Abstract

We study a scheduling environment that finds many real-world manufacturing applications, in which there is a close connection between a hybrid multiprocessor open shop and multiple parallel identical flow shops. In this environment, there is an extended two-stage open shop, where in one stage we have a set of parallel identical machines, while in the other we have a two-machine flow shop. Our objective is to minimize the makespan, that is, the latest completion time of all jobs. We pursue approximation algorithms with provable performance, and we achieve a 2-approximation when the number of parallel identical machines is constant or is part of the input; we also design a 5/3-approximation for the special case where there is only one machine in the multiprocessor stage, which remains weakly NP-hard. Our empirical experiments show that both approximation algorithms perform much better in simulated instances; their average ratios over the proposed lower bound are around 1.5 and 1.2, respectively.

Similar content being viewed by others

Notes

By “consecutively,” we mean the machine processes the jobs one immediately after another without any idling period in between.

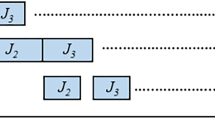

Note that the length \(\Delta \) of idle time for machine B guarantees that the new time gap between the start times of \(J_\ell \) on machine A and on machine B is exactly the same as the time gap in the initial schedule \(\pi ^0\) (and thus ensures job processing consecutiveness). Likewise, the length \(\Delta _2\) of idle time for machine C guarantees that the new time gap between the start times of \(J_\ell \) on machine B and on machine C is exactly the same as the time gap in the initial schedule \(\pi ^0\) (and thus ensures job processing consecutiveness).

Compared to the schedule \(\pi ^2\), the revision is on the processing order of the jobs of \(\mathcal{J}^1\) on the three machines.

References

Chen, B., Glass, C. A., Potts, C. N., & Strusevich, V. A. (1996). A new heuristic for three-machine flow shop scheduling. Operations Research, 44, 891–898.

Dong, J., Tong, W., Luo, T., Wang, X., Hu, J., Xu, Y., et al. (2017). An FPTAS for the parallel two-machine flowshop problem. Theoretical Computer Science, 657, 64–72.

Garey, M. R., & Johnson, D. S. (1979). Computers and intractability: A guide to the theory of NP-completeness. San Francisco: W. H. Freeman and Company.

Garey, M. R., Johnson, D. S., & Sethi, R. (1976). The complexity of flowshop and jobshop scheduling. Mathematics of Operations Research, 1, 117–129.

Gonzalez, T., & Sahni, S. (1976). Open shop scheduling to minimize finish time. Journal of the ACM, 23, 665–679.

Graham, R. L. (1966). Bounds for certain multiprocessing anomalies. Bell Labs Technical Journal, 45, 1563–1581.

Gupta, J. N. D. (1988). Two-stage, hybrid flowshop scheduling problem. The Journal of the Operational Research Society, 39, 359–364.

Halldórsson, M. M. (1998). Approximations of independent sets in graphs. In Proceedings of the second international workshop on approximation algorithms for combinatorial optimization problems (APPROX’98) (pp. 1–15).

He, D. W., Kusiak, A., & Artiba, A. (1996). A scheduling problem in glass manufacturing. IIE Transactions, 28, 129–139.

Hochbaum, D., & Shmoys, D. (1987). Using dual approximation algorithms for scheduling problems: Theoretical and practical results. Journal of the ACM, 34, 144–162.

Hoogeveen, J. A., Lenstra, J. K., & Veltman, B. (1996). Preemptive scheduling in a two-stage multiprocessor flow shop is NP-hard. European Journal of Operational Research, 89, 172–175.

Jansen, K. & Sviridenko, M. I. (2000). Polynomial time approximation schemes for the multiprocessor open and flow shop scheduling problem. In Proceedings of STACS 2000 (pp. 455–465). LNCS 1770.

Johnson, S. M. (1954). Optimal two- and three-machine production schedules with setup times included. Naval Research Logistics, 1, 61–68.

Ruiz, R., & Vázquez-Rodríguez, J. A. (2010). The hybrid flow shop scheduling problem. European Journal of Operational Research, 205, 1–18.

Sevastianov, S. V., & Woeginger, G. J. (1998). Makespan minimization in open shops: A polynomial time approximation scheme. Mathematical Programming, 82, 191–198.

Sherali, H. D., Sarin, S. C., & Kodialam, M. S. (1990). Models and algorithms for a two-stage production process. Production Planning and Control, 1, 27–39.

Tong, W., Miyano, E., Goebel, R., & Lin, G. (2016). A PTAS for multiple parallel identical multi-stage flowshops to minimize the makespan. In Proceedings of the 10th international frontiers of algorithmics workshop (FAW 2016) (pp. 227–237). LNCS 9711.

Vairaktarakis, G., & Elhafsi, M. (2000). The use of flowlines to simplify routing complexity in two-stage flowshops. IIE Transactions, 32, 687–699.

Williamson, D. P., Hall, L. A., Hoogeveen, J. A., Hurkens, C. A. J., Lenstra, J. K., Sevastianov, S. V., et al. (1997). Short shop schedules. Operations Research, 45, 288–294.

Zhang, X., & van de Velde, S. (2012). Approximation algorithms for the parallel flow shop problem. European Journal of Operational Research, 216, 544–552.

Acknowledgements

The authors would like to thank the anonymous reviewers for their many suggestions and comments that helped improve the paper presentation. JD was supported by NNSF China Grants 11971435 and 11501512 and PNSF Zhejiang China Grant LY18A010029. JC and GL were supported by NSERC Canada.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dong, J., Chang, J., Su, B. et al. Two-stage open-shop scheduling with a two-machine flow shop as a stage: approximation algorithms and empirical experiments. J Sched 23, 595–608 (2020). https://doi.org/10.1007/s10951-019-00633-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10951-019-00633-7