Abstract

Equations were derived for the biodegradative erosion of the surfaces of arbitrarily-sized circular and square objects, i.e., the decrease in volume caused by the catalytic activity of enzymes secreted by microorganisms attached to the object surfaces. Surface erosion is the primary mode of biodegradation for polyhydroxyalkanoate (PHA) objects resting on the ocean floor. Although the derivations were motivated by a need to assess the time-varying biodegradation and ultimate disintegration of PHA tubes and straws in the benthic environment, generality was maintained during the mathematical development such that the resulting equations are also applicable to other circular and square objects, including cylindrical rings, discs, and solid rods, and square plates, cubes, and prisms. Moreover, the equations are applicable to abiotic degradation via physical erosion, not just to biotic degradation caused by microbes. Surface erosion is expressed in terms of the ratio of the instantaneous mass to the initial mass, which is generally nonlinear with respect to time. The value of this ratio and the relative dimensions of the object establish a surface erosion function and its evolution over the lifetime of the object. Hence, the rate of degradation is not constant in the theory, but rather is prescribed by the irregular mass loss and the original geometry of the 3D object.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Motivation for this Study

This research stemmed from an initiative to find a means to protect juvenile corals [22] and coral microfragments [45] transplanted from laboratories to the ocean as part of a coordinated effort to restore Florida’s coral reef [14] amidst a devastating disease outbreak that began in 2014 and that has spread throughout the entire Florida coral reef tract and the Caribbean [1, 2, 24, 43, 62]. Attempts to replenish Florida’s coral reef in this manner have been hampered by corallivores predating on the transplanted laboratory corals, causing dislodgment of the corals from their substrate support or tissue loss that often leads to mortality, particularly in small colonies [33]. The corallivores that do the most damage are parrotfish (Photo 1) some of which are ‘excavators’ [37] that have the ability to sheer off chunks of the coral’s calcium carbonate skeleton with their strong jaws and tough teeth [38]. To date, all efforts to protect transplanted corals have met with limited success. Galvanized steel cages have been placed over the transplants, and steel spikes have been embedded around them [50]. Regular cleaning of these permanent devices or their removal eventually becomes necessary due to the accumulation of algae, which can smother and kill the coral. Feeding laboratory corals with powdered brown algae to make them unpalatable to parrotfish has been explored [20]. Alteration of parrotfish foraging behavior by placing decoys resembling black groupers, a parrotfish predator, in coral reefs has also been studied [7].

An optimal solution to the parrotfish predation problem is one that is inexpensive, can be applied on a massive scale (protection for millions of corals is needed), and does not require substantial labor by divers at deployment or maintenance post-deployment. Parrotfish are territorial [53] and, for reasons that are still not fully understood, stop predating on transplanted corals sometime between one week to six months after the transplants first appear in their territory [33, 50, 54]. We therefore sought to design a ‘fence’ of biodegradable plastic that would protect the coral outplants and disintegrate within a few months, specifically, after the parrotfish stop targeting the coral transplants but before the excessive growth of algae.

Polyhydroxyalkanoate

Polyhydroxyalkanoate (PHA) and polycaprolactone (PCL) are known to degrade in the marine environment much more rapidly than other biodegradable polymers that have a larger market share [21, 49, 55, 61]. Although PCL was deemed suitable with respect to biodegradability, it was dropped from consideration for the parrotfish deterrence fence because of its low tensile strength and high elongation at yield [51, 55, 61]. Studies of PHA biodegradation in the marine environment have been conducted using films, powders, pellets, and ‘dogbones’ designed for tensile tests [11, 35, 41, 59]. The absence of biodegradation studies using other shapes is perhaps due to the fact that three-dimensional (3D) printing with PHA pellets [9, 28] and extrusion of shapes using PHA resin [58] are relatively new developments. However, the commercial use of PHA is expanding rapidly [44, 46, 49]. Despite its high production cost, PHA is being adopted in the food-packaging industry [4, 5, 44] and is now commonplace in the biomedical field for drug delivery, tissue engineering, and numerous other applications [29, 30].

It appears that the first extruded PHA shapes in the US commercial market were made using resin from Danimer Scientific, currently the only supplier of PHA in the US [44]. PHA drinking straws, manufactured by the company Phade using Danimer Scientific resin, became commercially available in January 2021. PHA tubes, manufactured by the company Humidi, are likewise produced using Danimer Scientific resin and were first marketed in January 2022. Since then, produce bags, thermoform sheets, and cutlery have also been made with Danimer Scientific resin and sold commercially (per personal communication with a Danimer Scientific representative).

The patent-pending protective device (application no. 63/423,201) developed by our research on the parrotfish predation problem comprises Phade PHA straws and Humidi PHA tubes that are secured to a cement base and surround the coral transplant (Photo 2). The emergence of commercially-available PHA tubes and straws thus facilitated construction of a parrotfish deterrence fence that is both inexpensive and easy to mass produce. PHA’s superior strength and stiffness relative to those of many other biopolymers [40, 51] also make the fence structurally stable and more resistant to parrotfish bites. In-water tests of design prototypes were conducted in the summer of 2023 [48]. Sect. “Results for PHA Straws” provides a brief study of the biodegradation of PHA straws in the benthic environment using experimental results from [48].

Surface Erosion vs. Bulk Erosion

All degrading polymers undergo surface erosion or bulk erosion [60]. In the former, all mass loss occurs from the object surfaces as it erodes; in the latter, mass is lost uniformly throughout the object’s volume, not just from its surfaces. The two modes of degradation are not mutually exclusive [34]. If the velocity of degradation of polymer bonds at the object’s surface exceeds the diffusion of water into the object, then surface erosion dominates [60]. Bulk erosion dominates when the diffusion of water into the object is faster than the degradation at the object’s surface. Therefore, polymers can undergo mass loss due to surface erosion and bulk erosion simultaneously, but to different degrees [34]. In particular, surface erosion may dominate early in the polymer’s lifetime and then be overcome by bulk erosion as mass loss progresses and the diffusion of water into the remaining volume is expedited [19]. Indeed, theory shows that a critical dimension exists below which bulk erosion takes over for any given biodegrading polymer type [60].

There is overwhelming evidence that surface erosion dominates during biodegradation of PHA in the marine environment. Biotic degradation occurs primarily at the surface because enzymes secreted by microorganisms are too large to penetrate the polymer matrix [34, 40]. Loss of mass during surface erosion is also characterized by a continuous, predictable velocity, unlike bulk erosion, for which mass loss is sudden and spontaneous [17, 34, 60]. All of the studies identified in our literature search that present well-defined curves of biodegradation vs. time for PHA in the marine environment exhibit steady mass loss, consistent with surface erosion [5, 11, 12, 31, 35, 56].

Furthermore, as noted in [40], under ideal conditions, plots of biodegradation vs. time resemble the classic curve of bacterial growth [63] with distinct lag, exponential, and stationary phases. Indeed, [23] shows a correlation between time series of colony forming units (CFU/g) and mass loss for degrading PHA. Three of the six studies cited above [12, 31, 35] have sufficient detail to identify lag, exponential, and stationary phases.Footnote 1 The approximate correspondence of mass loss and microbial growth characteristics provides circumstantial evidence that surface erosion, caused by enzymes secreted by microbes, is the dominant mode of biodegradation for PHA in the marine environment.

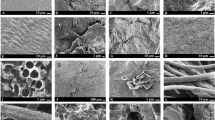

Finally, of the six studies cited above, only one [35] presents experimental results that extend to complete disintegration. In that study, the stationary phase persisted until the end, i.e., there was no abrupt mass loss even as full disintegration approached. However, scanning electron microscopy [42] has been used to reveal pitting of the surface of a PHA film as degradation progresses, which produces more surface area and better conditions for water diffusion into what remains of the polymer matrix [34], so it is not precluded that bulk erosion could eventually occur under some test conditions as complete disintegration approaches. Nevertheless, based on all the data examined, it seems reasonable to assume that mass loss can be solely attributed to surface erosion over essentially the entire lifetime of PHA objects in the marine environment.

Analysis Approach

Our literature search did not identify any publications in the field of polymer degradation that rigorously developed mathematical relationships for surface erosion of 3D shapes. However, studies were found that addressed analytical modeling of films, fibers, spheres, and particles [8, 13, 25, 36]. In principle, these objects are three-dimensional, but their degradation occurs predominantly along one axis, which simplifies the mathematics involved. For example, for films, the surface area of the two film faces is commonly assumed to remain constant during degradation, with mass loss attributed entirely to the film’s diminishing thickness [8, 13, 36]. Moreover, the surfaces that are analyzed in these models are assumed to erode uniformly, that is, without any circumferential, radial, or longitudinal variations. To the best of our knowledge, the spatial characteristics of surface erosion have not been investigated, and the assumption of uniformity remains unverified. The derivations herein for 3D shapes align with previous degradation models in that uniform surface erosion is presumed in the absence of germane experimental data. Finally, we also identified two studies from the biomedical field [16, 18] that presented numerical and experimental results for degrading solid cylinders and cubes, and these may be compared with the surface erosion equations derived in Sect. “Solid Cylinders”.

Nothing that follows restricts application of the derivations to PHA in the marine environment, although that was the motivation for their development. Indeed, the derivations can be applied to any object experiencing uniform surface erosion in any environment whatsoever, including for abiotic physical degradation and for biodegrading in-vivo medical devices. Generality during the mathematical development was maintained such that the equations can be applied to arbitrary dimensions of the tubes, solid rods, hollow rings, and solid discs illustrated in Fig. 1. Square versions of the circular cross sections are also encompassed by the theory.

Degradation vs. Time

Under aerobic conditions, the products of polymer biodegradation are water, carbon dioxide, and microbial biomass [49, 51, 61]. Physical, thermal, respirometric, spectroscopic, and chromatographic methods have been employed to analyze biodegradable polymers [3]. Among these, physical and respirometric methods are most often used to assess temporal biodegradation processes [3, 13]. In particular, measurements of (physical) mass loss and (respirometric) carbon dioxide release are common means of establishing the evolution of biodegradation [11, 13]. Measurements of mass loss, however, cannot ascertain when mineralization, the last stage of biodegradation, has concluded [3, 8, 13]. Thus, respirometric methods, not mass loss assessments, are generally the foundation for biodegradation standards [13]. Conversely, respirometric methods are often inappropriate for lifetime predictions of polymers in the environment, because full polymer disintegration usually occurs prior to completion of the mineralization stage of biodegradation [11, 13]. Because this study is only interested in degradation until the instant at which the polymer matrix physically disappears, mass loss measurements are used as inputs for predictions of surface erosion magnitudes and construction of degradation time series.

In the derivations, we generally adopt the approach and nomenclature used in [13], which emphasized films owing to their prevalence in PHA biodegradation studies for the marine environment (Appendix A provides a table of the symbols used in the present theory). Special care was taken when comparing the biodegradation assessments for films with the derivations herein for 3D shapes. Surface erosion is designated by the symbol ∆ (cm) and is solely a function of the initial geometry of the object and instantaneous mass loss, which generally has an irregular variation with respect to time and, hence, is incompatible with a constant rate of degradation. The resulting equations can be used with mass measurements during degradation experiments to define a time-varying function ∆. A constant rate of degradation is neither implied, nor introduced as an approximation, in the present theory.

The relationship between ∆ and time is nonlinear because biodegradation occurs in phases. As noted above, several published plots of PHA biodegradation in the marine environment roughly mimic the classic shape of bacterial growth curves, which have lag, exponential, stationary, and death phases [63].Footnote 2 Some researchers have grouped the biodegradation process into three or four major steps [13, 15, 61]. Biofilm formation is the term generally used for the first step in the process, and its correspondence with the bacterial lag phase has been established [26]. As mentioned above, mineralization defines the last step of biodegradation. The correlation of processes between biofilm formation and mineralization with stages of microbial growth has not been elucidated. Surprisingly, it does not appear that mass loss vs. time data for biodegrading polymers have been plotted on a semi-log scale, consistent with displays of the classic bacterial growth curve [63]. Perhaps such a transformation of the ordinate would linearize much of the mass loss vs. time curves, providing a more reliable estimate for use in studies of the lifetime of objects made of PHA.

Degradation Variables

The biodegradation process is discussed in depth in [13], which concluded that a linear variation of mass loss with time is acceptable. This approximation is not adopted herein, i.e., a constant rate of mass loss is not used in the mathematical development.

Polymer lifetime is estimated in [13] using a constant degradation rate λ (cm/day) for films exposed to seawater on both sides:

where \({h}_{o}\) is the initial thickness of the film (cm), \({t}_{d}\) is the time for complete disintegration (days), and the integer 2 reflects that degradation occurs on both of the film surfaces. Equation (1) can be generalized to objects of any shape:

where \({h}_{m} ({\text{cm}})\) corresponds to the thickest part of the object and S is a scalar. If the surface of the object is exposed to seawater on only one contour (as is the case for a sealed container, or when the object is completely solid) then S = 1, whereas S = 2 if the object has two surfaces and both are exposed to seawater. Equation (2) does not appear in [13] but was used implicitly to estimate the lifetimes of bags, straws, bottles, cutlery, etc. that could be made from PHA resin.

In [13] a function r, the specific rate of mass loss, was also introduced:

where \(\Delta m ({\text{mg}})\) is the mass loss over the duration t (days) of the experiment and \(A ({{\text{cm}}}^{2})\) is the initial surface area. It was confirmed through personal communication with the corresponding author of [13] that initial surface area means the total area exposed to seawater and that, for films exposed on both sides, twice the surface area of one face of the film was used as input for (3).

In [13], a meta-study of existing research on PHA biodegradation was conducted and constants r were computed. For the marine environment, 14 data points yielded a mean of r (at the 95% confidence level) equal to 0.04–0.09 mg/(cm2 day). Herein, we treat r not as a constant rate, but rather as an instantaneous variable.Footnote 3 The area term in the denominator of (3) is also redefined as the time-varying total surface area of the object exposed to seawater. For a degrading film with a constant (i.e., non-degrading) face surface area \(A(0)\), diminishing thickness \(L({\text{cm}})\), instantaneous mass \(m({\text{mg}})\), and density \(\rho ({\text{mg}}/{{\text{cm}}}^{3})\), (3) can be rewritten as

where \(\Delta ({\text{cm}})\) is the time-varying erosion of one side of the film only.

Hollow Cylinders

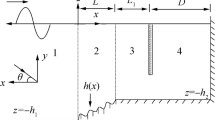

The model for the degradation of tubes, straws, and rings is shown in Fig. 2. A straw is simply a long cylinder with a thin wall, and a ring is a slim circular shape with a central hole, like a washer. The derivations encompass all of the shapes in Fig. 1 and everything in between. It is assumed that degradation is uniform, i.e., all surfaces degrade at the same rate. It is also assumed that both ends of the cylinder are exposed and degrade. Modifications to these assumptions could be introduced, but they are beyond the scope of this paper.Footnote 4

Surface Erosion Equations

The instantaneous inner diameter, outer diameter, and length are defined by

It is important to recognize that this model is invalid for a completely solid cross-section \(\left[{D}_{i}(0)\equiv 0\right]\) because the second expression in (7) allows an interior diameter to emerge ex nihilo as degradation initiates \(({D}_{i}=2\Delta )\), which is physically impossible. The degradation of solid cylinders is analyzed in Sect. “Solid Cylinders”. The time-varying and initial areas and volumes of the body are defined by

The instantaneous and initial masses are therefore defined by

The ratio of (11a) and (11b) yields the relationship

Note that the cylinder’s initial outer diameter \({D}_{o}(0)\) does not appear in (12). The only dimensions that define surface erosion for hollow cylinders are the initial wall thickness \(W(0)\) and length \(L(0)\). As \(L(0)\) increases relative to \(W(0)\), the hollow cylinder becomes a long tube. As \(L(0)\) decreases relative to \(W(0)\), the hollow cylinder becomes a thin ring.Footnote 5 From (11a), the corresponding limits are

Equation (12) yields the following quadratic equation involving ∆

where

The coefficients a (16a) and b (16b) do not vary with time. Only the ratio \(m/m(0)\) within the term c (16c) changes during degradation. Expressing the erosion relationship in this form is convenient, because it only requires that the original dimensions of the object be known, and that it be weighed at various points in time during degradation. The solution of a quadratic equation is, of course, given by

Substituting (16a), (16b), and (16c) into (17) yields the surface erosion equation for a hollow cylinder with arbitrary values of \(L(0)\) and \(W(0)\):

Note that only the negative sign in front of the radical in (17) has been retained. Although the positive sign also yields a valid solution of (15), adding the square root to the first term in (17) increases the size of ∆. As will be shown in Sect. “Delineation between Tubes & Rings”, only the smaller surface-erosion value, corresponding to subtraction of the radical, is physically meaningful.

Specific Rate of Mass Loss

Recall that for films, the approximation \(A=SA(0)\) yielded the concise relationship \(\lambda =r/\rho\) (5). Using (9a), (9b), and (11a), it can be shown that an analogous normalization with respect to the initial hollow cylinder surface area gives

The ratio \(A/A(0)\) is itself a function of time-varying surface erosion ∆ and consequently is not known a priori. Nevertheless, it can be shown using (19b) that \(A\sim A(0)\) when \(L(0)\gg W(0)\) or when \(L(0)\ll W(0)\), which leads to \(\lambda \sim r/\rho\).Footnote 6 In other words, normalization with respect to the initial surface area \(A(0)\) is reasonable for the two limiting cases: long tubes (13) and thin, washer-like rings (14). More generally, the instantaneous value of the exposed area must be retained in the definition of \(r\) and should be used when generating comparisons with the specific rate of mass loss values reported in [13]. It is evident from (19a) that normalization with respect to \(A\), rather than the initial surface area \(A(0)\), does indeed yield \(\lambda = r/\rho\) for all hollow cylinder configurations. That is,

This conclusion is not unique to hollow cylinders. Note that

Therefore, (20) is valid for any object that has the property

The derivative of an object’s volume with respect to some relevant length generally does not yield the object’s surface area [39]. For example, the derivative of (10b) with respect to \({D}_{o}(0)\), L(0) or W(0) does not yield (9b). The universality of (22) is unproven and thus should be verified before using \(\lambda =r/\rho\) in degradation studies for the object.The relevance of (22) is best understood when expressed as

where \(\delta V\) and \(\delta\Delta\) are small but finite changes in volume and surface erosion, respectively. As illustrated in Fig. 3, degradation in this discrete model is a succession of small steps \(\delta\Delta\) that cause incremental volume losses \(\delta V\) equal to the surface area, at that point in time, multiplied by the erosion step size. The evolution of degradation can thus be viewed as the sequential eradication of thin, onion-like layers of the object. For any given value of surface erosion ∆, the next degradation step is \(\Delta +\delta \Delta\). Using (10a), it can be shown that the reduction in volume associated with \(\delta\Delta\) for a hollow cylinder is defined by

For small values of \(\delta\Delta\), the second-order term \((\delta {\Delta }^{2})\) can be ignored, such that (24) reduces to (23).

Degradation Time Series

For 3D shapes that have more than one significant degrading dimension, a set of ∆ values corresponding to the experimental measurements \(m/m(0)\) can be compiled from output of the object’s surface erosion equation. For example, for hollow cylinders, the mass measurement \({m}_{i}/m(0)\) at time point \({t}_{i}\) provides input for (18), which yields the surface erosion value \({\Delta }_{i}\) at \({t}_{i}\). The duration of the experiment is accordingly modeled as a series of adjacent time intervals, beginning with the initial condition ∆ = 0 at t = 0. The approximate rates of surface erosion and specific mass loss, over any given time interval \({t}_{i-1}\) to \({t}_{i}\), are thus defined by the following three stepsFootnote 7:

Application of (25a) for all of the measurement time points yields the following arrays (row vectors):

where \(n\) equals the number of mass measurements. The level of detail, and accuracy, of the time series \(\Delta \left(t\right)\), \(\lambda \left(t\right)\), and \(r\left(t\right)\) that can be assembled from the arrays depend on the number of mass measurements recorded and on the size of the time steps between them. The numerical analysis described by (25a) and (25b) is the most realistic and accurate way to depict degradation as a function of time for an arbitrarily-sized 3D object.

However, if the instantaneous surface area \(A\) is approximately equal to the initial surface area \(A(0)\) over the lifetime of the 3D object—as is the case for straws and washers (cf. footnote 6)—it is unnecessary to compute \({\Delta }_{i}\) values using a surface erosion equation for the object; \(r\left(t\right)\) can be constructed directly from the mass loss measurements. In this case, for any given time interval, the approximate specific rate of mass loss and rate of surface erosion are defined by just two steps:

The values \({\lambda }_{i}\) may differ significantly in magnitude due to the irregular nature of mass loss. The average of the values represents a linearized rate of degradation:

where all of the time intervals \(\left({t}_{i}-{t}_{i-1}\right)\) are assumed to be of approximately the same size. Equation (25d) is presented for thoroughness, because constant rates of degradation have been advocated and reported in the literature [8, 13, 36]. It is important to recognize though that \(\overline{\lambda }\) is a single rudimentary parameter for degradation, and is thus generally inferior to the nonlinear time series \(\lambda \left(t\right)\) and \(r\left(t\right)\) assembled from the output of (25a) using experimental mass measurements and the surface erosion equations derived in this paper.

Nonetheless, instead of acquiring mass measurements through experimentation, the variation of \(m/m(0)\) with respect to time can be crudely approximated by adopting a constant rate of surface erosion that was reported in a previous biodegradation study for the plastic material in the subject environment. It is evident from (12) that for hollow cylinders:

where the constraints on \(\overline{\lambda }t\) imposed by the relative sizes of \(L(0)\) and \(W(0)\) are elucidated in Sect. "Delineation between Tubes & Rings". Aside from the uncertainty introduced by adopting a previously-reported erosion rate, the accuracy of (25e) depends on the appropriateness of linearizing \(\Delta (t)\) over the lifetime of the object through the use of a constant rate value. Equation (25e) therefore should be used with considerable caution. The process described by (25a) and (25b) is advocated whenever mass measurements are acquired during a degradation experiment for a 3D object.

Degradation curves are typically plotted as a percentile of mass loss vs. time, with values on the ordinate defined by

The degradation of films exposed on both faces theoretically has the same variation with time as the two limiting cases for hollow cylinders (13) and (14) because all of these geometries have a single degrading dimension. Therefore, if a biodegradation curve for a film exposed on both sides has adequate resolution, and the test conditions corresponding to the degrading film are considered representative, then the ordinate of the published curve (26) can be used as input for (13) and (14) to generate time series of surface erosion for thin tubes and slim rings in that specific environment. Although \(\left[1-m/m(0)\right]\) also appears in (18), the comprehensive solution for hollow cylinders involves two significant degrading dimensions such that \(f\left(t\right)\) for films generally should not be used as input.

Effect of Cylinder Ends

Equation (18) can be expressed as

The surface erosion of any hollow cylinder is then related to that of an infinitely long tube (13) by

The factor \({F}_{h}\) is a relative measure of the effect of the cylinder ends on total surface erosion. Ignoring the end effects yields \(\Delta\) values that overestimate the actual erosion because the measured mass loss is attributed entirely to reduction of the wall thickness (7) without any mass loss from reduction of the cylinder length (8). The factor \({F}_{h}\), consequently, is always less than unity. Equation (28b) can be written in the compressed form:

where

\({F}_{h}\) can be computed directly using (29). However, an equation involving only polynomials can be established by introducing a Taylor series expansion [6] of the radical:

Retaining all of the terms shown in the expansion above yields

After normalizing (30) with respect to \({D}_{o}\left(0\right)\), it can be shown that:

respectively, which agrees with (13) and (14). Equation (31b) indicates that, although \({F}_{h}\) was written in a form that modifies \({\Delta }_{W}\), it still yields the correct result as length \(L(0)\) becomes small. Therefore, (30) is valid for rings, as well as tubes.

The factor \({F}_{h}\) (30) is plotted in Fig. 4 for \(m/m(0) = 0.5\). As the normalized length increases, \({F}_{h}\) approaches unity and \(\Delta\) approaches \({\Delta }_{W}\) (13). As expected, when the tube has a thick wall [large value of \(W(0)/{D}_{o}(0)\)], the effect of the ends of the cylinder on degradation is greater and the length required for convergence of \({F}_{h}\) to unity increases. The steep decrease in \({F}_{h}\) that occurs when \(L\left(0\right)/{D}_{o}(0)\) falls below unity reflects the transition of the hollow cylinder to a ring shape, and convergence of \({F}_{h}\) to \(L(0)/W(0)\) (31b) and \(\Delta\) to \({\Delta }_{L}\) (14).

Delineation between Tubes & Rings

Using (18), it can be shown that the critical point that separates rings from tubes is defined byFootnote 8

The physical significance of this threshold can be explained. There are three possible end states of the degradation of hollow cylinders: (1) The wall thickness disappears, while the length is still nonzero; (2) the length disappears, while the wall thickness is still nonzero; and (3) the wall thickness and length disappear simultaneously. Equations (7) and (8) show that:

Because degradation occurs uniformly on all of the exposed surfaces of the hollow cylinder, its progression is also identical on those surfaces. If \(\lambda\) represents the rate of degradation at any instant of time, then the wall thickness and length will disappear when

respectively. Equations (34a) and (34b) do not require that the rate of degradation be constant, only that the wall and cylinder end surfaces degrade in accordance with the same time-varying function \(\lambda\). It can be concluded that the three end states defined above correspond to:

These relationships are intuitive because, if degradation occurs uniformly, then the smallest dimension is critical and will be the first to vanish. The line of reasoning is also corroborated by (12), which has two solutions (roots) when \(m/m(0)= 0 :\Delta =W(0)/2\) and \(\Delta =L(0)/2\). Because the hollow cylinder is a physical object that experiences progressive degradation over time, only the smaller of the two roots that satisfy (12) has any real significance. The larger \(\Delta\) value is irrelevant because the cylinder no longer exists after the smaller \(\Delta\) value has been attained during degradation. Hence, when \(m/m(0) = 0\) and \(L(0)>W(0)\), the only meaningful solution of (12) is \(\Delta =W(0)/2\), whereas when \(L(0)<W(0)\) the only meaningful solution is \(\Delta =L(0)/2\).

In summary, when \(L(0)\equiv W(0)\), the cylinder wall and length disappear simultaneously at complete disintegration \(\left[m/m(0)=0\right]\). We can now define tubes as hollow cylinders with \(L(0)>W(0)\) and thus dominated by a degrading wall thickness. Rings are likewise defined as hollow cylinders with \(L(0)<W(0)\) and thus dominated by a degrading length. Using (7) and (8), it is easy to show that the end state for (35a) is a tube that has an infinitesimal wall thickness and has shortened by the amount \(W(0) \left[L=L(0)-W(0)\right]\), as illustrated in Fig. 3. Similarly, the end state of (35b) is a ring with an infinitesimal height and a centered hole whose diameter has increased by the amount \(L\left(0\right) \left[{D}_{i}={D}_{i}(0)+L(0)\right]\). The threshold \(({\Delta }_{WL})\) and convergence to the tube and ring limits (\({\Delta }_{W}\) and \({\Delta }_{L}\)) are illustrated in Fig. 5.

Tube Examples

Applications of (18) are provided in Figs. 6 and 7. Figure 6 shows the results for a tube with a relatively thin wall \([W\left(0\right)/{D}_{o}\left(0\right) = 0.05]\). The limit \({\Delta }_{W}\) is a good approximation, even when the tube length equals its diameter \([L(0)={D}_{o}(0)= 3\mathrm{ cm}]\). The ‘long’ size of Humidi tubes is slightly tapered, with average values of \(L(0)/{D}_{o}(0)\) and \(W(0)/{D}_{o}(0)\) equal to 4 and 0.04, respectively. The ‘giant’ size of Phade straws, cut to the same length as the long Humidi tubes, has \(L(0)/{D}_{o}(0)= 16\) and \(W(0)/{D}_{o }\left(0\right) = 0.01\). It can be inferred from Fig. 6 that \({\Delta }_{W}\) is a reasonable approximation for both Phade straws and Humidi tubes.

Figure 7 compares the results from (18) with those from the Taylor series expansion (30) for a tube with \(L(0)/{D}_{o}(0) = 1\). The expansion appropriately reduces \({\Delta }_{W}\) to account for erosion of the tube ends, but its accuracy decreases as disintegration approaches, a deficiency that is easily overcome by resorting to the exact formulation (29). Figure 7 also demonstrates that the results from (18) and those of the Taylor series expansion converge to the limit \({\Delta }_{W}\) as the inner diameter increases (tube wall thickness diminishes). It can be concluded that the exact solution or the Taylor series expansion should be used for short cylinders with thick walls, but that otherwise the limit \({\Delta }_{W}\) is a reasonable approximation.

Solid Cylinders

As noted in Sect. "Surface Erosion Equations” the model for hollow cylinders is invalid for solid cylinders, even when the inner diameter is set to zero, because it allows degradation to initiate within a completely solid cross section.

Surface Erosion Equations

The degradation model for a solid cylinder is shown in Fig. 2. The time-varying surface area is defined by

where \(D(0)\) is the initial diameter of the cylinder, and \(L(0)\) is its initial length. The instantaneous volume of the cylinder is given by

Therefore, the initial mass and time-varying mass equal

The ratio of (38a) and (38b) yields the relationship

Using (36) and (37), it is easy to show that (22) is valid for solid cylinders, such that \(\lambda =r/\rho\) for arbitrary values of \(D(0)\) and \(L(0)\).

Delineation between Discs and Rods

The dominance of a single degrading dimension yields the following limits of (39):

Note that (14) and (41) are identical, even though they were derived for different circular shapes (hollow rings vs. solid discs). Indeed, \({\Delta }_{L}\) is believed to be applicable for any plastic material with a small thickness and faces that have a large surface area.

A solid cylinder with a length equal to its diameter defines the threshold at which (39) converges to either \({\Delta }_{D}\) or \({\Delta }_{L}\). Surface erosion can also be established in closed form for this special case:

The physical significance of this threshold is analogous to that for (32). There are three possible end states of the degradation for solid cylinders: (1) The diameter disappears, while the length is still nonzero; (2) the length disappears, while the diameter is still nonzero; and (3) the diameter and length disappear simultaneously.

Vanishing cylinder diameter and length correspond to:

Therefore, the time required for the cylinder diameter and length to disappear are

respectively. It can be concluded that the three end states described above correspond to:

This finding is corroborated by (39), which has two solutions (roots) when \(m/m(0) = 0 : \Delta =D(0)/2\) and \(\Delta =L(0)/2\). Because the solid cylinder is a physical object that experiences progressive degradation over time, only the smaller of the two roots that satisfy (39) has any real significance. The larger \(\Delta\) value is irrelevant because the cylinder no longer exists after the smaller \(\Delta\) value has been attained during degradation. Hence, when \(m/m(0) = 0\) and \(L(0)>D(0)\) the only meaningful solution of (39) is \(\Delta =D(0)/2\), whereas when \(L(0)<D(0)\) the only meaningful solution is \(\Delta =L(0)/2\).

In summary, at the threshold (42), the cylinder diameter and length disappear simultaneously at complete disintegration \([m/m\left(0\right) = 0]\). We can now define rods as solid cylinders with \(L(0)>D(0)\) and thus dominated by a degrading diameter. Discs are likewise defined as solid cylinders with \(L(0)<D(0)\) and thus dominated by a degrading length. Finally, the end state for (45a) is a solid rod that has an infinitesimal diameter and has shortened by the amount \(D\left(0\right) [L=L\left(0\right)-D(0)]\), as illustrated in Fig. 3. Similarly, the end state of (45b) is a solid disc with an infinitesimal thickness and a diameter that has decreased by the amount \(L\left(0\right) [D=D(0)-L(0)]\). The threshold \({(\Delta }_{DL})\) and convergence to the rod and disc limits (\({\Delta }_{D}\) and \({\Delta }_{L}\)) are shown in Fig. 8.

Numerical Solution

Equation (39) is a cubic equation involving the variable ∆. The roots of (39) are established in Appendix B using Cardano’s formula [27], which yields different relationships for positive and negative values of its discriminant. Solving (39) numerically is prioritized herein due to its ability to quickly identify the root with the smallest value—the only one that is physically meaningful. Nevertheless, Appendix B is available for readers that prefer a closed-form solution and/or wish to define all of the roots.

Equation (39) can be written in nondimensional form:

The results of (46) are plotted in Fig. 9 for the state of complete disintegration \([m/m(0)=0]\) and for several \(L(0)/D(0)\) values. Because \(2\Delta\) may not exceed the diameter size, only roots within the range \(0\le \Delta /D(0)\le 0.5\) are physically meaningful. For values of \(L(0)/D\left(0\right)\) less than unity, there are two roots within this range, the first of which \([\Delta /D\left(0\right)=\frac{1}{2}L\left(0\right)/D\left(0\right)]\) is determinative. For values of \(L(0)/D(0)\) greater than unity, there is a single valid root at \(\Delta /D(0)=0.5\). Therefore, when \(L(0)/D(0)<1\), \({\Delta }_{L}=L(0)/2\) is the value at the origin of ∆ vs. \(m/m(0)\) curves, while the origin is at \({\Delta }_{D}=D(0)/2\) when \(L(0)/D(0)>1\).

Results of (46) for complete disintegration \(\left[m/m(0)=0\right]\)

A numerical sweep, with a small incremental step size, could be conducted over a broad \(\Delta /D(0)\) range to home in on the roots of (46), given the inputs \(L(0)/D(0)\) and \(m/m(0)\). The Newton–Raphson method [10] is advocated instead, due to its superior efficiency and precision. The following compressed version of (46) facilitates use of the Newton–Raphson method:

The derivative of (47) with respect to z (i.e., the slope of the tangent line at the value z) is given by

In the Newton–Raphson method, an initial estimate of the root (denoted \({z}_{o}\)) and the tangent of \(f(z)\) at \({z}_{o}\) are used to improve the accuracy of the initial estimate:

This first iteration, \({z}_{1}\), is then used to compute a second one, \({z}_{2}\), and so on, according to the general relationship:

Our experience using (50) indicates that all small values of \({z}_{o}\) consistently yield iterations that rapidly converge to the solution of (46). No more than four iterations are typically needed to achieve accuracy greater than three significant digits.

Effect of Cylinder Ends

For hollow cylinders, a Taylor series expansion was used to derive a factor \({F}_{h}\) (30) that modifies the limit \({\Delta }_{W}\) (13) to account for mass loss due to degradation of the cylinder ends. The closed-form solution in Appendix B for solid cylinders cannot be easily expressed as a similar expansion. Instead, the results \(\Delta /D(0)\) of (46) for given values of \(m/m(0)\) and \(L(0)/D(0)\) were divided by the nondimensional term \({\Delta }_{D}/D(0)\) (40) to define a factor \({F}_{s}\) for solid cylinders that is analogous to \({F}_{h}\) for hollow cylinders:

The values of \({F}_{s}\) computed in this manner are exact. The variation of \({F}_{s}\) with respect to \(L(0)/D(0)\) is shown in Fig. 10 for five values of \(m/m(0)\). These curves can be used to quickly approximate \(\Delta\) for given values of \(L(0)/D(0)\) and \(m/m(0)\), instead of employing the Newton–Raphson method or the exact solution of (39) in Appendix B.

As expected, \({F}_{s }\) in Fig. 10 approaches unity as \(L(0)/D(0)\) increases. That is, surface erosion tends toward the limit \({\Delta }_{D}\) as the solid cylinder lengthens. As \(L(0)/D(0)\) decreases, the value of \({F}_{s}\) plummets, reflecting the fact that the limit for a long solid cylinder must be modified markedly to represent surface erosion for a thin disc. For hollow cylinders (Fig. 4), as \(L(0)/{D}_{o}(0)\) decreases, the shape becomes a thin washer-like ring and \({F}_{h}\) approaches \(L(0)/W(0)\) (31b), which is independent of mass loss because \({\Delta }_{W}\) (13) and \({\Delta }_{L}\) (14) are both functions of \([1-m/m(0)]\). In contrast, the limits for solid cylinders, i.e., \({\Delta }_{D}\) (40) and \({\Delta }_{L}\) (41), do not share the same relationship with respect to \(m/m(0)\) such that \({F}_{s}\) is a function of mass loss as the cylinder becomes a thin disc. Using (40) and (41), it can be shown that as \(L(0)/D(0)\) diminishes

Rod and Disc Examples

Applications of the Newton–Raphson method to solve (39) are provided in Figs. 11 and 12. Figure 11 shows surface erosion as a function of \(m/m(0)\) for a disc with a 20-cm diameter and four different lengths. The deviation from the limit \({\Delta }_{L}\) for \(L(0) = 4\mathrm{ cm} [L\left(0\right)/D\left(0\right) = 0.2]\) is due to the contribution of degradation on the periphery of the disc to total mass loss. As expected, agreement with the limit improves as \(L(0)\) decreases. For discs less than one cm thick \([L\left(0\right)/D\left(0\right)\le 0.05]\) the exact solution is effectively equal to \({\Delta }_{L}\). Figure 12 shows surface erosion for a solid cylinder with a 3-cm diameter and four different lengths. The dashed curve for \(L(0)=3\mathrm{ cm }[L\left(0\right)/D\left(0\right)= 1]\) represents the threshold \({\Delta }_{DL}\) (42). For cylinders longer than 3 cm, the results correspond to rods and converge to \({\Delta }_{D}\) as \(L(0)\) increases. Cylinders shorter than 3 cm correspond to discs and converge to \({\Delta }_{L}\) as \(L(0)\) decreases.

Finally, Fig. 13 displays the ratio of surface erosion values for a solid cylinder \({\Delta }_{S}\) (42) and for a hollow cylinder \({\Delta }_{H}\) (18) when both have a 3-cm length and a 3-cm diameter. The effect of different wall thicknesses \(\left[W(0)/{D}_{o}(0)\right]\) for the hollow cylinder is shown. Employing the same logic as in Sect. “Delineation between Discs and Rods”, this ratio k represents the multiple of time required for the solid cylinder \({(t}_{S})\) to attain the same \(m/m(0)\) value as that for the hollow cylinder (\({t}_{H}\)):

From (34a) and (44a), it is evident that at complete disintegration \(\left[m/m(0)=0\right]\)

The hollow cylinder undergoes faster relative mass loss than the solid cylinder because the former experiences degradation on two surfaces rather than on just one (2). As expected, k decreases as the wall thickness of the hollow cylinder increases. Figure 13 suggests that hollow cylinders, even when they have relatively thick walls, are a more effective geometry for rapid drug delivery than solid cylinders, provided that the interior and exterior of in-vivo hollow medical devices can indeed degrade at the same rate.

Surface Erosion for Biomedical Devices

No publications were found to compare with the theory in Sect. “Hollow Cylinders”. Concerning surface erosion of solid cylinders, three publications from the biomedical field provided some corroboration [16, 18, 25]. Equations are derived in [25] for controlled drug release from spheres, solid cylinders, and slabs (referred to as discs herein). Degradation of cylinder ends is not accounted for in [25]. The equations for drug release from solid cylinders and slabs have the same form as the limits \({\Delta }_{D}\) (40) and \({\Delta }_{L}\) (41). A computational grid is constructed in [18] for simulating the degradation of solid discs with \(L(0)<D(0)\). The plotted trends of \(m/m(0)\) vs. \(L(0)/D(0)\) in [18] are consistent with those in Fig. 8. Surface erosion of 3D-printed solid cylinders with \(L(0)\le D(0)\) are studied in [16]. The \(m/m(0)\) time series in [16] for experiments with low values of \(L(0)/D(0)\) are roughly linear, consistent with (41), and the curve fits of experimental results for cylinders with \(L(0)=D(0)\) show the best agreement when a cubic function is used, which is consistent with (42).

Importantly, it is stated in [16] that the ratio of surface area to volume is an essential parameter in drug delivery. For arbitrary values of \(L(0)\) and \(D(0)\) for solid cylinders, the ratio \(A/V\) can be computed using (36) and (37) after the value of \(\Delta\) has been established by the solution of (39). However, solid cylinders with \(L(0)=D(0)\) are emphasized in [16], and a closed-form surface erosion equation is available for this special case. Substituting (42) into (36) and (37) provides a simple expression for the surface-area-to-volume ratio when the cylinder length and diameter are equal:

Revisiting hollow cylinders, it can be shown that substituting (18) into (9a) and (10a) yields the following surface-area-to-volume ratio for arbitrary values of \(L(0)\) and \(W(0)\):

When the length and wall thickness of the hollow cylinder are equal, (56a) reduces to:

Square Cross Sections

The derivations thus far have addressed hollow and solid circular cross sections. In this final set of derivations, it will be shown that these equations also generally apply to hollow and solid square cross sections.

Hollow Square Prisms

This shape encompasses square plates and square tubes, both with a central square hole. The degradation model is shown in Fig. 14. The time-varying volume and exposed area of a degrading hollow square prism are defined by

Therefore, the initial mass and instantaneous mass are given by

The ratio of (59a) and (59b) yields the relationship

Equations (12) and (60) are exactly the same. Therefore, all of the equations, limits, and figures based on (12) for hollow cylinders also apply for hollow square prisms, provided that \({D}_{o}(0)\), \({D}_{i}(0)\), and \(W(0)\) are now defined by Fig. 14. Using (57) and (58), it is easy to show that (22) is valid, such that \(\lambda =r/\rho\) for arbitrary values of \({D}_{o}(0)\), \(L(0)\), and \(W(0)\) for a hollow square prism.

Solid Square Prisms

This shape encompasses square plates and films, rods with a solid square cross-section, and cubes. The degradation model is shown in Fig. 14. The time-varying volume and exposed area of a degrading solid square prism are defined by

Therefore, the initial mass and instantaneous mass are given by

The ratio of (63a) and (63b) yields the relationship

Equations (39) and (64) are exactly the same. Therefore, all of the equations, limits, and figures based on (39) for solid cylinders also apply for solid square prisms, provided that \(D(0)\) is now defined by Fig. 14. Using (61) and (62) it can be shown that (22) is valid, such that \(\lambda =r/\rho\) for arbitrary values of \(D(0)\) and \(L(0)\) for a solid square prism.

Finally, note that a cube is a solid square prism with \(L(0)=D(0)\). Experiments were conducted in [16] with 3-D printed cubes. Using (42), (61) and (62) it can be shown that the ratio \(A/V\) for cubes is also defined by (55), where \(D(0)\) now represents the length and width of the sides of the cube.

Results for PHA Straws

Recall that PHA straws and tubes are used in our patent-pending fence design to protect coral transplants from parrotfish predation [48]. Photos were taken by a team of divers to monitor predation at the following times during the experiments: at deployment, at 24 h, at one week, and at one month, two months, three months, and four months. Dive surveys ceased at the four-month mark. Photos 3, 4, and 5 show that the Phade straws were intact after one month in the benthic environment of Southeast Florida, but had collapsed before the dive survey at the end of the second month [48]. However, it is unclear from Photo 5 if remnants of the straws were present on the cement disc or ocean floor, or were possibly displaced by currents. Thus, it cannot be firmly established that complete disintegration of the straws occurred by the two-month mark. At four months, the Humidi tubes, which have a larger diameter and wall thickness than the Phade straws, were still intact [48]. Photos 3, 4, and 5 indicate that the fence protected the coral fragment from predation and that corallivores did not bite the fragment after the fence collapsed, which was the desired outcome.

Our evidence of disintegration of PHA straws can be used to create a comparison with the \(\overline{r }\) values presented in [13] for PHA biodegradation in the overall marine environment. Figure 6 supports the use of \({\Delta }_{W}\) (13) for surface erosion of both Humidi tubes and Phade straws. It has also been shown that \(\lambda =r/\rho\) is valid for all hollow cylinder configurations (20). Therefore, (2) yields the simple relationship

where \(\overline{\lambda }\) and \(\overline{r }\) are the average values of the surface erosion rate and of the specific rate of mass loss, respectively, over the lifetime of the straw; \(S=2\), because the inner and outer surfaces of the straw are assumed to degrade uniformly; \(\rho = 1.34\mathrm{ g}/{\text{cm}}^3\); \({h}_{m }= 0.0178\mathrm{ cm}\); and \({t}_{d}\) equals two months.Footnote 9 Interestingly, disintegration of Phade straws around two months after deployment in the benthic environment corresponds closely with complete disintegration of a Phade straw at day 58 in a time-lapse video of biodegradation in a saltwater aquarium [47]. Using these input values, (65) yields \(\overline{r }=0.20\mathrm{ \,mg}/({{\text{cm}}}^{2}\mathrm{ \,day})\) for our offshore experiments.

Appendix A of [13] provides 14 data points \(\overline{r }\) for PHA biodegradation in a broad range of marine environments. The test sites included harbors in Poland, Belgium, and France; the coastal waters of Japan and Vietnam; and a mangrove island and reef in Puerto Rico. The \(\overline{r }\) value from our experiments was added to this data set. The frequency of the resulting 15 data points is plotted in Fig. 15 using bins of size 0.02. The mean, with 95% confidence, of the expanded data set does not differ significantly from that reported in [13]. However, our \(\overline{r }\) value for PHA straws on the ocean floor in Southeast Florida is notably the largest.

Frequency, in bins, of the 14 data points reported in [13] for PHA biodegradation in the marine environment, plus the \(\overline{r }\) value from our experiments for PHA straws, assuming uniform surface erosion and disintegration two months after deployment

There are several environmental factors at the various test sites that could have contributed to the dispersion of the data in Fig. 15. These include temperature, location in the water column, the density and composition of the microbial community, nutrient levels, pH, salinity, UV exposure, and dissolved oxygen [13, 35, 55, 61].

Eleven of the 14 experiments reported in [13] were conducted with PHA samples suspended in the water column. A possible explanation for our rather large value of \(\overline{r }\) is that, except in the deep sea, microbial abundance in the benthos is typically greater than in the water above it [61]. Thus, the ocean floor is generally more advantageous for biodegradation. In addition, contact with sediment is known to significantly affect biodegradation rates [11, 13]. The straws in our parrotfish deterrence fence pass all the way through the cement disc, so they are exposed to the substrate on which the disc is attached. Microbes, therefore, have access to the straw’s interior at both the top and bottom ends.

As mentioned in Footnote 4, there is considerable uncertainty regarding biodegradation inside of long tubes and straws. Note that, if surface erosion on the interior of the straws in our experiments were negligible, the scalar S in (65) would equal unity because, in that case, degradation only occurred on the straw’s outer surface (cf. Figure 2). Without degradation on the interior, our value of \(\overline{r }\), based on uniform surface erosion, would double to 0.40 mg/(cm2 day), which is over seven standard deviations above the mean of the data reported in [13]. It is improbable that the ocean benthos in Southeast Florida is such an enormous departure from the diverse marine environments represented in the meta-study. Therefore, (65) provides prima facie evidence that substantial surface erosion occurred on the interior of the Phade straws used in our experiments.Footnote 10

Conclusion

Equations were derived that predict the surface erosion of plastic materials with circular or square cross sections, that are solid or hollow, and that are of arbitrary length. Implementation of these equations only requires the original dimensions of the shape and mass measurements taken during the degradation process, or, more crudely, adoption of an erosion rate function from a previous degradation study. The theory did not assume or employ a constant rate of degradation. Instead, a novel procedure was developed for computing time-varying values of the rate of degradation using experimental mass loss measurements and a mathematical model for the 3D object’s shape. It was assumed that erosion occurs uniformly over all of the exposed surfaces of the object. Modification of the degradation model to account for closure of the ends, or diminished degradation within the interior of hollow cross sections, could be introduced. The derivations established how surface erosion characteristics can change based on the ratio of length to wall thickness (for hollow cross sections) and length to diameter (for solid cross sections). The biodegradation of PHA drinking straws on the ocean floor was also briefly studied. These offshore experiments appear to be the first to exhibit disintegration (and thus establish the actual lifetime) of a 3D plastic object in the marine environment. Only relatively thin tubes and straws are used in our parrotfish deterrence fence - the motivation for this surface erosion study. It is hoped that the generality maintained during the mathematical development may benefit degradation studies in other research areas. Nothing in the derivations limits application of the equations to biodegradation in the marine environment, nor to any particular plastic material. It is only required that (biotic or abiotic) surface erosion dominate over the lifetime of the degrading object.

Notes

The death phase of classic bacterial growth curves is not evident in any of the mass loss vs. time data found in the literature for PHA biodegradation. This is expected because, if mass loss is indeed correlated with microbial density, the gradual death of the microbes attached to the biopolymer would slowly halt mass loss of the object, not allow it to somehow be recovered by the biopolymer. An emergent plateau in the biodegradation curve, therefore, is consistent with the death phase of microbial growth. Moreover, a lag between microbial growth and biodegradation is expected because it takes time for enzymes secreted by the microbes to induce mass loss. Thus, the measured rapid increase in mass loss evident in many biodegradation curves, by definition, must trail the exponential growth of microbes attached to the plastic material. Finally, during the stationary phase, while microbial density is stable but not increasing, the rate of mass loss should diminish relative to that during the exponential phase of bacterial growth. All of these characteristics are indeed evident in [23]. The correlation between microbial growth and biodegradation merits further study.

In the literature on degradation, the ratio of the instantaneous mass to the original mass has been expressed as: \(\frac{{M}_{t}}{{M}_{o}}\) [16], \(\frac{{m}_{t}}{{m}_{o}}\) [36], and \(\frac{m(t)}{m(0)}\) [18, 19].

To maintain brevity in the notation while preserving the subscript niche for other important designations, a subscripted or bracketed value t is not used to indicate an instantaneous variable. Instead, initial values are denoted by a zero with brackets. The absence of a bracketed zero indicates that the function varies with time. Accordingly, the ratio of the instantaneous mass and initial mass is written as \(m/m(0)\). A table of the symbols used in the present theory is provided in Appendix A.

Degradation of one or both ends of the cylinder could be omitted if the cylinder is fastened. Degradation on the interior of the cylinder wall could also be scaled down or omitted if the cylinder is sealed at the ends, or if the microbial density, oxygen level, or nutrient supply are significantly less than on the cylinder’s outer surface. The latter quantities are expected to be most important for tubes that are long relative to the size of the inner diameter. In other words, degradation on the cylinder’s interior likely tends to zero as \(L(0)/{D}_{i}(0)\) increases. It is believed that uniform degradation is a reasonable initial assumption from which refinements can be introduced. It is also a plausible limiting case, because surface erosion on the interior of the cylinder is expected to be bounded by (i.e., no greater than) the surface erosion on the exterior.

As \(L(0)\) becomes small relative to the diameter \({D}_{o}(0)\), this ‘length’ measurement is better referred to as the thickness of the object. However, to avoid confusion with the tube wall thickness \(W(0)\), the nomenclature \(L(0)\) is retained, even for thin objects like hollow rings and solid discs.

If \(L(0)\gg W(0)\), then according to (13), \(\Delta \le W(0)/2\). Therefore,

$$\frac{4\Delta }{L(0)+W(0)} \le \frac{2W(0)}{L(0)+W(0)}= \frac{2W(0)/L(0)}{1+W(0)/L(0)}\to 0\, \mathrm{as }\frac{W(0)}{L(0)}\to 0$$If \(L(0)\ll W(0)\), then according to (14), \(\Delta \le L(0)/2\). Therefore,

$$\frac{4\Delta }{L(0)+W(0)} \le \frac{2L(0)}{L(0)+W(0)}=\frac{2L(0)/W(0)}{1+L(0)/W(0)}\to 0\, \mathrm{as }\frac{L(0)}{W(0)}\to 0$$Consequently, in both of the limiting cases,

$$\frac{A}{A(0)}=1-\frac{4\Delta }{L(0)+W(0)} \to 1$$Backward differencing for numerical differentiation [32] is shown in (25a) and (25c). Forward differencing (which employs \({\Delta }_{i}\) and \({\Delta }_{i+1}\)) and central differencing (which employs \({\Delta }_{i-1}\) and \({\Delta }_{i+1}\)) could be implemented instead [32]. The latter is the most accurate of the three, but it is only applicable if the time intervals bracketing \({m}_{i}\) are of the same size [32].

For all values of \(m/m\left(0\right)<1\), the partial derivatives \(\partial\Delta /\partial L(0)\) and \(\partial\Delta /\partial W(0)\) of (18) are simultaneously equal to zero only when \(L\left(0\right)\equiv W\left(0\right)\). Therefore, for any given value of \(L\left(0\right)\) or \(W\left(0\right)\) there exists a single critical point \(\Delta \left[L\left(0\right),W\left(0\right)\right]=\Delta \left[L\left(0\right),L\left(0\right)\right]=\Delta \left[W\left(0\right),W\left(0\right)\right]\). The discriminant \(\left[{\partial }^{2}\Delta /{\partial L(0)}^{2}\right]\left[{\partial }^{2}\Delta /{\partial W(0)}^{2}\right]-{\left[{\partial }^{2}\Delta /\partial L(0)\partial W(0)\right]}^{2}\) of (18) equals zero when \(L\left(0\right)\equiv W(0)\), such that the second derivative test is inconclusive, and thus cannot establish whether the critical point is a local minimum, maximum, or saddle point. Nevertheless, the condition when \(L\left(0\right)\equiv W(0)\), which is herein referred to as the threshold at which \(\Delta\) tends toward either (13) or (14), can be understood by simply contemplating the evolution of the hollow cylinder’s geometry during uniform degradation.

The wall thickness and density values were provided by Phade. The latter is somewhat larger than 1.25 g/cm3, the value commonly reported for PHA [44, 51]. The \(\overline{r }\) value can also be calculated using (25c), where the time from deployment to full disintegration \(= \left({t}_{i}-{t}_{i-1}\right) \sim 60\mathrm{ \,days}\), \(\left({m}_{i}-{m}_{i-1}\right)=-m(0)=-506.14\mathrm{ \,mg}\), and \(A(0)=42.52\mathrm{ \,cm}^2\). As discussed in Sect. “Degradation Time Series”, the instantaneous rate of surface erosion \(\lambda\) may deviate significantly from the average value \(\overline{\lambda }\) over the lifetime of the straw. A more sophisticated biodegradation analysis using equations in Sect. “Hollow Cylinders” could not be conducted for the offshore experiments because the mass of the straws was not measured after the parrotfish deterrence fences were attached to the ocean floor.

Definitive proof of uniform degradation for tubes and straws requires experimental measurements of the inner and outer diameters (or of the outer diameter and wall thickness) at locations along the length, and at several instances over the polymer lifetime. Moreover, a thorough study of spatial variations in surface erosion for tubes and straws would assess a broad range of initial lengths and inner diameters. Recall that footnote 4 hypothesizes that biotic degradation on the interior of tubes and straws tends to zero as \(L\left(0\right)/{D}_{i}(0)\) increases.

References

Alvarez-Filip L, Estrada-Saldívar N, Pérez-Cervantes E, Molina-Hernández A, González-Barrios F (2019) A rapid spread of the stony coral tissue loss disease outbreak in the mexican caribbean. PeerJ 7:e8069. https://doi.org/10.7717/peerj.8069

Alvarez-Filip L, González-Barrios FJ, Pérez-Cervantes E, Molina-Hernández A, Estrada-Saldivar N (2022) Stony coral tissue loss disease decimated caribbean coral populations and reshaped reef functionality. Commun Biol 5:440. https://doi.org/10.1038/s42003-022-03398-6

Baidurah S (2022) Methods of analyses for biodegradable polymers: a review. Polym 14:4928. https://doi.org/10.3390/polym14224928

Boey JY, Mohamad L, Khok YS, Tay GS, Baidurah S (2021) A review of the applications and biodegradation of polyhydroxyalkanoates and poly(lactic acid) and its composites. Polym 13:1544. https://doi.org/10.3390/polym13101544

Bugnicourt E, Cinelli P, Lazzeri A, Alvarez V (2014) Polyhydroxyalkanoate (PHA): review of synthesis, characteristics, processing and potential applications in packaging. eXPRESS Polym Lett 8:791–808. https://doi.org/10.3144/expresspolymlett.2014.82

Canuto C, Tabacco A (2008) Taylor expansions and applications. In: Mathematical Analysis I. Universitext. Springer, Milano. https://doi.org/10.1007/978-88-470-0876-2_7

Catano LB, Rojas MC, Malossi RJ, Peters JR, Heithaus MR, Fourqurean JW, Burkepile DE (2016) Reefscapes of fear: predation risk and reef heterogeneity interact to shape herbivore foraging behaviour. J Anim Ecol 85:146–156. https://doi.org/10.1111/1365-2656.12440

Chamas A, Moon H, Zheng J, Qiu Y, Tabassum T, Jang JH, Abu-Omar M, Scott SL, Suh S (2020) Degradation rates of plastics in the environment. ACS Sustain Chem Eng 8:3494–3511. https://doi.org/10.1021/acssuschemeng.9b06635

Collet C, Vaidya AA, Gaugler M, West M, Lloyd-Jones G (2022) Extrusion of PHA-containing bacterial biomass and the fate of endotoxins: a cost-reducing platform for applications in molding, coating and 3D printing. Mater Today Commun 33:104162. https://doi.org/10.1016/j.mtcomm.2022.104162

Dedieu J-P (2015) Newton-Raphson method. In: Engquist B (ed) Encyclopedia of Applied and Computational Mathematics. Springer, Berlin. https://doi.org/10.1007/978-3-540-70529-1_374

Deroiné M, César G, Le Duigou A, Davies P, Bruzaud S (2015) Natural degradation and biodegradation of poly (3-hydroxybutyrate-co-3-hydroxyvalerate) in liquid and solid marine environments. J Polym Environ 23:493–505. https://doi.org/10.1007/s10924-015-0736-5

Deroiné M, Le Duigou A, Corre Y-M, Le Gac P-Y, Davies P, César G, Bruzaud S (2014) Seawater accelerated ageing of poly(3-hydroxybutyrate-co-3-hydroxyvalerate). Polym Degrad Stab 105:237–247. https://doi.org/10.1016/j.polymdegradstab.2014.04.026

Dilkes-Hoffman LS, Lant PA, Laycock B, Pratt S (2019) The rate of biodegradation of PHA bioplastics in the marine environment: a meta-study. Mar Pollut Bull 142:15–24. https://doi.org/10.1016/j.marpolbul.2019.03.020

Florida Department of Environmental Protection. Coral Reef Conservation Program 2020–2025 Strategic Plan. https://floridadep.gov/rcp/coral/documents/dep-coral-reef-conservation-program-2020-2025-strategic-plan. Accessed 23 Jan 2024

Ganesh Kumar A, Anjana K, Hinduja M, Sujitha K, Dharani G (2020) Review on plastic wastes in marine environment—biodegradation and biotechnological solutions. Mar Pollut Bull 150:110733. https://doi.org/10.1016/j.marpolbul.2019.110733

Geraili A, Mequanint K (2020) Systematic studies on surface erosion of photocrosslinked polyanhydride tablets and data correlation with release kinetic models. Polym 12:1105. https://doi.org/10.3390/polym12051105

Göpferich A (1996) Mechanisms of polymer degradation and erosion. In: Williams DF (ed) The Biomaterials: silver jubilee compendium. Elsevier Science, Amsterdam. https://doi.org/10.1016/B978-008045154-1.50016-2

Göpferich A, Langer R (1995) Modeling of polymer erosion in three dimensions: rotationally symmetric devices. AlCheE J 41:2292–2299. https://doi.org/10.1002/aic.690411012

Göpferich A, Tessmar J (2002) Polyanhydride degradation and erosion. Adv Drug Deliv Rev 54:911–931. https://doi.org/10.1016/S0169-409X(02)00051-0

Harrell C, Lirman D (2023) Dictyota defense: developing effective chemical protection against intense fish predation for outplanted massive corals. PeerJ 11:e14995. https://doi.org/10.7717/peerj.14995

Heimowska A, Morawska M, Bocho-Janiszewska A (2017) Biodegradation of poly(ε-caprolactone) in natural water environments. Pol J Chem Tech 19:120–126. https://doi.org/10.1515/pjct-2017-0017

Henry JA, O’Neil KL, Pilnick AR, Patterson JT (2021) Strategies for integrating sexually propagated corals into caribbean reef restoration: experimental results and considerations. Coral Reefs 40:1667–1677. https://doi.org/10.1007/s00338-021-02154-2

Hermida ÉB, Yashchuk O, Miyazaki SS (2009) Changes in the mechanical properties of compression moulded samples of poly(3-hydroxybutyrate-co-3-hydroxyvalerate) degraded by Streptomyces omiyaensis SSM 5670. Polym Degrad Stab 94:267–271. https://doi.org/10.1016/j.polymdegradstab.2008.10.019

Hing CL, Guifarro Z, Dueñas D, Ochoa G, Nunez A, Forman K, Craig N, McField M (2022) Management responses in Belize and Honduras, as stony coral tissue loss disease expands its prevalence in the Mesoamerican reef. Front Mar Sci 9:883062. https://doi.org/10.3389/fmars.2022.883062

Hopfenberg HB (1976) Controlled release from erodible slabs, cylinders, and spheres. In: Paul DR, Harris FW (eds) Controlled release polymeric formulations. ACS Sym Ser, Amer Chem Soc, Washington, DC. https://doi.org/10.1021/bk-1976-0033.ch003

Imam SH, Gordon SH, Shogren RL, Tosteson TR, Govind NS, Greene RV (1999) Degradation of starch-poly(β-hydroxybutyrate-co-β-hydroxyvalerate) bioplastic in tropical coastal waters. Appl Environ Microbiol 65:431–437. https://doi.org/10.1128/aem.65.2.431-437.1999

Irving R (2013) Beyond the quadratic formula. Math Assoc of Amer, Inc., Washington, DC

Ivorra-Martinez J, Peydro MÁ, Gomez-Caturla J, Sanchez-Nacher L, Boronat T, Balart R (2023) The effects of processing parameters on mechanical properties of 3D-printed polyhydroxyalkanoates parts. Virt Phys Prototyp 18:e2164734. https://doi.org/10.1080/17452759.2022.2164734

Kalia VC, Patel SKS, Lee J-K (2023) Exploiting polyhydroxyalkanoates for biomedical applications. Polym 15:1937. https://doi.org/10.3390/polym15081937

Kaniuk L, Stachewicz U (2021) Development and advantages of biodegradable PHA polymers based on electrospun PHBV fibers for tissue engineering and other biomedical applications. ACS Biomater Sci Eng 7:5339–5362. https://doi.org/10.1021/acsbiomaterials.1c00757

Kasuya K-i, Takagi K-o, Ishiwatari S-i, Yoshida Y, Doi Y (1998) Biodegradabilities of various aliphatic polyesters in natural waters. Polym Degrad Stab 59:327–332. https://doi.org/10.1016/S0141-3910(97)00155-9

Kong Q, Siauw T, Bayen AM (2021) Chapter 20 – Numerical differentiation. In: Python programming and numerical methods: A guide for engineers and scientists. Academic Press, Cambridge. https://doi.org/10.1016/C2018-0-04165-1

Koval G, Rivas N, D’Alessandro M, Hesley D, Santos R, Lirman D (2020) Fish predation hinders the success of coral restoration efforts using fragmented massive corals. PeerJ 8:e9978. https://doi.org/10.7717/peerj.9978

Laycock B, Nikolic M, Colwell JM, Gauthier E, Halley P, Bottle S, George G (2017) Lifetime prediction of biodegradable polymers. Prog Polym Sci 71:144–189. https://doi.org/10.1016/j.progpolymsci.2017.02.004

Lott C, Eich A, Makarow D, Unger B, van Eekert M, Schuman E, Reinach MS, Lasut MT, Weber M (2021) Half-life of biodegradable plastics in the marine environment depends on material, habitat, and climate zone. Front Mar Sci 8:662074. https://doi.org/10.3389/fmars.2021.662074

Maga D, Galafton C, Blömer J, Thonemann N, Özdamar A, Bertling J (2022) Methodology to address potential impacts of plastic emissions in life cycle assessment. Int J LCA 27:469–491. https://doi.org/10.1007/s11367-022-02040-1

Mallela J, Fox RJ (2018) The role of parrotfishes in the destruction and construction of coral reefs. In: Hoey AS, Bonaldo RM (eds) Biology of parrotfishes. CRC Press, New York

Marcus MA, Amini S, Stifler CA, Sun C-Y, Tamura N, Bechtel HA, Parkinson DY, Barnard HS, Zhang XXX, Chua JQI, Miserez A, Gilbert PUPA (2017) Parrotfish teeth: stiff biominerals whose microstructure makes them tough and abrasion-resistant to bite stony corals. ACS Nano 11:11856–11865. https://doi.org/10.1021/acsnano.7b05044

Marichal J-L, Dorff M (2007) Derivative relationships between volume and surface area of compact regions in Rd. Rocky Mt J Math 37:551–571. https://doi.org/10.1216/rmjm/1181068766

Meereboer KW, Misra M, Mohanty AK (2020) Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem 22:5519–5558. https://doi.org/10.1039/D0GC01647K

Mergaert J, Wouters A, Swings J, Anderson C (1995) In situ biodegradation of poly(3-hydroxybutyrate) and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) in natural waters. Can J Microbiol 41:154–159. https://doi.org/10.1139/m95-182

Molitoris HP, Moss ST, de Koning GJM, Jendrossek D (1996) Scanning electron microscopy of polyhydroxyalkanoate degradation by bacteria. Appl Microbiol Biotechnol 46:570–579. https://doi.org/10.1007/s002530050863

Muller EM, Sartor C, Alcaraz NI, van Woesik R (2020) Spatial epidemiology of the stony-coral-tissue-loss disease in Florida. Front Mar Sci 7:163. https://doi.org/10.3389/fmars.2020.00163

Naser AZ, Deiab I, Darras BM (2021) Poly(lactic acid) (PLA) and polyhydroxyalkanoates (PHAs), green alternatives to petroleum-based plastics: a review. RSC Adv 11:17151–17196. https://doi.org/10.1039/D1RA02390J

Page CA, Muller EM, Vaughan DE (2018) Microfragmenting for the successful restoration of slow growing massive corals. Ecol Eng 123:86–94. https://doi.org/10.1016/j.ecoleng.2018.08.017

Palmeiro-Sánchez T, O’Flaherty V, Lens PNL (2022) Polyhydroxyalkanoate bio-production and its rise as biomaterial of the future. J Biotechnol 348:10–25. https://doi.org/10.1016/j.jbiotec.2022.03.001

Phade. Straws shouldn’t last centuries. https://www.phadeproducts.com/timelapse/#. Accessed 23 Jan 2024

Pisano K (2023) Coral castles: Protecting polyps from parrotfish predation. Master’s thesis. Nova Southeastern University. https://nsuworks.nova.edu/hcas_etd_all/149. Accessed 23 Jan 2024

Ribba L, Lopretti M, de Oca-Vásquez GM, Batista D, Goyanes S, Vega-Baudrit JR (2022) Biodegradable plastics in aquatic ecosystems: latest findings, research gaps, and recommendations. Environ Res Lett 17:033003. https://doi.org/10.1088/1748-9326/ac548d

Rivas N, Hesley D, Kaufman M, Unsworth J, D’Alessandro M, Lirman D (2021) Developing best practices for the restoration of massive corals and the mitigation of predation impacts: influences of physical protection, colony size, and genotype on outplant mortality. Coral Reefs 40:1227–1241. https://doi.org/10.1007/s00338-021-02127-5

Samir A, Ashour FH, Abdel Hakim AA, Bassyouni M (2022) Recent advances in biodegradable polymers for sustainable applications. npj Mater Degrad 6:68. https://doi.org/10.1038/s41529-022-00277-7

Schechter E. The cubic formula (solving any 3rd degree polynomial equation). Vanderbilt Univ. https://math.vanderbilt.edu/schectex/courses/cubic/. Accessed 23 Jan 2024

Smith KM, Chamberlain L, Whitaker S, Kimbrel A, Childress MJ (2023) Factors influencing stoplight parrotfish territoriality and social structure in the middle Florida Keys. Environ Biol Fish 106:585–595. https://doi.org/10.1007/s10641-023-01394-1

Smith KM, Pharo DM, Shea CP, Reckenbeil BA, Maxwell KE, Sharp C (2021) Recovery from finfish predation on newly outplanted boulder coral colonies on three reefs in the Florida Keys. Bull Mar Sci 97:337–350. https://doi.org/10.5343/bms.2020.0056

Suzuki M, Tachibana Y, Kasuya K-i (2021) Biodegradability of poly(3-hydroxyalkanoate) and poly(ε-caprolactone) via biological carbon cycles in marine environments. Polym J 53:47–66. https://doi.org/10.1038/s41428-020-00396-5

Tanadchangsaeng N, Pattanasupong A (2022) Evaluation of biodegradabilities of biosynthetic polyhydroxyalkanoates in Thailand seawater and toxicity assessment of environmental safety levels. Polym 14:428. https://doi.org/10.3390/polym14030428

Testbook Edu Solutions (2023) Descartes rule of signs: Definitions, state, proof, chart, table, uses, applications and solved examples. https://testbook.com/maths/descartes-rules-of-signs. Accessed 23 Jan 2024

Vanheusden C, Samyn P, Goderis B, Hamid M, Reddy N, Ethirajan A, Peeters R, Buntinx M (2021) Extrusion and injection molding of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBHHx): influence of processing conditions on mechanical properties and microstructure. Polym 13:4012. https://doi.org/10.3390/polym13224012

Volova TG, Boyandin AN, Vasiliev AD, Karpov VA, Prudnikova SV, Mishukova OV, Boyarskikh UA, Filipenko ML, Rudnev VP, Xuân BB, Dung VV, Gitelson II (2010) Biodegradation of polyhydroxyalkanoates (PHAs) in tropical coastal waters and identification of PHA-degrading bacteria. Polym Degrad Stab 95:2350–2359. https://doi.org/10.1016/j.polymdegradstab.2010.08.023

von Burkersroda F, Schedl L, Göpferich A (2002) Why degradable polymers undergo surface erosion or bulk erosion. Biomater 23:4221–4231. https://doi.org/10.1016/s0142-9612(02)00170-9

Wang G-X, Huang D, Ji J-H, Völker C, Wurm FR (2021) Seawater-degradable polymers—fighting the marine plastic pollution. Adv Sci 8:2001121. https://doi.org/10.1002/advs.202001121

Williams SM, García-Sais J, Sabater-Clavell J (2021) Prevalence of stony coral tissue loss disease at El Seco, a mesophotic reef system off Vieques Island, Puerto Rico. Front Mar Sci 8:668669. https://doi.org/10.3389/fmars.2021.668669

Zwietering MH, Jongenburger I, Rombouts FM, van ‘t Riet K (1990) Modeling of the bacterial growth curve. Appl Environ Microbiol 56:1875–1881. https://doi.org/10.1128/aem.56.6.1875-1881.1990

Funding

No funding was received for conducting this study.

Author information

Authors and Affiliations

Contributions

The offshore experiments with the parrotfish exclusion device were conducted by KP in partial fulfillment of the Master of Science degree at Nova Southeastern University. DR was the faculty advisor for this research. KD developed the mathematical relationships for surface erosion, generated the associated data and figures, and wrote the sections pertaining to mathematics. KP and DR provided background and references regarding the Florida Reef Tract, stony coral tissue loss disease, and parrotfish exclusion devices that have been used to date. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing Interests

KD is the inventor of the parrotfish deterrence fence and has filed an application with the US Patent and Trademark Office. KD received no funding for inventing the device, nor has he received any funding for its use. All three authors are directors of a new corporation called Reef Fortify Inc., which intends to develop products made of PHA for use in coral reef restoration efforts. Reef Fortify Inc. does not yet have a physical location, and nothing has been manufactured or sold to date.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

2020 Mathematics Subject Classification. Primary 51N20, 70P99; Secondary 41A25, 62P12.

Appendices

Appendix A

Nomenclature

Symbol | Definition | Units |

|---|---|---|

\(A(0)\) | exposed surface area: initial | cm2 |

\(A\) | exposed surface area: instantaneous | |

\(D(0)\) | diameter: initial, solid cylinder | cm |

\(D\) | diameter: instantaneous, solid cylinder | |

\({D}_{i}(0)\) | inner diameter: initial, hollow cylinder | |

\({D}_{i}\) | inner diameter: instantaneous, hollow cylinder | |

\({D}_{o}(0)\) | outer diameter: initial, hollow cylinder | |

\({D}_{o}\) | outer diameter: instantaneous, hollow cylinder | |

\({F}_{h}\) | scalar: modifies \({\Delta }_{W}\), hollow cylinder | dl |

\({F}_{s}\) | scalar: modifies \({\Delta }_{D}\), solid cylinder | |

\({h}_{o}\) | thickness: initial, film | cm |

\({h}_{m}\) | thickness: initial, largest part of object | |