Abstract

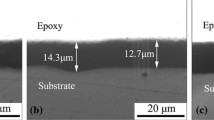

Due to their biodegradable nature and enhanced adhesive strength at the interface, poly– (lactic acid) (PLA) based coatings are frequently used in biomedical alloys. But it is unable to create metal-tissue interaction because of its very hydrophobic surface feature. Researchers are therefore looking at composite coatings that are reinforced with hydroxyapatite (HA). In this study, the effect of halloysite nanotube (HNT) was investigated to hydroxyapatite (HA) reinforced PLA coatings synthesized on Ti–6Al–4V (Ti64) biomedical alloy. Investigations were conducted on the hybrid coatings’ characterization such as SEM/EDS, FTIR, contact angle tests, and XRD analyses. Adhesion tests at alloy-coating interface were revealed with ASTM D3359–09 standards. In-vitro electrochemical corrosion tests (ASTM–G59) and immersion tests (ISO-23317) were conducted on coatings for reveal both biodegradability and osteoconductivity behaviours of coatings. SEM morphologies revealed that surfaces have micron-sized pores on both coatings. But HA/HNT reinforced coatings have more homogenous morphology with decreased pore size. The elemental distribution of coatings was confirmed by the EDS analyses. While FTIR research demonstrated a variation in the influence of HNT on the coating of PLA depending on the bond status, XRD results showed that there were no phase changes in the coatings. It was found that coatings with HNT reinforcement, have higher adhesion strength at the substrate-coating interface (1B for HA and 4B for HA/HNT reinforced coatings). Following in-vitro electrochemical corrosion experiments, it was discovered that the corrosion current density (Icorr) value reduced even more with the PLA/HA-HNT coating (1.784, 0.245, and 0.032 µA cm–1) than it did with the PLA/HA coating alone. The results of the impedance spectroscopy (Nyquist curves) confirmed that the coatings’ corrosion resistance increased as the Icorr value decreased. Possible corrosion mechanism was discussed with equivalent circuit model which consist two–constant elements. It was found that both coatings exhibited a characteristic that induced calcium phosphates (CaPs) on their surfaces after in-vitro immersion tests. The contact angle tests revealed that the high hydrophobic effects of coatings would have a positive effect on the alloy–tissue interaction in the long term due to the bioactive compounds that they have. The dense and homogeneous CaPs in the PHH coatings increased with HNT reinforcement, leading to more effective interaction with surrounding tissues during in-vitro tests. The findings led to the conclusion that the hybrid coatings produced with the reinforcement of HA/HNT will not readily delaminate during application and will improve the interaction between the alloy and the tissue under prolonged physiological conditions.

Graphical Abstract

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Niinomi M (2008) Mechanical biocompatibilities of titanium alloys for biomedical applications. J Mech Behav Biomed Mater 1:30–42. https://doi.org/10.1016/j.jmbbm.2007.07.001

Topuz M, Dikici B, Gavgali M (2021) Titanium-based composite scaffolds reinforced with hydroxyapatite-zirconia: production, mechanical and in-vitro characterization. J Mech Behav Biomed Mater 118:104480. https://doi.org/10.1016/j.jmbbm.2021.104480

Liu H, Niinomi M, Nakai M et al (2015) Mechanical properties and cytocompatibility of oxygen-modified β-type Ti-Cr alloys for spinal fixation devices. Acta Biomater 12:352–361. https://doi.org/10.1016/j.actbio.2014.10.014

Leyens C, Peters M (2003) Titanium and its Alloys for Medical Applications. In: Titanium and Titanium Alloys. pp xix, 423

Zhou YL, Niinomi M, Akahori T et al (2005) Corrosion resistance and biocompatibility of Ti-Ta alloys for biomedical applications. Mater Sci Eng A 398:28–36. https://doi.org/10.1016/j.msea.2005.03.032

Topuz M, Dikici B, Gavgali M, Kaseem M (2021) Processing of Ti/(HA + ZrO2) biocomposite and 50% porous hybrid scaffolds with low Young’s modulus by powder metallurgy: comparing of structural, mechanical, and corrosion properties. Mater Today Commun. https://doi.org/10.1016/j.mtcomm.2021.102813

Williams D (1993) Titanium: of biocompatibility or cause. J Bone Jt Surg 1993–1994

Catauro M, Bollino F, Papale F (2014) Biocompatibility improvement of titanium implants by coating with hybrid materials synthesized by sol-gel technique. J Biomed Mater Res - Part A 102:4473–4479. https://doi.org/10.1002/jbm.a.35116

Dikici B, Niinomi M, Topuz M et al (2018) Synthesis of biphasic calcium phosphate (BCP) coatings on β–type titanium alloys reinforced with rutile-TiO2 compounds: adhesion resistance and in-vitro corrosion. J Sol-Gel Sci Technol 87:713–724. https://doi.org/10.1007/s10971-018-4755-2

Dikici B, Niinomi M, Topuz M et al (2018) Synthesis and characterization of hydroxyapatite/TiO2 coatings on the β-type titanium alloys with different sintering parameters using Sol-Gel Method. Prot Met Phys Chem Surfaces 54:457–462. https://doi.org/10.1134/S2070205118030255

Topuz M, Dikici B, Gavgalı M (2021) Challenges in the production of titanium–based Scaffolds bio–functionalized with hydroxyapatite by powder metallurgy technique. Eur J Sci Technol 2021:46–51. https://doi.org/10.31590/ejosat.980402

Topuz M (2022) Effect of ZrO2 on morphological and adhesion properties of hydroxyapatite reinforced poly– (lactic) acid matrix hybrid coatings on mg substrates. Res Eng Struct Mater 8:721–733. https://doi.org/10.17515/resm2022.434me0520

Topuz M, Dikici B, Gavgalı M, Yılmazer Y (2022) Effect of hydroxyapatite:zirconia volume fraction ratio on mechanical and corrosive properties of Ti-matrix composite scaffolds. Trans Nonferrous Met Soc China 32:882–894. https://doi.org/10.1016/s1003-6326(22)65840-0

Chozhanathmisra M, Ramya S, Kavitha L, Gopi D (2016) Development of zinc-halloysite nanotube/minerals substituted hydroxyapatite bilayer coatings on titanium alloy for orthopedic applications. Colloids Surf Physicochem Eng Asp 511:357–365. https://doi.org/10.1016/j.colsurfa.2016.10.018

Dharmaraj BM, Subramani R, Dhanaraj G, Louis K (2020) Multifunctional halloysite nanotube based composite coatings on titanium as metal implant for orthopedic applications. Compos Part C Open Access 3:100077. https://doi.org/10.1016/j.jcomc.2020.100077

Topuz M (2023) Hydroxyapatite – Al2O3 reinforced poly– (lactic acid) hybrid coatings on magnesium: characterization, mechanical and in-vitro bioactivity properties. Surf Interfaces 37:102724. https://doi.org/10.1016/j.surfin.2023.102724

Chen Y, Geever LM, Killion JA et al (2016) Review of multifarious applications of poly (lactic acid). Polym - Plast Technol Eng 55:1057–1075. https://doi.org/10.1080/03602559.2015.1132465

Igwe Idumah C, Nwabanne JT, Tanjung FA (2021) Novel trends in poly (lactic) acid hybrid bionanocomposites. Clean Mater 2:100022. https://doi.org/10.1016/j.clema.2021.100022

Chozhanathmisra M, Pandian K, Govindaraj D et al (2019) Halloysite nanotube-reinforced ion-incorporated hydroxyapatite-chitosan composite coating on Ti-6Al-4 v alloy for implant application. J Chem. https://doi.org/10.1155/2019/7472058

Chozhanathmisra M, Murugesan L, Murugesan A et al (2022) Enhancement on physical, chemical, and biological properties of HNT-PVA-ALG-HAp biocomposite coating on implant substrate for biomedical application. Ceram Int 48:16868–16876. https://doi.org/10.1016/j.ceramint.2022.02.241

Molaei A, Yari M, Afshar MR (2017) Investigation of halloysite nanotube content on electrophoretic deposition (EPD) of chitosan-bioglass-hydroxyapatite-halloysite nanotube nanocomposites films in surface engineering. Appl Clay Sci 135:75–81. https://doi.org/10.1016/j.clay.2016.09.008

Gkouma E, Gianni E, Avgoustakis K, Papoulis D (2021) Applications of halloysite in tissue engineering. Appl Clay Sci 214:106291. https://doi.org/10.1016/j.clay.2021.106291

Zahidah KA, Kakooei S, Ismail MC, Bothi Raja P (2017) Halloysite nanotubes as nanocontainer for smart coating application: a review. Prog Org Coatings 111:175–185. https://doi.org/10.1016/j.porgcoat.2017.05.018

Ranganatha S, Venkatesha TV, Vathsala K (2012) Development of high performance electroless Ni-P-HNT composite coatings. Appl Surf Sci 263:149–156. https://doi.org/10.1016/j.apsusc.2012.09.020

Molaei A, Amadeh A, Yari M, Reza Afshar M (2016) Structure, apatite inducing ability, and corrosion behavior of chitosan/halloysite nanotube coatings prepared by electrophoretic deposition on titanium substrate. Mater Sci Eng C 59:740–747. https://doi.org/10.1016/j.msec.2015.10.073

Abdullayev E, Lvov Y (2011) Halloysite clay nanotubes for controlled release of protective agents. J Nanosci Nanotechnol 11:10007–10026. https://doi.org/10.1166/jnn.2011.5724

Zhou Z, Cai K, Shen J et al (2022) Fabrication and biological assessment of halloysite-doped micro/nano structures on titanium surface. Ceram Int 49:8886–8896. https://doi.org/10.1016/j.ceramint.2022.11.044

Topuz M, Dikici B (2020) Two simple methods for surface modification of lithium disilicate dental blocks with hydroxyapatite. Res Eng Struct Mater 6:97–104. https://doi.org/10.17515/resm2019.132me0506tn

Ding Z, Tang Y, Liu L et al (2021) Improving the adhesive, mechanical, tribological properties and corrosion resistance of reactive sputtered tantalum oxide coating on Ti6Al4V alloy via introducing multiple interlayers. Ceram Int 48:5983–5994. https://doi.org/10.1016/j.ceramint.2021.11.134

Wang Y, Yang Y, Liu M (2022) Electrophoretic deposition of halloysite nanotubes/PVA composite coatings for corrosion protection of metals. Appl Mater Today 29:101657. https://doi.org/10.1016/j.apmt.2022.101657

Onder OC, Nazeer MA, Yilgör E, Yilgör I (2018) Spontaneous formation of microporous poly(lactic acid) coatings. Prog Org Coatings 125:249–256. https://doi.org/10.1016/j.porgcoat.2018.09.016

Shi P, Niu B et al (2015) Preparation and characterization of PLA coating and PLA/MAO composite coatings on AZ31 magnesium alloy for improvement of corrosion resistance. Surf Coat Technol 262:26–32. https://doi.org/10.1016/j.surfcoat.2014.11.069

ASTM D3359-09 (2012) Standard test methods for Measuring. Adhesion by Tape Test

ISO 23317 (2009) Implants for surgery —In vitro evaluation for apatite-forming ability of implant materials Implants

Bhagya Mathi D, Gopi D, Kavitha L (2020) Halloysite nanotubes strengthened hydroxyapatite/biopolymer composite coating on titanium for implant applications. AIP Conf Proc 2270:2–6. https://doi.org/10.1063/5.0019799

Dong Y, Marshall J, Haroosh HJ et al (2015) Polylactic acid (PLA)/halloysite nanotube (HNT) composite mats: influence of HNT content and modification. Compos Part A Appl Sci Manuf 76:28–36. https://doi.org/10.1016/j.compositesa.2015.05.011

Shugurov AR, Panin AV, Dmitriev AI, Nikonov AY (2020) Recovery of scratch grooves in Ti-6Al-4V alloy caused by reversible phase transformations. Met (Basel) 10:1–14. https://doi.org/10.3390/met10101332

Benea L, Mardare-Danaila E, Mardare M, Celis JP (2014) Preparation of titanium oxide and hydroxyapatite on Ti-6Al-4V alloy surface and electrochemical behaviour in bio-simulated fluid solution. Corros Sci 80:331–338. https://doi.org/10.1016/j.corsci.2013.11.059

Machado-López MM, Faure J, Espinosa-Medina MA et al (2015) Enhanced corrosion resistance in artificial saliva of Ti6Al4V with ZrO2 nanostructured coating. J Electrochem Soc 162:D3090–D3100. https://doi.org/10.1149/2.0231511jes

Wu WX, Wang WP, Lin HC (2021) A study on corrosion behavior of micro-arc oxidation coatings doped with 2-aminobenzimidazole loaded halloysite nanotubes on AZ31 magnesium alloys. Surf Coat Technol. https://doi.org/10.1016/j.surfcoat.2021.127116

Yigit O, Dikici B, Ozdemir N et al (2021) Plasma electrolytic oxidation of Ti-6Al-4V alloys in nHA/GNS containing electrolytes for biomedical applications: the combined effect of the deposition frequency and GNS weight%. Surf Coat Technol 32:127139. https://doi.org/10.1007/s10856-021-06514-w

Rastegari S, Salahinejad E (2019) Surface modification of Ti-6Al-4V alloy for osseointegration by alkaline treatment and chitosan-matrix glass-reinforced nanocomposite coating. Carbohydr Polym 205:302–311. https://doi.org/10.1016/j.carbpol.2018.10.082

Scharnweber D, Beutner R, Rößler S, Worch H (2002) Electrochemical behavior of titanium-based materials - are there relations to biocompatibility? J Mater Sci Mater Med 13:1215–1220. https://doi.org/10.1023/A:1021118811893

Agrawal G, Negi YS, Pradhan S et al (2017) Wettability and contact angle of polymeric biomaterials. Characterization of polymeric biomaterials. Elsevier, Amsterdam, pp 57–81

Magueta F, Fernandes A, Hortigüela MH et al (2021) Poly (L-lactic acid) coatings on 316 SS substrates for biomedical devices: the impact of surface silanization. Prog Org Coatings 157:106289. https://doi.org/10.1016/j.porgcoat.2021.106289

Strnad G, Chirila N, Petrovan C, Russu O (2016) Contact angle measurement on medical implant titanium based biomaterials. Procedia Technol 22:946–953. https://doi.org/10.1016/j.protcy.2016.01.094

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

MT confirms sole responsibility for the following: study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The author has no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Topuz, M. Investigation of Halloysite Nanotube Effect in Poly– (Lactic acid)/Hydroxyapatite Coatings on Ti–6Al–4V Biomedical Alloy. J Polym Environ 31, 4112–4126 (2023). https://doi.org/10.1007/s10924-023-02926-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02926-7