Abstract

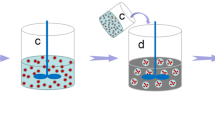

In this research, the microcapsules were individually prepared via internal phase separation technique using reactive bio-based acrylated epoxidized soybean oil, AESO, and trimethylolpropane tris(3-mercaptopropionate), TMPMP as healing and curing agents respectively in PMMA shell for self-healing intentions. The desired variables used were the ratio of the shell/core, the type of surfactant (ionic and polymeric) and PMMA molecular weights. FTIR confirmed very fast crosslinking reaction between reactive epoxy and acrylate functional groups in AESO and thiol groups in TMPMP, which is very important for self-healing purposes. Furthermore, FTIR and thermal characterization results confirmed the encapsulation of both the resin and the curing agent components in two different core–shell microcapsules. The surface morphology of microcapsules obtained changed from dimpled and holed to plain for AESO and TMPMP respectively suggesting that it depends strongly on the nature of the core, type of surfactant and the ratio of shell/core. The produced core–shell microcapsules had a mean diameter of 7.9–169.7 µm and 9.9–64.1 µm for AESO/PMMA and TMPMP/PMMA, respectively. With changing the percentage of shell revealed that increasing the PMMA dosage in both surfactants causes a decrease in the size of TMPMP-filled microcapsules.

Similar content being viewed by others

References

Chen S, Xu Z, Zhang D (2018) Synthesis and application of epoxy-ended hyperbranched polymers. Chem Eng J 343:283–302

Xu Z, Liang Y, Ma X, Chen S, Yu C, Wang Y, Zhang D, Miao M (2020) Recyclable thermoset hyperbranched polymers containing reversible hexahydro-s-triazine. Nat Sustain 3(1):29–34

Ataei S, Hassan A, Azari P, Pingguan-Murphy B, Yahya R, Basirun WJ, Shahabudin N (2020) Electrosprayed PMMA microcapsules containing green soybean oil-based acrylated epoxy and a thiol: a novel resin for smart self-healing coatings. Smart Mater Struct 29(8):085037

Ataei S, Khorasani SN, Torkaman R, Neisiany RE, Koochaki MS (2018) Self-healing performance of an epoxy coating containing microencapsulated alkyd resin based on coconut oil. Prog Org Coat 120:160–166

Koochaki MS, Khorasani SN, Neisiany RE, Ashrafi A, Trasatti SP, Magni M (2020) A highly responsive healing agent for the autonomous repair of anti-corrosion coatings on wet surfaces. In operando assessment of the self-healing process. J Mater Sci 56(2):1794–1813

Bekas D, Tsirka K, Baltzis D, Paipetis A (2016) Self-healing materials: a review of advances in materials, evaluation, characterization and monitoring techniques. Composites Part B 87:92–119

Khorasani SN, Ataei S, Neisiany RE (2017) Microencapsulation of a coconut oil-based alkyd resin into poly (melamine–urea–formaldehyde) as shell for self-healing purposes. Prog Org Coat 111:99–106

Malekkhouyan R, Nouri Khorasani S, Esmaeely Neisiany R, Torkaman R, Koochaki MS, Das O (2020) Preparation and characterization of electrosprayed nanocapsules containing coconut-oil-based alkyd resin for the fabrication of self-healing epoxy coatings. Appl Sci 10(9):3171

Rodrigues SN, Fernandes I, Martins IM, Mata VG, Barreiro F, Rodrigues AE (2008) Microencapsulation of limonene for textile application. Ind Eng Chem Res 47(12):4142–4147

Pena B, Panisello C, Aresté G, Garcia-Valls R, Gumí T (2012) Preparation and characterization of polysulfone microcapsules for perfume release. Chem Eng J 179:394–403

Neisiany RE, Khorasani SN, Lee JKY, Ramakrishna SJRA (2016) Encapsulation of epoxy and amine curing agent in PAN nanofibers by coaxial electrospinning for self-healing purposes. RSC Adv 6(74):70056–70063

Loxley A, Vincent BJJO, I, (1998) Preparation of poly (methylmethacrylate) microcapsules with liquid cores. J Colloid Interface Sci 208(1):49–62

Jamekhorshid A, Sadrameli S, Farid MJR (2014) A review of microencapsulation methods of phase change materials (PCMs) as a thermal energy storage (TES) medium. Renew Sustain Energy Rev 31:531–542

Wang Y, Guo B-H, Wan X, Xu J, Wang X, Zhang Y-PJP (2009) Janus-like polymer particles prepared via internal phase separation from emulsified polymer/oil droplets. Polymer 50(14):3361–3369

Ahangaran F, Hayaty M, Navarchian AH (2017) Morphological study of polymethyl methacrylate microcapsules filled with self-healing agents. Appl Surf Sci 399:721–731

de la Paz Miguel M, Vallo CI (2019) Influence of the emulsifying system to obtain linseed oil-filled microcapsules with a robust poly (melamine-formaldehyde)-based shell. Prog Org Coat 129:236–246

Wang H, Zhou Q (2018) Evaluation and failure analysis of linseed oil encapsulated self-healing anticorrosive coating. Prog Org Coat 118:108–115

Kardar PJ (2015) Preparation of polyurethane microcapsules with different polyols component for encapsulation of isophorone diisocyanate healing agent. Prog Org Coat 89:271–276

Gite VV, Tatiya PD, Marathe RJ, Mahulikar PP, Hundiwale DG (2015) Microencapsulation of quinoline as a corrosion inhibitor in polyurea microcapsules for application in anticorrosive PU coatings. Prog Org Coat 83:11–18

Xu H, Fang Z, Tong L (2008) Effect of microencapsulated curing agents on the curing behavior for diglycidyl ether of bisphenol A epoxy resin systems. J Appl Polym Sci 107(3):1661–1669

Mallepally RR, Parrish CC, Mc Hugh MA, Ward KR (2014) Hydrogen peroxide filled poly (methyl methacrylate) microcapsules: potential oxygen delivery materials. Int J Pharm 475(1–2):130–137

Feuser PE, Bubniak LD, Bodack CD, Valério A, Silva MC, Ricci-Júnior E, Sayer C, Araújo PH (2016) Nanotechnology, In vitro cytotoxicity of poly (methyl methacrylate) nanoparticles and nanocapsules obtained by miniemulsion polymerization for drug delivery application. J Nanosci Nanotechnol 16(7):7669–7676

Li Q, Mishra AK, Kim NH, Kuila T, Lau KT, Lee JH (2013) Effects of processing conditions of poly (methylmethacrylate) encapsulated liquid curing agent on the properties of self-healing composites. Composites Part B 49:6–15

Li Q, Kim NH, Hui D, Lee JH (2013) Effects of dual component microcapsules of resin and curing agent on the self-healing efficiency of epoxy. Smart Mater Struct 55:79–85

Ahangaran F, Navarchian AH, Hayaty M, Esmailpour K (2016) Structures, effect of mixing mode and emulsifying agents on micro/nanoencapsulation of low viscosity self-healing agents in polymethyl methacrylate shell. Smart Mater Struct 25(9):095035

Ahangaran F, Hayaty M, Navarchian AH, Pei Y, Picchioni F (2019) Development of self-healing epoxy composites via incorporation of microencapsulated epoxy and mercaptan in poly (methyl methacrylate) shell. Polym Test 73:395–403

Gonzalez L, Kostrzewska M, Baoguang M, Li L, Hansen JH, Hvilsted S, Skov AL (2014) Preparation and characterization of silicone liquid core/polymer shell microcapsules via internal phase separation. Macromol Mater Eng 299(10):1259–1267

Guo H, Zhao X (2008) Preparation of microcapsules with narrow-size distribution by complex coacervation: effect of sodium dodecyl sulphate concentration and agitation rate. J Microencapsul 25(4):221–227

Bachtsi AR, Boutris CJ, Kiparissides C (1996) Production of oil-containing crosslinked poly (vinyl alcohol) microcapsules by phase separation: Effect of process parameters on the capsule size distribution. J Appl Polym Sci 60(1):9–20

Fujibayashi T, Komatsu Y, Konishi N, Yamori H, Okubo M (2008) Effect of polymer polarity on the shape of “golf ball-like” particles prepared by seeded dispersion polymerization. Ind Eng Chem Res 47(17):6445–6449

Lavergne F-M, Cot D, Ganachaud F (2007) Polymer microcapsules with “foamed” membranes. Langmuir 23(12):6744–6753

Konishi N, Fujibayashi T, Tanaka T, Minami H, Okubo M (2010) Effects of properties of the surface layer of seed particles on the formation of golf ball-like polymer particles by seeded dispersion polymerization. Polym J 42(1):66–71

Berg J, Sundberg D, Kronberg B (1989) Microencapsulation of emulsified oil droplets by in-situ vinyl polymerization. J Microencapsul 6(3):327–337

Luo WS, Yu SF, Zhou JM (2014) Effect of Core/shell ratio on performance of paraffin/polyurea phase change microencapsules, applied mechanics and materials. Trans Tech Publ, pp 32–35

Feiz S, Navarchian AH (2012) Emulsion polymerization of styrene: Simulation the effects of mixed ionic and non-ionic surfactant system in the presence of coagulation. Chem Eng Sci 69(1):431–439

Willner L, Poppe A, Allgaier J, Monkenbusch M, Lindner P, Richter D (2000) Micellization of amphiphilic diblock copolymers: Corona shape and mean-field to scaling crossover. EPL 51(6):628

Guzmán D, Mateu B, Fernández-Francos X, Ramis X, Serra A (2017) Novel thermal curing of cycloaliphatic resins by thiol–epoxy click process with several multifunctional thiols. Polym Int 66(12):1697–1707

Konuray A, Fernández-Francos X, Ramis X (2017) Analysis of the reaction mechanism of the thiol–epoxy addition initiated by nucleophilic tertiary amines. Polym Chem 8:5934–5947

Chen Z, Chisholm BJ, Patani R, Wu JF, Fernando S, Jogodzinski K, Webster DC (2010) Soy-based UV-curable thiol–ene coatings. J Coat Technol Res 7(5):603–613

Klein DR (2017) Student study guide and solutions manual to accompany organic chemistry, 3rd edn. Wiley, New York

Sehon A, deB Darwent B (1954) The thermal decomposition of mercaptans. J Am Chem Soc 76(19):4806–4810

Thompson C, Meyer R, Ball J (1952) Thermal decomposition of sulfur compounds. II. 1-Pentanethiol. J Am Chem Soc 74(13):3287–3289

Kashiwagi T, Inaba A, Brown JE, Hatada K, Kitayama T, Masuda E (1986) Effects of weak linkages on the thermal and oxidative degradation of poly (methyl methacrylates). Macromolecules 19(8):2160–2168

Manring LE (1991) Thermal degradation of poly (methyl methacrylate). 4. Random side-group scission. Macromolecules 24(11):3304–3309

Fu L, Yang L, Dai C, Zhao C, Ma L (2010) Thermal and mechanical properties of acrylated expoxidized-soybean oil‐based thermosets. J Appl Polym Sci 117(4):2220–2225

Acknowledgements

The authors wish to thank the University of Malaya for financial assistance under Grant No. FG031-17AFR.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ataei, S., Hassan, A. & Yahya, R. Dual Microcapsulation of an Environmentally‐Friendly‐Based Reactive Multifunctional Acrylated Epoxy Resin and Thiol by Internal Phase Separation Technique for Self‐healing Applications. J Polym Environ 29, 2901–2915 (2021). https://doi.org/10.1007/s10924-021-02085-7

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02085-7