Abstract

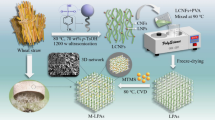

Converting agricultural residues into valuable materials has been recently a hot trend because biomass is a cellulose-rich source to efficiently manufacture cellulose-based materials. In this study, sponge-like carbon aerogels from biomass-derived cellulose are successfully fabricated using a rapid, simple, and cost-effective method without using harmful and toxic ingredients. The synthesized carbon aerogels are promising candidates for oil spill removal due to their hydrophobicity and oleophilicity. The aerogels producing from pineapple leaf fibers with the usage of polyamidoamine epichlorohydrin (PAE) as a cross-linker are pyrolyzed at 750 °C to form an ultra-light (density of 0.0088 g cm−3), super porous (99.68%) and flexible carbon aerogels. The as-fabricated aerogels show a fast adsorption rate (less than 30 s) and preeminent adsorption capability to various types of oil, in particular for the pump oil, at approx. 130 g g−1. Carbon aerogels with 5 wt% of PAE compared to dry microfibrilled cellulose (MFC) weight exhibit the highest capacity of oil adsorption by the value of 113 g g−1 for olive oil. A plinth freezing by a copper block results in vertically-aligned aerogels having oil adsorption capacity increased by 25% compared with the non-directional ones. Additionally, the adsorption capacity of the material maintains 75% of the initial value after 7 adsorption–desorption cycles. Therefore, our high-performance aerogels from affordable resources show great potential in treating oil spills effectively.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

A.A. Al-Majed, A.R. Adebayo, M.E. Hossain, A sustainable approach to controlling oil spills. J. Environ. Manage. 113, 213–227 (2012). https://doi.org/10.1016/j.jenvman.2012.07.034

J. Vilcáez, L. Li, and S. S. Hubbard, A new model for the biodegradation kinetics of oil droplets: application to the Deepwater Horizon oil spill in the Gulf of Mexico. (2013). [Online]. Available: http://www.geochemicaltransactions.com/content/14/1/4. Accessed 29 Oct 2022

Z.Y. Wu et al., Carbon nanofiber aerogels for emergent cleanup of oil spillage and chemical leakage under harsh conditions. Sci. Rep. (2014). https://doi.org/10.1038/srep04079

Y. Wang, L. Zhu, F. Zhu, L. You, X. Shen, S. Li, Removal of organic solvents/oils using carbon aerogels derived from waste durian shell. J. Taiwan Inst. Chem. Eng. 78, 351–358 (2017). https://doi.org/10.1016/j.jtice.2017.06.037

S.T. Nguyen et al., Cellulose aerogel from paper waste for crude oil spill cleaning. Ind. Eng. Chem. Res. 52(51), 18386–18391 (2013). https://doi.org/10.1021/ie4032567

H. Yang, J. Sun, Y. Zhang, Q. Xue, S. Xia, Preparation of hydrophobic carbon aerogel using cellulose extracted from luffa sponge for adsorption of diesel oil. Ceram. Int. 47(23), 33827–33834 (2021). https://doi.org/10.1016/j.ceramint.2021.08.294

Y. Meng, T.M. Young, P. Liu, C.I. Contescu, B. Huang, S. Wang, Ultralight carbon aerogel from nanocellulose as a highly selective oil absorption material. Cellulose 22(1), 435–447 (2015). https://doi.org/10.1007/s10570-014-0519-5

H. Chen, X. Wang, J. Li, X. Wang, Cotton derived carbonaceous aerogels for the efficient removal of organic pollutants and heavy metal ions. J. Mater. Chem. A 3(11), 6073–6081 (2015). https://doi.org/10.1039/c5ta00299k

D. Peng, Z. Lan, C. Guo, C. Yang, Z. Dang, Application of cellulase for the modification of corn stalk: Leading to oil sorption. Bioresour. Technol. 137, 414–418 (2013). https://doi.org/10.1016/j.biortech.2013.03.178

L. Hu, R. He, H. Lei, D. Fang, Carbon aerogel for insulation applications: a review. Int. J. Thermophys. (2019). https://doi.org/10.1007/s10765-019-2505-5

J.H. Lee, S.J. Park, Recent advances in preparations and applications of carbon aerogels: a review. Carbon 163, 1–18 (2020). https://doi.org/10.1016/j.carbon.2020.02.073

L.V. Petridis, N.C. Kokkinos, A.C. Mitropoulos, G.Z. Kyzas, Graphene aerogels for oil absorption. Int. Sci. Technol. (2019). https://doi.org/10.1016/B978-0-12-814178-6.00008-X

Y. Zhao, C. Hu, Y. Hu, H. Cheng, G. Shi, L. Qu, A versatile, ultralight, nitrogen-doped graphene framework. Angew. Chem.—Int. Ed. 51(45), 11371–11375 (2012). https://doi.org/10.1002/anie.201206554

S.V. Thakkar et al., Performance of oil sorbents based on reduced graphene oxide-silica composite aerogels. J. Environ. Chem. Eng. (2020). https://doi.org/10.1016/j.jece.2019.103632

W. Wan et al., Graphene-carbon nanotube aerogel as an ultra-light, compressible and recyclable highly efficient absorbent for oil and dyes. Environ. Sci. Nano 3(1), 107–113 (2016). https://doi.org/10.1039/c5en00125k

H. Khoshnevis et al., Super high-rate fabrication of high-purity carbon nanotube aerogels from floating catalyst method for oil spill cleaning. Chem. Phys. Lett. (2018). https://doi.org/10.1016/j.cplett.2018.01.001

X. Gui et al., Carbon nanotube sponges. Adv. Mater. 22(5), 617–621 (2010). https://doi.org/10.1002/adma.200902986

S. Wang et al., An ultralight, elastic, cost-effective, and highly recyclable superabsorbent from microfibrillated cellulose fibers for oil spillage cleanup. J. Mater. Chem. A 3(16), 8772–8781 (2015). https://doi.org/10.1039/c4ta07057g

P. Dubey, V. Shrivastav, P.H. Maheshwari, S. Sundriyal, Recent advances in biomass derived activated carbon electrodes for hybrid electrochemical capacitor applications: challenges and opportunities. Carbon 170, 1–29 (2020). https://doi.org/10.1016/j.carbon.2020.07.056

S. Lee, M.J. Jeong, K.Y. Kang, Preparation of cellulose aerogels as a nano-biomaterial from lignocellulosic biomass. J. Korean Phys. Soc. 67(4), 738–741 (2015). https://doi.org/10.3938/JKPS.67.738

Y.Q. Li, Y.A. Samad, K. Polychronopoulou, S.M. Alhassan, K. Liao, Carbon aerogel from winter melon for highly efficient and recyclable oils and organic solvents absorption. ACS Sustain. Chem. Eng. 2(6), 1492–1497 (2014). https://doi.org/10.1021/sc500161b

L.Y. Long, Y.X. Weng, Y.Z. Wang, Cellulose aerogels: synthesis, applications, and prospects. Polymers (2018). https://doi.org/10.3390/polym10060623

N. Lavoine, L. Bergström, Nanocellulose-based foams and aerogels: processing, properties, and applications. J. Mater. Chem. A 5(31), 16105–16117 (2017). https://doi.org/10.1039/c7ta02807e

L. Zhou, S. Zhai, Y. Chen, Z. Xu, Anisotropic cellulose nanofibers/polyvinyl alcohol/graphene aerogels fabricated by directional freeze-drying as effective oil adsorbents. Polymers (Basel) (2019). https://doi.org/10.3390/polym11040712

L. Zhou, Z. Xu, Ultralight, highly compressible, hydrophobic and anisotropic lamellar carbon aerogels from graphene/polyvinyl alcohol/cellulose nanofiber aerogel as oil removing absorbents. J. Hazard. Mater. (2020). https://doi.org/10.1016/j.jhazmat.2019.121804

L.N. Tan, N.C.T. Nguyen, A.M.H. Trinh, N.H.N. Do, K.A. Le, P.K. Le, Eco-friendly synthesis of durable aerogel composites from chitosan and pineapple leaf-based cellulose for Cr(VI) removal. Sep. Purif. Technol. (2023). https://doi.org/10.1016/j.seppur.2022.122415

N.H.N. Do et al., Heat and sound insulation applications of pineapple aerogels from pineapple waste. Mater. Chem. Phys. (2020). https://doi.org/10.1016/j.matchemphys.2019.122267

M.T. Tuyet Phan, L.N. Pham, L.H. Nguyen, L.P. To, Investigation on synthesis of hydrogel starting from vietnamese pineapple leaf waste-derived carboxymethylcellulose. J. Anal. Methods Chem. (2021). https://doi.org/10.1155/2021/6639964

N.H.N. Do et al., Advanced fabrication and application of pineapple aerogels from agricultural waste. Mater. Technol. 35(11–12), 807–814 (2020). https://doi.org/10.1080/10667857.2019.1688537

M. Asim et al., A review on pineapple leaves fibre and its composites. J. Polym. Sci. Int. (2015). https://doi.org/10.1155/2015/950567

C.H. Dong, Z. Lv, L. Zhang, H.J. Shen, N.N. Li, P. Zhu, Structure and characteristics of pineapple leaf fibers obtained from pineapple leaves. Adv. Mater. Res. (2014). https://doi.org/10.4028/www.scientific.net/AMR.998-999.316

W. Yang, H. Bian, L. Jiao, W. Wu, Y. Deng, H. Dai, High wet-strength, thermally stable and transparent TEMPO-oxidized cellulose nanofibril film: via cross-linking with poly-amide epichlorohydrin resin. RSC Adv. 7(50), 31567–31573 (2017). https://doi.org/10.1039/c7ra05009g

L. Nguyen et al., Microfibrillated cellulose from pineapple leaves for synthesizing novel thermal insulation aerogels. Chem. Eng. Trans. 97, 61–66 (2022). https://doi.org/10.3303/CET2297011

M. Dilamian, B. Noroozi, Rice straw agri-waste for water pollutant adsorption: relevant mesoporous super hydrophobic cellulose aerogel. Carbohydr. Polym. (2021). https://doi.org/10.1016/j.carbpol.2020.117016

H. Cheng, B. Gu, M.P. Pennefather, T.X. Nguyen, N. Phan-Thien, H.M. Duong, Cotton aerogels and cotton-cellulose aerogels from environmental waste for oil spillage cleanup. Mater. Des. 130, 452–458 (2017). https://doi.org/10.1016/j.matdes.2017.05.082

X. Zhang, H. Wang, Z. Cai, N. Yan, M. Liu, Y. Yu, Highly compressible and hydrophobic anisotropic aerogels for selective oil/organic solvent absorption. ACS Sustain. Chem. Eng. 7(1), 332–340 (2019). https://doi.org/10.1021/acssuschemeng.8b03554

H. Wang et al., A universal aqueous conductive binder for flexible electrodes. Adv. Funct. Mater. (2021). https://doi.org/10.1002/adfm.202102284

S. Sharma, Y. Deng, Dual mechanism of dry strength improvement of cellulose nanofibril films by polyamide-epichlorohydrin resin cross-linking. Ind. Eng. Chem. Res. 55(44), 11467–11474 (2016). https://doi.org/10.1021/acs.iecr.6b02910

X. Sun, L. Bai, J. Li, L. Huang, H. Sun, X. Gao, Robust preparation of flexibly super-hydrophobic carbon fiber membrane by electrospinning for efficient oil-water separation in harsh environments. Carbon 182, 11–22 (2021). https://doi.org/10.1016/j.carbon.2021.05.047

Z. He, X. Zhang, W. Batchelor, Cellulose nanofibre aerogel filter with tuneable pore structure for oil/water separation and recovery. RSC Adv. 6(26), 21435–21438 (2016). https://doi.org/10.1039/c5ra27413c

A. Mulyadi, Z. Zhang, Y. Deng, Fluorine-free oil absorbents made from cellulose nanofibril aerogels. ACS Appl. Mater. Interfaces 8(4), 2732–2740 (2016). https://doi.org/10.1021/acsami.5b10985

S. Yang, L. Chen, L. Mu, B. Hao, P.C. Ma, Low cost carbon fiber aerogel derived from bamboo for the adsorption of oils and organic solvents with excellent performances. RSC Adv. 5(48), 38470–38478 (2015). https://doi.org/10.1039/c5ra03701h

Q. Ma, Y. Liu, Z. Dong, J. Wang, X. Hou, Hydrophobic and nanoporous chitosan-silica composite aerogels for oil absorption. J. Appl. Polym. Sci. (2015). https://doi.org/10.1002/app.41770

S. Han, Q. Sun, H. Zheng, J. Li, C. Jin, Green and facile fabrication of carbon aerogels from cellulose-based waste newspaper for solving organic pollution. Carbohydr. Polym. 136, 95–100 (2016). https://doi.org/10.1016/j.carbpol.2015.09.024

S.F. Chin, A.N. Binti Romainor, S.C. Pang, Fabrication of hydrophobic and magnetic cellulose aerogel with high oil absorption capacity. Mater. Lett. 115, 241–243 (2014). https://doi.org/10.1016/j.matlet.2013.10.061

Y. Liu, Y. Peng, T. Zhang, F. Qiu, D. Yuan, Superhydrophobic, ultralight and flexible biomass carbon aerogels derived from sisal fibers for highly efficient oil–water separation. Cellulose 25(5), 3067–3078 (2018). https://doi.org/10.1007/s10570-018-1774-7

Acknowledgements

We acknowledge Ho Chi Minh City University of Technology (HCMUT), VNU-HCM for supporting this study.

Author information

Authors and Affiliations

Contributions

CKTP: methodology, characterization, investigation, data collection, data analysis, writing—original draft; TKD: characterization, investigation, visualization; NHND: validation, writing—review & editing; LTN: validation, writing—review & editing, PTM: data curation, validation; KAL: data curation, writing—review & editing; PKL: resources, validation, project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no potential conflicts of interest concerning the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pham, C.K.T., Duy, T.K., Do, N.H.N. et al. A facile route to fabricate anisotropic and flexible carbon aerogels from pineapple leaf for oil spills and solvent removal. J Porous Mater 30, 1911–1923 (2023). https://doi.org/10.1007/s10934-023-01474-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-023-01474-8