Abstract

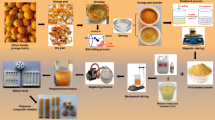

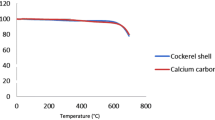

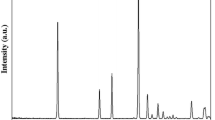

The recycling of polymers by manufacturing them into composite materials in processes using natural waste has been of interest due to the appeal to mitigate various environmental problems. Therefore, this study aims to investigate the properties of postconsumer recycled polypropylene (PPrec) composites with 20% (by weight) calcined mollusk shell waste. The calcination was carried out at 500 °C for 12, in order to deagglomerate the particles of the shell calcined (CS). Two more composites were prepared from calcined shell: one CS/CNSL, where CS was treated with the liquid from the cashew nut shell—CNSL (an agricultural by-product) and the other CS/PEG, where CS was treated with polyethylene glycol—PEG (a synthetic product). Based on morphological aspect, PPrec showed nanoparticles of calcium carbonate (CaCO3) well dispersed with size around 290.9 nm. The surface treatment of CS with PEG resulted in composites with voids and agglomerated particles. Some of the CS particles were anchored as well as detached from the matrix. Some clusters involving the CaCO3 nanoparticles and shell microparticles treated with CNSL were observed. The TGA curves revealed an ash content in the range of 9.46% for the recycled Polypropylene, suggesting the presence of CaCO3. The thermal stability of the matrix was improved by adding the calcined shell and also by treating it with CNSL. From the DSC, the degree of crystallinity of the CS/CNSL and CS/PEG composites were similar to that of the PPrec. However, an 11.9% reduction in the crystallinity of composite with CS was observed, which exhibited a broader melting peak indicating that smaller polymer spherulites may be present. The investigation of Mechanical properties allowed to verify an increase in both the tensile and flexural modulus of the PPrec/CS, while CS/CNSL composite presents a mild decrease in the both. In addition, CS particles were more effective in improving the toughness of PPrec, increasing its impact strength by 41%.

Similar content being viewed by others

References

Ardanuy M, Antunes M, Velasco JI (2012) Vegetable fibres from agricultural residues as thermo-mechanical reinforcement in recycled polypropylene-based green foams. Waste Manage 2:256

Santos EBC, Barros JJP, Moura AA, Moreno CG, Fim FB, Silva LB (2019) Rheological and thermal behavior of PHB/piassava fiber residue-based green composites modified with warm water. J Mater Res Technol 8:531

Mohamad N, Latiff A, Maulod H, Azam M, Edeerozey MA (2014) Sustainable polymer composite from recycled polypropylene filled with shrimp shell waste. Polym-Plast Technol Eng 53:167

Balart JF, Montanes N, Fombuena V, Boronat T, Sanchez-Nacher L (2018) Disintegration in compost conditions and water uptake of green composites from poly (lactic acid) and hazelnut shell flour. J Polym Environ 26:701–715

Kocaman S, Ahmetli G (2020) Effects of various methods of chemical modification of lignocellulose hazelnut shell waste on a newly synthesized bio-based epoxy composite. J Polym Environ 28:1190

Conceição MM, Alves MFP, Conceição JTP, Castro P (2018) Waste in portugal-An analysis of plastic waste. Res Soc Dev 7:1

Herbort AF, Sturm MT, Fiedler S, Abkai G, Schuhen K (2018) Alkoxy-silyl induced agglomeration: a new approach for the sustainable removal of microplastic from aquatic systems. J Polym Environ 26:4258

Ares A, Bouza R, Pardo SG, Abad MJ, Barral L (2010) Rheological, mechanical and thermal behaviour of wood polymer composites based on recycled polypropylene. J Polym Environ 18:318

Camargo RV, Saron C (2020) Mechanical-chemical recycling of low-density polyethylene waste with polypropylene. J Polym Environ 28:794

Tamboura S, Meftah H, Fitoussi J, Bendaly H, Tcharkhtchi A (2018) Thermal aging kinetic and effects on mechanical behavior of fully recycled composite based on polypropylene/polyethylene blend. J Appl Polym Sci 135:46640

Danesh MA, Tabari HZ, Hosseinpourpia R, Nazarnezhad N, Shamse M (2012) Investigation of the morphological and thermal properties of waste newsprint/ recycled polypropylene/ nanoclay composite. BioResources 7:936

Zhang X, Bo X, Wang R (2013) Study on mechanical properties and water absorption behaviour of wastepaper fibre/recycled polypropylene composites. Polym Polym Compo 21:395

Samat N, Mokhtar WNA, Zulkifl NI (2014) Properties of eco-friendly composite from recycled polypropylene. Adv Environ Biol 8:2760

Majka TM, Bartyzel O, Raftopoulos KN, Pagacz J, Leszczynska A, Pielichowski K (2016) Recycling of polypropylene/montmorillonite nanocomposites by pyrolysis. J Anal Appl Pyrol 119:1

Pardo SG, Bernal C, Ares A, Abad MJ, Cano J (2010) Rheological, thermal, and mechanical characterization of Fly Ash-thermoplastic composites with different coupling agents. Polym Composite 31:1722

Zhang QX, Yu ZZ, Xie XL, Mai YW (2004) Crystallization and impact energy of polypropylene/CaCO3 nanocomposites with nonionic modifier. Polymer 45:5985

Bhagavatheswaran ES, Das A, Rastin H, Saeidi H, Jafari SH, Vahabi H, Najafi F, Khonakdar HA, Formela K, Jouyandeh M, Zarrintaj P, Saeb MR (2019) The taste of waste: the edge of eggshell over calcium carbonate in acrylonitrile butadiene rubber. J Polym Environ 27:2478

Munusamy Y, Sethupathi S, Choon CH (2019) Potential use of waste cockle shell as filler for thermoplastic composite. J Mater Cycles Waste 21:1063

Bezerra UT, Almeida FL, Silva LB, Barbosa NP, Passos TA, Cavalcante DGL (2011) Production of filler aggregate from waste of bivalves molluscs shells. J Civil Eng Archi 5:363

Kaewtatip K, Chiarathanakrit C, Riyajan S (2018) The effects of egg shell and shrimp shell on the properties of baked starch foam. Powder Technol 335:354

Li HY, Tan YQ, Zhang L, Zhang YX, Song YH, Ye Y, Xia MS (2012) Bio-filler from waste shellfish shell: preparation, characterization, and its effect on the mechanical properties on polypropylene composites. J Hazard Mater 217–218:256

Ghabeer T, Dweiri R, Al-Khateeb S (2013) Thermal and mechanical characterization of polypropylene/eggshell Biocomposites. J Reinf Plast Comp 32:402

Mohamed M, Rashidi NA, Yusup S, Lee KT, Rashid U, Ali RM (2012) Effects of experimental variables on conversion of cockle shell to calcium oxide using thermal gravimetric analysis. J Clean Prod 37:394

Melo PMA, Macêdo OB, Barbosa GP, Ueki MM, Silva LB (2019) High-density polyethylene/mollusk shell-waste composites: effects of particle size and coupling agent on morphology, mechanical and thermal properties. J Mater Res Technol 8:1915

Santos RP, Santiago AAX, Gadelha CAA, Cajazeiras JB, Cavada BS, Martins JL, Oliveira TM, Bezerra GA, Santos RP, Freire VN (2007) Production and characterization of the cashew (Anacardium occidentale L.) peduncle bagasse ashes. J Food Eng. 79:1432

Idah PA, Simeon MI, Mohammed MA (2014) Extraction and characterization of cashew nut (Anacardium Occidentale) oil and cashew shell liquid oil. Acad Res Int 5:50

Selvaraj V, Jayanthi KP, Alagar M (2018) Development of biocomposites from agro wastes for low dielectric applications. J Polym Environ 26:3655

Gomes VNC, Carvalho GA, Furukava M, Medeiros ES, Colombo CR, Melo TJA, Araujo EM, Morais DDS, Ueki MM, Paskocimas CA, Santos ASF (2018) Characterization of wood plastic composite based on HDPE and cashew nutshellspProcessed in a thermokinetic mixer. Polym Compos 39:2662

Moreira LFB, González G, Lucas EF (1998) Interactivity study between asphaltene macromolecules and stabilizing compounds: LCC and cardanol. Polimeros 8:46

Mazzetto SE, Lomonaco D, Mele G (2009) Cashew nut oil: opportunities and challenges in the context of sustainability industrial development. Quim Nova 32:732

Graça DCS, Cardoso G, Mothe CG (2019) Thermal behavior of asphalt binder with modifying agents from industrial residues. J Therm Anal Calorim 138:3619

Bhattacharyya DN, Krishnan S, Kelkar RY, Chikale SV (1984) Preparation and emulsifying properties of polyethylene glycol (15OO) diesters of fatty acids. J Am Oil Chem Soc 61:1925

Dieble CR, Petrosko P, Johnson PC, Beckman EJ, Russell AJ, Wagner WR (1998) Molecular barriers to biomaterial thrombosis by modification of surface proteins with polyethylene glycol. Biomaterials 19:1885

Borsacch S, Matin F, Geppi M, Pilati F, Toselli M (2011) Structure, dynamics and interactions of complex sol–gel hybrid materials through SSNMR and DSC: Part II, ternary systems based on PE–PEG block copolymer. PHS and silica Polymer 52:4545

He S, He H, Li Y, Wang D (2015) Effects of maleic anhydride grafted polyethylene on rheological, thermal, and mechanical properties of ultrahigh molecular weight polyethylene/poly (ethylene glycol) blends. J Appl Polym Sci 132:42171

Xie M, Liu X, Li H (2006) Influence of poly (ethylene glycol)-containing additives on extrusion of ultrahigh molecular weight polyethylene/polypropylene blend. J Appl Polym Sci 100:1282

Saeb MR, Ghaffari M, Rastin H, Khonakdar HA, Simon F, Najafi F, Goodarzi V, Puglia D, Asl FH, Formela K (2017) RSC Adv 7:2218

Saeb MR, Rastin H, Nonahal M, Paran SMR, Khonakdar HA, Puglia D (2018) Biowaste chicken eggshell powder as a potential cure modifier for epoxy/anhydride systems: competitiveness with terpolymer-modified calcium carbonate at low loading levels. Prog Org Coat 114:208

Nakatani N, Takamor H, Takeda K, Sakugawa H (2009) Transesterification of soybean oil using combusted oyster shell waste as a catalyst. Bioresource Technol 100:1510

Firmino HCT, Chagas TF, Melo PMA, Silva LB (2017) Characterization of the particulate composites of high density polyethylene/polyethylene/mollusk shell powder. Materia 22:1

Ayrilmis N, Kaymakci A, Ozdemir F (2013) Physical, mechanical, and thermal properties of polypropylene composites filled with walnut shell flour. J Ind Eng Chem 19:908

Wang Y, Shen H, Li G, Mai K (2009) Effect of interfacial interaction on the crystallization and mechanical properties of PP/Nano-CaCO3 composites modified by compatibilizers. J Appl Polym Sci 113:1584

Costa HM, Ramos VD, Esteves LL (2018) Effect of grape seed oil upon recycled polypropylene (PP) Part I: degradation kinetics. JCEC 4:49

Li TQ, Wolcott MP (2005) Rheology of wood plastics melt. Part 1. Capillary rheometry of HDPE filled with maple. Polym Eng Sci 45:549

Haq S, Srivastava R (2017) Composites manufactured by mango wood waste with virgin or recycled PP: mechanical, morphology, melt flow index and crystalline behaviour. J Polym Environ 25:640

Zuiderduin WCJ, Westzaan C, Huetink J, Gaymans RJ (2003) Rheology of wood plastics melt. Part 1. Capillary rheometry of HDPE filled with maple. Polymer 44:261

Huang L, Mu B, Yi X, Li S, Wang O (2018) Sustainable use of coffee husks for reinforcing polyethylene composites. J Polym Environ 26:48

Chan CM, Wu J, Li JX, Cheung YK (2002) Polypropylene-calcium carbonate nanocomposites. Polymer 43:2981

Zhitong Y, Meisheng X, Liugin G, Tao C, Haiyan L, Ying Y, Zheng H (2014) Mechanical and thermal properties of polypropylene (PP) composites filled with CaCO3and shell-waste derived bio-fillers. Fiber Polym 15:1278

Ogah AO (2017) Characterization of sorghum bran/recycled low density polyethylene for the manufacturing of polymer composites. J Polym Environ 25:533

Varga J, Mudra I, Ehrenstein GW (1999) Highly active thermally stable b-Nucleating agents for isotactic polypropylene. J App Polym Sci 74:235

Rungruang P, Grady BP, Supaphol P (2006) Surface-modified calcium carbonate particles by admicellar polymerization to be used as filler for isotactic polypropylene. Eng Aspects 275:114

Cho K, Sahebo DN, Cho J, Yang H (2002) Real time in situ X-ray diffraction studies on the melting memory effect in the crystallization of β-isotactic polypropylene. Polymer 43:1407

Dong HH, Hong YS (2002) Calcined calcium magnesium acetate as a superior SO2sorbent: I. Thermal decomposition AlChE Journal 48:2971

Sheng LN, Hua HK, Mei LC (2011) Kinetic calculations for the thermal decomposition of calcium propionate under non-isothermal conditions. Chin Sci Bull 56:1278

Feng C, Liang M, Jiang J, Huang J, Liu H (2016) Preparation and characterization of oligomeric char forming agent and its effect on the thermal degradation and flame retardant properties of LDPE with ammonium polyphosphate. J Anal Appl Pyrolysis 119:75

Thio YS, Argon AS, Cohen RE, Weinberg M (2002) Toughening of isotactic polypropylene with CaCO3 particles. Polymer 43:3661

Ferrage E, Martin F, Boudet A, Petit S, Fourty G, Jouffret F, Micoud P, De Parseval P, Salvi S, Bourgerette C, Ferret J, Saint-Gerard Y, Buratto S, Fortune JP (2002) Talc as nucleating agent of polypropylene: morphology induced by lamellar particles addition and interface mineral-matrix modelization. J Mater Sci 37:1561

Mi HC, Byoung CC, Yong-Chan C, Bong GC (2006) Fire-retardant plastic material from oyster-shell powder and recycled polyethylene. J Appl Polymer Sci 99:1583

Nielsen LE (1994) Mechanical properties of polymers and composites, 2nd edn. Marcel Dekker, New York

Leong YW, Ishak ZAM, Ariffin A (2004) Mechanical and thermal properties of talc and calcium carbonate filled polypropylene hybrid composites. J Appl Polym Sci 91:3327

Thammahiwes S, Riyajan S, Kaewtatip K (2018) Effect of shrimp shell waste on the properties of wheat gluten based-bioplastics. J Polym Environ 26:1775

Yao ZT, Chen T, Li HY, Xia MS, Ye Y, Zheng H (2013) Mechanical and thermal properties of polypropylene (PP) composites filled with modified shell-waste. J Hazard Mater 262:2012

Jose J, Nag A, Nando GB (2010) Processing and characterization of recycled polypropylene and acrylonitrile butadiene rubber blends. J Polym Environ 18:155

Fuad MYA, Hanim H, Zarina R, Ishak ZAM, Hassan A (2010) Polypropylene/calcium carbonate nanocomposites – effects of processing techniques and maleated polypropylene compatibilizer. Express Polym Lett 4:611

Greco R, Coppola F (1986) Influence of crystallization conditions on the mechanical properties of isotactic polypropylene. Plast Rubber Proc Applic 6:35

Kowaleski T, Galeski A (1986) The mechanical properties of chalk-filled polypropylene: a preliminary investigation. J Appl Polym Sc 32:2919

Vollenberg PHT, Heikens D (1990) The mechanical properties of chalk-filled polypropylene: a preliminary investigation. J Mater Sci 25:3089

Kamar KV, Pavendhan R, Subramaniyan GGR, Loganathan TG (2020) Effect of bio waste (conch shell) particle dispersion on the performance of GFRP composite. J Mater Res Technol 9:7123

Acknowledgements

The authors gratefully acknowledge the financial/technical support from the scholarship provided by Amazonas State Research Support Foundation (FAPEAM) and the technical support provided by Fast Solidification Laboratory (LSR) at Federal University of Paraiba. We thank Plastex Indústria e Comércio de Material Plásticos for its kind donation of recycled polymer.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Melo, P.M.A., Macêdo, O.B., Barbosa, G.P. et al. Reuse of Natural Waste to Improve the Thermal Stability, Stiffness, and Toughness of Postconsumer Polypropylene Composites. J Polym Environ 29, 538–551 (2021). https://doi.org/10.1007/s10924-020-01907-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01907-4