Abstract

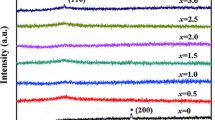

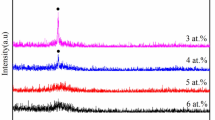

In the paper, we have studied the effects on glass forming ability (GFA), microstructure, crystallization behaviors, and saturation magnetization (Ms) of Si substitution for P in Fe-rich Fe86B12SixP1−xCu0.4Hf0.6 alloys. The amorphous structure is identified by X-ray diffraction first, and the patterns with Si addition less than x = 0.75 only show one halo scattering peak at 2θ = 45°; further, the ribbons with entirely amorphous structure have been fabricated successfully and the alloys have a good GFA. Then, by differential scanning calorimetry testing, the curves show two separated exothermic peaks and the ribbons will go through a two-step crystallization before reaching stable state; further, the first peak is ensured by the crystallization of a-Fe phase while the second peak is ensured by the precipitation of FeB or Fe(BP) compounds. As Si was added, the apparent activation energy of the first crystallization (Ea1) and the second crystallization (Ea2) shows an increased tendency first and then decreases slightly. By comparison, as x = 0, x = 0.25, and x = 0.5, the ribbons easily form Hf3P2 compounds during the first crystallization process simultaneously, where the ribbons of x = 0.75 and x = 1.0 are easier to finish the first crystallization for forming the uniform a-Fe phase entirely. By vibrating sample magnetometer testing, with the addition of Si, Ms value shows an increased trend and reaches to the maximum about 177.5 emu/g (x = 1.0), and which shows an increased trend in the subsequent annealing process and reaches to the maximum 206.3 emu/g (x = 0), 212.3 emu/g (x = 0.25), 214.2 emu/g (x = 0.5), 214.9 emu/g (x = 0.75), and 208.3 emu/g (x = 1.0) as the annealing temperature higher than Tp1 but less than Tx2.

Similar content being viewed by others

References

Zhang, X.Y., Zhang, J.W., Xiao, F.R., et al.: Ordering of the crystalline phase α-Fe(Si) in annealed Fe73.5Cu1Nb3Si13.5B9 alloy. Mater. Lett. 34, 85–89 (1998)

Borrego, J.M., Conde, C.F., Conde, A.: Thermomagnetic study of devitrification in Fe-Si-B-Cu-Nb(-X) alloys. Phil. Mag. Lett. 80, 359–365 (2000)

Silveyra, J.M., Illeková, E.: Effect of air annealing on Fe-Si-B-M-Cu (M=Nb, Mo) alloys. J. Alloys Compd 610, 180–183 (2014)

Makino, A., He, M., Kubota, T., et al.: New excellent soft magnetic fesiBPCu nanocrystallized alloys with high Bs of 1.9T from nanohetero-amorphous phase. IEEE Trans. Magn. 45, 4303–4305 (2009)

Xu, J., Yang, Y.Z., Li, W., et al.: Effect of P addition on glass forming ability and soft magnetic properties of melt-spun fesiBCuc alloy ribbons. J. Magn. Magn. Mater. 417, 291–293 (2016)

Kubota, T., Makino, A., Inoue, A.: Low core loss of Fe85Si2B8P4Cu1 nanocrystalline alloys with high Bs and B800. J. Alloys Compd. 509, S416–S419 (2011)

Zhou, L., Wang, G.T., Yuan, H., Yang, Y.Z.: https://doi.org/10.1016/j.jnoncrysol.2017.11.044 (2017)

Dan, Z.H., Qin, F.X., Zhang, Y., et al.: Mechanism of active dissolution of nanocrystalline Fe-Si-B-P-Cu soft magnetic alloys. Mater. Charact. 121, 9–16 (2016)

Dan, Z.H., Zhang, Y., Takeuchi, A., et al.: Effect of substitution of Cu by Au and Ag on nanocrystallization behavior of Fe83.3Si4B8P4Cu0.7 soft magnetic alloy. J. Alloys Compd. 683, 263–270 (2016)

Tang, J., Hu, D., Tai, Z., et al.: Microstructures and soft magnetic properties of nanocrystalline Fe86B13Cu1 alloy annealed by hot isothermal pressing. J. Alloys Compd. 493, 134–136 (2010)

Takeuchi, A., Inoue, A.: Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying elements. Magn. Trans. 12, 2817–2829 (2005)

Chau, N., Luong, N.H., Chien, N.X., et al.: Influence of P substitution for B on the structure and properties of nanocrystalline Fe73.5Si15.5Nb3Cu1B7−xPx alloys. Physica B 327, 241–243 (2003)

Parson, R., Garitaonandia, J.S., Yanai, T., et al.: Effect of Si on the field-induced anisotropy in Fe-rich nanocrystalline soft magnetic alloys. J. Alloys Compd. 695, 3156–3162 (2017)

Zhang, Y., Yan, B., Yang, Y., et al.: Non-isothermal nanocrystallization kinetics study on (Fe0.8Ni0.15M0.05)78Si8B14 (M=Nb, Ta, W) amorphous alloys. J. Alloys Compd. 574, 556–559 (2013)

Fu, C.Q., Xu, L.J., Dan, Z.H., et al.: Annealing effect of amorphous Fe-Si-B-P-Cu precursors on microstructural evolution and redox behavior of nanoporous counterparts. J. Alloys Compd. 726, 810–819 (2017)

Blázquez, J. S., Conde, C.F., Conde, A.: Non-isothermal approach to isokinetic crystallization processes: Application to the nanocrystallization of HITPERM alloys. Acta Mater. 53, 2305–2311 (2005)

Jafari, S., Beitollahi, A., Eftekhari Yekta, B., et al.: Three-dimensional atom probe analysis and magnetic properties of Fe85Cu1Si2B8P4 melt spun ribbons. J. Magn. Magn. Mater. 401, 1123–1129 (2016)

Jafari, S., Beitollahi, A., Eftekhari Yekta, B., et al.: Atom probe analysis and magnetic properties of nanocrystalline Fe84.3Si4B8P3Cu0.7. J. Alloys Compd. 674, 136–144 (2016)

Pradeep, K.G., Herzer, G., Raabe, D.: Atomic scale study of Cu clustering and pseudo-homogeneous Fe-Si nanocrystallization in soft magnetic FeSiNbB(Cu) alloys. Ultramicroscopy 159, 285–291 (2015)

Xia, G.T., Wang, Y.G., Dai, J., et al.: Effects of Cu cluster evolution on soft magnetic properties of Fe83B10C6Cu1 metallic glass in two-step annealing. J. Alloys Compd. 690, 281–286 (2017)

Sato, K., Takenaka, K., Makino, A., et al.: Structural heterogeneity of the melt-spun (Fe, Co)-Si-B-P-Cu alloy with excellent soft magnetic properties. Phys. Proc. 75, 1376–1380 (2015)

Funding

This work is supported by the Specialized Research Fund for the Doctoral Program of Higher Education (No. 20124420110007), the Demonstration Dase Fund for Joint Training Graduate of Guangdong Province (No. 2013JDXM27), the National Natural Science Foundation of China (No. 51201038) and the National Natural Science Foundation of Guangdong (No. 2015A030313488).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, L., Wang, G.T., Zheng, L.B. et al. Effects on Glass Forming Ability, Microstructure, Crystallization Behaviors, and Magnetic Properties of Si Substituting for P in Fe-Rich Fe86B13−xSixP1Cu0.6Hf0.4 Alloys. J Supercond Nov Magn 32, 431–439 (2019). https://doi.org/10.1007/s10948-018-4728-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10948-018-4728-2