-Juhani A, Shawabkeh R, Ul-Hamid A, Hussein I (2011) Chemical modification of waste oil fly ash for improved mechanical and thermal properties of low density polyethylene composites. J Polym Res 18:2275–2284

Dorigato A, D’Amato M, Pegoretti A (2012) Thermo-mechanical properties of high density polyethylene – fumed silica nanocomposites: effect of filler surface area and treatment. J Polym Res 19:1–11

Salleh F, Hassan A, Yahya R, Lafia-Araga R, Azzahari A, Nazir M (2014) Improvement in the mechanical performance and interfacial behavior of kenaf fiber reinforced high density polyethylene composites by the addition of maleic anhydride grafted high density polyethylene. J Polym Res 21:1–11

Yang J-M, Huang P-Y, Yang M-C (1997) The effect of ultra-high molecular weight polyethylene fiber on the mechanical properties of acrylic bone cement. J Polym Res 4:41–46

Klein J, Kumacheva E, Mahalu D, Perahia D, Fetters LJ (1994) Reduction of frictional forces between solid surfaces bearing polymer brushes. Nature 370:634–636

Kitano K, Inoue Y, Matsuno R, Takai M, Ishihara K (2009) Nanoscale evaluation of lubricity on well-defined polymer brush surfaces using QCM-D and AFM. Colloids Surf B: Biointerfaces 74:350–357

Tsujii Y, Ohno K, Yamamoto S, Goto A, Fukuda T (2006) Structure and Properties of High-Density Polymer Brushes Prepared by Surface-Initiated Living Radical Polymerization. In: Jordan R, editor. Surface-Initiated Polymerization I: Springer Berlin Heidelberg 1–45

Deng Y, Xiong D, Shao S (2013) Study on biotribological properties of UHMWPE grafted with MPDSAH. Mater Sci Eng C 33:1339–1343

Deng Y, Xiong D, Wang K (2013) Biotribological properties of UHMWPE grafted with AA under lubrication as artificial joint. J Mater Sci Mater Med 24:2085–2091

Saraydın D, Ünver-Saraydın S, Karadağ E, Koptagel E, Güven O (2004) In vivo biocompatibility of radiation crosslinked acrylamide copolymers. Nucl Instrum Methods Phys Res Sect B: Beam Interact Mater Atoms 217:281–292

Zhou PP, Zhao YF, Liu HL, Ma YJ, Li XW, Yang X et al (2013) Dietary exposure of the chinese population to acrylamide. Biomed Environ Sci 26:421–429

Karadaǧ E, Saraydin D, Çetinkaya S, Güven O (1996) < i > In vitro</i > swelling studies and preliminary biocompatibility evaluation of acrylamide-based hydrogels. Biomaterials 17:67–70

Saraydin D, Karadag B, Cetinkaya S, Güven O (1995) Preparation of acrylamide/maleic acid hydrogels and their biocompatibility with some biochemical parameters of human serum. Radiat Phys Chem 46:1049–1052

Merlin DL, Sivasankar B (2009) Synthesis and characterization of semi-interpenetrating polymer networks using biocompatible polyurethane and acrylamide monomer. Eur Polym J 45:165–170

ISO 14243-1 (2002) Implants for surgery—wear of total knee joint prostheses Part 1: Loading and displacement parameters for wear-testing machines with load control and corresponding environmental conditions for test

Xiong L, Xiong D (2012) The influence of irradiation dose on mechanical properties and wear resistance of molded and extruded ultra high molecular weight polyethylene. J Mech Behav Biomed Mater 9:73–82

Gulmine J, Janissek P, Heise H, Akcelrud L (2002) Polyethylene characterization by FTIR. Polym Test 21:557–5563

Briscoe WH, Titmuss S, Tiberg F, Thomas RK, McGillivray DJ, Klein J (2006) Boundary lubrication under water. Nature 444:191–194

Raviv U, Giasson S, Kampf N, Gohy J-F, Jérôme R, Klein J (2003) Lubrication by charged polymers. Nature 425:163–165

Tadmor R, Janik J, Klein J, Fetters LJ (2003) Sliding friction with polymer brushes. Phys Rev Lett 91:115503

Acknowledgments

The authors wish to express thanks to the financial support of National Natural Science Foundation of China (Grant No. 51575278, 11172142) and Innovation of graduate student training plan in Jiangsu province (Grant No. CXZZ13_0202).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, Y., Xiong, D. Fabrication and properties of UHMWPE grafted with acrylamide polymer brushes. J Polym Res 22, 195 (2015). https://doi.org/10.1007/s10965-015-0836-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-015-0836-x