Abstract

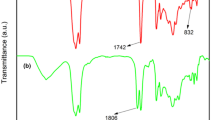

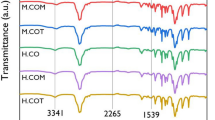

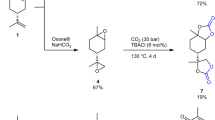

A three-step synthetic route was proposed and tested to obtain a chain-end functional di-sorbitan oleate monomer: First, 1,18-octadec-9-enedioic acid compound was produced by self-metathesis reaction of an oleic acid; then, the 1,18-octadec-9-enoyl dichloride compound was yielded by chlorination of the di-acid with thionyl chloride, and finally, the 1,18-di-sorbitan oleate monomer was yielded by esterification of the dichloride with 1,4-sorbitan. The di-sorbitan oleate monomer was purified and then characterized by FTIR, 1H-NMR, DSC and TGA to establish its structure and properties. A bio-based polyurethane (PU) was synthesized by reacting the obtained 1,18-di-sorbitan oleate monomer and MDI. Rheological analysis showed that a curing reaction occurs as a significant increase of the storage modulus (G’) and the complex viscosity (η*) at 100 °C. The obtained bio-based PU was characterized by FTIR, TGA and DMA, confirming that 1,18-di-sorbitan oleate is a feasible monomer for synthesizing polyurethanes.

Similar content being viewed by others

References

Mülhaupt R (2013) Macromol Chem Phys 214:159

Budzianowski WM (2017) Renew Sustain Energy Rev 70:793

Sheldon RA (2016) J Mol Catal A: Chem 422:3

Wang J et al (2017) Waste Manage 65:11

John G et al (2019) Prog Polym Sci 92:158

Zhang C et al (2017) Prog Polym Sci 71:91

Gandini A, Lacerda TM (2015) Prog Polym Sci 48:1

Salimon J, Salih N, Yousif E (2012) Arab J Chem 5(2):135

Yabushita M, Kobayashi H, Fukuoka A (2014) Appl Catal B 145:1

Rose M, Palkovits R (2012) Chemsuschem 5(1):167

Rusu OA et al (2015) Appl Catal B 176–177:139

Cao D et al (2016) Appl Catal A 528:59

Ginés-Molina MJ et al (2017) Appl Catal A 537:66

Cubo A et al (2017) Appl Catal A 531:151

Zhang Y et al (2018) Mol Catal 458:19

Dussenne C et al (2019) Mol Catal 463:61

Yuan D et al (2019) Appl Catal B 240:182

Gustini L et al (2015) Eur Polymer J 67:459

Bersot JC et al (2011) Macromol Chem Phys 212(19):2114

Brack, H., et al. (2011) US 2011/0077377A1 SABIC Innov Plast IP BV.

Jeong G-T et al (2007) Appl Biochem Biotechnol 137(1):935

Ng SH et al (2013) J Nanobiotechnol 11(1):27

Ciriminna R et al (2014) Sustain Chem Process 2(1):26

Hojabri L, Kong X, Narine S (2010) J Polym Sci A: Polym Chem 48(15):3302

More AS et al (2013) Eur Polymer J 49(4):823

Charlon M et al (2014) Eur Polymer J 61:197

del Río E et al (2011) Macromol Chem Phys 212(13):1392

Miao S et al (2012) Eur J Lipid Sci Technol 114(12):1345

Kalita H, Karak N (2014) J Appl Polym Sci 131(1):39579

Fourati Y et al (2017) Prog Org Coat 105:48

Mol J (1994) J Mol Catal 90(1–2):185

Mol J, Khosravi E, SzymanskaBuzar T (2002) Ring Open Metathesis Polym Relat Chem 56:377

Mol J (2004) Top Catal 27(1–4):97

Mol JC (2004) J Mol Catal A: Chem 213(1):39

Ngo H, Jones K, Foglia T (2006) J Am Oil Chem Soc 83(7):629

Ngo H, Foglia T (2007) J Am Oil Chem Soc 84(8):777

Zerkowski J, Solaiman D (2012) J Am Oil Chem Soc 89(7):1325

Kadyrov R et al (2012) Top Catal 55(7–10):538

Vyshnavi Y, Prasad RBN, Karuna MSL (2013) Ind Crops Prod 50:701

Aguilar-Castro C et al (2019) J Appl Polym Sci 136(8):47095

Yabushita , M. (2016) in a study on catalytic conversion of non-food biomass into chemicals: fusion of chemical sciences and engineering, Springer, Editor p.127

Yabushita M et al (2015) Bull Chem Soc Jpn 88(7):996

Petrović ZS et al (2010) Eur J Lipid Sci Technol 112(1):97

Miao S et al (2014) Acta Biomater 10:1692

Riyapan D, Saetung A, Saetung N (2019) J Polym Environ 27:1693

Dhaliwal GS, Anandan S, Chandrashekhara K et al (2019) J Polym Environ 27:1897

Bresolin D, Valério A, de Oliveira D et al (2018) J Polym Environ 26:2467

Zhuang JM, Steiner Paul R (1993) in Holzforschung – Int J Biol. Chem, Phys Technol Wood p, p 425

Yang PF, Han YD, Li TD (2011) Adv Mater Res 150–151:23

Lu M-Y et al (2018) Croat Chem Acta 91(3):299

Krämer RH et al (2010) Polym Degrad Stab 95(6):1115

Ketata N et al (2005) Polym Polym Compos 13(1):1

Acknowledgements

The authors wish to thank the National Council of Science and Technology of Mexico (CONACYT) for supporting this research work through the project CB-2015–01-257591.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Valencia-Bermudez, S., Hernández-López, S., Gutiérrez-Nava, M. et al. Chain-End Functional di-Sorbitan Oleate Monomer Obtained from Renewable Resources as Precursors for Bio-Based Polyurethanes. J Polym Environ 28, 1406–1419 (2020). https://doi.org/10.1007/s10924-020-01692-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01692-0