Abstract

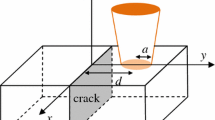

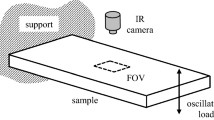

The present paper proposes a new procedure to analyze the temperature field distribution during Flying Laser Spot and Laser Line Thermographic scanning (FLST, FLLT) of metallic components, in order to detect vertical surface cracks. The methodology exploits the changes in the temperature field produced by a vertical crack, acting as a barrier towards heat diffusion, when the laser approaches the defect. A number of small regions of interests (ROIs) is placed nearby and around the laser source. The average temperature from each ROI is then monitored during the laser scanning. Vertical cracks can be detected by analyzing and comparing the temperature fluctuations from each ROI when the laser crosses a crack. The paper, in particular, illustrates how the use of multiple ROIs, placed at different locations, may provide additional information that can be used to characterize the defect, and to identify the crack tip location. The approach is validated on plates made of steel and aluminum alloy, where natural cracks have been introduced by fatigue loading, and whose surface has been painted to enhance emissivity. Scratches in the paint have been artificially made in order to analyze their influence on the defect signature. The proposed experimental setup is further simplified by moving the plate samples, mounted on slits, in front of a still laser source and camera head.

Similar content being viewed by others

References

Scruby, C.B., Drain, L.E.: Laser Ultrasonics: Techniques and Applications. Adam Hilger, Bristol (1990)

Kubiak, E.J.: Infrared detection of fatigue cracks and other near-surface defects. Appl. Opt. 7, 1743–1747 (1968). https://doi.org/10.1364/AO.7.001743

Kaufman, I., Chang, P.-T., Hsu, H.-S., Huang, W.-Y., Shyong, D.-Y.: Photothermal radiometric detection and imaging of surface cracks. J. Nondestruct. Eval. 6, 87–100 (1987). https://doi.org/10.1007/bf00568887

Gruss, C., Balageas, D.: Nondestructive evaluation using a flying-spot camera. In: QIRT Conference (1992)

Montinaro, N., Cerniglia, D., Pitarresi, G.: Detection and characterisation of disbonds on Fibre Metal Laminate hybrid composites by flying laser spot thermography. Compos. Part B Eng. 108, 164–173 (2017). https://doi.org/10.1016/j.compositesb.2016.09.084

Montinaro, N., Cerniglia, D., Pitarresi, G.: A numerical study on interlaminar defects characterization in fibre metal laminates with flying laser spot thermography. J. Nondestruct. Eval. 37, 41 (2018). https://doi.org/10.1007/s10921-018-0494-0

Montinaro, N., Cerniglia, D., Pitarresi, G.: A numerical and experimental study through laser thermography for defect detection on metal additive manufactured parts. Frat. ed Integrita Strutt. 12, 231–240 (2018). https://doi.org/10.3221/IGF-ESIS.43.18

Wang, Y., Kuo, P., Favro, L., Thomas, R.: Flying laser spot thermal wave IR imaging of horizontal and vertical cracks. In: Review of Progress in Quantitative Nondestructive Evaluation, pp. 453–456 (1990)

Krapez, J.: Solution spatiale De La camera thermique source volante. Int. J. Therm. Sci. 38, 769–779 (1999). https://doi.org/10.1016/S1290-0729(99)80033-7

Krapez, J.-C., Gruss, C., Huttner, R., Lepoutre, F., Legrandjacques, L.: La caméra photothermique (flying spot camera) I—principe, modélisation, application à la détection de. Instrum. Mes. Métrologie. 1, 9–39 (2001)

Krapez, J.-C., Lepoutre, F., Huttner, R., Gruss, C., Legrandjacques, L., Piriou, M., Gros, J., Gente, D., Hermosilla-lara, S., Joubert, P.Y., Placko, D.: La caméra photothermique (flying spot camera) II—applications industrielles, perspectives. Instrum. Mes. LaMétrologie. 1, 41–67 (2001)

Bodnar, J.L., Egée, M.: Wear crack characterization by photothermal radiometry. Wear 196, 54–59 (1996). https://doi.org/10.1016/0043-1648(95)06837-6

Bodnar, J.L., Menu, C., Egée, M., Pigeon, P., Le Blanc, A.: Detection of wear cracks by photothermal radiometry. Wear 162–164, 590–592 (1993). https://doi.org/10.1016/0043-1648(93)90546-X

Krapez, J.: Spatial resolution of the flying spot camera with respect to cracks and optical variations. AIP Conf. Proc. 463(377), 1–4 (1999)

Hermosilla-lara, S., Joubert, P.Y., Placko, D.: Enhancement of open-cracks detection using a principal component analysis/wavelet technique in photothermal nondestructive testing, pp. 41–46 (2002)

Joubert, P.-Y., Hermosilla-Lara, S., Placko, D., Lepoutre, F., Piriou, M.: Enhancement of open-crack detection in flying-spot photothermal non-destructive testing using physical effect identification. Quant. Infrared Thermogr. J. 3, 53–70 (2006). https://doi.org/10.3166/qirt.3.53-70

Legrandjacques, L., Krapez, J.-C., Lepoutre, F., Balageas, D.: Nothing but the cracks : a new kind of photothermal camera. In: 7 th European Conference on Non-destructive Testing (ECNDT) (1998)

Li, T., Almond, D.P., Rees, D.A.S.: Crack imaging by scanning pulsed laser spot thermography. NDT E Int. 44, 216–225 (2011). https://doi.org/10.1016/j.ndteint.2010.08.006

Jiao, D., Shi, W., Liu, Z., Xie, H.: Laser multi-mode scanning thermography method for fast inspection of micro-cracks in TBCs surface. J. Nondestruct. Eval. 37, 1–10 (2018). https://doi.org/10.1007/s10921-018-0485-1

Ciampa, F., Mahmoodi, P., Pinto, F., Meo, M.: Recent advances in active infrared thermography for non-destructive testing of aerospace components. Sensors 18(2), 609 (2018)

Burrows, S.E., Dixon, S., Pickering, S.G., Li, T., Almond, D.P.: Thermographic detection of surface breaking defects using a scanning laser source. NDT E Int. 44, 589–596 (2011). https://doi.org/10.1016/j.ndteint.2011.06.001

Li, T., Almond, D.P., Rees, D.A.S., Weekes, B.: Crack imaging by pulsed laser spot thermography. J. Phys: Conf. Ser. 214(1), 012072 (2010). https://doi.org/10.1088/1742-6596/214/1/012072

Li, T., Almond, D.P., Rees, D.A.S.: Crack imaging by scanning laser-line thermography and laser-spot thermography. Meas. Sci. Technol. 22, 035701 (2011). https://doi.org/10.1088/0957-0233/22/3/035701

Beuve, S., Qin, Z., Roger, J.P., Holé, S., Boué, C.: Open cracks depth sizing by multi-frequency laser stimulated lock-in thermography combined with image processing. Sens. Actuators, A 247, 494–503 (2016). https://doi.org/10.1016/j.sna.2016.06.028

Schlichting, J., Ziegler, M., Maierhofer, C., Kreutzbruck, M.: Flying laser spot thermography for the fast detection of surface breaking cracks. In: 18th World Conf. Nondestruct. Test (2012)

Schlichting, J., Maierhofer, C., Kreutzbruck, M.: Crack sizing by laser excited thermography. NDT E Int. 45, 133–140 (2012). https://doi.org/10.1016/j.ndteint.2011.09.014

Fedala, Y., Streza, M., Sepulveda, F., Roger, J.P., Tessier, G., Boué, C.: Infrared lock-in thermography crack localization on metallic surfaces for industrial diagnosis. J. Nondestruct. Eval. 33, 335–341 (2014). https://doi.org/10.1007/s10921-013-0218-4

Fedala, Y., Streza, M., Roger, J.-P., Tessier, G., Boué, C.: Open crack depth sizing by laser stimulated infrared lock-in thermography. J. Phys. D Appl. Phys. 47, 465501 (2014). https://doi.org/10.1088/0022-3727/47/46/465501

Netzelmann, U.: Flying-spot lock-in thermography and its application to thickness measurement and crack detection. In: Proc. 2014 Int. Conf. Quant. InfraRed Thermogr. (2014). https://doi.org/10.21611/qirt.2014.064

Boué, C., Holé, S.: Open crack depth sizing by multi-speed continuous laser stimulated lock-in thermography. Meas. Sci. Technol. 28(6), 065901 (2017). https://doi.org/10.1088/1361-6501/aa687b

de Uralde, P.L., Gorostegui-Colinas, E., Muniategui, A., Gorosmendi, I., Hériz, B., Ayuso, M., Sabalza, X.: A new method for surface crack detection by laser thermography based on Thermal Barrier effect. In: 14 th Quantitative InfraRed Thermography Conference (2018)

Montinaro, N., Cerniglia, D., Pitarresi, G.: Flying laser spot thermography technique for the NDE of fibre metal laminates disbonds. Compos. Struct. 171, 63–76 (2017). https://doi.org/10.1016/j.compstruct.2017.03.035

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Montinaro, N., Cerniglia, D. & Pitarresi, G. Evaluation of Vertical Fatigue Cracks by Means of Flying Laser Thermography. J Nondestruct Eval 38, 48 (2019). https://doi.org/10.1007/s10921-019-0586-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10921-019-0586-5