Abstract

A new adsorbent, starch grafted polyacrylic acid copolymer with polyacrylamide (SG@AA-co-AM), was synthesized using free radical polymerization techniques. Proton nuclear magnetic resonance (1H NMR), Fourier-transform infrared spectrophotometry (FTIR), X-ray diffraction analysis (XRD), thermogravimetric analysis (TGA), scanning electron microscopy (SEM), particle size distribution (PSD), and fluorescent electron microscopy (FEM) were employed to elucidate the structure, crystalline nature, thermal stability, and surface morphology of SG@AA-co-AM. SG@AA-co-AM was utilized as an adsorbent for the removal of Victoria green B (VGB) dye from wastewater. SG@AA-co-AM exhibited a removal percentage (% R) of 97.6% towards VGB under optimized conditions: a contact time of 30 min, temperature of 25 °C, adsorbent dose of 20 mg, pH of 8, concentration of dye solution of 20 ppm, and volume of dye solution of 30 mL. The point of zero charge (PZC) for SG@AA-co-AM was determined to be 5.2. Nonlinear pseudo-second-order (PSO) and Langmuir adsorption isotherm models best fitted to the experimental data, with regression coefficients (R2) of 0.95 and 0.99, respectively. The results confirmed the chemi-sorption and monolayer adsorption of VGB onto SG@AA-co-AM. Thermodynamic studies revealed that the adsorption of VGB onto SG@AA-co-AM is endothermic and spontaneous. Furthermore, the regeneration experiment showed a decline of 3.9% after five cycles, confirming the economical and reusable nature of SG@AA-co-AM.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Water pollution, originating from natural and artificial sources, introduces diverse contaminants into water bodies, threatening human health [1]. Industrial effluents discharge a plethora of dyes, non-biodegradable and toxic, posing serious risks, particularly to human well-being. Such pollutants endanger aquatic ecosystems and human health, encompassing inorganic, organic, thermal, and radioactive pollutants, among others [2]. Dyes, widely used in industries like textiles, rubber, cosmetics, and plastics, impart vibrant colors to various products. However, their mutagenic, carcinogenic, and immunogenic characteristics render them hazardous pollutants in water systems. The presence of dyes, notably in textile effluents, demands their removal to avert environmental damage. VGB is an organic cationic dye that dissolves in water, is extensively used in textile coloring for materials like cotton, silk, and leather, emphasizing its relevance in the textile industry [3, 4]. VGB, categorized as a triphenylmethane dye, finds diverse applications in industries such as paper, medical disinfection, and food processing due to its water solubility and green crystalline powder form [5, 6]. Despite its widespread use, VGB’s potential teratogenic and carcinogenic nature raises concerns regarding its detrimental effects on human health. The presence of VGB and similar dyes in water sources poses severe health risks, including neurological, renal, reproductive, and intestinal dysfunctions upon consumption. Health hazards associated with VGB exposure include damage to organs like the liver, kidney, and heart, as well as skin, lung, and bone lesions [7].

Additionally, these dyes obstruct sunlight penetration, negatively impacting photosynthesis and overall aquatic life quality. Developing effective methods for removing such contaminants from aquatic environments remains an imperative focus in contemporary research [8, 9]. An innovative and cost-effective system was designed to efficiently eliminate toxic VGB azo dyes [10]. Different adsorbents like sawdust, clay, zeolite, carbon nanocage, fly ash, activated carbons, and starch are used for VGB and other dye adsorption. The intrinsic biodegradability, abundant availability, and annual renewability of starch position it as one of the most promising natural polymers [11]. Starch is a complex macromolecule that typically consists of two primary glucose polymers: amylose and amylopectin. In most native starches, these polymers exist in a ratio of 1:3, except for certain varieties like waxy, genetically modified, and high-amylose starch. Amylose is a glucose unit-based linear polysaccharide connected by α-(1,4) bonds, and it typically has a polymerization degree ranging between 105 and 106.

Additionally, about 1% of α-(1,6) linkages are present in it, causing the main backbone to split into a couple of extended branching. On the other hand, amylose is significantly smaller than amylopectin, with a polymerization degree exceeding 106 glucose units. The linear regions contain α-(1,4) linkages; in addition, amylopectin contains approximately 5% α-(1,6) linkages, which contribute to its highly branched structure [12]. Starch is valued for its affordability, biodegradability, and accessibility. However, native starches have limitations, such as insolubility in water and gradual retrogradation, restricting their applications [13]. Various modifications, including thermal or non-thermal treatments, chemical processes, or enzymatic actions, enhance native starch properties, addressing challenges like insolubility and retrogradation. Chemical modifications, particularly through the introduction of different functional groups, have gained prominence due to their cost-effectiveness [14].

Modified starches, derived from chemical alterations, offer improved properties for various applications. The cyclic structure of starch allows for hydrophobic forms through esterification, etherification, crosslinking, grafting, and condensing reactions [15,16,17]. Adsorption, recognized as an efficient, safe, and cost-effective method, is widely employed for removing dyes like VGB from wastewater.

Several published studies have demonstrated the effective capacity of polymeric-based adsorbents for removing various dyes from wastewater. These adsorbents are increasingly favored for their affordability, lack of toxicity, eco-friendliness, and high levels of biodegradability and biocompatibility [18, 19].

Recently, sustainable magnetic alginate composite beads were designed, incorporating citric acid-modified sawdust (CA-sawdust), a bio-waste material, along with Fe3O4 nanoparticles. The efficiency of these beads in removing VGB was determined to be 90% to 95% [20]. Similarly, a novel magnetic hydrochar, grafted onto chitosan (MWSHC@CS), was developed for extracting VGB dye from aqueous solutions. Findings unveiled that MWSHC@CS demonstrated outstanding removal efficiency, reaching 96.47% for VGB dye [21]. Activated biochar was synthesized through hydrothermal carbonization (AHTC) of palm leaves. It was then thoroughly characterized. Subsequently, it was employed as an adsorbent for VGB. The maximum adsorption capacity of AHTC for VGB was determined to be 88% [22]. Oil palm empty fruit bunch (EFB) was investigated as a cost-effective adsorbent for removing VGB. The characteristics of both untreated and treated EFB were analyzed using FT-IR and SEM. The results demonstrated significant efficacy in VGB removal, with untreated EFB and treated EFB achieving removal rates of 88.3% and 94.5%, respectively [23]. Spent tea leaves, a waste material, were used to produce active carbon (STAC). STAC was then employed as a low-cost adsorbent to remove VGB from aqueous solutions. The effectiveness of STAC was evident as it removed 94% of VGB from the aqueous solution [24].

Despite these respectable removal rates, the adsorption efficiency of these materials falls short of being sufficiently appealing, leaving room for further research and improvement.

In response to this challenge, we have developed a more efficient adsorbent, SG@AA-co-AM. SG@AA-co-AM exhibits a notably strong affinity towards VBG compared to previously described adsorbents. What sets SG@AA-co-AM apart is its ability to swiftly remove VBG due to the presence of highly active carboxylic, amide, and hydroxyl groups.

Beyond its impressive performance, SG@AA-co-AM boasts additional merits. It is both economical and biodegradable, aligning with eco-friendly principles. These attributes not only contribute to its effectiveness but also elevate its demand in various applications. Embrace the enhanced capabilities of SG@AA-co-AM, where efficiency, speed, and environmental responsibility converge seamlessly.

The study details the grafting of acrylic acid and acrylamide onto starch molecular structures through free radical polymerization. This graft copolymerization enhances water absorption capacity and alters physical, morphological, and mechanical characteristics, making it a novel avenue for the chemical modification of carbohydrate polymers. The synthesis SG@AA-co-AM using aqueous solution polymerization is explored, with a focus on its performance in VGB adsorption. The technique has the potential to improve sustainable water treatment methods and the field of industrial chemistry.

Materials and Method

Materials

Starch, acrylamide (≥ 99%), acrylic acid (99%), and Victoria green B were acquired from Sigma-Aldrich. Potassium persulfate (KPS), methanol (99.8%), ethanol (99.5%), hydrochloric acid (HCl 37%) and sodium hydroxide (NaOH 99%) were purchased from all across Organics Ltd. Sodium chloride (99.5%) was purchased from Merck.

Methodology

To synthesize SG@AA-co-AM, a round-bottom flask with three necks was used in the following procedure. Initially, 1 g of starch was dissolved in 30 mL of distilled water on a hot plate inside the flask. The flask had a spherical bottom. At 60 °C and 600 rpm of stirring, the reaction was carried out for 30 min. Afterwards, 0.216 g of KPS was dissolved in 20 mL of distilled water and put into the reaction mixture using a syringe. The reaction was extended for an extra 30 min under identical temperature and stirring rate. Following the KPS addition, 2.536 mL of acrylic acid (AA) was injected into the reaction mixture through a syringe. Simultaneously, 2.627 g of acrylamide (AM) dissolved in 20 mL of distilled water was added to the mixture. The reaction was then maintained at a constant temperature and stirring rate for 2 h.

Following that, the reaction was stopped and centrifuged at 3000 rpm for 10 min in a solution of methanol and distilled water (30:70) to wash. Methanol was employed in the final step of the process to remove any water stains from the product. Ultimately, the product was dried completely by placing it in a vacuum oven set at 40 °C for 24 h. To obtain a fine powder, the dried product was ground using a pestle and mortar. Figure 1 shows the synthetic scheme and the whole procedure for the synthesis of SG@AA-co-AM.

Mechanism

Thermal Dissociation of Initiator KPS

At a temperature of 60℃, thermal dissociation of KPS takes place, and free radicals are generated at SO−4.

Native Starch Produces Macro-Free Radicles by Initiator KPS

Free radicals generated from KPS react with the starch macromolecules and also generate free radicals on the starch polymer.

Macro Radicles Initiate Acrylic Acid and Copolymer with Acrylamide

The starch-free radicals react with the acrylic acid and acryl amide via free radical polymerization and, as a result, form an efficient adsorbent SG@AA-co-AM. Here, the grafting of the starch molecule at the position of 2,3 and 6 of the OH− group takes place by monomer AA and AM. The functional groups introduced at the backbone of starch increase the density of SG@AA-co-AM, which makes it more efficient in the removal of VGB dye.

Characterization

State-of-the-art analytical techniques were employed to scrutinize the properties and structure of both native starch and SG@AA-co-AM. A comprehensive 1HNMR study was conducted using the Bruker advance III HD 600 MHz instrument, with spectra acquired in D2O (basic) conditions. To evaluate the structural integrity of SG@AA-co-AM using an X-ray diffractometer named XPert PRO, which made use of 1.54 Å wavelength Cu Kα radiation. The crystallinity percentage (Crystallinity %) was calculated from the following Eq. 1 [25].

The FT-IR spectra were recorded on DW-FTIR-510A/520A IR spectrophotometer using KBr disc method. Using the Oxford X-max80 SU-8010 spectrometer, which is made by Hitachi Ltd., microstructure details of native starch and SG@AA-co-AM were recorded through SEM images. The thermal properties of the samples were examined by a TGA analyzer (Q50 TGA). The fluorescent images are supported by the Laboratory Fluorescence Microscope OPTIKA model B-383FL with 3.1 MP CAMERA. The pH of the various solutions was measured by the LLC-AI501 PH700 pH meter. Similarly, the concentration of VGB in the solutions was measured by a spectrophotometer (U2020). Purification processes were executed with the assistance of an (80-1C) centrifuge machine. This comprehensive array of analytical tools provided a detailed understanding of the composition, structure, and characteristics of native starch and SG@AA-co-AM.

Applications

An experimental investigation was undertaken to assess the practical utility of SG@AA-co-AM as an adsorbent material, specifically focusing on its interaction with the model dye VGB. The procedure involved preparing a standard solution of 100 ppm concentration, subsequently employing a dilution equation to create solutions with varying concentrations of VGB. The concentrations of VGB in each solution were accurately measured using spectrophotometry at the maximum absorption wavelength of 624 nm, utilizing a U2020 spectrometer for precise quantification. The experiment sought to determine the quantity of dye absorbed (qe), percentages of dye removal (% R) by SG@AA-co-AM and desorption efficiency (D %) calculated through Eqs. (2), (3), and (4), respectively.

In this case, V and m stand for the volume (L) of the VGB solution and the weight (g) of the SG@AA-co-AM, respectively, while Ce and Ci represent the equilibrium and initial concentrations of VGB. Similarly, Ve and Cd represent the volume of eluent and concentration of desorbed VGB dye. The physi-sorption and chemi-sorption behaviors of VGB onto SG@AA-co-AM were investigated through the application of pseudo-first order (PFO) and pseudo-second order (PSO) kinetic models. The mathematical expressions representing the nonlinear forms of these models are depicted in Eqs. (5) and (6), respectively [26, 27]. These equations serve to characterize the kinetics of the sorption process and provide insights into the interaction mechanisms between VGB and SG@AA-co-AM.

In these equations, qt and qe represent the amounts of VGB adsorbed by SG@AA-co-AM at time t and at equilibrium, respectively. Similarly, k1 and k2 denote the rate constants associated with the PFO and PSO kinetic models.

The investigation into the monolayer and multilayer adsorption of VGB on the surface of SG@AA-co-AM involved fitting the nonlinear forms of the Langmuir and Freundlich equations to the adsorption data. The nonlinear mathematical expressions for the Langmuir and Freundlich isotherms are depicted in Eqs. (7) and (8), respectively [28].

where qe (mg/g) represents the amount of VGB adsorbed at equilibrium, and qmax (mg/g) denotes the maximum adsorption capacity. Additionally, Ce (mg/L) stands for the equilibrium concentration of VGB. Similarly, 1/n and KF (mg/g) (mg/L)1/n are the parameters of the Freundlich isotherm. The study employed four distinct error functions to assess the alignment between theoretical model correlations and experimental data, aiming to minimize the discrepancies. These functions encompassed the chi-square statistic (χ2), mean square error (MSE), hybrid fractional error (HYBRID), and sum of squares error (SSE). Throughout the analysis, the labels “cal” and “exp” were used to denote the calculated and experimental data, respectively. The dataset under examination comprised n observations. The different values were calculated by the Eqs. (9), (10), (11), and (12) [29].

Furthermore, Eqs. (13), (14), and (15) were employed to calculate changes in ∆Go, ∆Ho, and ∆So during the sorption process, providing information on the thermodynamics and viability of the adsorption process.

The temperature in Kelvin is represented by “T” in these equations, and the natural gas constant is represented by “R”. These calculations contributed to a comprehensive understanding of the thermodynamic properties of adsorption properties.

Point of Zero Charge (PZC)

To determine the pH of PZC on the surface of SG@AA-co-AM, 30 mL of NaCl (0.1 M) was added to nine different Erlenmeyer flasks, each maintaining a pH ranging from 1 to 9. Subsequently, 10 mg of SG@AA-co-AM was added to each flask, and stirring was conducted for 24 h on a hot plate at 600 rpm. Afterward, the mixture was filtered, and the final pH was determined using a pH meter. The change in pH (ΔpH) was calculated by subtracting the final pH (pHf) from the initial pH (pHi).

Results and Discussions

Characterizations

1H NMR Analysis

The chemical shift values that are given correlate to various regions within a 1H NMR [30]. These chemical changes in the grafted SG@AA-co-AM explained the typical range of chemical shifts for the anomeric proton (C1H) in starch. In SG@AA-co-AM, the connection between glucose units is linked to the anomeric carbon (C1). The presence of the anomeric proton in the SG@AA-co-AM structure is suggested by the chemical shift in this area [31, 32].

The chemical shift δ = peak of 4.71–4.87 ppm solvent in the H1NMR spectrum; this range usually corresponds to the solvent peak’s chemical shift. The solvent D2O will determine the precise chemical shift value. The chemical shift δ = 3.35–4.13 ppm for C2-C6’s of 6H aliphatic protons (C2 to C6) in organic compounds fall into this range. These protons most likely correspond to the starch backbone and the grafted moieties in the SG@AA-co-AM, suggesting the presence of aliphatic side chains or functional groups. The presence of methylene (-CH2) protons is suggested by the chemical shift range of 2.03–2.37 ppm. These protons most likely come from the side chains or functional groups that were added to the starch backbone when AA and AM were grafted on, and the presence of neighboring functional groups or electronic effects can influence the chemical shift. Protons on carbons C8 and C9, which are most likely connected to protons of methylene (CH2), fall into this range of 1.37–1.80 ppm. Conformational changes or steric hindrance around C7 and C10 may contribute to the observed chemical shift values [33]. The presence of particular protons in the grafted side chains is indicated by the chemical shift in this area [34, 35]. 1HNMR spectrum is shown in Fig. 2.

FT-IR Analysis

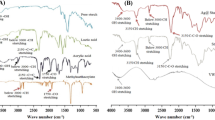

FT-IR analysis is a widely used technique in chemistry to study the infrared adsorption and transmission of a sample. It delivers important information about the functional groups and molecular vibrations. FTIR measurements were performed to analyze the structure of the synthesized material. Differences between the native starch and the SG@AA-co-AM are evident in the FTIR spectra, with two new peaks of AA and AM [36]. The provided spectra of starch exhibit significant bands, with key features highlighted. A wide band detected at 3421 cm−1 is associated with the presence of a hydroxyl group engaged in various degrees of hydrogen bonding. Around 2930 cm−1, the observed band corresponds to diverse –CH2 stretching vibrations and the characteristic absorption peak at 980 cm−1 related to isotactic sequence and -C–OH vibration were evident [37]. The strong peaks noted at 1638 cm−1 and 1454 cm−1 represent the presence of carboxylic groups. The appearance of peaks at 1239 cm−1 in the spectral data indicates the existence of C–O–C functional groups [38]. Furthermore, the band observed at 1031 cm−1 is attributed to the stretching vibration of C–O. At approximately 600 cm−1, the spectral analysis of native starch during polymerization revealed prominent absorption peaks corresponding to the glucose unit’s cyclic structure. This phenomenon is indicative of the presence of the free radicals-initiated monomers, which underwent concurrent grafting copolymerization [39].

SG@AA-co-AM spectra revealed distinct characteristics; O–H bond stretching vibration is indicated by the broad and robust band at 3421 cm−1 [40]. The absorption peak ranging from 1470 to 1500 cm−1 was assigned to stretching vibrations of carbonyl units present in the AA and AM groups in the spectrum of SG@AA-co-AM [41]. Additionally, the intense peak at 1638 cm−1 was assigned to carboxylic groups within the newly synthesized sorbent (SG@AA-co-AM). An intense merged peak at 1679 cm−1 was represented by acrylamide, representing the CONH2 stretching vibration and C-N (amide). Within the SG@AA-co-AM spectrum, the symmetrical -CH2 stretching vibration was observed at 2930 cm−1. The spectra displayed characteristic absorption peaks attributed to starch and SG@AA-co-AM. For starch, notable absorption peaks were observed at 1144 cm−1, corresponding to the C–O–C bond. The shift of the 1239 cm−1 peaks in the native starch C–O–C stretching vibration to a lower wavenumber, specifically 1144 cm−1, resulted in copolymerization between starch and AA-co-AM.

Additionally, the significant reduction in the vibration absorption peak of the C–O–C bond in starch was attributed to crosslinking. SG@AA-co-AM FT-IR spectra lacked information related to the isotactic sequence of starch, which is the characteristic absorption band, which was observed at 980 cm−1 in native starch spectra, signifying the completion of SG@AA-co-AM synthesis [42]. Around 600 cm−1, the glucose units’ cyclic structure absorption peak was notably diminished due to the rupture of the C–C bond connected to the OH of the glucose units’ ring during polymerization [43]. The combined and wide peak observed at 3196 cm−1 signifies the stretching vibration associated with the NH2 group in acrylamide, as well as the OH group in acrylic acid in the SG@AA-co-AM spectrum. The simultaneous grafting copolymerization of monomers is initiated by free radicles. These outcomes provided conclusive evidence of the successful preparation of SG@AA-co-AM. The FT-IR spectra are shown in Fig. 3a.

XRD Analysis

XRD analysis has revealed the inherent semi-crystalline nature of native starch. Starch’s semi-crystalline nature is due to its arrangement of glucose units in amylose and amylopectin, forming a linear chain with helical structure and branched structure. Starch`s semi-crystalline structure is due to its crystalline and amorphous components [44]. Prominent diffraction peaks corresponding to starch are evident at 2θ values of 15°, 17°, 18° and 23°. After the modification of starch by graft polymerization, new chemical structures or interactions are formed that alter the scattering properties of the starch [45]. The absence of peaks in the XRD pattern of SG@AA-co-AM indicates that the modifications have disrupted the crystalline regions to such an extent that they are no longer detectable by X-ray diffraction. The changes in the SG@AA-co-AM into amorphous nature due to grafting can lead to increased disorder and decreased crystallinity, making it difficult to observe distinct peaks in the diffraction pattern [46]. The loss of peaks in the XRD pattern of SG@AA-co-AM as compared to native starch can be attributed to the structural changes that occur during the grafting process. Grafting involves the introduction of new chemical groups (in that case AA, AM) onto the starch, which can lead to alterations in the crystalline and amorphous regions of the starch [47]. XRD pattern of SG@AA-co-AM showed smooth structure disruption, reduced crystallinity, and altered scattering behavior. The loss of crystallinity in SG@AA-co-AM is attributed to disrupting of intra-molecular hydrogen bonding [48]. The analysis revealed that the SG@AA-co-AM material possesses a crystallinity % of 33.28%. This finding indicates that a substantial portion, specifically 66.72%, of SG@AA-co-AM comprises an amorphous structure. Hydrolysis reactions break starch chains’ glycosidic bonds, forming smaller fragments and altering crystalline structure. Incorporating ionic groups into the starch structure can introduce repulsive forces between starch molecules, preventing them from arranging into well-defined crystalline domains. XRD spectra reveal ionic group incorporation in starch structure, altering crystalline arrangement and physical properties. SG@AA-co-AM can create amorphous domains with reduced crystallinity and disorder, impacting physical properties like mechanical strength, transparency, and response to external factors as a result of a smooth XRD pattern [49]. The steric effect caused by the attachment of polymer segments to the active sites of starch macromolecular radicals restricted starch molecule mobility and disrupted their capacity to establish an organized structure, ultimately leading to the disruption of the regularity of starch molecular chains. As a result of AA and AM grafting, disrupt starch structure and increase the disorder, causing the loss of sharp peaks. The XRD patterns are depicted in Fig. 3b [50].

TGA Analysis

The sophisticated analytical technique TGA uses to investigate the behavior of various materials and their thermal properties [51, 52]. TGA is widely used in polymer research to determine glass transition temperatures, degradation temperatures, and other critical polymer properties [53, 54]. The findings indicate the successful grafting of the poly(AA-AM) chain onto the starch framework [55]. TGA showed a distinct thermal behavior of native starch, with a consistent weight at 150 °C followed by a phase of thermal degradation from 268 °C to 333 °C. The weight loss, 76.3% of the initial weight, was attributed to water and volatile constituents’ volatilization. The thermal degradation process involved the decomposition of glycosidic linkages, causing the fragmentation of starch molecules into smaller entities. the phenomenon entails the separation of chemical bonds that interlink individual glucose units, ultimately resulting in the fragmentation and dissolution of starch molecules [56]. This cleavage process confirmed the observed weight loss during the TGA analysis. There were three main similar degradation processes occurring in the TGA analysis of SG@-AA-co-AM. Clearly, SG@-AA-co-AM underwent a multi-phase decomposition process, primarily marked by weight loss unfolding between 126.8℃ and 250 °C, about 8.3% of this attributed to the process of water evaporation. The most pronounced reduction in weight materialized precisely at 328 °C to 400℃. Evident features emerged within the 250 to 328 °C and 328℃ to 400 °C temperature ranges for the SG@AA-co-AM composite, respectively 24.1% and 64.1%. The weight loss experienced within the 160 to 250 °C interval finds its origin in the structural breakdown of the core SG@AA-co-AM framework. The decrease in weight of SG@AA-co-AM, occurring between temperatures of 250 to 328℃, can be attributed to its swift degradation into carbon dioxide (CO2) and volatile hydrocarbons. In contrast, the weight decrease spanning 328℃ to 400 °C stems from the collapse of chain structures intrinsic to the SG@AA-co-AM copolymers. The weight reduction observed during the second and third phases of degradation is attributed to the decomposition of the AM and AA constituents [57]. Upon confronting the elevated temperature of 400 °C, the cumulative weight loss registered 76.3% for starch, while the SG@AA-co-AM composite remarkably exhibited a comprehensive weight loss of 96.5%. The thermograms distinctly illustrate the thermal decomposition patterns of SG@AA-co-AM. This parameter is favored for investigating the thermal stability of the grafted polymer SG@AA-co-AM [58]. A comparative analysis of the graft copolymer’s thermal stability can be achieved by evaluating the onset temperature of decomposition as well as the proportion of weight reduction during various stages of the degradation process. Hence, it is deduced that the grafting of AA and AM onto starch holds potential as a viable approach to achieve a thermally enhanced composite compared to native starch. From that TGA analysis of native starch and grafted starch in Fig. 3c, it can be concluded that the SG@AA-co-AM is thermally more stable and effective as compared to native starch [59].

Scanning Electron Microscopy Analysis (SEM)

The surface morphology was checked by the SEM technique of the SG@AA-co-AM [60,61,62]. Incorporating AA and AM into the starch copolymer results in the creation of composites characterized by a uniform morphology and a significantly increased specific surface area [63]. The grafting of copolymer AA-co-AM introduces irregularly shaped structures on the starch surface. These irregularities create gaps, furrows, and cavities within the SG@AA-co-AM, which is particularly evident in the arrangement of bright bulges (furrows), gray areas (gullies), and dark regions (cavities) on the composite’s surface. The prominent elevations are thought to correspond to furrows within the composite; the intermediate gray areas likely represent the spaces between these furrows, and the darker regions are hypothesized to arise from the formation of cavities during the process of graft copolymerization [64]. SEM images of SG@AA-co-AM reveal interconnected patterns of uneven pores within the modified starch matrix; the distribution of pore sizes became more focused, resulting in an intricate porous arrangement with numerous cavities capable of capturing large volumes of liquids. SG@AA-co-AM has a textured and rugged surface due to chemical covalent bonding between grafted polymer segments and starch molecules. This results in increased surface areas and a flower-shaped structure, facilitating active adsorption for dye molecules due to increase surface area, with numerous gaps and ravines enhancing efficiency and interaction [59]. The incorporation of AA and AM results in a unique self-assembly behavior, with evenly encapsulated starch particles and uniform distribution of polymer chains across the starch surface [65]. When these segments are merged, the composition of SG@AA-co-AM consists of fine particles, showcasing not only an expansive surface area but also a stable and uniform structure. From Fig. 4a, it is clear that the increased surface area and uniform morphology are crucial for the successful grafting of AA and AM onto starch. Starch has flattened granules, while SG@AA-co-AM has a porous architecture, facilitating water and dye penetration and interactions with hydrophilic components [66]. These factors improve efficiency, effectiveness, and overall composite material quality by enhancing contact and reaction sites, monomer distribution, reactivity, adsorption, stabilization, and structural integrity [67].

The analysis of particle size distribution (PSD) is accomplished using SEM imagery of the particles [68]. The size distribution of particles ranged between 2000 and 20,000 nm. In Fig. 4b, the standard deviation curve showed that the particles have an average particle size of 6565 nm. The average particle size is denoted on the graph, which gives a central point around which the particle sizes are clustered. This averagely small particle size helps in the maximum adsorption of dye molecules on the surface of SG@AA-co-AM.

Fluorescent Electron Microscope Analysis (FEM)

The image of SG@AA-co-AM reveals intricate patterns of interconnected, uneven pores within an SG@AA-co-AM. These results in a complex porous arrangement with numerous cavities, furrows and gaps, allowing for efficient VGB dye capture. The SG@AA-co-AM has a textured surface, enhancing active adsorption for VGB dye molecules. The introduction of AA and AM induces a unique self-assembly behavior, resulting in evenly encapsulated starch particles and a uniform polymer distribution. These factors improve the efficiency, effectiveness, and composite material quality of SG@AA-co-AM.

The electron fluorescent microscopy presents imaging and scrutinizing samples exhibiting surface properties conducive to adsorption [69]. This amalgamation facilitates the observation of intricate structures at the nanoscale, establishes accurate connections between light and electron microscopy images, and enables intelligent tracking of fluorescent structures [70]. Consequently, this integration significantly amplifies the potential for sophisticated microscopy techniques and advanced analytical processes. Therefore, Fig. 4c, d completely supports the SEM analysis, which concludes the complete synthesis of SG@AA-co-AM.

Applications

The adsorption efficacy of SG@AA-co-AM was examined as a potential adsorbent for the remediation of VGB dye. Various adsorption parameters were investigated to assess the capacity of SG@AA-co-AM for capturing VGB dye.

Comparative Adsorption Study

The aim of the comparative adsorption study was to investigate the influence of AA-co-AM grafting on the backbone of starch in the adsorption process. Different adsorbents have varying properties, such as porosity, functional groups and surface area, which influence their adsorption capacity [71]. The comparative study helps determine the most suitable adsorbent for a particular application based on its performance and cost-effectiveness. Grafting modifications can offer functional groups or modify the starch structure, increasing the number of active sites accessible for VGB dye adsorption. By comparing the adsorption capacity of native starch with SG@AA-co-AM, we can determine that grafting enhances adsorption efficiency. From Fig. 5a, SG@AA-co-AM may exhibit improved selectivity towards VGB dye compared to native starch. By conducting a comparative adsorption study between SSt and SG@AA-co-AM for VGB adsorption, researchers aim to identify the optimal adsorbent and understand how grafting modifications enhance adsorption performance. This information is valuable for designing efficient and cost-effective dye removal processes and contributes to the development of sustainable adsorption technologies for water treatment and environmental remediation. The experimental results indicate that the % R (57.2%) of SSt was less as compared to the SG@AA-co-AM, which was 97.62%, which showed that the SG@AA-co-AM has maximum capacity to adsorb the VGB dye. Based on these results, it can be inferred that grafting has led to an increase in the density of –COOH and –CONH2 groups on the starch backbone. This increase in density subsequently enhances the adsorption efficiency of SG@AA-co-AM in comparison to SSt. Similar results were observed when carboxymethyl starch grafted polymethacrylic acid was employed for phenol adsorption [72].

(a) Comparative study of native starch and SG@AA-co-AM, (b) Determination of point of zero charge, (c) Effect of PH on adsorption of VGB dye, (d) Effect of time contact, (e) Effect of different SG@AA-co-AM adsorbent doses on VGB dye adsorption and (f) impact of different concentrations of VGB dye solution

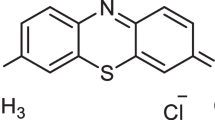

Effect of pH

pH plays a vital role in the adsorption process, as it defines the charges on the surface of the adsorbent and adsorbate [73]. To prepare the acidic and basic solutions of VGB dye, 0.1 M HCl and 0.1 M NaOH were added, respectively, to achieve the desired pH values. This is crucial because pH determines the surface charges of both SG@AA-co-AM and VGB. In acidic conditions, the VGB dye becomes protonated, whereas in basic conditions, the hydrogen dissociates from the nitrogen of the VGB dye [74]. The protonated and deprotonated structures of the VGB dye in acidic and basic environments are depicted in Scheme 1. Similar alterations were noted for SG@AA-co-AM.

Similarly, the adsorbent also showed different surface charges in different pH environments. To determine the net charge on the surface of the SG@AA-co-AM, a PZC experiment was conducted. The PZC represents the pH level where the overall surface charge of the SG@AA-co-AM becomes neutral [75]. Determining the PZC provides insights into the ionization behavior of functional groups. It also sheds light on their interaction with VGB dye when in contact with SG@AA-co-AM in an aqueous solution. With a determined PZC of 5.2 for SG@AA-co-AM, it was observed that the surface exhibited a positive charge when the pH was below 5.2. Above this pH, a negative charge was present on the surface of the SG@AA-co-AM [76]. These findings are pivotal for understanding the adsorption mechanism of VGB dye onto SG@AA-co-AM. The results of the PZC experiment are shown in Fig. 5b.

To investigate the impact of pH, five distinct experiments were conducted, covering a pH range from 5 to 9. A very low % R of 55.4% was achieved at pH 5. As at low pH, SG@AA-co-AM was in protonated form containing a positively charged surface. So, electrostatic repulsive forces were generated between SG@AA-co-AM and VGB dye. In this case, hydrogen bonding was developed between the lone pair of electrons on the nitrogen atom of VGB dye with the hydrogen of –OH or –COOH groups on the surface of the SG@AA-co-AM. The maximum % R of 97.6% was achieved at pH 8. At this pH, the surface of the SG@AA-co-AM was converted into a negatively charged bed. As at this pH, de-protonation occurred and the –OH and –COOH were converted into –O‒ and –COO‒, respectively. The similar results were also observed when bio-mass ash was used for the adsorption of dipyrone from water [77]. So, in this case, attractive electrostatic interactions were produced between the negatively charged SG@AA-co-AM and positively charged VGB dye. A further increase in pH resulted in a decline in % R. This trend is observed in Fig. 5c, where a low % R of 95.5% was observed at pH 9. This decrease in % R is attributed to the high concentration of –OH‒ in the solution which competes with negatively charged SG@AA-co-AM and retards the free flow of positively charged GVB towards SG@AA-co-AM. These results are supported by the work of Ahmad et al., where they used nickel oxide doped in porous carbon derived from Hyphaene thebaica seeds for the removal of methyl red dye from water [78].

Effect of Contact Time

The adhesion and dispersion of adsorption are significantly influenced by the duration of contact time. Various experiments were conducted at different time intervals to investigate the impact of contact time on the adsorption mechanism. Various factors influence the adsorption process, and the contact time is one of the critical parameters that affect the efficiency of adsorption [79]. The contact time determines how long the adsorbate molecules have to diffuse and interact with the active sites on the adsorbent surface SG@AA-co-AM. During the initial stage of adsorption, the concentration of VGB dye was relatively low compared to the surface adsorbent concentration. Because, at that time there was less interaction and diffusion with the active site on the adsorbent surface. At that point, there was a considerably low concentration gradient between the solution and the adsorbent, which drove the movement of adsorbate molecules toward the adsorbent surface. This was because fewer adsorbate molecules were available to attach to the limited number of remaining unoccupied sites. However, as the adsorbate molecules approach the surface and begin to interact with the adsorbent’s active sites, the available binding sites are relatively abundant. This allowed a high number of adsorbate molecules to bind to the surface in a short period, leading to a significant increase in the rate of adsorption after some stages of contact time. As an increasing number of active sites are occupied, the solution and the adsorbent surface exhibit an increasing concentration gradient, and the number of unoccupied active sites reduces. Consequently, the adsorption rate gradually high over time. Ultimately, as the adsorption process reaches equilibrium, the adsorption rate becomes equal to the desorption rate, and the amount of VGB dye adsorbed on the SG@AA-co-AM surface remains constant. This stage is known as “saturation” or “equilibrium adsorption.” The adsorption efficiency of SG@AA-co-AM for the uptake of VGB dye was studied at various time intervals. The results revealed a positive correlation between the adsorption capacity and the contact time of the adsorbent. Analysis of the graphical representation in Fig. 5d showed that after 10 and 20 min of dye adsorption, the %R was measured at 89.57% and 94.47%, respectively. With a further increase in contact time to 30 and 40 min, the adsorption capacity continued to rise, reaching a %R of 97.62%.

Similarly, the same %R of 97.62% was observed after 50 and 60 min of stirring rate under the same conditions. This %R was the same as 40 to 60 min. Beyond this point, extending the contact time did not result in a significant increase in adsorption capacity. This observation is attributed to the saturation of active sites on the adsorbent’s surface SG@AA-co-AM, which had already captured a substantial amount of VGB dye. As a consequence, no additional sites were available for further VGB dye removal. This finding indicates that an optimal contact time of 60 min is sufficient to maximize the adsorption of VGB dye, utilizing all available active sites on the adsorbent’s surface. The adsorption rate is low at the beginning of the adsorption process due to the limited interaction between the adsorbate and the adsorbent. As the adsorbate molecules start to accumulate on the surface and the available active sites decrease, the adsorption rate progressively slows down until it reaches equilibrium. Similar results were reported by Wakili et al., who utilized walnut shell activated carbon as an adsorbent for the removal of methylene blue dye [80].

Effect of an Adsorbent Dose

The role of adsorbent dose is of utmost importance in the adsorption process. The adsorbent dose plays a crucial role in determining the adsorption capacity of an adsorbent [81]. In order to investigate the impact of adsorbent dose on the dye adsorption process, a series of four experiments were conducted using specific SG@AA-co-AM adsorbent doses.

To investigate this impact, the adsorption behavior of SG@AA-co-AM concerning VGB dye was carefully studied. The results demonstrated a direct correlation between the percentage removal (%R) of VGB and the increase in adsorbent dose. Specifically, elevating the adsorbent dosage from 20 to 60 mg resulted in a remarkable increase in %R, escalating from 97.6% to an impressive 99.7%. Higher SG@AA-co-AM adsorbent doses mean more adsorbent material is present in the system, which results in a larger surface area available for dye adsorption [82]. More active sites for VGB dye molecules to bind to the adsorbent surface are provided by the larger surface area, leading to higher removal efficiency and extended adsorbent-dye-containing solution contact time. Adsorption occurs due to attractive forces between the SG@AA-co-AM and VGB dye molecules; with the increase in the adsorbent dose, there are more adsorbate particles available to interaction with the adsorbent particles. As increases in the adsorbent dose, the system may eventually reach adsorption saturation, where VGB molecules occupy all the available adsorption sites. Beyond this point, further increasing the adsorbent dose won’t significantly increase adsorption efficiency, as the system has reached equilibrium. This substantial enhancement is ascribed to the augmented presence of adsorbent active sites, particularly the rise in the number of carboxylic, hydroxyl, and amide groups on the copolymer SG@AA-co-AM particles. These groups demonstrated a remarkable affinity for VGB dye, contributing significantly to the enhanced %R observed [83]. The experimental data in Fig. 5e indicated that at an adsorbent dosage of 20 mg, the %R for VGB dye was 97.6%. This lower efficiency can be attributed to an excess of dye molecules compared to the available active sites on the adsorbent. Consequently, some dye molecules were not treated and remained unabsorbed. When the adsorbent dose increases to 30 mg, the %R also enhances, resulting increase of 98.3%. This improvement in %R can be attributed to the accessibility of additional adsorbent active sites, allowing for a higher uptake of VGB dye molecules. Further increasing the adsorbent dosage to 40 mg led to a higher %R of 98.9%. This increase suggests that the additional adsorbent dosage provided more active sites on the adsorbent structure, leading to a more effective removal of VGB dye [84].

At an adsorbent dosage of 50 mg, %R was approximately 99.3%. At 60 mg maximum adsorption achieved was 99.7%. Which was comparable to the efficiency observed at 20 mg. This indicates that all the dye molecules were successfully captured by the adsorbent, leaving none behind. Consequently, further increases in the adsorbent dosage did not significantly impact the adsorption efficiency. The experimental results demonstrate that the maximum adsorption efficiency for VGB was achieved at an adsorbent dosage of 60 mg. At this dosage, all the dye molecules were adsorbed, resulting in a highly efficient removal of VGB dye. Hambisa et al. observed a similar trend of results when using Anchote peels powder for the removal of methyl orange dye from wastewater [85].

Dye Concentration

By employing the dilution equation to create a range of VGB solutions with varying concentrations. In order to determine the adsorption capability of the adsorbent material, SG@AA-co-AM, on the different VGB solution concentrations,

Typically, when the initial concentration of dye is increased, the %R decreases because the dye molecules are greater in number than the available adsorbent surface active sites [86]. The experimental data presented in the graph illustrates this trend. The %R dropped from 99.8% to 97.6% when the initial concentration of dye was raised from 10 to 20 ppm. These findings suggest that the VGB dye molecules were comparatively low as compared to the high number of the adsorbent active site in a 10 ppm solution. As a result, all dye molecules were effectively taken by the SG@AA-co-AM, leading to a 99.8%. As the VGB dye initial concentration was further raised from 10 to 50 ppm, the %R decreased. That change is attributed to the decreased accessibility of active sites on the SG@AA-co-AM adsorbent surface because of the large number of molecules of VGB dye in the solution. At very high doses of adsorbent, there is a possibility of particle aggregation or pore blocking. Aggregation can reduce the effective surface area available for adsorption, while pore blocking can hinder the availability of VGB dye molecules to the adsorption sites inside the adsorbent, both of which may result in decreased adsorption efficiency. It is evident that an increase in the initial concentration of VGB dye leads to a decrease in adsorption capacity due to the blocking of active sites responsible for capturing VGB from the solution [87]. The experimental results in Fig. 5e indicate that for an initial concentration of 10 ppm, the %R was 99.8%, while for a 20 and 30 ppm solution, this decreased to 97.6% and 95.12% due to a reduction in the number of available active sites for VGB uptake. Further increase in concentration from 40 to 50 ppm, the %R decreased was respectively 91.54% and 87.07%. This was due to the fact that adsorption sites were already occupied by dye molecules, rendering further increases in dye concentration ineffective in enhancing the adsorption rate [88]. These results were further supported by the work of Batouti et al., who employed guar gum-grafted acrylamide hydrogel as a super-adsorbent for the removal of acid red 8 dye from industrial wastewater [89].

Effect of Temperature

The adsorption of VGB dye from wastewater relies significantly on the fundamental mechanism of adsorption, with temperature serving as a pivotal factor influencing both the rate and capacity of adsorption [79, 90]. In this study, the effect of temperature on the VGB dye adsorption onto SG@AA-co-AM was thoroughly investigated through experiments carried out between 25 °C and 55 °C in the temperature range. The results from Fig. 6a demonstrated a proportional increase in VGB adsorption onto the adsorbent with rising temperature, leading to a noticeable escalation in %R from 97.8% to 99.7% as the temperature elevated from 25 °C to 55 °C [91].

The results presented in Fig. 6a clearly demonstrate that the adsorption process is endothermic, meaning that heat must be added as an energy input. The relationship between the adsorption process and temperature can be elucidated by the consideration that the adsorption reaction requires activation energy to take place [92]. Elevated temperatures contribute to the elevated kinetic energy of the SG@AA-co-AM adsorbate molecules, thereby increasing successful collisions with the surface of the adsorbent [93]. Optimizing the conditions of the adsorption process suggested by the implications of these substantial results, particularly through the application of higher temperatures, can enhance its efficiency. Moreover, this insight is valuable for the design of effective adsorbents aimed at treating VGB dye.

The increase in temperature likely enhances the adsorption process by making it more thermodynamically favorable, promoting an endothermic nature, and facilitating the diffusion of dye molecules onto the adsorbent SG@AA-co-AM surface [94]. The positive values of thermodynamic parameters support the idea that the adsorption becomes more favorable with increasing temperature in the specified temperature range [95]. These results are in agreement with the findings published by Singh et al., who removed methylene blue dye using biochar derived from raw and torrefied Acacia nilotica as an adsorbent material [96].

Thermodynamic Study

The comprehension of entropy ΔH°, enthalpy ΔS°, and the change in free energy ΔG° parameters is pivotal in unraveling the characteristics and inherent spontaneity in the process of adsorption, crucial for the formulation of efficient water treatment methodologies. Employing an experimental apparatus, diverse thermodynamic parameters pertinent to the adsorption of VGB dye onto SG@AA-co-AM were meticulously determined [97, 98]. The experimental findings unveiled a ΔH° value of 52.49 kJ/mol, signifying the endothermic nature of the adsorption process, indicating a requisite input of energy [99, 100]. Concurrently, a computed ΔS° value of 208.48 J/Kmol was derived, suggesting that the adsorption of VGB dye onto SG@AA-co-AM induces an escalation in disorderliness within the solid–liquid mixture, thereby augmenting randomness within the system [101,102,103]. The exploration of ΔG° values across a temperature spectrum varying from 25℃ to 55℃ revealed consistently negative values (−10.486 kJ/mol to −17.182 kJ/mol). This negativity value of ΔG° indicates the spontaneous and inherent nature of the adsorption process, occurring without the necessity of external energy input [104, 105]. The amalgamation of an endothermic tendency and the spontaneity observed in Fig. 6b indicate that the adsorption of VGB dye by SG@AA-co-AM holds significant ramifications in adsorption-based water treatment. It not only underscores the efficiency of the process but also furnishes invaluable insights into the thermodynamic parameters governing the intricacies of adsorption, contributing to the advancement of water treatment technologies. In conclusion, these thermodynamic analyses offer valuable insights into the attributes of the adsorption process and its behavior across varying temperatures. The values of the thermodynamic study are shown in Fig. 6b.

Isothermal Adsorption Study

The Langmuir and Freundlich models serve as foundational frameworks for comprehending adsorption phenomena. The Langmuir model posits adsorption occurring in a single layer on a uniform surface, whereas the Freundlich model describes adsorption happening across multiple layers on diverse surfaces [106, 107]. The different parameters for Langmuir and Freundlich adsorption isotherms were obtained nonlinear regressions (NLR) as shown in Fig. 6c, d. The Langmuir adsorption isotherm was plotted with Ce versus qe, yielding a high nonlinear regression coefficient of R2 0.99. The calculated values for qmax and the Langmuir constant (KL) were determined as 159.9 mg/g and 25.5, respectively. Conversely, for the Freundlich adsorption isotherm, a nonlinear graph was constructed between Ce and qe, resulting in a qmax of 142.8 mg/g. The regression coefficient R2 was found to be 0.89, with an adsorption intensity of 0.05. The parameter 1/n holds significant importance as it indicates the favorability of the adsorption process. If the value of 1/n falls between 0 and 1, it suggests favorable adsorption. Conversely, if 1/n equals 1 or exceeds 1.46, the adsorption process is deemed unfavorable, indicating minimal interaction among the adsorbed molecules. The close proximity of the Langmuir adsorption isotherm’s R2 value to 1, at 0.99, suggests its superior fit to the experimental data. These findings imply that the VGB dye is adsorbed onto the surface of SG@AA-co-AM in a monolayer fashion. Similarly, the 1/n value of 0.05 supports the feasibility of VGB adsorption on the surface of SG@AA-co-AM. Similar outcomes were documented in another study where activated carbon sourced from palm kernel shells (PKSAC) and its composites with porous volcanic ash (PKSAC/BVA) were employed for the removal of indigo carmine dye [108]. The findings of A. Lime et al., further corroborated these results. In their study, they examined activated carbon derived from oil palm trunks for its effectiveness in adsorbing acid blue 25 and sunset yellow dyes [109].

Kinetic Adsorption Study

Nonlinear PFO and PSO models are crucial for deciphering adsorption processes, offering insights into underlying mechanisms. The PFO model depicts initial adsorption, showing a linear relationship between adsorption rate and adsorbate concentration [110]. Conversely, the PSO model implicates chemical adsorption mechanisms like electron transfer or sharing [111]. A NLR analysis for the PFO model was conducted, plotting Ce against qt. The resulting coefficient of determination R2 for PFO was determined as 0.87, with a corresponding qe value of 132.1 mg/g. additionally, the rate constant K1 for PFO was determined to be 0.25. These findings hold significance in understanding the kinetics of adsorption processes and help to evaluate the effectiveness of the PFO model in describing the adsorption behavior. Similarly, a graph was plotted between Ce and qt to determine various parameters of PSO model. The R2 value for PSO, along with qt, was determined to be 0.95 and 136.2 mg/g, respectively. The rate constant K2, for PSO was found to be 0.006. Figure 6e, f depict the NLR graphs for PFO and PSO, respectively. Comparing the results, PSO exhibited a better fit to the experimental data with an R2 value of 0.95, closer to the ideal value compared to PFO R2 of 0.87. Moreover, the value of qt (136.2 mg/g) for PSO exceeded that of PFO (132.1 mg/g). These findings suggest that PSO provides a more accurate description of the adsorption data, indicating the presence of a chemisorption [112] relationship between the VGB dye and SG@AA-co-AM. These results were further validated by the research conducted by W. Altowayti et al., demonstrating the successful removal of As+5 using dried bacterial biomass [113]. Likewise, comparable results were observed in the adsorption of aniline blue dye using activated carbon derived from pomegranate peels [114]. The different parameters of nonlinear PFO, PSO, Langmuir and Freundlich models are tabulated in Table 1.

Adsorption Mechanism

The effective removal of VGB dye molecules by the prepared SG@AA-co-AM is attributed to the robust electrostatic interactions at pH level 8 in the basic conditions established due to the de-protonation of amide, carboxylic ester groups between the functional groups having a negative charge on the SG@AA-co-AM and the cationic functional groups present in the VGB dye molecules. The significance of these electrostatic interactions lies in their strength and specificity, underscoring their crucial role in the adsorption process. Within the prepared sample, three distinct types of functional groups are identified, namely –CONH2, –COO−, and –COOH. Each of these functional groups exhibits unique properties, contributing to the overall adsorption behavior. The –CONH2, –COO−, and –COOH groups likely play varied roles in the adsorption mechanism, to interact with the VGB dye molecules, leveraging their specific chemical characteristics.

Furthermore, hydrogen bonding is another significant mode of interaction between the cationic dyes and the SG@AA-co-AM. Specifically, hydrogen bonding is anticipated to occur among the dye molecules and amide groups, hydroxyl and carboxylic groups on SG@AA-co-AM due to protonation at low pH (acidic media) [115]. This additional mode of interaction adds complexity to the intermolecular forces at play, potentially enhancing the overall adsorption capacity. Despite the anticipated occurrence of hydrogen bonding, electrostatic forces of attraction also developed between VGB and SG@AA-co-AM, thereby increasing the adsorption efficiency of the adsorbent towards the dye. This dominance suggests that the electrostatic forces play a pivotal role in facilitating the adsorption of VGB dye molecules onto the SG@AA-co-AM. The multifaceted intermolecular interactions, particularly the strong electrostatic forces, contribute significantly to the successful removal of VGB dye by SG@AA-co-AM. The versatility of the functional groups within the SG@AA-co-AM allows for diverse interaction mechanisms, ultimately enhancing the efficacy of the adsorption process. This understanding of the intermolecular interactions provides valuable insights for optimizing the design and performance of adsorbents in the adsorption of cationic dyes from aqueous solutions. The adsorption mechanism is represented in Fig. 7. Furthermore the adsorption mechanism was also evaluated by the FT-IR spectra of VGB dye and VGB-Loaded SG@AA-co-AM.

The FT-IR spectra of the VGB dye and VGB-Loaded SG@AA-co-AM are shown in Fig. 8a. The spectrum of the VGB dye showed peaks at 3030 cm−1 and 2943 cm−1, attributed to the stretching vibration of –CH and = CH, respectively [116, 117]. The peaks at 1587 cm−1 and 1492 cm−1 are corresponding to the characteristics vibrations of –C = C- of aromatic moieties present in the structure of VGB [118]. Similarly, the other characteristic peak appeared at 1185 cm−1 is assigned to the stretching vibration of –C-N [119]. In SG@AA-co-AM, the sites of interaction are –OH, -NH2, and –COOH groups. The FT-IR spectrum of SG@AA-co-AM after adsorption showed variations in peaks. The broad peak of the hydroxyl group shifted to a slightly narrower peak (from 3421 to 3323 cm−1), confirming the involvement of –OH in the adsorption process. Similarly, the peak for the -NH stretching vibration shifted from 3196 to 3208 cm−1. Other peaks also shifted after adsorption, such as 1679 to 1657 cm−1 and 1587 to 1600 cm−1. Additionally, the peak at 1492 cm−1 disappeared in the spectrum of SG@AA-co-AM. These variations confirm the adsorption of VGB onto SG@AA-co-AM, forming new bonds between VGB and SG@AA-co-AM. Muinde et al. reported similar results, wherein VGB dye was adsorbed onto the surface of rice husk [120].

Adsorption–Desorption and Regeneration Study

In practical applications, it is crucial to consider the desorption of loaded dye, the regeneration process, and the reusability of the adsorbent [121]. In the first and second cycles, the % R of VBG dye onto SG@AA-co-AM was measured at 97.6% and 96.5%, respectively. However, after five cycles, the % R dropped to 93.7%. This indicates a decrease in overall % R by 3.9% after five cycles, demonstrating the reusability and sustainability of SG@AA-co-AM. For the desorption process, the dye-loaded SG@AA-co-AM was treated with a 0.1 M HCl solution. Desorption efficiencies for the first two cycles were achieved at 95.8% and 95.1%, as depicted in Fig. 8b. Following five consecutive desorption cycles, a decline in desorption efficiency to 92.8% was observed. This decrease is attributed to the acidic environment, which diminishes the electrostatic attraction between VGB and SG@AA-co-AM. Similar observations were reported by Ansari et al., who utilized alginate-based porous polyHIPE for the removal of methylene blue dye [29].

Conclusion

A free radical polymerization technique was used to synthesize SG@AA-co-AM.. SG@AA-co-AM was utilized as an adsorbent for the removal of VGB dye from wastewater. SG@AA-co-AM exhibited a % R of 97.6% towards VGB under optimized conditions: a contact time of 30 min, temperature of 25 °C, adsorbent dose of 20 mg, pH of 8, concentration of dye solution of 20 ppm, and volume of dye solution of 30 mL. Notably, the determination of the PZC for SG@AA-co-AM at 5.2 elucidated its negatively charged nature above this specific pH. The excellent fitting of experimental data to the PSO and Langmuir adsorption isotherm models, with respective R2 values of 0.95 and 0.99, solidified the confirmation of chemi-sorption and monolayer adsorption of VGB onto SG@AA-co-AM. Moreover, thermodynamic studies unveiled the endothermic and spontaneous nature of the VGB adsorption onto SG@AA-co-AM. The adsorption mechanism suggested hydrogen bonding and electrostatic interactions between VGB and SG@AA-co-AM, which were also supported by FT-IR. Additionally, the regeneration experiment showcased a marginal decline of 3.9% after five cycles, further affirming the economical and reusable attributes of SG@AA-co-AM. Based on these compelling results, SG@AA-co-AM emerges as a promising alternative to other adsorbents in the field of wastewater treatment.

References

Singh J, Yadav P, Pal AK, Mishra V (2020) Water pollutants: origin and status. Sens Water Pollut Monitor Role Mater 5–20

Sridhar A, Ponnuchamy M, Kapoor A, Prabhakar S (2022) Valorization of food waste as adsorbents for toxic dye removal from contaminated waters: a review. J Hazard Mater 424:127432

Azari A, Noorisepehr M, Dehghanifard E, Karimyan K, Hashemi SY, Kalhori EM, Norouzi R, Agarwal S, Gupta VK (2019) Experimental design, modeling and mechanism of cationic dyes biosorption on to magnetic chitosan-lutaraldehyde composite. Int J Biol Macromol 131:633–645

Yin K, Wang Q, Lv M, Chen L (2019) Microorganism remediation strategies towards heavy metals. Chem Eng J 360:1553–1563

Raval AR, Kohli HP, Mahadwad OK (2022) Application of emulsion liquid membrane for removal of malachite green dye from aqueous solution: extraction and stability studies. Chem Eng J Adv 12:100398

Raval NP, Shah PU, Shah NK (2017) Malachite green “a cationic dye” and its removal from aqueous solution by adsorption. Appl Water Sci 7:3407–3445

Ismail M, Akhtar K, Khan M, Kamal T, Khan MA, Asiri AM, Seo J, Khan SB (2019) Pollution, toxicity and carcinogenicity of organic dyes and their catalytic bio-remediation. Curr Pharm Des 25(34):3645–3663

Eltaweil A, Mohamed HA, Abd El-Monaem EM, El-Subruiti G (2020) Mesoporous magnetic biochar composite for enhanced adsorption of malachite green dye: characterization, adsorption kinetics, thermodynamics and isotherms. Adv Powder Technol 31(3):1253–1263

Sharma G, Sharma S, Kumar A, Naushad M, Du B, Ahamad T, Ghfar AA, Alqadami AA, Stadler FJ (2019) Honeycomb structured activated carbon synthesized from Pinus roxburghii cone as effective bioadsorbent for toxic malachite green dye. J Water Proc Eng 32:100931

Pandey D, Daverey A, Dutta K, Arunachalam K (2022) Bioremoval of toxic malachite green from water through simultaneous decolorization and degradation using laccase immobilized biochar. Chemosphere 297:134126

Jiang T, Duan Q, Zhu J, Liu H, Yu L (2020) Starch-based biodegradable materials: challenges and opportunities. Adv Ind Eng Polymer Res 3(1):8–18

Majzoobi M, Farahnaky A (2021) Granular cold-water swelling starch; properties, preparation and applications, a review. Food Hydrocoll 111:106393

Angel N, Li S, Yan F, Kong L (2022) Recent advances in electrospinning of nanofibers from bio-based carbohydrate polymers and their applications. Trends Food Sci Technol 120:308–324

Punia S (2020) Barley starch modifications: physical, chemical and enzymatic-A review. Int J Biol Macromol 144:578–585

Tabasum S, Younas M, Zaeem MA, Majeed I, Majeed M, Noreen A, Iqbal MN, Zia KM (2019) A review on blending of corn starch with natural and synthetic polymers, and inorganic nanoparticles with mathematical modeling. Int J Biol Macromol 122:969–996

Haroon M, Wang L, Yu H, Ullah RS, Khan RU, Chen Q, Liu J (2018) Synthesis of carboxymethyl starch-g-polyvinylpyrolidones and their properties for the adsorption of Rhodamine 6G and ammonia. Carbohyd Polym 186:150–158

Radwan EK, El-Naggar ME, Abdel-Karim A, Wassel AR (2021) Multifunctional 3D cationic starch/nanofibrillated cellulose/silver nanoparticles nanocomposite cryogel: synthesis, adsorption, and antibacterial characteristics. Int J Biol Macromol 189:420–431

Oladipo AA, Gazi M, Saber-Samandari S (2014) Adsorption of anthraquinone dye onto eco-friendly semi-IPN biocomposite hydrogel: equilibrium isotherms, kinetic studies and optimization. J Taiwan Inst Chem Eng 45(2):653–664

Awode AU, Elaigwu S, Oladipo AA, Yilmaz O, Mustafa G. Removal of methylene blue dye from aqueous solution using trichlorovinylsilane chitosan–g–polyacrylamide hydrogel. J Turkish Chem Soc Sect A: Chem 10(4):1009–1018

Mallakpour S, Sirous F, Dinari M (2022) Bio-sorbent alginate/citric acid-sawdust/Fe3O4 nanocomposite beads for highly efficient removal of malachite green from water. Int J Biol Macromol 222:2683–2696

Algethami JS, Alhamami MA, Alqadami AA, Melhi S, Seliem AF (2024) Magnetic hydrochar grafted-chitosan for enhanced efficient adsorption of malachite green dye from aqueous solutions: modeling, adsorption behavior, and mechanism analysis. Int J Biol Macromol 254:127767

Hammud HH, Hammoud MH, Hussein AA, Fawaz YB, Abdul Hamid MHS, Sheikh NS (2023) Removal of malachite green using hydrochar from PALM leaves. Sustainability 15(11):8939

Mustapha R, Ali A, Subramaniam G, Zuki AAA, Awang M, Harun MHC, Hamzah S (2021) Removal of malachite green dye using oil palm empty fruit bunch as a low-cost adsorbent. Biointerface Res Appl Chem 11(6):14998–15008

Akar E, Altinişik A, Seki Y (2013) Using of activated carbon produced from spent tea leaves for the removal of malachite green from aqueous solution. Ecol Eng 52:19–27

Tarani E, Arvanitidis I, Christofilos D, Bikiaris DN, Chrissafis K, Vourlias G (2023) Calculation of the degree of crystallinity of HDPE/GNPs nanocomposites by using various experimental techniques: a comparative study. J Mater Sci 58(4):1621–1639

Lin J, Wang L (2009) Comparison between linear and non-linear forms of pseudo-first-order and pseudo-second-order adsorption kinetic models for the removal of methylene blue by activated carbon. Front Environ Sci Eng China 3:320–324

Boparai HK, Joseph M, O’Carroll DM (2011) Kinetics and thermodynamics of cadmium ion removal by adsorption onto nano zerovalent iron particles. J Hazard Mater 186(1):458–465

Kahya N, Şen BM, Berber D, Öztekin N (2024) Comparison of dye adsorption of chitosan and polyethylenimine modified bentonite clays: optimization, isotherm, and kinetic studies. ACS Omega

Ansari H, Oladipo AA, Gazi M (2023) Alginate-based porous polyHIPE for removal of single and multi-dye mixtures: competitive isotherm and molecular docking studies. Int J Biol Macromol 246:125736

Kolya H, Das S, Tripathy T (2014) Synthesis of Starch-g-Poly-(N-methylacrylamide-co-acrylic acid) and its application for the removal of mercury (II) from aqueous solution by adsorption. Eur Polymer J 58:1–10

Wang Z, Shi H, Wang F, Wang A, He Q, Cuan S (2021) Synthesis of cassava starch-g-acrylic acid/dimethylaminopropyl methacrylamide: a new hydrogel for brine solution. Carbohyd Polym 266:118109

Yasmeen U, Haq F, Kiran M, Farid A, Ullah N, Aziz T, Haroon M, Mehmood S, Muzammal M, Ghazanfar S (2022) Synthesis of starch-grafted polymethyl methacrylate via free radical polymerization reaction and its application for the uptake of methylene blue. Molecules 27(18):5844

Clasen SH, Müller CM, Parize AL, Pires AT (2018) Synthesis and characterization of cassava starch with maleic acid derivatives by etherification reaction. Carbohyd Polym 180:348–353

Liu J, Wang X, Bai R, Zhang N, Kan J, Jin C (2018) Synthesis, characterization, and antioxidant activity of caffeic-acid-grafted corn starch. Starch-Stärke 70(1–2):1700141

Xiao Z, Wang L, Lv C, Guo S, Lu X, Tao L, Duan Q, Yang Q, Luo Z (2020) Preparation and characterization of pH-responsive Pickering emulsion stabilized by grafted carboxymethyl starch nanoparticles. Int J Biol Macromol 143:401–412

Czarnecka E, Nowaczyk J (2021) Synthesis and characterization superabsorbent polymers made of starch, acrylic acid, acrylamide, poly (Vinyl alcohol), 2-hydroxyethyl methacrylate, 2-acrylamido-2-methylpropane sulfonic acid. Int J Mol Sci 22(9):4325

Al-Mokhalelati K, Karabet F, Allaf A, Naddaf M, Al Lafi A (2023) Spectroscopic investigations to reveal synergy between polystyrene waste and paraffin wax in super-hydrophobic sand. Sci Rep 13(1):9810

Norfarhana A, Ilyas R, Ngadi N, Othman MHD (2024) Optimization of ionic liquid pretreatment of sugar palm fiber for cellulose extraction. J Mol Liquids 124256

Siyamak S, Laycock B, Luckman P (2020) Synthesis of starch graft-copolymers via reactive extrusion and their ammonium sorption properties. Chem Eng J 398:124291

Din H, Kiran M, Haq F, Osman AI, Khan IA, Aziz T, Khan A, Jilani S (2024) synergizing date palm seeds-derived oxidized activated carbon: sustainable innovation for enhanced water retention, efficient wastewater treatment, and synthetic dye removal. Chem Eng Res Design

Abd El-Ghany NA, Elella MHA, Abdallah HM, Mostafa MS, Samy M (2023) Recent advances in various starch formulation for wastewater purification via adsorption technique: a review. J Polym Environ 1–34

He G, Ke W, Chen X, Kong Y, Zheng H, Yin Y, Cai W (2017) Preparation and properties of quaternary ammonium chitosan-g-poly (acrylic acid-co-acrylamide) superabsorbent hydrogels. React Funct Polym 111:14–21

Ma D, Zhu B, Cao B, Wang J, Zhang J (2016) The microstructure and swelling properties of poly acrylic acid-acrylamide grafted starch hydrogels. J Macromol Sci Part B 55(11):1124–1133

Seung D (2020) Amylose in starch: towards an understanding of biosynthesis, structure and function. New Phytol 228(5):1490–1504

Zhang Q, Wang Z, Zhang C, Aluko RE, Yuan J, Ju X, He R (2020) Structural and functional characterization of rice starch-based superabsorbent polymer materials. Int J Biol Macromol 153:1291–1298

Altaf F, Niazi MBK, Jahan Z, Ahmad T, Akram MA, Safdar A, Butt MS, Noor T, Sher F (2021) Synthesis and characterization of PVA/starch hydrogel membranes incorporating essential oils aimed to be used in wound dressing applications. J Polym Environ 29:156–174

Ojogbo E, Ogunsona EO, Mekonnen TH (2020) Chemical and physical modifications of starch for renewable polymeric materials. Mater Today Sustain 7:100028

Bustamante-Torres M, Romero-Fierro D, Arcentales-Vera B, Palomino K, Magaña H, Bucio E (2021) Hydrogels classification according to the physical or chemical interactions and as stimuli-sensitive materials. Gels 7(4):182

Hassan NA, Darwesh OM, Smuda SS, Altemimi AB, Hu A, Cacciola F, Haoujar I, Abedelmaksoud TG (2022) Recent trends in the preparation of nano-starch particles. Molecules 27(17):5497

Cummings S, Zhang Y, Smeets N, Cunningham M, Dubé MA (2019) On the use of starch in emulsion polymerizations. Processes 7(3):140

Farivar F, Yap PL, Hassan K, Tung TT, Tran DN, Pollard AJ, Losic D (2021) Unlocking thermogravimetric analysis (TGA) in the fight against “Fake graphene” materials. Carbon 179:505–513

Escalante J, Chen W-H, Tabatabaei M, Hoang AT, Kwon EE, Lin K-YA, Saravanakumar A (2022) Pyrolysis of lignocellulosic, algal, plastic, and other biomass wastes for biofuel production and circular bioeconomy: a review of thermogravimetric analysis (TGA) approach. Renew Sustain Energy Rev 169:112914

Mankar SV, Garcia Gonzalez MN, Warlin N, Valsange NG, Rehnberg N, Lundmark S, Jannasch P, Zhang B (2019) Synthesis, life cycle assessment, and polymerization of a vanillin-based spirocyclic diol toward polyesters with increased glass-transition temperature. ACS Sustain Chem Eng 7(23):19090–19103

Leyva-Porras C, Cruz-Alcantar P, Espinosa-Solís V, Martínez-Guerra E, Piñón-Balderrama CI, Compean Martínez I, Saavedra-Leos MZ (2019) Application of differential scanning calorimetry (DSC) and modulated differential scanning calorimetry (MDSC) in food and drug industries. Polymers 12(1):5

Olad A, Doustdar F, Gharekhani H (2020) Fabrication and characterization of a starch-based superabsorbent hydrogel composite reinforced with cellulose nanocrystals from potato peel waste. Colloids Surf A 601:124962

Elwakeel KZ, Al-Bogami AS, Guibal E (2021) 2-Mercaptobenzimidazole derivative of chitosan for silver sorption–Contribution of magnetite incorporation and sonication effects on enhanced metal recovery. Chem Eng J 403:126265

Dan S, Banivaheb S, Hashemipour H, Kalantari M (2021) Synthesis, characterization and absorption study of chitosan-g-poly (acrylamide-co-itaconic acid) hydrogel. Polym Bull 78:1887–1907

El-Hoshoudy A (2019) Synthesis of acryloylated starch-g-poly acrylates crosslinked polymer functionalized by emulsified vinyltrimethylsilane derivative as a novel EOR agent for severe polymer flooding strategy. Int J Biol Macromol 123:124–132

Zhu W, Yang Z, Yasin A, Liu Y, Zhang L (2021) Preparation of poly (acrylic acid-acrylamide/starch) composite and its adsorption properties for mercury (II). Materials 14(12):3277

Czarnecka E, Nowaczyk J (2020) Semi-Natural superabsorbents based on Starch-g-poly (acrylic acid): modification, synthesis and application. Polymers 12(8):1794

Chen X, Sun C, Wang Q, Tan H, Zhang Y (2022) Preparation of glycidyl methacrylate grafted starch adhesive to apply in high-performance and environment-friendly plywood. Int J Biol Macromol 194:954–961

Chen Q, Zhao Y, Xie Q, Liang C, Zong Z (2021) Polyethyleneimine grafted starch nanocrystals as a novel biosorbent for efficient removal of methyl blue dye. Carbohyd Polym 273:118579

Dai H, Zhang Y, Ma L, Zhang H, Huang H (2019) Synthesis and response of pineapple peel carboxymethyl cellulose-g-poly (acrylic acid-co-acrylamide)/graphene oxide hydrogels. Carbohyd Polym 215:366–376

Xun J, Lou T, Xing J, Zhang W, Xu Q, Peng J, Wang X (2019) Synthesis of a starch–acrylic acid–chitosan copolymer as flocculant for dye removal. J Appl Polym Sci 136(20):47437

Mirza I, Saha S (2020) Biocompatible anisotropic polymeric particles: synthesis, characterization, and biomedical applications. ACS Appl Bio Mater 3(12):8241–8270

Al-Aidy H, Amdeha E (2021) Green adsorbents based on polyacrylic acid-acrylamide grafted starch hydrogels: the new approach for enhanced adsorption of malachite green dye from aqueous solution. Int J Environ Anal Chem 101(15):2796–2816

Qi X, Tong X, Pan W, Zeng Q, You S, Shen J (2021) Recent advances in polysaccharide-based adsorbents for wastewater treatment. J Clean Prod 315:128221

Zhu W, Zheng X, Shi J, Wang Y (2021) A high-temperature resistant colloid gas aphron drilling fluid system prepared by using a novel graft copolymer xanthan gum-AA/AM/AMPS. J Petrol Sci Eng 205:108821

Cai C, Wei B, Jin Z, Tian Y (2017) Facile method for fluorescent labeling of starch nanocrystal. ACS Sustain Chem Eng 5(5):3751–3761

Li H, Zhang B, Lü S, Ma H, Liu M (2018) Synthesis and characterization of a nano fluorescent starch. Int J Biol Macromol 120:1225–1231

Tan X-F, Zhu S-S, Wang R-P, Chen Y-D, Show P-L, Zhang F-F, Ho S-H (2021) Role of biochar surface characteristics in the adsorption of aromatic compounds: pore structure and functional groups. Chin Chem Lett 32(10):2939–2946

Haq F, Yu H, Wang Y, Wang L, Haroon M, Khan A, Mehmood S, Lin T (2020) Synthesis of carboxymethyl starch grafted poly (methacrylic acids)(CMS-g-PMAAs) and their application as an adsorbent for the removal of ammonia and phenol. J Mol Struct 1207:127752

Zhang S, Lee J, Li B, Zhang T, Baeck SH, Shim SE (2024) Industrial solid waste-based layered double hydroxide composite with enhanced adsorption affinity to congo red, acid red, and reactive red. Korean J Chem Eng 1–10

Swan NB, Zaini MAA (2019) Adsorption of malachite green and congo red dyes from water: recent progress and future outlook. Ecol Chem Eng S 26(1):119–132

Iheanacho OC, Nwabanne JT, Obi CC, Igwegbe CA, Onu CE, Dahlan I (2023) Adsorptive dephenolization of aqueous solutions using thermally modified corn cob: mechanisms, point of zero charge, and isosteric heat studies. Adsorpt Sci Technol 2023

Praipipat P, Ngamsurach P, Sanghuayprai A (2023) Modification of sugarcane bagasse with iron (III) oxide-hydroxide to improve its adsorption property for removing lead (II) ions. Sci Rep 13(1):1467

dos Reis Oliveira M, Paulino IMR, Resende JF, Simão L, Vieira MF, Bergamasco R, Vieira AMS (2023) Valorization of biomass ash for the effective removal of dipyrone from water: an efficient and low-cost option. J Chem Technol Biotechnol 98(7):1690–1702

Ahmed AS, Sanad MM, Kotb A, Negm AN, Abdallah MH (2023) Removal of methyl red from wastewater using a NiO@ Hyphaene thebaica seed-derived porous carbon adsorbent: kinetics and isotherm studies. Mater Adv 4(14):2981–2990

Rápó E, Tonk S (2021) Factors affecting synthetic dye adsorption; desorption studies: a review of results from the last five years (2017–2021). Molecules 26(17):5419

Vakili A, Zinatizadeh A, Rahimi Z, Zinadini S, Mohammadi P, Azizi S, Karami A, Abdulgader M (2023) The impact of activation temperature and time on the characteristics and performance of agricultural waste-based activated carbons for removing dye and residual COD from wastewater. J Clean Prod 382:134899

Jiao G-J, Ma J, Li Y, Jin D, Guo Y, Zhou J, Sun R (2021) Enhanced adsorption activity for phosphate removal by functional lignin-derived carbon-based adsorbent: optimization, performance and evaluation. Sci Total Environ 761:143217

Ullah N, Haq F, Farid A, Kiran M, Al Othman ZA, Aljuwayid AM, Habila MA, Bokhari A, Rajendran S, Khoo KS (2023) Coupling of carboxymethyl starch with 2-carboxyethyl acrylate: a new sorbent for the wastewater remediation of methylene blue. Environ Res 219:115091