Abstract

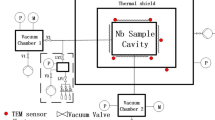

As a crucial temperature range for space applications as well as the pre-cooling temperature of mK-level refrigeration, the acquisition of the liquid-helium temperature has become a key research topic in recent years. Benefiting from the merits of no moving parts at the cold end, compact structure, high reliability, and low weight, high-frequency pulse tube cryocoolers (HPTCs) have become a conspicuous alternative for directly obtaining temperatures below 4 K. However, due to insufficient specific heat capacity of the commonly used regenerator materials at low temperatures, the large heat transfer losses of HPTCs limit its access to the liquid-helium temperature. Considering that the working gas 4He itself has a higher specific heat capacity than the commonly used rare earth materials below 10 K, an adsorptive regenerator scheme was proposed using non-magnetic, low-cost porous activated carbon (AC) to adsorb a part of working gas 4He as the low-temperature regenerator material to cool the remaining helium. Firstly, an adsorption model was established to simulate the dynamic adsorption characteristics of 4He with AC, and it was pointed out that low temperature and high pressure were beneficial to the adsorption of helium, which improves the cold storage capacity of the regenerator. Then, a three-stage HPTC was built for experimental verification. By filling AC in the low-temperature regenerator to substitute a part of the conventional rare earth material HoCu2, the cryocooler obtained a record-breaking no-load temperature of 3.27 K using 4He as the working gas. The cooling power at 4.0 K increased by 41.71%, verifying the feasibility of this adsorption scheme.

Similar content being viewed by others

Data Availability

Data will be made available on reasonable request.

References

G. Walker, R. Fauvel, G. Reader, Cryogenics 29(8), 841 (1989)

H.S. Cao, H.J.M. Ter Brake, Phys. Rev. Appl. 14(4), 044044 (2020)

R. Radebaugh, J. Phys.: Condens. Matter 21(16), 164219 (2009)

A. Zhang, Y. Wu, S. Liu, H. Yu, B. Yang, J. Low Temp. Phys. 191(3), 228 (2018)

B. Wang, Z.H. Gan, Prog. Aerosp. Sci. 61, 43 (2013)

B. Yang, Z. Gao, X. Xi, L. Chen, J. Wang, J. Low Temp. Phys. 206(5), 321 (2022)

X.Q. Zhi, L. Han, M. Dietrich, Z.H. Gan, L.M. Qiu, G. Thummes, Cryogenics 58, 93 (2013)

J. Quan, Y. Liu, D. Liu, K. Zhang, J. Liang, J. Li, Q. Yao, S. Shi, Chin. Sci. Bull. 59(27), 3490 (2014)

L. Chen, X. Wu, J. Wang, X. Liu, C. Pan, H. Jin, W. Cui, Y. Zhou, J. Wang, Cryogenics 94, 103 (2018)

H. Dang, R. Zha, J. Tan, T. Zhang, J. Li, N. Li, B. Zhao, Y. Zhao, H. Tan, R. Xue, Cryogenics 105, 103015 (2020)

X. Liu, L. Chen, X. Wu, B. Yang, J. Wang, W. Zhu, J. Wang, Y. Zhou, Sci. China Technol. Sci. 63(3), 434 (2020)

X. Xi, J. Wang, L. Chen, L. Guo, B. Yang, Y. Zhou, J. Wang, New Carbon Mater. 34(6), 524 (2019)

L. Chen, C. Kong, X. Wu, Y. Zhou, J. Wang, New Carbon Mater. 33(1), 47 (2018)

X. Xi, B. Yang, Y. Zhao, L. Chen, J. Wang, Appl. Phys. Lett. 118(14), 143902 (2021)

Acknowledgements

This research was supported by the National Natural Science Foundation of China (Nos. 12073058, U1831203), the China National Space Administration (Nos. D050104, D040305), and the Youth Innovation Promotion Association of the Chinese Academy of Sciences (No. 2019030).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, B., Xi, X., Gao, Z. et al. A 3.27 K High-Frequency Pulse Tube Cryocooler Using Adsorbed 4He as Part of the Regenerator Material. J Low Temp Phys 210, 393–405 (2023). https://doi.org/10.1007/s10909-022-02913-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10909-022-02913-7