Abstract

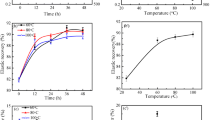

The use of biodegradable polymers is increasingly attracting interest over the last years, since they can reduce the environmental effects related to disposal of traditional plastics and, in general, the use of fossil, non-renewable resources. One of the most promising applications is represented by fibers production. However, the orientation and the crystallinity degrees can significantly affect the mechanical properties. Therefore, it is of interest to investigate on the optimum processing conditions, in order to improve the mechanical properties. In particular, while crystallinity can be slightly modified by the processing, orientation can be significantly improved. In this work, the effects of hot stretching on the mechanical and structural properties of fibers made from two different families of biodegradable blends were investigated. The orientation proved to significantly change the mechanical properties, and it was shown that factors such as the different relaxation times, the different crystallization temperatures and the cooling rate can give opposite effects in the three investigated polymer systems with significant consequences on the mechanical behaviour of the fibers. In particular, the behaviour during fiber production in hot stretching, and the orientation mechanisms were studied and explained on the basis of rheological and thermal properties of the polymers.

Similar content being viewed by others

References

Chandra R, Rustgi R (1998) Biodegradable polymers. Prog Polym Sci 23:1273–1335

An Tran NH, Brünig H, Hinüber C, Heinrich G (2014) Melt spinning of biodegradable nanofibrillary structures from poly(lactic acid) and poly(vinyl alcohol). Macromol Mat Eng 299:219–227

Gupta B, Revagade N, Hilborn J (2007) Poly(lactic acid) fiber: an overview. Prog Polym Sci 32:455–482

Lim LT, Auras R, Rubino M (2008) Processing technologies for poly(lactic acid). Prog Polym Sci 33:820–852

Eling B, Gogolewski S, Pennings AJ (1982) Biodegradable materials of poly(l-lactic acid): 1. Melt-spun and solution-spun fibers. Polymer 23:1587–1593

Fambri L, Pegoretti A, Fenner R, Incardona SD, Migliaresi C (1997) Biodegradable fibers of poly(L-lactic acid) produced by melt spinning. Polymer 38:79–85

Yuan X, Mak AFT, Kwok KW, Yung BKO, Yao K (2001) Characterization of poly(L-lactic acid) fibers produced by melt spinning. J Appl Polym Sci 81:251–260

Postema AR, Pennings AJ (1989) Study on the drawing behavior of poly(L-lactide) to obtain high-strength fibers. J Appl Polym Sci 37:2351–2369

Gupta B, Revagade N, Anjum N, Atthoff B, Hilborn J (2006) Preparation of poly(lactic acid) fiber by dry-jet-wet-spinning. I. Influence of draw ratio on fiber properties. J Appl Polym Sci 100:1239–1246

Kim MS, Kim JC, Kim YH (2008) Effects of take-up speed on the structure and properties of melt-spun poly(L-lactic acid) fibers. Polym Adv Technol 19:748–755

Schmack C, Jehnichen D, Vogel R, Tändler B (2000) Biodegradable fibers of poly(3-hydroxybutyrate) produced by high-speed melt spinning and spin drawing. J Polym Sci Part B Polym Phys 38:2841–2850

Lu L, Wu D, Zhang M, Zhou W (2012) Fabrication of polylactide/poly(ε-caprolactone) blend fibers by electrospinning: morphology and orientation. Ind Eng Chem Res 51:3682–3691

Marrucci G (1975) Limiting concepts in extensional flow. Polym Eng Sci 15:229–234

Ziabicki A (1993) Orientation mechanisms in the development of high-performance fibers. Prog Coll Polym Sci 92:1–7

Arbab S, Nosratian E, Zeinolebadi A, Mojtahedi MM, Shoshtari AM (2011) The effects of melt-spinning temperature and take-up speed on the physical and mechanical properties of as-spun polypropylene filaments. In: Haghi AK (ed) Recent progress in chemistry and chemical engineering research. Nova Science Publishers, Hauppauge, NY, pp 47–57

Mount EM (2012) Oriented films-troubleshooting and characterization. In: Wagner JR (ed) Handbook of troubleshooting plastics processes: a practical guide. Wiley, Hoboken, NJ, pp 133–165

Devaux E (2014) Understanding the behavior of synthetic polymer fibers during spinning. In: Zhang D (ed) Advances in filament yarn spinning of textiles and polymers. Woodhead Publishing Limited, Sawston, pp 31–47

Younes B, Fotheringham A, El-Dessouky HM, Haddad G (2011) Factorial optimization of the effects of melt-spinning conditions on as-spun aliphatic-aromatic copolyester fibers I. Spin draw ratio, overall orientation and drawability. Int J Polym Mat Polym Biomat 60:316–339

Cicero JA, Dorgan JR, Garrett J, Runt J, Lin JS (2002) Effect of molecular architecture on two-step, melt-spun poly(lactic acid) fibers. J Appl Polym Sci 86:2839–2846

Cicero JA, Dorgan JR, Janzen J, Garrett J, Runt J, Lin JS (2002) Supramolecular morphology of two-step, melt-spun poly (lactic acid) fibers. J Appl Polym Sci 86:2828–2838

Postema AR, Luiten AH, Oostra H, Pennings AJ (1990) High strength poly(L-lactide) fibers by a dry-spinning/hot drawing process. II. Influence of the extrusion speed and winding speed on the dry spinning process. J Appl Polym Sci 39:1275–1288

La Mantia FP, D’Amico R, Acierno D (1979) Uniaxial hot stretching of polystyrene and mechanical properties of the oriented samples. Acta Polym 30:685–691

La Mantia FP, Fontana P, Morreale M, Mistretta MC (2014) Orientation induced brittle–ductile transition in a polyethylene/polyamide 6 blend. Polym Test 36:20–23

Kucharczyk P, Otgonzu O, Kitano T, Gregorova A, Kreuh D, Cvelbar U, Sedlarik V, Saha P (2012) Correlation of morphology and viscoelastic properties of partially biodegradable polymer blends based on polyamide 6 and polylactide copolyester. Polym Plast Technol Eng 51:1432–1442

Sedlarik V, Otgonzul O, Kitano T, Gregorova A, Hrabalova M, Junkar I, Cvelbar U, Mozetic M, Saha P (2012) Effect of phase arrangement on solid state mechanical and thermal properties of polyamide 6/polylactide based co-polyester blends. J Macromol Sci Part B Phys 51:982–1001

Morreale M, Mistretta MC, Ceraulo M, La Mantia FP (2014) Rheological behavior under shear and non-isothermal elongational flow of biodegradable polymers for foam extrusion. J Polym Environ 22:112–118

Bastioli C (1998) Properties and applications of mater-Bi starch-based materials. Polym Degrad Stab 59:263–272

Gregorova A, Riedl E, Sedlarik V, Stelzer F (2012) Effect of 4,4′-methylenediphenyl diisocyanate on thermal and mechanical properties of Bioflex/lactic acid polycondensate blends. Asia Pac J Chem Eng 7:317–323

Mistretta MC, Ceraulo M, La Mantia FP, Morreale M (2015) Compatibilization of polyethylene/polyamide 6 blend nanocomposite films. Polym Compos 36:992–998

Wissbrun KF (1981) Rheology of rod-like polymers in the liquid crystalline state. J Rheol 25:619

La Mantia FP, Arrigo R, Morreale M (2014) Effect of the orientation and rheological behaviour of biodegradable polymer nanocomposites. Eur Polym J 54:11–17

Krishnamoorti R, Yurekli K (2001) Rheology of polymer layered silicate nanocomposites. Curr Opin Coll Interface Sci 6:464–470

Ren J, Krishnamoorti R (2003) Nonlinear viscoelastic properties of layered-silicate-based intercalated nanocomposites. Macromolecules 36:4443–4451

Tagaya A (2015) Birefringence of polymer. In: Kobayashi S, Müllen K (eds) Encyclopedia of polymeric nanomaterials. Springer, Berlin, Heidelberg

Gedde U (1999) Polymer physics. Kluwer Academic Publishers, Dordrecht

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

La Mantia, F.P., Ceraulo, M., Mistretta, M.C. et al. Effect of Hot Drawing on the Mechanical Properties of Biodegradable Fibers. J Polym Environ 24, 56–63 (2016). https://doi.org/10.1007/s10924-015-0747-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-015-0747-2