Abstract

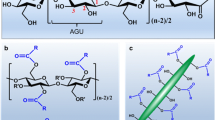

In the pursuit of a sustainable and pollution free environment, the need for bioplastic alternatives that satisfy many of the performance demands of persistent petroleum-derived plastics is paramount. Biopolymer films reinforced with nanostructures have become an interesting area of research. Poly(butylene adipate-co-terephthalate) (PBAT) is a synthetic polymer capable of biodegrading at ambient temperature. The polar nature of cellulose nanocrystals (CNCs) used as additive in PBAT matrix makes its dispersion challenging. In this work silylation was achieved by partial substitution of surface hydroxyl groups of nanocellulose with hydrophobic silicone moieties. The surface of nanocellulose was initially modified by 5 wt.% of triethoxyvinylsilane (TEVS) or trimethoxyphenylsilane (TMPS) and melt blended into the PBAT matrix. Phenyl modified nanocellulose used as additive in PBAT matrix achieved uniform dispersion. The phenyl silane modified CNCs based composite film had 12% higher tensile strength and −58% higher modulus of elasticity than pristine PBAT films. The phenyl silane modified CNCs substantially reduced the permeability of the composite films against both water vapour and oxygen. Food packaging applications may benefit from this material as it could meet many of the performance requirements in terms of morphological, mechanical, thermal and barrier properties.

Similar content being viewed by others

References

Cazón P, Vázquez M, Velazquez G (2018) Cellulose-glycerol-polyvinyl alcohol composite films for food packaging: evaluation of water adsorption, mechanical properties, light-barrier properties and transparency. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2018.04.120

Barbosa RF, Souza AG, Rosa DS (2020) Acetylated cellulose nanostructures as reinforcement materials for PBAT nanocomposites. Polym Compos. https://doi.org/10.1002/pc.25580

Venkatesan R, Rajeswari N (2017) ZnO/PBAT nanocomposite films: investigation on the mechanical and biological activity for food packaging. Polym Adv Technol. https://doi.org/10.1002/pat.3847

Venkatesan R, Rajeswari N (2019) Preparation, mechanical and antimicrobial properties of SiO2/poly (butylene adipate-co-terephthalate) films for active food packaging. Silicon. https://doi.org/10.1007/s12633-015-9402-8

Ding K, Wei N, Zhou Y, Wang Y, Wu D, Liu H, Yu H, Zhou C, Chen J, Chen C (2016) Viscoelastic behavior and model simulations of poly (butylene adipate-co-terephthalate) biocomposites with carbon nanotubes: hierarchical structures and relaxation. J. Compos. Mater. https://doi.org/10.1177/0021998315596592.

Chengwei Z, Yu Z, Zhihua W (2013) Study on degradation properties of filled PBAT composite. Plast. Sci. Technol 9:1–7

Scaffaro R, Maio A, Gulino EF, Morreale M, La Mantia FP (2020) The effects of nanoclay on the mechanical properties, carvacrol release and degradation of a PLA/PBAT blend. Materials. https://doi.org/10.3390/ma13040983

Falcão GA, Almeida TG, Bardi MA, Carvalho LH, Canedo EL (2019) PBAT/organoclay composite films—part 2: effect of UV aging on permeability, mechanical properties and biodegradation. Polym. Bull. https://doi.org/10.1007/s00289-018-2385-z.

Venkatesan R, Rajeswari N (2017) TiO2 nanoparticles/poly (butylene adipate-co‐terephthalate) bionanocomposite films for packaging applications. Polym. Adv. Technol. https://doi.org/10.1002/pat.4042.

Venkatesan R, Alagumalai K, Kim SC (2023) Preparation and performance of biodegradable poly (butylene adipate-co-terephthalate) composites Reinforced with Novel AgSnO2 microparticles for application in food packaging. Polymers. https://doi.org/10.3390/polym15030554

Zhong B, Tang Y, Chen Y, Luo Y, Jia Z, Jia D (2023) Improvement of UV aging resistance of PBAT composites with silica-immobilized UV absorber prepared by a facile method. Polym. Degrad. Stab. https://doi.org/10.1016/j.polymdegradstab.2023.110337.

Xiong SJ, Pang B, Zhou SJ, Li MK, Yang S, Wang YY, Shi Q, Wang SF, Yuan TQ, Sun RC (2020) Economically competitive biodegradable PBAT/lignin composites: Effect of lignin methylation and compatibilizer. ACS Sustain. Chem. Eng. https://doi.org/10.1021/acssuschemeng.0c00789.

Liu Y, Liu S, Liu Z, Lei Y, Jiang S, Zhang K, Yan W, Qin J, He M, Qin S, Yu J (2021) Enhanced mechanical and biodegradable properties of PBAT/lignin composites via silane grafting and reactive extrusion. Compos. B. Eng. https://doi.org/10.1016/j.compositesb.2021.108980.

Kargarzadeh H, Galeski A, Pawlak A (2020) PBAT green composites: Effects of kraft lignin particles on the morphological, thermal, crystalline, macro and micromechanical properties. Polymer. https://doi.org/10.1016/j.polymer.2020.122748

Botta L, Titone V, Teresi R, Scarlata MC, Re GL, La Mantia FP, Lopresti F (2022) Biocomposite PBAT/lignin blown films with enhanced photo-stability. Int. J. Biol. Macromol. https://doi.org/10.1016/j.ijbiomac.2022.07.048.

Shorey R, Mekonnen TH (2022) Sustainable paper coating with enhanced barrier properties based on esterified lignin and PBAT blend. Int. J. Biol. Macromol. https://doi.org/10.1016/j.ijbiomac.2022.04.037.

Xie L, Huang J, Xu H, Feng C, Na H, Liu F, Xue L, Zhu J (2023). Effect of large sized reed fillers on properties and degradability of PBAT composites. Polym. Compos. https://doi.org/10.1002/pc.27202.

Gupta A, Chudasama B, Chang BP Mekonnen T (2021) Robust and sustainable PBAT–Hemp residue biocomposites: reactive extrusion compatibilization and fabrication. Compos. Sci. Technol. https://doi.org/10.1016/j.compscitech.2021.109014.

Conzatti L, Brunengo E, Utzeri R, Castellano M, Hodge P, Stagnaro P (2018) Macrocyclic oligomers as compatibilizing agent for hemp fibres/biodegradable polyester eco-composites. Polymer. https://doi.org/10.1016/j.polymer.2018.05.053.

Li Z, Wang C, Liu T, Ye X, He M, Zhao L, Li H, Ren J, Algadi H, Li Y, Jiang Q (2023) Interfacial interaction enhancement between biodegradable poly (butylene adipate-co-terephthalate) and microcrystalline cellulose based on covalent bond for improving puncture, tearing, and enzymatic degradation properties. Adv. Compos. Hybrid. Mater. https://doi.org/10.1007/s42114-023-00638-z.

Dhali K, Ghasemlou M, Daver F, Cass P, Adhikari B (2021) A review of nanocellulose as a new material towards environmental sustainability. Sci. Total Environ. https://doi.org/10.1016/j.scitotenv.2021.145871.

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew. Chem. Int. Ed. https://doi.org/10.1002/anie.201001273.

Ghasemlou M, Daver F, Ivanova EP, Habibi Y, Adhikari B (2021) Surface modifications of nanocellulose: from synthesis to high-performance nanocomposites. Prog. Polym. Sci. https://doi.org/10.1016/j.progpolymsci.2021.101418.

Mondal S (2018) Review on nanocellulose polymer nanocomposites. Polym. Plast. Technol. Eng. https://doi.org/10.1080/03602559.2017.1381253.

Zhang X, Ma P, Zhang Y (2016) Structure and properties of surface-acetylated cellulose nanocrystal/poly (butylene adipate-co-terephthalate) composites. Polym. Bull. https://doi.org/10.1007/s00289-015-1594-y.

Morelli CL, Belgacem MN, Branciforti MC, Bretas RE, Crisci A, Bras J (2016) Supramolecular aromatic interactions to enhance biodegradable film properties through incorporation of functionalized cellulose nanocrystals. Compos. Part A Appl. Sci. https://doi.org/10.1016/j.compositesa.2015.10.038.

Morelli CL, Belgacem N, Bretas RE, Bras J (2016) Melt extruded nanocomposites of polybutylene adipate-co‐terephthalate (PBAT) with phenylbutyl isocyanate modified cellulose nanocrystals. J. Appl. Polym. Sci. https://doi.org/10.1002/app.43678.

Pinheiro IF, Ferreira FV, Souza DHS, Gouveia RF, Lona LMF, Morales AR, Mei LHI (2017) Mechanical, rheological and degradation properties of PBAT nanocomposites reinforced by functionalized cellulose nanocrystals. Eur. Polym. J. https://doi.org/10.1016/j.eurpolymj.2017.10.026.

Lai L, Wang S, Li J, Liu P, Wu L, Wu H, Xu J, Severtson SJ, Wang WJ (2020) Stiffening, strengthening, and toughening of biodegradable poly (butylene adipate-co-terephthalate) with a low nanoinclusion usage. Carbohydr. Polym. https://doi.org/10.1016/j.carbpol.2020.116687.

Dhali K, Daver F, Cass P, Adhikari B (2022) Surface modification of the cellulose nanocrystals through vinyl silane grafting. Int. J. Biol. Macromol. https://doi.org/10.1016/j.ijbiomac.2022.01.079.

Mariano M, El Kissi N, Dufresne A (2016) Structural reorganization of CNC in injection-molded CNC/PBAT materials under thermal annealing. Langmuir. https://doi.org/10.1021/acs.langmuir.6b03220.

Li F, Xu X, Hao Q, Li Q, Yu J, Cao A (2006) Effects of comonomer sequential structure on thermal and crystallization behaviors of biodegradable poly (butylene succinate-co‐butylene terephthalate) s. J. Polym. Sci. B Polym. Phys. https://doi.org/10.1002/polb.20797.

Makowski T (2020) Hydrophobization of cotton fabric with silanes with different substituents. Cellulose. https://doi.org/10.1007/s10570-019-02776-4.

Raditoiu A, Raditoiu V, Amariutei V, Ghiurea M, Nicolae CA, Gabor R, Fierascu RC, Wagner LE (2012) Coloured silica hybrids for functionalizing cellulose materials. J. Optoelectron. Adv. Mater. 14: 846.

Li YH, Buriak JM (2006) Dehydrogenative silane coupling on silicon surfaces via early transition metal catalysis. Inorg. Chem. https://doi.org/10.1021/ic051431r.

Beaumont M, Bacher M, Opietnik M, Gindl-Altmutter W, Potthast A, Rosenau T (2018) A general aqueous silanization protocol to introduce vinyl, mercapto or azido functionalities onto cellulose fibers and nanocelluloses. Molecules. https://doi.org/10.3390/molecules23061427

Gwon JG, Lee SY, Doh GH, Kim JH (2010) Characterization of chemically modified wood fibers using FTIR spectroscopy for biocomposites. J. Appl. Polym. Sci. https://doi.org/10.1002/app.31746.

Fernandes SC, Sadocco P, Alonso-Varona A, Palomares T, Eceiza A, Silvestre AJ, Mondragon I, Freire CS (2013) Bioinspired antimicrobial and biocompatible bacterial cellulose membranes obtained by surface functionalization with aminoalkyl groups. ACS Appl. Mater. Interfaces. https://doi.org/10.1021/am400338n.

Zhang Z, Tingaut P, Rentsch D, Zimmermann T, Sèbe G (2015) Controlled silylation of nanofibrillated cellulose in water: reinforcement of a model polydimethylsiloxane network. ChemSusChem. https://doi.org/10.1002/cssc.201500525

Li X, Tan D, Xie L, Sun H, Sun S, Zhong G, Ren P (2018) Effect of surface property of halloysite on the crystallization behavior of PBAT. Appl. Clay Sci. https://doi.org/10.1016/j.clay.2018.02.005.

Yu T, Ren J, Li S, Yuan H, Li Y (2010) Effect of fiber surface-treatments on the properties of poly (lactic acid)/ramie composites. Compos. Part A Appl. Sci. https://doi.org/10.1016/j.compositesa.2009.12.006.

Xie J, Wang Z, Zhao Q, Yang Y, Xu J, Waterhouse GI, Zhang K, Li S, Jin P, Jin G (2018) Scale-up fabrication of biodegradable poly (butylene adipate-co-terephthalate)/organophilic–clay nanocomposite films for potential packaging applications. ACS Omega 3. https://doi.org/10.1021/acsomega.7b02062

Šturcová A, Davies GR, Eichhorn SJ (2005) Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromolecules. https://doi.org/10.1021/bm049291k.

Wu CS (2012) Characterization of cellulose acetate-reinforced aliphatic–aromatic copolyester composites. Carbohydr. Polym. https://doi.org/10.1016/j.carbpol.2011.09.009.

Moustafa H, Guizani C, Dupont C, Martin V, Jeguirim M, Dufresne A (2017) Utilization of torrefied coffee grounds as reinforcing agent to produce high-quality biodegradable PBAT composites for food packaging applications. ACS Sustain. Chem. Eng. https://doi.org/10.1021/acssuschemeng.6b02633.

Xing Q, Ruch D, Dubois P, Wu L, Wang WJ (2017) Biodegradable and high-performance poly (butylene adipate-co-terephthalate)–lignin UV-blocking films. ACS Sustain. Chem. Eng. https://doi.org/10.1021/acssuschemeng.7b02370.

Li J, Lai L, Wu L, Severtson SJ, Wang WJ (2018) Enhancement of water vapor barrier properties of biodegradable poly (butylene adipate-co-terephthalate) films with highly oriented organomontmorillonite. ACS Sustain. Chem. Eng. https://doi.org/10.1021/acssuschemeng.8b00430.

Ferreira FV, Franceschi W, Menezes BRC, Brito FS, Lozano K, Coutinho AR, Cividanes LS, Thim GP (2017) Dodecylamine functionalization of carbon nanotubes to improve dispersion, thermal and mechanical properties of polyethylene based nanocomposites. Appl. Surf. Sci. https://doi.org/10.1016/j.apsusc.2017.03.098.

Mohanty S, Nayak SK (2010) Aromatic-aliphatic poly (butylene adipate‐co‐terephthalate) bionanocomposite: influence of organic modification on structure and properties. Polym. Compos. https://doi.org/10.1002/pc.20906.

Yang F, Qiu Z (2011) Preparation, crystallization, and properties of biodegradable poly (butylene adipate-co‐terephthalate)/organomodified montmorillonite nanocomposites. J. Appl. Polym. Sci. https://doi.org/10.1002/app.32619.

Kashani Rahimi S, Aeinehvand R, Kim K, Otaigbe JU (2017) Structure and biocompatibility of bioabsorbable nanocomposites of aliphatic-aromatic copolyester and cellulose nanocrystals. Biomacromolecules. https://doi.org/10.1021/acs.biomac.7b00578

Acknowledgements

The authors acknowledge the technical support provided by RMIT Microscopy & Microanalysis Facility (RMMF) of the University and thank the Australian Research Council (ARC) for funding the SEM Quanta 200. The authors also wish to acknowledge the technical support provided by Dr. Yesim Gozukara and Dr. Kyle Hearn on OTR analysis experiments and NMR experiments.

Funding

The first author acknowledges the scholarship support provided to him by RMIT University.

Author information

Authors and Affiliations

Contributions

Conceptualization: PC, BA; Methodology: KD, PC; Formal analysis and investigation: KD, MR Field; Writing—original draft preparation: KD; Writing—review and editing: FD, PC, BA; Supervision: FD, PC, BA.

Corresponding authors

Ethics declarations

Competing interest

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhali, K., Daver, F., Cass, P. et al. Development and Characterisation of Poly(butylene adipate-co-terephthalate)- Silane Modified Cellulose Nanocrystals Composite Materials and Films. J Polym Environ 31, 4506–4521 (2023). https://doi.org/10.1007/s10924-023-02896-w

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-023-02896-w