Abstract

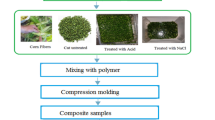

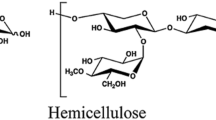

This review discusses the potentials of corn waste fibres as an alternative source of reinforcement to other natural fibres for bioplastic composites. The growing sustainability concern has urged the search for new composites and the potential exists to stimulate more research in bringing it to markets. Corn (Zea mays L.) waste fibres are lignocellulosic fibres that constituted of corn cob, corn husk, corn stalk and corn stover which are often discarded. Physico-chemical properties of the lignocellulosic fibres from different sources are compared. Studies on lignocellulosic fibre reinforced bioplastic composites and state-of-the-art of corn fibre reinforced composites are reviewed. The preparations of the fibres to form nanofibril, cellulose nanofibril and lignin-containing cellulose nanofibril are also discussed. Along with this, issues to improve fibre-plastic matrix compatibility through mechanical disintegration and surface modification treatment on fibre are also reported. This review shows that corn waste is suitable to be used as a reinforcement filler for bioplastic. Further treatment on the fibres could lead to improved properties of the composite for various applications.

Similar content being viewed by others

Abbreviations

- APS:

-

3-Aminopropyltrithoxysilance

- CNF:

-

Cellulosic nanofibril

- LCNF:

-

Lignin-containing cellulosic nanofibril

- PET:

-

Polyethylene terephthalate

- PHA:

-

Polyhydroxyalkanoate

- PHB:

-

Polyhydroxybutyrate

- PLA:

-

Polylactic acid

- TPS:

-

Thermoplastic starch

References

Karan H et al (2019) Green bioplastics as part of a circular bioeconomy. Trends Plant Sci 24(3):237–249

Brodin M et al (2017) Lignocellulosics as sustainable resources for production of bioplastics—a review. J Clean Prod 162:646–664

Thakur S et al (2018) Sustainability of bioplastics: opportunities and challenges. Curr Opin Green Sustain Chem 13:68–75

European Bioplastic (2018) Bioplastics—Industry standards & labels

European Bioplastic (2018) Bioplastics market data 2018

Al Jahwari F, Pervez T (2019) The potential of environmental-friendly biopolymers as an alternative to conventional petroleum-based polymers. In: Reference module in materials science and materials engineering. Elsevier.

Abdul Khalil HPS, Bhat AH, Ireana Yusra AF (2012) Green composites from sustainable cellulose nanofibrils: a review. Carbohyd Polym 87(2):963–979

Yang J, Ching YC, Chuah CH (2019) Applications of lignocellulosic fibers and lignin in bioplastics: a review. Polymers (Basel) 11(5):751

Nagaraj K, Bharath D, Basavarajappa S (2015) Applications of biocomposite materials based on natural fibers from renewable resources: a review. Sci Eng Compos Mater 23:123

Shalwan A, Yousif B (2012) In State of Art: mechanical and tribological behaviour of polymeric composites based on natural fibres. Mater Des 48:14

Moustafa H et al (2019) Eco-friendly polymer composites for green packaging: future vision and challenges. Composites B 172:16–25

Ferrer A et al (2012) Effect of residual lignin and heteropolysaccharides in nanofibrillar cellulose and nanopaper from wood fibers. Cellulose 19(6):2179–2193

Salit MS (2014) Tropical natural fibre composites. Springer, Singapore

Miranda MT et al (2018) Analysis of pelletizing from corn cob waste. J Environ Manag 228:303–311

FAOSTAT (2019) Data

Jawaid M, Abdul Khalil HPS (2011) Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohyd Polym 86(1):1–18

Grand View Research. Plastic packaging market size, share & trends analysis report by product ( bottles, bags, wraps & films), by type ( rigid, flexible ), by application ( food & beverages, industrial), and segment forecasts, 2018–2025, p 110

Xie Y et al (2010) Silane coupling agents used for natural fiber/polymer composites: a review. Composites A 41(7):806–819

Saxena M et al (2011) Composite materials from natural resources: recent trends and future potentials

Cardona CA, Sanchez OJ, Gutierrez LF (2010) Process synthesis for fuel ethanol production. CRC Press, Boca Raton

Lavoine N, Desloges I, Bras J (2014) Microfibrillated cellulose coatings as new release systems for active packaging. Carbohyd Polym 103:528–537

Fortunati E et al (2016) Lignocellulosic nanostructures as reinforcement in extruded and solvent casted polymeric nanocomposites: an overview. Eur Polym J 80:295–316

Klemm D et al (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem 50:5438–5466

Zhou X, Broadbelt LJ, Vinu R (2016) Chapter two—mechanistic understanding of thermochemical conversion of polymers and lignocellulosic biomass. In: Van Geem KM (ed) Advances in chemical engineering. Academic Press, New York, pp 95–198

Müssig J (2010) Industrial applications of natural fibres—structure, properties and technical applications. Wiley, Chichester

Dungani R et al (2016) Agricultural waste fibers towards sustainability and advanced utilization: a review. Asian J Plant Sci 15:42–55

Lomelí-Ramírez MG et al (2018) Study of green nanocomposites based on corn starch and cellulose nanofibrils from Agave tequilana Weber. Carbohyd Polym 201:9–19

Luo H et al (2014) Mechanical and thermo-mechanical behaviors of sizing-treated corn fiber/polylactide composites. Polym Test 39:45–52

Torres-Tello EV et al (2017) Effect of agave fiber content in the thermal and mechanical properties of green composites based on polyhydroxybutyrate or poly(hydroxybutyrate-co-hydroxyvalerate). Ind Crops Prod 99:117–125

Mohanty AK, Misra M, Drzal LT (2005) Natural fibers, biopolymers, and biocomposites, AK Mohanty, Misra M, Drzal LT (eds). Taylor & Francis/CRC Press, Boca Raton, FL

Song J, Kay M, Coles R (2011) Bioplastics. In: Food and beverage packaging technology, pp 295–319

Marques AP, Reis RL, Hunt JA (2002) The biocompatibility of novel starch-based polymers and composites: in vitro studies. Biomaterials 23(6):1471–1478

Martin O, Avérous L (2001) Poly(lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42(14):6209–6219

Ashok A, Rejeesh CR, Ravindranathan R (2016) Biodegradable polymers for sustainable packaging applications: a review. Int J Bion Biomater 2:1–11

Imam SH et al (1999) Degradation of starch-poly([β-hydroxybutyrate-Co-β-hydroxyvalerate) bioplastic in tropical coastal waters. Appl Environ Microbiol 65(2):431–437

Gómez EF, Michel FC (2013) Biodegradability of conventional and bio-based plastics and natural fiber composites during composting, anaerobic digestion and long-term soil incubation. Polym Degrad Stab 98(12):2583–2591

Emadian SM, Onay TT, Demirel B (2017) Biodegradation of bioplastics in natural environments. Waste Manag 59:526–536

Pelissari F et al (2017) Nanocomposites based on banana starch reinforced with cellulose nanofibers isolated from banana peels. J Coll Interface Sci 505:154

Fitch-Vargas PR et al (2019) Mechanical, physical and microstructural properties of acetylated starch-based biocomposites reinforced with acetylated sugarcane fiber. Carbohyd Polym 219:378–386

Ago M, Ferrer A, Rojas OJ (2016) Starch-based biofoams reinforced with lignocellulose nanofibrils from residual palm empty fruit bunches. Water Sorpt Mech Streng 4(10):5546–5552

Travalini AP et al (2019) Cassava starch films reinforced with lignocellulose nanofibers from cassava bagasse. Int J Biol Macromol 139:1151

Hottle TA, Bilec MM, Landis AE (2013) Sustainability assessments of bio-based polymers. Polym Degrad Stab 98(9):1898–1907

Jang JY et al (2012) Thermal stability and flammability of coconut fiber reinforced poly(lactic acid) composites. Composites B 43(5):2434–2438

Paunonen S (2013) Strength and barrier enhancements of cellophane and cellulose derivative films: a review. BioResources 8(2):3098–3121

Chan SW et al (2013) Comparative study on the physicochemical properties of κ-carrageenan extracted from Kappaphycus alvarezii (doty) doty ex Silva in Tawau, Sabah, Malaysia and commercial κ-carrageenans. Food Hydrocolloids 30(2):581–588

Mohanty AK et al (2004) Effect of process engineering on the performance of natural fiber reinforced cellulose acetate biocomposites. Composites A 35(3):363–370

Tabasum S et al (2019) A review on blending of corn starch with natural and synthetic polymers, and inorganic nanoparticles with mathematical modeling. Int J Biol Macromol 122:969–996

Takada M et al (2018) Characterization of three tissue fractions in corn (Zea mays) cob. Biomass Bioenerg 115:130–135

Kansas corn. Corn plant structures and functions

Boyrazlı M, Güler SH (2020) Synthesis of carbon nanostructures from corn stalk using mechano-thermal method. J Mol Struct 1199:126976

Lu Z et al (2016) Effects of corn stalk fiber content on properties of biomass brick. Constr Build Mater 127:11–17

Jarabo R et al (2013) Corn stalk from agricultural residue used as reinforcement fiber in fiber-cement production. Ind Crops Prod 43:832–839

Tran KQ, Satomi T, Takahashi H (2018) Effect of waste cornsilk fiber reinforcement on mechanical properties of soft soils. Transport Geotech 16:76–84

Luo Z et al (2017) Comparison of performances of corn fiber plastic composites made from different parts of corn stalk. Ind Crops Prod 95:521–527

Ibrahim MIJ et al (2019) Potential of using multiscale corn husk fiber as reinforcing filler in cornstarch-based biocomposites. Int J Biol Macromol 139:596–604

Wu M et al (2018) Processing of superfine grinding corn straw fiber-reinforced starch film and the enhancement on its mechanical properties. Polymers 10:855

Liu Y et al (2019) Characterization of silane treated and untreated natural cellulosic fibre from corn stalk waste as potential reinforcement in polymer composites. Carbohyd Polym 218:179–187

Ashori A, Nourbakhsh A, Tabrizi A (2014) Thermoplastic hybrid composites using bagasse, corn stalk and E-glass fibers: fabrication and characterization. Polymer 53:1–8

Kamel S (2007) Nanotechnology and its applications in lignocellulosic composites, a mini review. Express Polym Lett 1:546–575

Sharma B, Malik P, Jain P (2018) Biopolymer reinforced nanocomposites: a comprehensive review. Mater Today Commun 16:353–363

Saba N, Tahir PM, Jawaid M (2014) A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 6:2247–2273

Njuguna J, Pielichowski K, Alcock J (2007) Epoxy-based fibre reinforced nanocomposites. Adv Eng Mater 9:835–847

Jonoobi M et al (2015) Different preparation methods and properties of nanostructured cellulose from various natural resources and residues: a review. Cellulose 22:935

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crops Prod 93:2–25

Rol F et al (2019) Recent advances in surface-modified cellulose nanofibrils. Prog Polym Sci 88:241–264

Ibrahim R (2002) Chemical composition of alkaline pulps from oil palm empty fruit bunches. Oil Palm Bull 44:19–24

Abral H et al (2019) Characterization of disintegrated bacterial cellulose nanofibers/PVA bionanocomposites prepared via ultrasonication. Int J Biol Macromol 135:591–599

Huerta RR, Saldaña MDA (2019) Sequential treatment with pressurized fluid processing and ultrasonication for biorefinery of canola straw towards lignocellulosic nanofiber production. Ind Crops Prod 139:111521

Gonzalez D, Santos V, Carlos Parajo J (2012) Silane-treated lignocellulosic fibers as reinforcement material in polylactic acid biocomposites. J Thermoplast Compos Mater 25:1005–1022

Indarti E et al (2019) Silylation of TEMPO oxidized nanocellulose from oil palm empty fruit bunch by 3-aminopropyltriethoxysilane. Int J Biol Macromol 135:106–112

Sharma A et al (2019) Commercial application of cellulose nano-composites—a review. Biotechnol Rep 21:e00316

Herrick FW et al (1983) Microfibrillated cellulose: morphology and accessibility. J Appl Polym Sci: Appl Polym Symp

Brinchi L et al (2013) Production of nanocrystalline cellulose from lignocellulosic biomass: technology and applications. Carbohyd Polym 94(1):154–169

Ek M, Gellerstedt G, Henriksson G (2009) Pulp and paper chemistry and technology. Wood chemistry and wood biotechnology, Walter de Gruyter, Berlin1

Ferrer A et al (2011) Milox fractionation of empty fruit bunches from Elaeis guineensis. Biores Technol 102:9755–9762

Filippis PD, Scarsella M, Verdone N (2009) Peroxyformic acid formation: a kinetic study. Ind Eng Chem Res 48(3):1372–1375

Bolaski W, Gallatin A, Gallatin J (1962) Enzymatic conversion of cellulosic fibers. Patent US, 3041246

Nair S, Yan N (2015) Effect of high residual lignin on the thermal stability of nanofibrils and its enhanced mechanical performance in aqueous environments. Cellulose 22:3137–3150

Andrade Alves JA et al (2019) Sorghum straw: pulping and bleaching process optimization and synthesis of cellulose acetate. Int J Biol Macromol 135:877–886

Li M et al (2019) Effect of hydrogen peroxide bleaching on anionic groups and structures of sulfonated chemo-mechanical pulp fibers. Colloids Surf A 585:124068

Axegård P (2019) The effect of the transition from elemental chlorine bleaching to chlorine dioxide bleaching in the pulp industry on the formation of PCDD/Fs. Chemosphere 236:124386

Fonseca AS et al (2019) Improving cellulose nanofibrillation of non-wood fiber using alkaline and bleaching pre-treatments. Ind Crops Prod 131:203–212

Rojo E et al (2015) Comprehensive elucidation of the effect of residual lignin on the physical, barrier, mechanical and surface properties of nanocellulose films. Green Chem 17:1853

Chen H et al (2019) Lignin containing cellulose nanofibril application in pMDI wood adhesives for drastically improved gap-filling properties with robust bondline interfaces. Chem Eng J 360:393–401

Nair S et al (2018) Polylactic acid biocomposites reinforced with nanocellulose fibrils with high lignin content for improved mechanical, thermal, and barrier properties. ACS Sustain Chem Eng 6:10058

Winter A et al (2017) Reduced polarity and improved dispersion of microfibrillated cellulose in poly(lactic-acid) provided by residual lignin and hemicellulose. J Mater Sci 52:60

Wang X et al (2018) Influence of the lignin content on the properties of poly(lactic acid)/lignin-containing cellulose nanofibrils composite films. Polymers 10:1013

PRO Scientific Inc. (2019) PRO scientific homogenizers. https://proscientific.com/the-field-of-homogenizing. Accessed 8 Sept 2019

Ferrer A et al (2012) Valorization of residual Empty Palm Fruit Bunch Fibers (EPFBF) by microfluidization: production of nanofibrillated cellulose and EPFBF nanopaper. Biores Technol 125:249–255

Nechyporchuk O, Pignon F, Belgacem MN (2015) Morphological properties of nanofibrillated cellulose produced using wet grinding as an ultimate fibrillation process. J Mater Sci 50(2):531–541

Ämmälä A et al (2019) Key role of mild sulfonation of pine sawdust in the production of lignin containing microfibrillated cellulose by ultrafine wet grinding. Ind Crops Prod 140:111664

Li X, Tabil L, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Spence K (2011) Processing and properties of microfibrillated cellulose. In: Forest biomaterials

Heidbreder LM et al (2019) Tackling the plastic problem: a review on perceptions, behaviors, and interventions. Sci Total Environ 668:1077–1093

Acknowledgements

The authors would like to acknowledge Curtin University Malaysia in supporting this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chong, T.Y., Law, M.C. & Chan, Y.S. The Potentials of Corn Waste Lignocellulosic Fibre as an Improved Reinforced Bioplastic Composites. J Polym Environ 29, 363–381 (2021). https://doi.org/10.1007/s10924-020-01888-4

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01888-4