Abstract

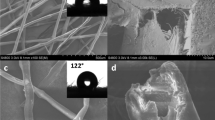

Polylactic acid (PLA) fibrous membrane (PFM) was prepared through solution blow spinning (SBS). The effects of spinning parameters (solution concentration, gas pressure, and spinning distance) on the fiber diameter were studied by response surface methodology. The optimized preparation conditions of PFM were the concentration of PLA solution 8%, gas pressure 0.2 MPa, spinning distance 12 cm. Under the optimized conditions, the average diameter of PLA fibers was 770.45 nm. The oil saturated adsorption capacity of PFM to crude oil, peanut oil and diesel oil was up to 32.28 g/g, 28.80 g/g, and 19.50 g/g, respectively, while that of the commercialized nonwoven polypropylene was only 9.34 g/g, 9.17 g/g, 7.79 g/g, respectively. The adsorption capacity remained at about 50% of the saturated adsorption capacity after 10 cycles of reuse. Similar membrane was also successfully prepared from a waste PLA lid through SBS, which expressed similar oil adsorption behavior with PFM. SBS is potential to deal with the pollutions from waste oil and waste plastic.

Similar content being viewed by others

References

Tai MH, Juay J, Sun DD (2015) Carbon–silica composite nanofiber membrane for high flux separation of water-in-oil emulsion: performance study and fouling mechanism. Sep Sci Technol 156(3):952–960

Yang Y, Deng Y, Tong Z (2014) Renewable lignin-based xerogels with self-cleaning properties and superhydrophobicity. Acs Sustain Chen Eng 2(7):1729–1733

Lin C, Huang CL, Shern CC (2008) Recycling waste tire powder for the recovery of oil spills. Resour Conserv Recy 52(10):1162–1166

Yoon H, Na SH, Choi JY (2014) Gravity-driven hybrID membrane for oleophobic–superhydrophilic oil–water separation and water purification by graphene. Langmuir 30(39):11761–11769

Maimaiti H, Arken K, Wumaier M (2016) Preparation and properties of cellulose-based oil absorbents. Mater Res Innov 19(S8):S8–S434

Zheng X, Guo Z, Tian D (2015) Underwater self-cleaning scaly fabric membrane for oily water separation. Mater Res Innov 7(7):4336–4343

Wang WH, Wang J, Kou XY (2013) Study on the oil adsorptive property of nano-Polypropylene fiber and its application on floating oil adsorption on water surface. Ocean Technol 2:27–33

Obaid M, Tolba GMK, Motlak M (2015) Effective polysulfone-amorphous SiO2, NPs electrospun nanofiber membrane for high flux oil/water separation. Chem Eng 279:631–638

Ge J, Zhao HY, Zhu HW, Huang J, Shi L, Yu S (2016) Advanced sorbents for oil-spill cleanup: recent advances and future perspectives. Adv Mater 28(47):10459–10490

Gao C, Sun Z, Li K, Chen Y, Cao Y, Zhang S, Feng L (2013) Integrated oil separation and water purification by a double-layer TiO2-based mesh. Energy Environ Sci 6(4):1147–1151

Dias JM, Alvim-Ferraz MC, AlmeIDa MF, Rivera-Utrilla J, Sánchez-PoloM (2007) Waste materials for activated carbon preparation and its use in aqueous-phase treatment: a review. J Environ Manage 85(4):833–846

Hu Y, Liu X, Zou J, Gu T, Chai W, Li H (2013) Graphite/isobutylene-isoprene rubber highly porous cryogels as new sorbents for oil spills and organic liquIDs. Acs Appl Mater Interfaces 5(16):7737–7742

Yang Y, Liu Z, Huang J, Wang C (2015) Multifunctional, robust sponges by a simple adsorption–combustion method. J Mater Chem A3(11):5875–5881

Ge X, Yang W, Wang J, Long D, Ling L, Qiao W (2015) Flexible carbon nanofiber sponges for highly efficient and recyclable oil absorption. RSC Adv 5(86):70025–70031

Mizukoshi T, Matsumoto H, Minagawa M, Tanioka A (2007) Control over wetability of textured surfaces by electrospray deposition. J Appl Polym Sci 103(6):3811–3817

Radetic M, Ilic V, Radojevic D, Miladinovic R, Jocic D, Jovancic P (2008) Efficiency of recycled wool-based nonwoven material for the removal of oils from water. Chemosphere 70(3):525–530

Oksman K, Skrifvars M, Selin JF (2003) Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol 63(9):1317–1324

Guo W, Jian T, Chao Y (2012) Introduction of environmentally degradable parameters to evaluate the biodegradability of biodegradable polymers. PLoS ONE 7(5):e38341

Wang S, Tao J, Guo T (2007) Thermal characteristics, mechanical properties and biodegradability of polycarbonates/poly(lactic acID) (PPC/PLA) blends. Ion Exch Adsorpt 23(1):1–9

Bhatia A, Gupta RK, Bhattacharya S, Choi HJ (2010) Effect of clay on thermal, mechanical and gas barrier properties of biodegradable poly(lactic acID)/poly(butylene succinate) (PLA/PBS) nanocomposites. Int Polym Proc 1:5–14

Li X, Teng K, Shi J, Wang W, Xu Z, Deng H, Lv H, Li F (2016) Electrospun preparation of polylactic acid nanoporous fiber membranes via thermal-nonsolvent induced phase separation. J Taiwan Inst Chem E 60:636–642

Liu Y, Huang G, Gao C, Zhang L, Chen M, Xu X, Gao J, Pan C, Yang N, Yu L (2015) Biodegradable polylactic acID porous monoliths as effective oil sorbents. Compos Sci Technol 118:9–15

Shi J, Zhang L, Peng X, Huang YJ, Chen P, Wang XF, Gu JC, Zhang JW, Chen T (2018) Biodegradable PLA non-woven fabric with controllable wetability for efficient water purification and photo-catalysis degradation. ACS Sustain Chem Eng 6(2):2445–2452

Bhardwaj N, Kundu SC (2010) Electrospinning: a fascinating fiber fabrication technique. Biotechnol Adv 28(3):325

Chu KH, Park M, Kim HY, Jin FL, Park SJ (2014) Preparation and characterization of polypropylene non-woven fabrics prepared by melt-blown spinning for filtration membranes. B Korean Chem Soc 35(6):1901–1903

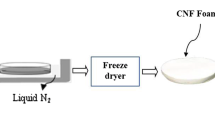

Medeiros ELG, Braz AL, Porto IJ (2016) Porous bioactive nanofibers via cryogenic solution blow spinning and their formation into 3D macroporous scaffolds. Acs Biomater Sci Eng 2(9):1442–1449

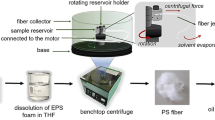

Ren L, Kotha SP (2014) Centrifugal jet spinning for highly efficient and large-scale fabrication of barium titanate nanofibers. Mater Lett 117(15):153–157

Medeiros ES, Glenn GM, Klamczynski AP, Orts WJ, Mattoso LHC (2009) Solution blow spinning: a new method to produce micro- and nano-fibers from polymer solutions. J Appl Polym Sci 113(4):2322–2330

Bilbao-Sainz C, Chiou BS, Valenzuela-Medina D, Du WX, Gregorski KS, Williams TG, Wood DF, Glenn GM, Orts WJ (2014) Solution blow spun poly(lactic acid)/hydroxypropyl methylcellulose nanofibers with antimicrobial properties. Eur Polym J 54(1):1–10

Çubuk M, Gürü M, Uğurlu El (2014) Elimination of oil pollution in water using waste styrofoam, tea fibre and polystyrene foaming. J Fac Eng Archit Gaz 29(2):281–289

Oliveira JE, Moraes EA, Costa RG, Afonso AS, Mattoso LH, Orts WJ, Medeiros ES (2011) Nano and submicrometric fibers of poly(D,L-lactIDe) obtained by solution blow spinning: process and solution variables. J Appl Polym Sci 122(5):3396–3405

Zhang X, Lv J, Yin X, Li Z, Lin Q, Zhu L (2018) Nanofibrous polystyrene membranes prepared through solution blow spinning with an airbrush and the facile application in oil recovery. Appl Phys A 124(5):362

Afanasiev SA, Muslimova EF, Nashchekina YA, Nikonov PO, Rogovskaya YV, Bolbasov EN, Tverdokhlebov SI (2017) Peculiarities of cell seeding on polylactic acID-based scaffolds fabricated using electrospinning and solution blow spinning technologies. Bull Exp Biol Med 164(2):1–4

Ewelina T, Michal W, Elzbieta J, Michal C, Tomasz C, Zbigniew B (2017) Poly(L-lactic acID) andpolyurethane nanofibers fabricatedby solution blow spinning as potential substrates for cardiac cell culture. Mater Sci Eng C 5:305–316

Roberta FB, Paulo RF, André UD, Danyel EC, Lúcio RC, Juliano EO, Eliton SM (2017) Poly(lactic acID)/poly(vinyl pyrrolIDone) membranes produced by solution blow spinning: structure, thermal, spectroscopic, and microbial barrier properties. J Appl Polym Sci 134(19):44802

Litviakov NV, Tverdokhlebov SI, Perelmuter VM, Kulbakin DE, Bolbasov EN, Tsyganov MM, Zheravin AA, Svetlichnyi VA, Cherdyntseva NV (2016) Composite implants coated with biodegradable polymers prevent stimulating tumor progression. AIP Conf Proc 1760(1):020043

Varadan VK, Rai, Pratyush OH, Chang S. Large scale manufacturing of hybrid nanostructured textile sensors. US 20160222539 A1 20160804

Medeiros, Eudes LG, Isaque JM, Angelika B, Alexander B, Aldo RL, William CN, Showan NM, Eliton SB, Jonny J (2016) Porous bioactive nanofibers via cryogenic solution blow spinning and their formation into 3D macroporous scaffolds. ACS Biomater Sci Eng 2(9):1442–1449

Rodrigo GF, Glaucia SB, Caue R, Luiz HC (2016) Nanocomposite fibers of poly(lactic acid)/titanium dioxide prepared by solution blow spinning. Polym Bull 73(11):2973–2985

Delne DS, Juliano EO, Milene MF, Jose MM, Luiz HC (2016) Poly(lactic acID) fibers obtained by solution blow spinning: effect of a greener solvent on the fiber diameter. J Appl Polym Sci 133(18):43379

Michelle A, Souza JE, Oliveira JE, Medeiros ES, Glenn GM, Mattoso LH (2015) Controlled release of linalool using nanofibrous membranes of poly(lactic acID) obtained by electrospinning and solution blow spinning: a comparative study. J Nanosci Nanotechnol 15(8):5628–5636

Martínez-Sanz M, Bilbao-Sainz C, Du WX, Chiou BS, Williams TG, Wood DF, Imam SH, Orts WJ, Lopez-Rubio A, Lagaron JM (2015) Antimicrobial poly(lactic acid)-based nanofibers developed by solution blow spinning. J Nanosci Nanotechnol 15(1):616–627

Oliveira J, Brichi GS, Marconcini JM, Mattoso LH, Glenn GM, Medeiros ES (2014) Effect of solvent on the physical and morphological properties of poly(lactic acid) nanofibers obtained by solution blow spinning. J Eng Fiber Fabr 9(4):117–125

Medeiros ES, Glenn, Gregory M, Klamczynski, Artur P, Orts WJ, Mattoso, Luiz HC. Solution blow spinning method for the production of nonwoven webs of micro and nano fibers. US, 8641960B1 20140204

Oliveira JE, Moraes EA, Marconcini JM, C. Mattoso LH, Glenn GM, Medeiros ES (2013) Properties of poly(lactic acid) and poly(ethylene oxide) solvent polymer mixtures and nanofibers made by solution blow spinning. J Appl Polym Sci1 29(6):3672–3681

Liu S, Wu G, Jia H, Zhang R, Dai Ji. Method for preparing heat-resistant polylactic acid fiber, CN 102839443A 20121226

Oliveira JE, Zucolotto V, LH, Medeiros ES (2012) Multi-walled carbon nanotubes and poly(lactic acID) nanocomposite fibrous membranes prepared by solution blow spinning. J Nanosci Nanotechnol 12(3):2733–2741

Yang Z. Preparation of fullerene-containing polythiophene-polylactic acid block copolymer-based ordered nanoporous organic thin film. CN 102391533 A 20120328

Oliveira JE, Moraes EA, Costa RGF, Afonso Andre S, Mattoso LHC, Orts WJ, Medeiros ES (2011) Nano and submicrometric fibers of poly(D,L-lactIDe) obtained by solution blow spinning: process and solution variables. J Appl Polym Sci 122(5):3396–3405

Medeiros ES, Glenn GM, Klamczynski AP, Orts WJ, Mattoso LHC (2009) Solution blow spinning: a new method to produce micro- and nanofibers from polymer solutions. J Appl Polym Sci 113(4):2322–2330

Afanasiev SA, Muslimova EF, Rogovskaya YV, Nashchekina YA, Nikonov PO, Bolbasov EN, Tverdokhlebov SI (2017) Peculiarities of cell seeding on polylactic acID-based scaffolds fabricated using electrospinning and solution blow spinning technologies. Bull Exp Biol Med 164(2):281–284

Lou H, Li W, Li C, Wang X (2013) Systematic investigation on parameters of solution blown micro/nanofibers using response surface methodology based on Box-Behnken design. J Appl Polym Sci 130(2):1383–1391

Faliszewski K, Wojasiński M, Ciach T (2013) Influence of process parameters on the size and morfology of poly-L-lactIDe acID nanofibers obtained by solution blow spinning. Eur Young Eng Conf 2:1–6

Kang S, Hsu SL, StIDham HD, Smith PB (2001) A spectroscopic analysis of poly(lactic acID) structure. Macromolecules 34(34):4542–4548

Anderson-Cook CM (2002) Response surface methodology: process and product optimization using designed experiments by Raymond H. Myers; Douglas C. montgomery. J Am Stat Assoc 97(460):293–300

Yun PN, Ray S, Easteal AJ (2012) Influence of solution and processing parameters towards the fabrication of electrospun zein fibers with sub-micron diameter. J Food Eng 109(4):645–651

Zhang L, Kopperstad P, West M, Hedin N, Hao F (2009) Generation of polymer ultrafine fibers through solution (air-) blowing. J Appl Polym Sci 114:3479–3486

Maizatul N, Norazowa I, Yunus WMZW, Abdan K (2012) FTIR and TGA analysis of biodegradable poly(lactic acID)/treated kenaf bast fibre: effect of plasticizers. Pertanika J Sci Technol 21(1):151–160

Dong SK, Kwak SY (2007) The hydrothermal synthesis of mesoporous TiO2, with high crystallinity, thermal stability, large surface area, and enhanced photocatalytic activity. Appl Catal A 323(3):110–118

Shiba K, NiIDome T, Katoh E (2010) Polydispersity as a parameter for indicating the thermal stability of proteins by dynamic light scattering. Anal Sci 26(6):659–663

Zhang J, Seeger S (2015) Polyester materials with superwetting silicone nanofilaments for oil/water separation and selective oil absorption. Adv Funct Mater 21(24):4699–4704

Wojasiński M, Pilarek M, Ciach T (2014) Comparative studies of electrospinning and solution blow spinning processes for the production of nanofibrous poly(L-Lactic AcID) materials for biomedical engineering. Pol J Chem Technol l16(2):43–50

Rupp F, Gittens RA, ScheIDeler L (2014) A review on the wettability of dental implant surfaces: theoretical and experimental aspects. Acta Biomater 10(7):2894–2906

BharathIDasan T, Kumar SV, Bobji MS (2014) Effect of wettability and surface roughness on ice-adhesion strength of hydrophilic, hydrophobic and superhydrophobic surfaces. Appl Surf Sci 314(31):241–250

Duan B, Gao H, He M (2014) Hydrophobic modification on surface of chitin sponges for highly effective separation of oil. ACS Appl Mater Interfaces 6(22):19933–19942

Lv J, Yin X, Li R, Chen J, Lin Q, Zhu L (2018) Superhydrophobic PCL/PS composite nanofibrous membranes prepared through solution blow spinning with an airbrush for oil adsorption. Polym Eng Sci 59:E171–E181

Lee MW, An S, Latthe SS (2013) Electrospun polystyrene nanofiber membrane with superhydrophobicity and superoleophilicity for selective separation of water and low viscous oil. Acs Appl Mater Interfaces 5(21):10597–10604

Pei H, Zhang G, Ge J (2012) The effect of oil viscosity, permeability, and resIDual oil saturation on the performance of alkaline flooding in the recovery of heavy oil. Energy Source Part A 34(8):702–710

Krasian T, Punyodom W, Worajittiphon P (2019) A hybrid of 2D materials (MoS2 and WS2) as an effective performance enhancer for poly(lactic acid) fibrous mats in oil adsorption and oil/water separation. Chem Eng J 369:563–575

Zhang D, Jin X, Huang T, Zhang N, Qi X, Yang J, Zhou Z, Wang Y (2019) Electrospun fibrous membranes with dual-scaled porous structure: super hydrophobicity, super lipophilicity, excellent water adhesion, and anti-icing for highly efficient oil adsorption/separation. ACS Appl Mater Interfaces 11:5073–5083

Dai X, Cao Y, Shi X, Wang X (2016) The PLA/ZIF-8 nanocomposite membranes: the diameter and surface roughness adjustment by ZIF-8 nanoParticles, high wettability, improved mechanical property, and efficient oil/water separation. Adv Mater Interfaces 19:1600725

Raghavan P, Manuel J, Zhao X, Kim DS, Ahn JH, Nah C (2011) Preparation and electrochemical characterization of gel polymer electrolyte based on electrospunpolyacrylonitrile nonwoven membranes for lithium batteries. J Power Sources 196(16):6742–6749

Acknowledgements

The authors appreciate the financial support from the Key Research and Development Plan of Hainan Province (ZDYF2018232), the Project of Scientific Research Platform construction of Hainan University (ZY2019HN09), and the Key projects of College Students' innovation and Entrepreneurship of Hainan University (201910589491). The authors also thank the financial support from the Key Laboratory of Water Pollution Treatment and Resource Reuse of Hainan Province.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, T., Tian, H., Yin, X. et al. Solution Blow Spinning of Polylactic Acid to Prepare Fibrous Oil Adsorbents Through Morphology Optimization with Response Surface Methodology. J Polym Environ 28, 812–825 (2020). https://doi.org/10.1007/s10924-019-01617-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01617-6