Abstract

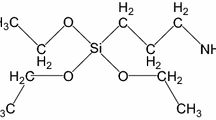

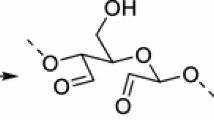

In this work, three composites with different contents (5, 10, and 15% w/w) of kraft pulp fibre were produced as reinforcing elements for natural latex matrix and the mechanical properties were evaluated. In order to improve the interfacial adhesion between the matrix and the reinforcing element, chemical modifications were carried out on the surface of the fibres using octanoyl and benzoyl chlorides as modifying agents. The extension of chemical modification of the fibres was visualized by the presence of absorption bands in the spectroscopy analyzes of the modified fibre in relation to the crude fibre (ester carbonyl 1700–1740 cm−1); in addition, the hydroxyl band was preserved, which indicates a modification of surface character. The modified fibres became more hydrophobic due to the decrease in surface energy and the change in the dispersive and polar components. An increase in the storage modulus was observed for the composites with surface-modified fibres, which agrees with the improved dispersion between the surface-modified fibres and the matrix verified by means of scanning electron microscopy images. The incorporation of fibres did not cause changes in the thermal properties of the composites.

Similar content being viewed by others

References

Miranda CS, Fiuza RP, Carvalho RF, José NM (2014) Quim Nova 38:161

Silva R, Haraguchi SK, Muniz EC, Rubira AF (2009) Quim Nova 32:661

Wei J, Meyer C (2015) Cem Concr Res 73:1

Heinze T, Liebert T (2001) Prog Polym Sci 26:1689

Zhang C, Dan Y, Peng J, Turng L-S, Sabo R, Clemons C (2014) Adv Polym Technol 33:21448

Kato H, Nakatsubo F, Abe K, Yano H, Ikkala O, Clemons C, Anandjiwala R, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2015) RSC Adv 5:29814

Flauzino Neto WP, Mariano M, da Silva ISV, Silvério HA, Putaux J-L, Otaguro H, Pasquini D, Dufresne A (2016) Carbohydr Polym 153:143

Demir H, Atikler U, Balköse D, Tıhmınlıoğlu F (2006) Composites A 37:447

Pasquini D, de Teixeira EM, da Curvelo AAS, Belgacem MN, Dufresne A (2008) Compos Sci Technol 68:193

Bledzki A, Gassan J (1999) Prog Polym Sci 24:221

Boldizar A, Klason C, Kubát J, Näslund P, Sáha P (1987) Int J Polym Mater 11:229

Belgacem MN, Gandini A (2005) Compos Interfaces 12:41

Jacob M, Thomas S, Varughese KT (2004) Compos Sci Technol 64:955

Abdelmouleh M, Boufi S, Belgacem MN, Dufresne A (2007) Compos Sci Technol 67:1627

Pittayavinai P, Thanawan S, Amornsakchai T (2016) Polym Test 54:84

Kamaruddin NKN, Abdullah I, Ahmad I (2014) Int J Mater Eng Innov 5:70

Leão RM, Luz SM, Christoforo AL (2016) J Bioprocess Biotech 6:269

Owens DK, Wendt RC (1969) J Appl Polym Sci 13:1741

Jiang F, Hsieh Y-L (2013) Carbohydr Polym 95:32

Pasquini D, Belgacem MN, Gandini A, da Curvelo AAS (2006) J Colloid Interface Sci 295:79

Drelich J, Miller JD (1995) Miner Metall Proc 12:197

Mousa A, Heinrich G, Wagenknecht U (2012) J Wood Chem Technol 32:82

Zhang X, Wang J, Jia H, You S, Xiong X, Ding L, Xu Z (2016) Composites B 4:121

Yue X, Liu P, Ning Y, Xu Y (2016) Compos Interfaces 23:873

Nagalakshmaiah M, El kissi N, Mortha G, Dufresne A (2016) Carbohydr Polym 136:945

Roman M, Winter WT (2004) Biomacromolecules 5:1671

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prado, N.S., da Silva, I.S.V., de Morais, L.C. et al. Effects of Surface Modifications of Kraft Wood Pulp Cellulose Fibres on Improving the Mechanical Properties of Cellulose Fibre/Latex Composites. J Polym Environ 27, 2445–2453 (2019). https://doi.org/10.1007/s10924-019-01516-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01516-w