Abstract

Cellulose nanocrystals (CNCs) were successfully isolated by hydrochloric acid hydrolysis followed by ultrasonic homogenization of oil palm empty fruit bunches (OPEFB), which are a major form of agricultural waste in Southeast Asia. Currently sulfuric acid is mainly used in CNC preparation to achieve high dispersibility; however, we demonstrated that CNC suspensions prepared from OPEFB by hydrochloric acid hydrolysis remained stable without any sedimentation over 6 months. The obtained CNCs were fully characterized by elemental analysis, electron microscopic observation, X-ray diffraction measurement, and thermal analysis. The OPEFB-derived CNCs exhibited higher aspect ratios of 23–29 and higher thermal stability of 347–359 °C as maximum degradation temperature, as compared with those of woody CNCs prepared by sulfuric acid hydrolysis (15 and 311 °C, respectively). Although as-prepared CNCs showed comparable morphological and physicochemical properties to those prepared from oil palm biomass by other methods including sulfuric acid hydrolysis, use of hydrochloric acid and ultrasonication for hydrolysis of OPEFB was effective to yield crystalline CNCs with long-term nanodispersibility showing clear birefringence.

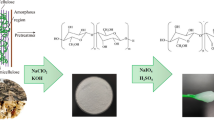

Graphical Abstract

Similar content being viewed by others

References

Directorate General of Estate Crops (2016) Tree crop estate statistics of Indonesia 2014–2016. DGEC, Jakarta

Sudiyani Y, Styarini D, Triwahyuni E, Sembiring KC, Aristiawan Y, Abimanyu H, Han MH (2013) Utilization of biomass waste empty fruit bunch fiber of palm oil for bioethanol production using pilot-scale unit. Energy Procedia 32:31–38

Nieves DC, Karimi K, Horvath IS (2011) Improvement of biogas production from oil palm empty fruit bunches (OPEFB). Ind Crop Prod 34:1097–1101

Or KH, Putra A, Selamat MZ (2017) Oil palm empty fruit bunch fibres as sustainable acoustic absorber. Appl Acoust 119:9–16

Osman NB, Shamsuddin N, Uemura Y (2016) Activated carbon of oil palm empty fruit bunch (EFB); core and shaggy. Procedia Eng 148:758–764

Fahma F, Iwamoto S, Hori N, Iwata T, Takemura A (2010) Isolation, preparation, and characterization of nanofibers from oil palm empty-fruit-bunch (OPEFB). Cellulose 17:977–985

Haafiz MKM, Hassan A, Zakaria Z, Inuwa IM (2014) Isolation and characterization of cellulose nanowhiskers from oil palm biomass microcrystalline cellulose. Carbohydr Polym 103:119–125

Azrina ZAZ, Beg MDH, Rosli MY, Ramli R, Junadi N, Alam AKMM. (2017) Spherical nanocrystalline cellulose (NCC) from oil palm empty fruit bunch pulp via ultrasound assisted hydrolysis. Carbohydr Polym 162:115–120

Nechyporchuk O, Belgacem MN, Bras J (2016) Production of cellulose nanofibrils: a review of recent advances. Ind Crop Prod 93:2–25

Lamaming J, Hashim R, Sulaiman O, Leh CP, Sugimoto T, Nordin NA (2015) Cellulose nanocrystals isolated from oil palm trunk. Carbohydr Polym 127:202–208

Mondal S (2017) Preparation, properties and applications of nanocellulosic materials. Carbohydr Polym 163:301–316

Lamaming J, Hashim R, Leh CP, Sulaiman O, Sugimoto T, Nasir M (2015) Isolation and characterization of cellulose nanocrystals from parenchyma and vascular bundle of oil palm trunk (Elaeis guineensis). Carbohydr Polym 134:534–540

Lamaming J, Hashim R, Leh CP, Sulaiman O (2017) Properties of cellulose nanocrystals from oil palm trunk isolated by total chlorine free method. Carbohydr Polym 156:409–416

Chen YW, Lee HV, Hamid SBA (2017) Facile production of nanostructured cellulose from Elaeis guineensis empty fruit bunch via one pot oxidative-hydrolysis isolation approach. Carbohydr Polym 157:1511–1524

Haafiz MKM, Hassan A, Zakaria Z, Inuwa IM, Islam MS (2013) Physicochemical characterization of cellulose nanowhiskers extracted from oil palm biomass microcrystalline cellulose. Mater Lett 113:87–89

Araki J (2013) Electrostatic or steric? Preparations and characterizations of well-dispersed systems containing rod-like nanowhiskers of crystalline polysaccharides. Soft Matter 9:4125–4141

Wang Z, Yao Z, Zhou J, Zhang Y (2017) Reuse of waste cotton cloth for the extraction of cellulose. Carbohydr Polym 15:945–952

Kalashnikova I, Bizot H, Cathala B, Capron I (2012) Modulation of cellulose nanocrystals amphiphilic properties to stabilize oil/water interface. Biomacromol 13:267–275

Kalashnikova I, Bizot H, Bertoncini P, Cathala B, Capron I (2013) Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 9:952–959

Segal L, Creely L, Martin A, Conrad C (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J 29:786–794

Pereira ALS, Nascimento DMD, Filho MDSMS., Morais JPS, Vasconcelos NF, Feitosa JPA, Brígida AIS, Rosa MDF (2014) Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr Polym 112:165–172

Kallel F, Bettaieb F, Khiari R, García A, Bras J, Chaabouni SE (2016) Isolation and structural characterization of cellulose nanocrystals extracted from garlic straw residues. Ind Crop Prod 87:287–296

Fortunati E, Benincasa P, Balestra GM, Luzi F, Mazzaglia A, Buono DD, Puglia D, Torre L (2016) Revalorization of barley straw and husk as precursors for cellulose nanocrystals extraction and their effect on PVA-CH nanocomposites. Ind Crops Prod 92:201–217

Ditzel FI, Prestes E, Carvalho BM, Demiate IM, Pinheiro LA (2017) Nanocrystalline cellulose extracted from pine wood and corncob. Carbohydr Polym 157:1577–1585

Bano S, Negi YS (2017) Studies on cellulose nanocrystals isolated from groundnut shells. Carbohydr Polym 157:1041–1049

Zhang K, Sun P, Liu H, Shang S, Song J, Wang D (2016) Extraction and comparison of carboxylated cellulose nanocrystals from bleached sugarcane bagasse pulp using two differentoxidation methods. Carbohydr Polym 138:237–243

Labet M, Thielemans W (2011) Improving the reproducibility of chemical reactions on the surface of cellulose nanocrystals: ROP of ɛ-caprolactone as a case study. Cellulose 18:607–617

Okura H, Wada M, Serizawa T (2014) Dispersibility of HCl-treated cellulose nanocrystals with water-dispersible properties in organic solvents. Chem Lett 43:601–603

Araki J, Wada M, Kuga S, Okano T (1998) Flow properties of microcrystalline cellulose suspension prepared by acid treatment of native cellulose. Colloids Surf A 142:75–82

Berg O van den, Capadona JR, Weder C (2007) Preparation of homogeneous dispersions of tunicate cellulose whiskers in organic solvents. Biomacromol 8:1353–1357

Jonoobi M, Khazaeian A, Tahir PM, Azry SS, Oksman K (2011) Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 18:1085–1095

Fujisawa S, Saito T, Kimura S, Iwata T, Isogai A (2013) Surface engineering of ultrafine cellulose nanofibrils toward polymer nanocomposite materials. Biomacromolecules 14:1541–1546

Montanari S, Roumani M, Heux L, Vignon MR (2005) Topochemistry of carboxylated cellulose nanocrystals resulting from TEMPO-mediated oxidation. Macromolecules 38:1665–1671

Eichhorn SJ, Dufresne A, Aranguren M, Marcovich NE, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W, Veigel S, Keckes J, Yano H, Abe K, Nogi M, Nakagaito AN, Mangalam A, Simonsen J, Benight AS, Bismarck A, Berglund LA, Peijs T (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

Rohaizu R, Wanrosli WD (2017) Sono-assisted TEMPO oxidation of oil palm lignocellulosic biomass for isolation of nanocrystalline cellulose. Ultrason Sonochem 34:631–639

Campos A de, Neto AR, de S, Rodrigues, Luchesi VB, Moreira BR, Correa FKV, Mattoso AC, Marconcini LHC JM (2017) Bionanocomposites produced from cassava starch and oil palm mesocarp cellulose nanowhiskers. Carbohydr Polym 175:330–336

Oun AA, Rhim JW (2016) Isolation of cellulose nanocrystals from grain straws and their use for the preparation of carboxymethyl cellulose-based nanocomposite films. Carbohydr Polym 150:187–200

Lu P, Hsieh Y (2012) Preparation and characterization of cellulose nanocrystals from rice straw. Carbohydr Polym 87:564–573

Johar N, Ahmad I, Dufresne A (2012) Extraction, preparation and characterization of cellulose fibres and nanocrystals from rice husk. Ind Crop Prod 37:93–99

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Slavutsky AM, Bertuzzi MA (2014) Water barrier properties of starch films reinforced with cellulose nanocrystals obtained from sugarcane bagasse. Carbohydr Polym 110:53–61

Luo X, Wang X (2017) Preparation and characterization of nanocellulose fibers from NaOH/Urea pretreatment of oil palm fibers. Bioresources 12:5826–5837

Reddy JP, Rhim JW (2014) Isolation and characterization of cellulose nanocrystals from garlic skin. Mater Lett 129:20–23

Taflick T, Schwendler LA, Rosa SML, Bica CID, Nachtigall SMB (2017) Cellulose nanocrystals from acacia bark—influence of solvent extraction. Int J Biol Macromol 101:553–561

Ninduangdee P, Kuprianov VI, Young CE, Kaewrath R, Youngyen P, Attawethworawuth W (2015) Thermogravimetric studies of oil palm empty fruit bunch and palm kernel shell: TG/DTG analysis and modeling. Energy Procedia 79:453–458

Liu JC, Martin DJ, Moon RJ, Youngblood JP (2015) Enhanced thermal stability of biomedical thermoplastic polyurethane with the addition of cellulose nanocrystals. J Appl Polym Sci 132(41970):1–8

Yang X, Han F, Xu C, Jiang S, Huang L, Liu L, Xia Z (2017) Effects of preparation methods on the morphology and properties of nanocellulose (NC) extracted from corn husk. Ind Crops Prod 109:241–247

Fukuzumi H, Saito T, Okita Y, Isogai A (2010) Thermal stability of TEMPO-oxidized cellulose. Polym Degrad Stabil 95:1502–1508

Acknowledgements

This research was supported by an Advanced Low Carbon Technology Research and Development Program from the Japan Science and Technology Agency (T.K.) and by a Research Fellowship for Young Scientists from Japan Society for the Promotion of Science (K.K.). The authors are grateful to Kurnia Wiji Prasetyo, M.Sc. from Biomaterial Research Institute, Indonesian Institute of Sciences, for kindly providing oil palm empty fruit bunches pulp for this research, and the Ministry of Education and Culture, Republic of Indonesia, for partial financial support through the Unggulan Scholarship (N.H.). The authors also thank Prof. Dr. Syuntaro Hiradate and Prof. Dr. Yuki Mori for performing XRD analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hastuti, N., Kanomata, K. & Kitaoka, T. Hydrochloric Acid Hydrolysis of Pulps from Oil Palm Empty Fruit Bunches to Produce Cellulose Nanocrystals. J Polym Environ 26, 3698–3709 (2018). https://doi.org/10.1007/s10924-018-1248-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-018-1248-x