Abstract

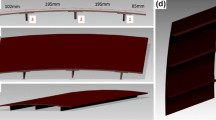

An ultrasonic reflectometry method has been used successfully to detect elasticity changes following the curing of 100 \(\upmu \)m thick epoxy films (DGEBA-PAA) coated onto 1.5 mm thick steel plates. The method employs a goniometric apparatus to measure the reflection coefficient amplitude around 5 MHz followed by a standard FFT analysis of the reflected signal. A specific ultrasonic wave mode was identified which was dependent on, and correlated with, the presence of the coating layer. The goniometer angle associated with this mode was different from that associated with Lamb modes of the plate, enabling the new mode to be detected reliably. The sensitivity of the new mode to variations in the paint mass density, longitudinal and transverse velocities and thickness has been quantified numerically by using Brekhovskikh’s model with due account taken of the finite width of the ultrasonic fields of the transducers. The method was tested for the detection of the evolution of the coating elasticity during curing at 80 \(^{\circ }\)C for 400 h. Compensation was applied to correct for the effect of the natural swelling of the paint layer on the angular position of the tracked mode, and this was validated experimentally. The evolution of the angular position was found to offer a reliable means to detect elasticity changes during the cure of the coating. The mass density variation in the coating during cure only weakly affected the angular position. This method will provide a promising tool for the non destructive evaluation of paint coatings, particularly in service for the detection of ageing effects in the longer term.

Similar content being viewed by others

References

Lindrose, A.M.: Ultrasonic wave and moduli changes in a curing epoxy resin. Exp. Mech. 18, 227–232 (1978)

White, S.R., Mather, P.T., Smith, M.J.: Characterisation of the cure-state od DGEBA-DDS epoxy using ultrasonic, dynamic mechanical, and thermal probes. Polym. Eng. Sci. 42(1), 51–67 (2002)

Sugasawa, S.: Measurements of elastic properties of plasma-sprayed coatings using bulk ultrasonic pulses. Jpn. J. Appl. Phys. 43(5B), 3109–3114 (2004)

Sugasawa, S., Shibata, T.: Evaluation of elastic constants of antifouling paint film using group delay spectrum method. Jpn. J. Appl. Phys. 46(7B), 4583–4588 (2007)

Alig, I., et al.: Monitoring of film formation, curing and ageing of coatings by an ultrasonic reflection method. Prog. Org. Coat. Coat. Sci. Internat. 58, 200–208 (2007)

Alig, I., et al.: Polymerization and network formation of UV-curable materials monitored by hyphenated real-time ultrasound reflectometry and near-infrared spectroscopy (RT-US/NIRS). Prog. Org. Coat. 55(2), 88–96 (2006)

Challis, R.E., Wilkinson, G.P., Freemantle, R.J.: Errors and uncertainties in the ultrasonic reflectometry method for measuring acoustic impedance. Meas. Sci. Technol. 9, 692–700 (1998)

Kinra, V.K., Zhu, C.: Ultrasonic nondestructive evaluation of thin (sub-wavelength) coatings. J. Acoust. Soc. Am. 93(5), 2454–2467 (1993)

Bridge, B., Ramli, A.: Non-destructive evaluation of the quality (cure) of polymeric coatings on steel foods cans by means of high frequency Lamb wave propagation : a preliminary study. J. Mater. Sci. 25, 1794–1802 (1990)

Lavrentyev, A.I., Rokhlin, S.I.: Determination of elastic moduli, density, attenuation and thickness of a layer using ultrasonic spectroscopy at two angles. J. Acoust. Soc. Am. 102(6), 3467–3477 (1997)

Viktorov, I.A.: Rayleigh and Lamb Waves : Physical Theory and Applications. Plenum press, New York (1967)

Brekhovskikh, L.M.: Waves in Layered Media. Academic press, New York (1960)

Folds, D.L., Loggins, C.D.: Transmission and reflection of ultrasonic waves in layered media. J. Acous. Soc. Am. 62, 1102–1109 (1977)

Goodman, J.W.: The angular spectrum of plane waves. Introduction to Fourier Optics, pp. 55–61. McGraw-Hill, New York (1996)

Chen, W., Wu, J.: Reflectometry using longitudinal, shear and Rayleigh waves. Ultrasonics 38, 909–913 (2000)

Kino, G.S.: Acoustic Waves: Devices, Imaging and Analog Signal Processing. Prentice-Hall, Englewood Cliffs, New Jersey (1987)

Lavrentyev, A.I., Rokhlin, S.I.: An ultrasonic method for determination of elastic moduli, density, attenuation and thickness of a polymer coating on a stiff plate. Ultrasonics 39, 211–221 (2000)

Abdelkader, A.F., White, J.R.: Curing characteristics and internal stresses in epoxy coatings: effect of crosslinking agent. J. Mater. Sci. 40, 1843–1854 (2005)

Galant, C., et al.: Thermal and radio-oxidation of epoxy coatings. Prog. Org. Coat. 69, 322–329 (2010)

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

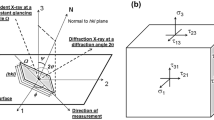

A plane harmonic wave is assumed to impinge on the coated plate immersed in water in a manner which matches our experimental measurement configuration. All the layers are assumed infinite in the \(x\) and \(y\) directions, and the incident wave is assumed to lie in the \(x-z\) plane. By doing this, the problem reduces to one of two dimensions. Viscosity of the coating does not have to be taken into account in the model because paint is usually assumed to behave as a purely elastic material at the ultrasonic frequencies employed. The surface of paint and the interface with the plate are assumed to be plane and homogeneous. The origin of the \(z\)-axis is chosen at the interface between paint and steel to simplify the analysis.

The system is simulated by using the continuity of normal and tangential velocities (\(v_{x}\) and \(v_{z})\) and for normal and shear stresses (\(\sigma _{x}\) and \(\sigma _{z})\) at the interface between layers. For a harmonic wave, the potential function for longitudinal waves \(\varphi \) and the potential function for transverse waves \(\psi \) in layer \(i\) can be expressed by:

where \(k\) is the \(x\) component of the wave vector which is same for all layers, \(k_{L,I}\) and \(k_{T,I}\) are the longitudinal and shear wave vectors for each layer and \(j^{2}=-1\). The quantities \(A_{i}\), \(B_{i}\), \(C_{i}\) and \(D_{i}\) are constants for a given layer.

From the potential function (7), the velocities and stresses at the interface between water and paint (at \(z=d_3 -\xi \), where \(\xi \) is infinitesimal) are obtained.

where \(P_3 =\alpha _3 d_3 \), \(Q_3 =\beta _3 d_3 \), \(g_3 =2\mu _3 k/\omega \)and \(e_3 =(\lambda _3 k_{L,3} ^{2}+2\mu _3 \alpha _3 ^{2})/\omega \). Now, at the interface between paint and steel (at \(z = -\xi \)), because of the continuity, the velocities and stresses are given by substituting \(d_{3}\) into 0 in Eq. (9):

So, by solving the Eqs. (9) and (10), the relation between velocities and stresses of layer 3 and layer 2 is obtained:

The same calculation is done for the layers 2 and 1. Now the relationship between velocities and stresses of layer 4 and layer 1 is obtained.

The layers 4 and 1 correspond to water, so we have:

And the potential functions in layer 4 are:

So, the velocity and stress at the interface between water and paint are:

Similarly at the interface between steel and water:

Substitution of these values, Eqs. (15), (16), (17) and (18) into Eq. (12) gives the reflection coefficient function \(R_{plane}\):

where:

\(Z_1 =\rho _1 \omega /\alpha _1 \) and \(Z_4 =\rho _4 \omega /\alpha _4 \) are the acoustic impedances of layers 1 and 4 (in our experiment, Z\(_{1}\) = Z\(_{4}\) = Z\(_{water})\)

From this model, we can calculate the reflection coefficient for any incident angle and wave frequency for a plane incident wave on an immersed coated plate.

Rights and permissions

About this article

Cite this article

Zhang, X., Augereau, F., Laux, D. et al. Non-destructive Testing of Paint Coatings on Steel Plates by Ultrasonic Reflectometry. J Nondestruct Eval 33, 504–514 (2014). https://doi.org/10.1007/s10921-014-0246-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10921-014-0246-8