Abstract

Oil spills causes severe degradation to marine ecosystems and poses long term health effects on many animals on the food chain, including humans. A potential viable eco-friendly solution to oil spill clean-ups is the utilization of wool waste fibers as sorbent material, due to is naturally oleophilic nature and abundance as a waste. Repurposing wool waste also allow us to tackle another issue this waste poses: decreasing landfill spaces. This study aims to develop wool aerogels using wool waste fibers and polyvinyl alcohol (PVA) as a cross-linking binder. The synthesized aerogels exhibit high porosity (97.73–99.63%) and low densities (0.004–0.023 g/cm3). After being coated with methyltriethoxysilane (MTEOS), the aerogels exhibit great hydrophobicity with contact angles up to 138°. Using pseudo-first and pseudo-second order models to study the kinetics of the aerogels’ oil absorption performance, it is found that the oil absorption kinetics is better modelled after the pseudo-second order model. The best performing wool-based aerogel recorded an oil absorption capacity of 136.2 g/g, an estimated 9.1 and 15.3 times better than commercial counterparts, polypropylene mat and nonwoven polypropylene respectively. The aerogel fabrication technique (freeze–drying) employed in this study is also 2.5 times faster than the conventional solgel method. The promising results obtained demonstrate that the wool fiber as a great material capable of generating high engineering value and provides a novel alternative in solving environmental impacts plagued by oil spills and landfill-demanding wool waste.

Similar content being viewed by others

References

Feng J, Nguyen ST, Fan Z, Duong HM (2015) Advanced fabrication and oil absorption properties of super-hydrophobic recycled cellulose aerogels. Chem Eng J 270:168–175. https://doi.org/10.1016/j.cej.2015.02.034

Thai QB et al (2020) Advanced aerogels from waste tire fibers for oil spill-cleaning applications. J Environ Chem Eng 8(4):104016. https://doi.org/10.1016/j.jece.2020.104016

Macrotrends (n.d.) Crude oil prices—70 year historical chart. MacroTrends. https://www.macrotrends.net/1369/crude-oil-price-history-chart. Accessed 19 Dec 2020

Nguyen ST et al (2013) Cellulose aerogel from paper waste for crude oil spill cleaning. Ind Eng Chem Res 52(51):18386–18391. https://doi.org/10.1021/ie4032567

Ge J et al (2017) Joule-heated graphene-wrapped sponge enables fast clean-up of viscous crude-oil spill. Nat Nanotechnol 12(5):434. https://doi.org/10.1038/nnano.2017.33

Wu Z-Y et al (2014) Carbon nanofiber aerogels for emergent cleanup of oil spillage and chemical leakage under harsh conditions. Sci Rep. https://doi.org/10.1038/srep04079

Wu D, Yu Z, Wu W, Fang L, Zhu H (2014) Continuous oil–water separation with surface modified sponge for cleanup of oil spills. RSC Adv 4(96):53514–53519. https://doi.org/10.1039/C4RA07583H

Deschamps G, Caruel H, Borredon M-E, Bonnin C, Vignoles C (2003) Oil removal from water by selective sorption on hydrophobic cotton fibers. 1. Study of sorption properties and comparison with other cotton fiber-based sorbents. Environ Sci Technol 37(5):1013–1015. https://doi.org/10.1021/es020061s

Ba Thai Q, Ee Siang T, Khac Le D, Shah WA, Phan-Thien N, Duong HM (2019) Advanced fabrication and multi-properties of rubber aerogels from car tire waste. Colloids Surf A 577:702–708. https://doi.org/10.1016/j.colsurfa.2019.06.029

Yu M, Mishra D, Cui Z, Wang X, Lu Q (2021) Recycling papermill waste lignin into recyclable and flowerlike composites for effective oil/water separation. Compos B Eng 216:108884. https://doi.org/10.1016/j.compositesb.2021.108884

Hao W, Xu J, Li R, Zhao X, Qiu L, Yang W (2019) Developing superhydrophobic rock wool for high-viscosity oil/water separation. Chem Eng J 368:837–846. https://doi.org/10.1016/j.cej.2019.02.161

Meng G et al (2017) Fabrication of superhydrophobic cellulose/chitosan composite aerogel for oil/water separation. Fibers Polym 18(4):706–712. https://doi.org/10.1007/s12221-017-1099-4

Cheng Y et al (2017) Highly hydrophobic and ultralight graphene aerogel as high efficiency oil absorbent material. J Environ Chem Eng 5(2):1957–1963. https://doi.org/10.1016/j.jece.2017.04.005

Xu X et al (2019) Preparation and characterization of cellulose grafted with epoxidized soybean oil aerogels for oil-absorbing materials. J Agric Food Chem 67(2):637–643. https://doi.org/10.1021/acs.jafc.8b05161

Huang J, Liu H, Chen S, Ding C (2016) Hierarchical porous MWCNTs-silica aerogel synthesis for high-efficiency oily water treatment. J Environ Chem Eng 4(3):3274–3282. https://doi.org/10.1016/j.jece.2016.06.039

Siddiqa A, Shahid A, Gill R (2015) Silica decorated CNTs sponge for selective removal of toxic contaminants and oil spills from water. J Environ Chem Eng 3(2):892–897. https://doi.org/10.1016/j.jece.2015.02.026

Ravi S, Vadukumpully S (2016) Sustainable carbon nanomaterials: recent advances and its applications in energy and environmental remediation. J Environ Chem Eng 4(1):835–856. https://doi.org/10.1016/j.jece.2015.11.026

Aerogel.org (2009) What is Aerogel? http://www.aerogel.org/?p=3. Accessed 18 Dec 2020

Nordvik AB, Simmons JL, Bitting KR, Lewis A, Strøm-Kristiansen T (1996) Oil and water separation in marine oil spill clean-up operations. Spill Sci Technol Bull 3(3):107–122. https://doi.org/10.1016/S1353-2561(96)00021-7

Rajabinejad H, Buciscanu I-I, Maier S (2018) Current approaches for raw wool waste management and unconventional valorization: a review. Environ Eng Manage J 18:1439. https://doi.org/10.30638/eemj.2019.136

Periolatto M, Gozzelino G (2015) Greasy raw wool for cleanup process of marine oil spill: from laboratory test to scaled prototype. Chem Eng Trans 43:2269–2274. https://doi.org/10.3303/CET1543379

IWTO, Wool industry. International Wool Textile Organisation (n.d.). https://iwto.org/wool-industry/. Accessed 18 Dec 2020.

IWTO, Statistics. International Wool Textile Organisation (n.d.). https://iwto.org/resources/statistics/. Accessed 23 Apr 2021

Common Objective (2018) Global wool production and sustainable standards. Common Objective. http://www.commonobjective.co/article/global-wool-production-and-sustainable-standards. Accessed 18 Dec 2020

Popescu C, Segal E, Iditoiu C (1995) A kinetic model for the thermal decomposition of wool. Thermochim Acta 256(2):419–427. https://doi.org/10.1016/0040-6031(94)02186-R

Wesolek D, Kozlowski R (2002) Toxic gaseous products of thermal decomposition and combustion of natural and synthetic fabrics with and without flame retardant. Fire Mater 26(4–5):215–224. https://doi.org/10.1002/fam.800

Pistoni S.r.l. (2018) Wool waste. https://www.texile-plastic-materials-recycling.com/focus/44/wool-waste. Accessed 18 Dec 2020

Crick CR, Bhachu DS, Parkin IP (2014) Superhydrophobic silica wool—a facile route to separating oil and hydrophobic solvents from water. Sci Technol Adv Mater 15(6):065003. https://doi.org/10.1088/1468-6996/15/6/065003

Aerogel.org (2010) Hydrophobic and subcritically-dried silica aerogel. http://www.aerogel.org/?p=1443. Accessed 23 Apr 2021

Do NHN et al (2020) Heat and sound insulation applications of pineapple aerogels from pineapple waste. Mater Chem Phys 242:122267. https://doi.org/10.1016/j.matchemphys.2019.122267

Soleimani Dorcheh A, Abbasi MH (2008) Silica aerogel; synthesis, properties and characterization. J Mater Process Technol 199(1):10–26. https://doi.org/10.1016/j.jmatprotec.2007.10.060

Cao Oanh TH, Thibthong Pha P, Thai Quoc B, Tran Tuan D, Huynh Ha KP, Nguyen Son T (2020) Composite aerogel for heat insulation. Chem Eng Trans 78:361–366. https://doi.org/10.3303/CET2078061

Nguyen ST et al (2020) Effects of phenyltrimethoxysilane and polyvinyl alcohol on the properties of methyltrimethoxysilane-based silica aerogels. Chem Eng Trans 78:313–318. https://doi.org/10.3303/CET2078053

Le DK et al (2019) Applications of functionalized polyethylene terephthalate aerogels from plastic bottle waste. Waste Manage 100:296–305. https://doi.org/10.1016/j.wasman.2019.09.031

Wen Zhen L et al (2019) Recycled cellulose aerogels from paper waste for a heat insulation design of canteen bottles. Fluids 4(3):174. https://doi.org/10.3390/fluids4030174

Zhang X, Kwek LP, Le DK, Tan MS, Duong HM (2019) Fabrication and properties of hybrid coffee-cellulose aerogels from spent coffee grounds. Polymers 11(12):1942. https://doi.org/10.3390/polym11121942

Luu TP et al (2020) Morphology control and advanced properties of bio-aerogels from pineapple leaf waste. Chem Eng Trans 78:433–438. https://doi.org/10.3303/CET2078073

Schaefer DW, Keefer KD (1986) Structure of random porous materials: silica aerogel. Phys Rev Lett 56(20):2199–2202. https://doi.org/10.1103/PhysRevLett.56.2199

Schmidt M, Schwertfeger F (1998) Applications for silica aerogel products. J Non-Cryst Solids 225:364–368. https://doi.org/10.1016/S0022-3093(98)00054-4

Meador MAB et al (2014) Dielectric and other properties of polyimide aerogels containing fluorinated blocks. ACS Appl Mater Interfaces 6(9):6062–6068. https://doi.org/10.1021/am405106h

Wang L, Feng J, Jiang Y, Li L, Feng J (2019) Elastic methyltrimethoxysilane based silica aerogels reinforced with polyvinylmethyldimethoxysilane. RSC Adv 9(19):10948–10957. https://doi.org/10.1039/C9RA00970A

Alhosseini, S. N. et al (2012) Synthesis and characterization of electrospun polyvinyl alcohol nanofibrous scaffolds modified by blending with chitosan for neural tissue engineering. International journal of nanomedicine, 7, 25. https://doi.org/10.2147/IJN.S25376.

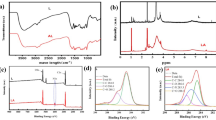

Smith B (2018) Infrared spectral interpretation: a systematic approach. CRC Press, Florida

Peets P, Kaupmees K, Vahur S, Leito I (2019) Reflectance FT-IR spectroscopy as a viable option for textile fiber identification. Herit Sci 7(1):93. https://doi.org/10.1186/s40494-019-0337-z

McGregor BA, Liu X, Wang XG (2018) Comparisons of the fourier transform infrared spectra of cashmere, guard hair, wool and other animal fibres. J Text Inst 109(6):813–822. https://doi.org/10.1080/00405000.2017.1372057

Oh SY, Yoo DI, Shin Y, Seo G (2005) FTIR analysis of cellulose treated with sodium hydroxide and carbon dioxide. Carbohyd Res 340(3):417–428. https://doi.org/10.1016/j.carres.2004.11.027

Proniewicz LM, Paluszkiewicz C, Wesełucha-Birczyńska A, Majcherczyk H, Barański A, Konieczna A (2001) FT-IR and FT-Raman study of hydrothermally degradated cellulose. J Mol Struct 596(1):163–169. https://doi.org/10.1016/S0022-2860(01)00706-2

Acevedo B, Fernández AM, Barriocanal C (2015) Identification of polymers in waste tyre reinforcing fibre by thermal analysis and pyrolysis. J Anal Appl Pyrol 111:224–232. https://doi.org/10.1016/j.jaap.2014.11.005

Yang H-S, Choi S-Y, Hyun S-H, Park H-H, Hong J-K (1997) Ambient-dried low dielectric SiO2 aerogel thin film. J Non-Cryst Solids 221(2):151–156. https://doi.org/10.1016/S0022-3093(97)00335-9

Shokri B, Firouzjah MA, Hosseini SI (2009) FTIR analysis of silicon dioxide thin film deposited by metal organic-based PECVD. In: Proceedings of 19th international symposium on plasma chemistry society, vol 2631, pp 26–31

Le DK et al (2020) Methyltrimethoxysilane-coated recycled polyethylene terephthalate aerogels for oil spill cleaning applications. Mater Chem Phys 239:122064. https://doi.org/10.1016/j.matchemphys.2019.122064

Si Y et al (2015) Superelastic and superhydrophobic nanofiber-assembled cellular aerogels for effective separation of oil/water emulsions. ACS Nano 9(4):3791–3799. https://doi.org/10.1021/nn506633b

Chen N, Pan Q (2013) Versatile fabrication of ultralight magnetic foams and application for oil-water separation. ACS Nano 7(8):6875–6883. https://doi.org/10.1021/nn4020533

Do NHN et al (2021) Green fabrication of flexible aerogels from polypropylene fibers for heat insulation and oil/water separation. J Porous Mater 28(2):617–627. https://doi.org/10.1007/s10934-020-01022-8

Thai QB et al (2020) Cellulose-based aerogels from sugarcane bagasse for oil spill-cleaning and heat insulation applications. Carbohyd Polym 228:115365. https://doi.org/10.1016/j.carbpol.2019.115365

Shi M et al (2017) Superhydrophobic silica aerogels reinforced with polyacrylonitrile fibers for adsorbing oil from water and oil mixtures. RSC Advances (RSC Publishing). https://pubs.rsc.org/en/content/articlelanding/2017/RA/C6RA26831E#!divAbstract. Accessed 01 Jan 2021

Wan W et al (2016) Graphene–carbon nanotube aerogel as an ultra-light, compressible and recyclable highly efficient absorbent for oil and dyes. Environ Sci 3(1):107–113. https://doi.org/10.1039/C5EN00125K

Gui X et al (2010) Carbon nanotube sponges. Advanced materials, Wiley Online Library. https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.200902986. Accessed 01 Jan 2021

Hong J-Y, Sohn E-H, Park S, Park HS (2015) Highly-efficient and recyclable oil absorbing performance of functionalized graphene aerogel. Chem Eng J 269:229–235. https://doi.org/10.1016/j.cej.2015.01.066

Patel PSD, Shepherd DET, Hukins DWL (2008) Compressive properties of commercially available polyurethane foams as mechanical models for osteoporotic human cancellous bone. BMC Musculoskelet Disord 9:137. https://doi.org/10.1186/1471-2474-9-137

Frederick G et al (1995) Optimization of expanded polypropylene foam coring to improve bumper foam core energy absorbing capability. SAE Int. https://doi.org/10.4271/950549

Acknowledgements

Authors would like to thank Temasek Laboratories @ NUS, R-265-000-682-720 (Mapletree Gift), R-265-000-682-114 (MOE Tier 1 FRC), R-265-000-682-133 (ODPRT) and R-265-000-682-731 (ME) for the financial support for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Loh, J.W., Goh, X.Y., Nguyen, P.T.T. et al. Advanced Aerogels from Wool Waste Fibers for Oil Spill Cleaning Applications. J Polym Environ 30, 681–694 (2022). https://doi.org/10.1007/s10924-021-02234-y

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02234-y