Abstract

The Simons Observatory is a cosmic microwave background experiment stationed atop Cerro Toco, at an elevation of 5200 ms in Chile’s Atacama Desert. The receivers of the Observatory will contain more than 60,000 transition edge sensor bolometers. In order to read out this large detector count in a scalable manner, we utilize a microwave superconducting quantum interference device (SQUID) multiplexing scheme where each detector is inductively coupled to an rf SQUID, which in turn is inductively coupled to a GHz resonator. More than 2000 SQUIDs and resonators are fabricated on a single 76.2-mm-diameter silicon wafer. To qualify wafers before integration, we cryogenically screen \(\sim\) 10% of the devices on each wafer by use of a standard set of measurements. From these data, we report parameter value trends in 47 wafers that were fabricated in the past two years. We show good control in key parameters such as frequency placement, internal quality factor, and response to applied flux. We demonstrate a wafer acceptance yield of 86%.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The Simons Observatory (SO) is a cosmic microwave background experiment located in the Atacama Desert of Chile [1]. The initial instrument configuration contains over 60,000 transition edge sensor (TES) bolometers. To read out the large number of sensors in a scalable manner, we utilize microwave superconducting quantum interference device (SQUID) multiplexers (\(\mu\)mux), a frequency-division multiplexer capable of reading out thousands of signal channels on one microwave transmission line [2, 3]. Different implementations of the \(\mu\)mux have been developed by other research groups for separate applications [4, 5]. The cryogenic multiplexer topology and 65-channel chip design used for the SO are described in [6]. When packaged into 1820-channel detector modules and read out with custom room temperature electronics [7], the \(\mu\)mux read out noise has been shown to be 2.5\(\times\) less than the expected detector noise [8]. Currently in SO, we have used the \(\mu\)mux to characterize twenty-six 90/150 GHz detector modules totaling 38,000 TES bolometers [9]. The remaining detector module verification is in progress. Here we report on the cryogenic qualification of 47 \(\mu\)mux wafers, prior to their delivery and integration into SO detector modules.

2 Experimental Setup and Method

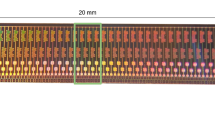

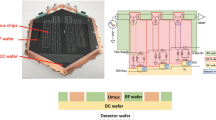

Microwave SQUID multiplexer wafers are fabricated in the Boulder Microfabricaton Facility at the National Institute of Standards and Technology (NIST). Each 76.2mm wafer contains 32 \(\mu\)mux chips (see Fig. 1 left): two copies of a 14-chip multiplexer set with resonant frequencies spanning 4–6 GHz and four additional chips that are packaged into a single microwave line and screened to determine wafer fidelity. In addition, there are a variety of test structures useful for directly probing the Josephson junction fabrication quality. The relevant test structure to this work is one that consists of 200 2.5 \(\upmu\)m\(\times\)2.5\(\upmu\)m junctions wired in series.

We have fabricated, screened, and qualified 47 \(\mu\)mux wafers over two years. All of these wafers are the final design version, v3.3.2; thus, earlier versions are not included. v3.3.2 is currently comprised of wafers 21–65 and additionally includes wafers 52b and 56b which were both created using experimental processes that are still under development. Occasionally, wafers were excluded solely by room temperature tests or by cursory cryogenic checks and are not represented in this analysis either. Wafer qualification consists of two primary measurements that are both taken at 120 mK. We install the devices at the cold stage of an adiabatic demagnetization refrigerator within the rf readout chain shown schematically on the right of Fig. 1. First, we measure the microwave transmission (S\(_{21}\)) across 4–6 GHz to determine the resonance frequency (\(f_r\)), pairwise spacing (\(f_{r_{j+1}}\) - \(f_{r_{j}}\), where j is the resonator index), and the internal quality factor (\(Q_i\)) of each resonator. Second, we determine the device response to an applied stimulus. We measure \(S_{21}\) for each resonator channel as a function of dc magnetic flux applied to the channel’s rf SQUID. This applied flux shifts \(f_r\) periodically. We fit the response to determine \(\lambda\), a critical design parameter defined as:

where \(L_\textrm{s}\) is the self-inductance of the rf SQUID, \(L_\textrm{J} = \Phi _o/2\pi I_c\) is the Josephson inductance, \(\Phi _0\) is the magnetic flux quantum, and \(I_\textrm{c}\) is the junction superconducting critical current. In-depth screening details, parameter definitions and fitting functions are described in [10]. In the remaining sections, we present wafer trend screening results of these 47 \(\mu\)mux wafers and comment on a few critical developments.

3 Results

Figure 2 presents the resonator frequency statistics of up to 4 chips screened from each of the 47 wafers. The left-hand-side plot shows the difference between the designed and achieved chip band edges, that is, the maximum and minimum \(f_r\) within each chip. The data show an absolute resonator placement error of \(\sim\) 0.5%. The right-hand-side plot of Fig. 2 shows that the typical range of interquartile nearest neighbor frequency spacing is well above the 0.5 MHz specification, which is determined from considerations of cross talk [11].

Figure 3 depicts the \(Q_i\) statistics for each wafer screened at NIST. \(Q_i\) is an important performance parameter as it impacts sensitivity, the number of channels that can be multiplexed on one rf transmission line, and cross talk. Through broader development within SO, we have empirically determined that \(Q_i > 50000\) meets or exceeds our dynamic range and sensitivity requirements [8]. This \(Q_i\) specification is exceeded in 92% of the screened wafers. The root cause of low \(Q_i\) wafers has yet to be determined, but the low occurrence rate still allows the timely delivery of readout devices to the SO. We also note that the reported \(Q_i\) in Fig. 3 may be a lower limit due to our wirebonding configuration used for the screening process. We intentionally use few microwave grounding wirebonds to conserve bondpad space needed in the final SO multiplexer assemblies. In separate work, insufficient chip grounding has been shown to reduce \(Q_i\) [10].

Figure 4 shows the \(\lambda\) values across all wafers screened at NIST. \(\lambda\) values for wafers 21–39 are highly variable and consistently greater than the target of \(\lambda \ \sim 1/3\). While values in the range of \(\sim\)0.5 are still usable, albeit with decreased sensitivity, occasionally wafers were produced with \(\lambda\) exceeding 1 (not included in Fig. 4), leading to a hysteretic response that is unusable. By ensuring the devices have a \(\lambda\) value of \(\sim 1/3\), we avoid hysteresis while simultaneously optimizing sensitivity. In contrast, wafers 40–65 are on target with substantially lower variation. The reason for this trend is discussed below.

4 Discussion

The results show good control of the main performance parameters throughout two years of multiplexer fabrication, with one exception. The median \(\lambda\) of wafer numbers < 40 is both higher than designed and highly varying, \(\lambda =~0.43~\pm ~0.15\). Upon further investigation, transmission electron microscope images suggested that the 7 nm aluminum layer used in the Josephson junctions provided inconsistent coverage. This non-uniformity resulted in pinhole defects which lead to shorts in the Josephson junctions. Beginning with wafer 40, we doubled the thickness of the aluminum layer in the \(\textrm{Nb}-\textrm{Al}-\) \(\textrm{Al}_2\) \(\textrm{O}_3\) \(-\textrm{Nb}\) junction stackup to 14 nm, which resulted in more consistent yield. For wafer numbers \(\ge\) 40, \(\lambda ~=~0.32~\pm ~0.03\), reducing the standard deviation by a factor of 5.

During the process, we implemented a new diagnostic test for each wafer, which makes use of the Josephson junction test structure. Figure 5 plots the median \(\lambda\) values determined from cryogenic measurements versus the room temperature resistance (R) values of the test structure. From the Ambegaokar–Baratoff relation, the \(I_cR_n\) product of a Josephson junction is proportional to the superconducting gap \(\Delta\) [12]. Therefore a measurement of R constrains \(I_c\) and thus \(\lambda\). Occasionally we have encountered R values of \(\sim 10\) k\(\Omega\) which correspond to unusable, hysteretic \(\mu\)mux channels. This test structure has become a useful diagnostic, not only for finished devices but throughout the wafer fabrication process. As shown in Fig. 5, \(R<40\) k\(\Omega\) produces \(\lambda\) outliers. In-process wafers with \(R<40\) k\(\Omega\) are terminated and new wafers begun, which has resulted in an increased turnaround time of reliable devices.

In general, the absolute frequency of the resonators is largely inconsequential. However, in the SO implementation there exists a requirement to avoid \(\sim\) 30 MHz of bandwidth in each 500 MHz block due to the room temperature electronics architecture [7]. Resonators that fall within these bandwidths are not read out. The absolute frequency error presented in Fig. 2 results in a yield reduction of \(\sim 6\%\). Nonetheless, the SO detector modules presented in [9] exceed their overall yield requirements.

5 Conclusion

We have demonstrated a screening protocol that has been used to qualify over 87,000 readout channels for Simons Observatory. This method does not require that each chip be screened individually, in contrast to what has been done historically for other multiplexers. It has been determined that spot-checking \(\sim 10\%\) of the chips on a wafer is sufficient, streamlining the qualification process. The nature of the rapid test result feedback aided in the quick diagnosis and resolution of the variable \(\lambda\) issue. After solving the aluminum junction thickness issue, our wafer yield is 86%. From these screening results, we have demonstrated long-term fabrication stability of microwave SQUID multiplexer chips. Looking forward, the conclusion of Simons Observatory paves the way for the Advanced Simons Observatory (ASO). ASO requires 18 additional \(\mu\)mux wafers, and so, we will continue to utilize this method until its completion.

Data Availability Statement

No datasets were generated or analyzed during the current study.

References

The Simons Observatory. Collaboration et al., The Simons Observatory: science goals and forecasts. J. Cosmol. Astropart. Phys. 2019, 056 (2019). https://doi.org/10.1088/1475-7516/2019/02/056

K.D. Irwin, K. Lehnert, Microwave squid multiplexer. Appl. Phys. Lett. 85, 2107–2109 (2004)

J. A. B. Mates, The microwave squid multiplexer. University of Colorado (2011)

Y. Nakashima et al., Low-noise microwave SQUID multiplexed readout of 38 x-ray transition-edge sensor microcalorimeters. Appl. Phys. Lett. 117, 122601 (2020). https://doi.org/10.1063/5.0016333

S. Kempf et al., Demonstration of a scalable frequency-domain readout of metallic magnetic calorimeters by means of a microwave SQUID multiplexer. AIP Adv. 7, 015007 (2017). https://doi.org/10.1063/1.4973872

B. Dober, et al. A Microwave SQUID Multiplexer Optimized for Bolometric Applications (2020). arXiv:2010.07998

C. Yu et al., SLAC Microresonator RF (SMuRF) Electronics: A tone-tracking readout system for superconducting microwave resonator arrays. Rev. Sci. Instrum. 94, 014712 (2023). arXiv:2208.10523

H. McCarrick et al., The simons observatory microwave SQUID multiplexing detector module design. ApJ 922, 38 (2021). https://doi.org/10.3847/1538-4357/ac2232

D. Dutcher, The simons observatory: large-scale characterization of 90/150 GHz TES detector modules. J. Low Temp. Phys. (2023)

Z. Whipps, et al. A high-capacity microwave squid multiplexer chip screening system. J. Low Temp. Phys. 1–8 (2023)

J. Groh, Crosstalk effects in microwave SQUID multiplexed TES bolometer readout. J. Low Temp. Phys. (2023)

V. Ambegaokar, A. Baratoff, Tunneling between superconductors. Phys. Rev. Lett. 10, 486–489 (1963). https://doi.org/10.1103/PhysRevLett.10.486

Author information

Authors and Affiliations

Contributions

Text was written by DJ. Figures were obtained by DJ and RS. Data were collected by DJ, and the final analysis was carried out by DJ and JH. JA, JB, DD, JG, JH, BJ, SS, JU and YW have aided in system development, testing method and interpretation of results. Detector module components were produced by RS, DD, SD, RL, ML, TL, LV, JVL and MV, and screened by DJ.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jones, D., Singh, R., Austermann, J. et al. Qualification of Microwave SQUID Multiplexer Chips for Simons Observatory. J Low Temp Phys (2024). https://doi.org/10.1007/s10909-024-03102-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10909-024-03102-4