Abstract

The Schiff base N,N-bis(salicylidene)-o-phenylenediamine (salophen) was prepared by the condensation of salicylaldehyde with o-phenylenediamine in ethanol solution. Two new Zn(II) and Ni(II) salophen complexes, were synthesized, fully characterized by infrared (IR), 1H NMR spectroscopic measurements, UV–Vis spectra, photoluminescence (PL), and X-ray diffraction (XRD). The prepared complexes were used as phosphors to fabricate complexes/PMMA slab-based luminescent solar concentrators (LSC). The thermal stability of pure and doped PMMA polymer was examined by differential scanning calorimetry. Various parameters such as the optical energy gap, refractive index, AC and DC conductivity, dielectric constant, dielectric loss, Urbach energy, fluorescence quantum yield, and Stokes shift have been calculated and discussed. Optical absorption is carried out in wavelength region 200–900 nm at room temperature before and after the samples have been exposed to sunlight for up to 8 h. Photodegradation studies showed that the Zn(II) complex/PMMA LSC has the lowest rate of degradation compared with Ni(II) complex/PMMA LSC with the same concentration (0.06% weight). I–V characteristics of the photovoltaic devices with and without collectors were examined. The PV cell coupled with LSC shows an increase in maximum efficiency by about 50% compared to the normal one. This indicates that the proposed technique is very useful for improving the efficiency of solar cells.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

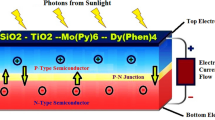

In recent years, the development of a new clean energy source has widely attracted attention because of the environmental pollution caused by fossil fuels. Based on this, solar energy as clean energy is a promising alternative to oil and coal [1]. However, the power conversion efficiency of single crystalline commercial silicon solar cells is 20–25% with a 15% reduction in outdoor applications, which is relatively low. That’s why using luminescent solar concentrators (LSCs) is an excellent complementary approach to the traditional solar cell [2].

LSCs consist of luminescent materials dispersed in a high refractive index waveguide substrate. The luminescent materials absorb sunlight and re-emit it at a lower frequency, via total internal reflection, the emitted photons can be redirected and harvested on the solar cell [1, 3, 4].

The photophysical properties of the luminescent material are a critical factor in the determination of the PCE of LSCs. Several luminescent materials have been used in LSCs as organic dyes [5], QDs [2], rare-earth ions [6], and perovskite nanocrystals [7]. Organic dyes have been utilized widely in LSCs due to near unity PLQY and large stock shifts like Lumogen F red 305 [8]. Forbidden F–F transitions in rare-earth ions, which exhibit narrow PL charts and good stability, make it an ideal candidate for LSCs [9, 10]. The use of organic dyes and rare earth ions is restricted in LSCs by their stability and high toxicity, respectively. Perovskite nanocrystals have drawn attention in the past few years as Cspbx3 due to high PLQY, narrow PL bands, and tunable gap energy but it’s limited due to instability and toxicity [8].

In this work, we present low-cost complexes as efficient fluorescent materials to fabricate salophen complex/PMMA slab-based LSC. Salophen metal complexes could face the challenge of fabricating efficient LSC with a cost-effective approach and eco-friendly materials. Salophen complexes exhibit unique properties including high thermal stability, photostability, tunable band gab, and good dispersion in polymer with broad absorption spectra which make them ideal to be used in LSCs [11].

2 Experimental

2.1 Materials

Salicylaldehyde and methyl methacrylate (MMA) were purchased from Fluka. 1,2-phenylenediamine, benzoyl peroxide, Nickel chloride hexahydrate (NiCl2·6H2O), and Zinc acetate dehydrate (Zn(CH3COO)2·2H2O) were purchased from Sigma-Aldrich (USA). All the chemicals were of analytical grade, commercially available, and used without further purification.

2.2 Synthesis Producers

2.2.1 Synthesis of Ligand and Metal Complexes

N,N-bis(salicylidene)o-phenylenediamine (salophen ligand) was synthesized by refluxing salicylaldehyde (20 mmol) and o-phenylenediamine (10 mmol) in absolute ethanol for 3 h at 60 °C. The crystalline product was separated on cooling, which on recrystallization from ethanol produced bright orange colored crystals after drying on a vacuum desiccator (yield: 65%) [12, 13].

Zn(II) salophen complex was synthesized by refluxing a methanolic solution of 4 mmol of zinc acetate dihydrate with 4 mmol of Schiff base (salophen) for 4 h at 60 °C. The polycrystalline yellow compound was obtained and collected by filtration, then washed several times with cold methanol. The obtained complex was dried at room temperature overnight in a vacuum desiccator (yield: 90%) [14].

Ni(II) salophen complex was synthesized in the same manner using 4 mmol of Nickel chloride hexahydrate. Reddish-brown Ni(II) complex with a 93% yield was obtained [15]. The synthetic protocols for the preparation of Zn II and Ni II–Schiff base complexes were shown in Scheme 1.

2.2.2 Synthesis of Polymethylmethacrylate (PMMA)

Thermoplastic PMMA was prepared through a catalytic polymerization process. 10 mL of MMA monomer was mixed with 0.01 g of benzoyl peroxide as an initiator for 45 min at 45 °C. After the elapsed time, the ampoule was left to cool to ambient temperature, broken to release its contents under acetone solvent, and then precipitated using 95% methanol. Purification of PMMA was achieved by reprecipitation from a toluene solution poured into 95% methanol, subsequently drying to constant mass at room temperature.

A polymer film with a thickness of 0.25 mm was formed by casting the polymer solutions onto glass dishes (10 cm diameter). The cast film was dried at room temperature for 24 h to remove any residual solvent [16].

2.2.3 Fabrication of Complex/PMMA LSCs

Zn(II) complex/PMMA LSCs have been prepared by the pour casting method, Scheme 2. PMMA was dissolved in acetone. Subsequently, 0.08 mg of the Zn(II) complex was added to the above solution with continuous stirring to get a complex content of 0.06 weight%. The resulting solution was stirred for homogeneity and transparency for 2 h at room temperature. After that, the mixture was poured onto a glass substrate. The LSCs formed were left for 24 h at room temperature to allow the evaporation of the solvent. Finally, the resulting Zn(II) complex/PMMA LSCs were cut into squares and polished for optical measurement. The same method was used to prepare Ni(II) complex/PMMA LSCs with Ni(II) complex content of 0.06 weight% [9]. The dimensions of our investigated complex/PMMA LSC are 6.8 cm × 4.2 cm.

2.3 Characterization Techniques

The UV–visible absorption spectra were measured using a JASCO spectrophotometer in the range of 200–1000 nm with BaSO4 as the reflectance standard. PL emission spectra were assessed using a Lumina-model fluorescence spectrophotometer from Thermo-Scientific. The Fourier transform infrared (FTIR) spectra for the powder complexes have been recorded via a test scan Shimadzu FTIR spectrometer with a resolution of 2 cm−1 using the KBr method from 400 to 4000 cm−1 at room temperature. The ATR-FTIR for the polymer films was conducted by FT-IR spectroscopy ALPHA II, Bruker, Germany, using ATR crystal. 1H NMR data were carried out on a Varian 400 MHz NMR spectrophotometer Bruker biospin AG Avance III HD nanobay using DMSO-d6 at room temperature using TMS as internal standard. The structure of the synthesized products was characterized by using X-ray diffraction (XRD), collected by an 18 kW diffractometer (Bruker; model D8 advance) with monochromator Cu-Kα radiation (1.54178 Å). Scanning electron microscope (SEM) images were captured by a field emission electron microscope (FE-SEM) with a microscope (JOEL JSM 6510 LV). The glass transition temperature was established for polymers by DSC studies using Setaram LABSYS evo DTA, DSC thermal Analysis instrument. The dielectric measurements were obtained using B&K Precision Bench LCR Meter Model 891. The films were discs of thickness ca 0.05 mm and radius 7 mm. The films were put in a holder of special design to minimize stray capacitance. The range of frequencies (f) was 20 Hz to 300 kHz at RT. The salophen complexes LSCs with dimensions of 6.8 × 4.2 cm3 were used to couple with a commercial Si solar cell of dimensions (5.1 × 3.9 cm3). LSC was placed over the top of the PV cell. The efficiency of the cell was measured before and after coupling with the salophen complexes LSCs under direct sunlight illumination intensity of 1000 W/m2. The open-circuit voltage (Voc) and the short-circuit photocurrent (Isc) were measured using Keithley instrument, model 2400, 4100306, c33 at room temperature (Fig. 1).

3 Results and Discussion

3.1 Structural Characterization of the Ligand and the Metal Complexes

The 1H NMR spectra of the Schiff base ligand are recorded at room temperature using DMSO-d6 as solvent. Analytical data (in ppm): 12.95 (s, 2H, OH), 8.93 (s, 2H, HC=N), 7.65–7.68 (m, 2H), 7.39–7.47 (m, 6H, Aromatic), 6.96–6.99 (m, 4H, Aromatic). The abbreviations “m” and “s” refer to multiplet and singlet, respectively [13, 17].

Figure 2 shows the IR spectra of salophen ligand and metal complexes. This figure shows the disappearance of the NH2 vibration of 1,2-phenylenediamine at 3386 and 3364 cm−1 and the observation of a C=N stretching vibration at 1611 cm−1, this confirms the formation of salophen ligand [17]. The downshift of the OH stretching mode near 2500–3000 cm−1 is due to the intramolecular bond between the hydrogen atom of the OH group and the azomethine nitrogen atom (OH…..N), which leads to changes in the force constant of the hydrogen oscillator [13]. As shown in Fig. 2. the band with a maximum at 1400 cm−1 in the spectra of the salophen ligand is assigned to the O–H deformation [18, 19]. The phenolic C–O stretching vibrations 1275 cm−1 in the ligand shifted to higher frequencies 1339 cm−1 and 1324 cm−1 for Ni(II) and Zn(II) complexes, respectively, Table 1 [18]. The coordination of the phenolic oxygen to the respective metal ion was confirmed by the disappearance of the OH group and the appearance of two new bands in the range 437–458 cm−1 and 532–543 cm−1, indicating the stretching frequency of M–N and M–O, respectively [15, 18]. This confirms the formation of the metal complexes.

The PXRD of the synthesized complexes is shown in Fig. 3. All the reflection peaks in this figure are indexed to the crystalline nature of the salophen ligand and its complexes. The complexes exhibit less intense reflections than the free ligand which indicates that the crystallinity of the free ligand decreases upon complexation with Ni(ΙΙ) ion and Zn(ΙΙ) ion [14, 15]. No obvious peaks of impurities are seen in these patterns which indicates the high crystallinity of our complexes.

The average crystallite size D was calculated from most sharp lines using Sherrer’s formula [14]:

where λ is the X-ray wavelength used in XRD (1.5418 Å); θ is the Bragg angle; and β is the pure diffraction broadening of a peak at half-height, that is, broadening due to the crystallite dimensions. The average crystallite diameters calculated are 50.14, 77.52, and 79.25 nm for salophen ligand, Ni(II), and Zn(II) complexes, respectively. This indicates that crystal size increases upon complexation.

Electronic absorption spectra of the Schiff base ligand (salophen) and the complexes were recorded in ethanol, and the data obtained are presented in Table 2 and Fig. 4. The absorption spectra of the Schiff base ligand exhibit three absorption bands centered at 211, 268, and 336 nm assigned to π–π* electronic transitions which involve the frontier orbitals spread over the ligand structure [19, 20]. Due to the increment of the electron delocalization of the macrocycle in the complex, the ligand absorption bands were red-shifted to (246, 302 nm) for the Zn(II) complex and to (256, 292 nm) for Ni(II) complex. The new band was observed at 473 nm for the Ni(II) complex due to the ligand to metal charge transfer transitions (MLCT) [20, 21]. The band observed at 404 nm for Zn(II) complex due to intra-molecular CT transitions [22].

Photoluminescence spectra of salophen and its complexes obtained in ethanol at λex 300, 350, and 320 nm for salophen, Ni(II) and Zn(II) complexes, respectively, are presented in Fig. 5. The figure shows only one emission band at λPL = 555, 425, 529 nm with Stock shifts equal to 219, 48, and 125 nm, for salophen, Ni(II) and Zn(II) complexes, respectively, which is similar to the results in the literature [20,21,22,23,24]. The lower Stock shift of complexes may be due to the increment of the rigidity of the ligand after the coordination of the metal atom [21]. Hence, the free ligand emission band appears at a higher wavelength than the complexes.

The absolute fluorescence quantum yield “ϕf” of salophen ligand and its complexes was measured using fluorescein as reference (ϕf = 0.9) and computed using equations [25, 26]:

where ϕref is the fluorescence quantum yield of the reference, a is the absorbance, n is the refractive index of the matrix, A is the area under the fluorescence curve, λf (max) and λa (max) are the wavelengths at the fluorescence and absorbance maxima, respectively. The ϕf of salophen, Zn(II), and Ni(II) complexes are 0.11, 0.12, and 0.01, respectively. The Zn(II) complex has the highest ϕf value. Therefore this complex can be selected for field performance of fluorescent solar collectors.

3.2 Characterization of Complex/PMMA LSCs

The FTIR spectra of pure PMMA and complex/PMMA LSCs are shown in Fig. 6. The spectra of pure PMMA and those of complex/PMMA LSCs are almost identical, which could be attributed to Zn(II) and Ni(II) salophen complexes crystallites in the pores of PMMA networks without variation in the continuous three-dimensional network in the polymer matrices, and both are independent in their chemical behavior. All the stretching vibrations observed in the PMMA appeared in the complex/PMMA LSCs with higher intensity. The van der Waals interactions between PMMA and the metal complex are very weak, and the amount of complex used does not affect the transparency of the LSCs [27,28,29].

The FTIR spectrum in Fig. 6 show also no visible band around 3400 cm−1 assigned to the symmetric stretching of OH bonds corresponding to physically adsorbed water on the solid. There is no peak in the range of 1630–1640 cm−1 which confirms the absence of unsaturation and complete transformation of MMA monomer into PMMA [30, 31]. Pure PMMA shows spectra regions at around 2950, 1723, 1142, and 750 cm−1, which corresponded to the presence of CH3, CO stretching, COC, and CH2 twisting modes, respectively [32, 33].

To investigate the changes in structural/crystalline properties of PMMA before and after Zn(II) and Ni(II) complexes doping, XRD measurements were carried out. The XRD patterns of pure PMMA and the complexes doped films are depicted in Fig. 7. The pure PMMA displays a broad peak centered at 2\(\theta\) = 14.8° which corresponds to the (111) plane with interplanar spacing (d) of 6.047 Å. This peak reflects the ordered packing of polymer chains. Another weak peak at 2\(\theta\) = 30.4° appeared with d = 2.841 Å, corresponding to the (112) plane. It reflects the ordering inside the main chains. These two broad peaks confirm the amorphous nature of PMMA [29, 34,35,36]. No additional shift in the positions of the amorphous peaks was reported due to complexes loading, but the peak became broader with a reduced intensity, i.e. such loading increases the amorphicity of PMMA. Besides, there are no characteristic peaks for complexes, which suggests its miscibility within the PMMA matrix. In other words, some of the complex molecules could settle in the free volume regions in the PMMA matrix. There was mixed physically and obviously no chemical reaction occurred between the two components [34].

Figure 8, illustrates the DSC pattern of pure PMMA and PMMA/complex LSCs. As shown in this figure the metal complex enhances the glass transition temperature (Tg) of PMMA from 130 to 245 °C for Ni(II) complex LSCs. While Zn(II) complex LSCs have the same Tg as PMMA. This indicates that the Ni(II) metal complex improves the thermal stability of PMMA.

SEM study is a good tool to visualize the morphology of the salophen complexes in PMMA film. SEM images of Ni(II) salophen/PMMA and Zn(II) salophen/PMMA are indicated in Fig. 9. Ni(II) salophen/PMMA film shows a well-smooth surface of the polymer with complex aggregation throughout the matrix. While Zn(II) salophen/PMMA shows that Zn(II) salophen spreads all over the surface of PMMA with no aggregation. Figure 9, shows also that the transparent and well-smooth nature of the PMMA blends confirms that there are good matrixes for LSCs.

3.3 Electrical Conductivity

The DC electrical conductivity, \(\upsigma\)DC of pure PMMA was measured at room temperature using equation [35]:

where d is the thickness of the film, R is the resistance of the film and A is the upper electrode area over the sample. The results are listed in Table 3. The electrical conductivity values were found to be 7.94 × 10–7 Ω−1 cm−1, 1.42 × 10–6 Ω−1 cm−1, and 2.56 × 10–6 Ω−1 cm−1 for pure PMMA, Ni(II) complex/PMMA LSC and Zn(II) complex/PMMA LSC, respectively. This indicates that the introducing complexes in the polymer matrix may act as localized centers improving the conduction process in PMMA.

Figure 10 shows the AC conductivity Log (\(\upsigma\)ac) of pure PMMA, and the complexes doped films as a function of Log (ω) at room temperature, As ω is the angular frequency. Apparently, Log (\(\upsigma\)ac) increases linearly with increasing Log (ω). As shown, \(\upsigma\)ac of pure PMMA is 1.82 × 10−9 S m−1 at 50 kHz which increases to 2.11 × 10–9 S m−1 and 1.15 × 10–8 S m−1 after doping with Zn(II) complex and Ni(II) complex, respectively. The origin of the improvement in σac, when the complexes are loaded, is assigned to (1) the increase in imperfections, such as dangling bonds or impurities at point defects, with increasing PMMA amorphous regions could increase sub-levels within the bandgap (localized states), (2) the presence of the carbonyl group (C=O) as an electron donor group in PMMA which is consistent with the Lewis concept and (3) the increase of charge carriers inside complexes doped PMMA film [34].

\(\upsigma\)AC (ω) depending on the measuring frequency according to equation [35]:

The values of the exponent s can be found by plotting Log \(\upsigma\)AC vs. Log ω, Fig. 10. The values of exponent s are listed in Table 3. As noted, the s values of Ni(II) complex/PMMA LSCs are the same as the pure PMMA, while it is less than pure PMMA in Zn(II) complex/PMMA film. This indicates that the presence of the Zn(II) complex enhances the polarization of PMMA [34].

3.4 Dielectric Characterization

Dielectric constant ε′that describes the stored energy inside the film and dielectric loss ε″ which measures the energy dissipation by Joule’s heating effect were measured using equations [34]:

where C and tan \(\delta\) are the measured capacitance and loss tangent, respectively, \({\varepsilon }_{0}\) the free space permittivity, t is the thickness of the film. The dependences of ε′ and loss ε″ of pure PMMA and the complexes doped PMMA film on the frequencies f, from 1 to 300 kHz, are depicted in Figs. 11 and 12. As is clear, the value of ε′ of pure PMMA is ca 0.03 at 100 kHz [37] reported a value of ca 4.5 for PMMA, at f = 100 kHz and at RT. Such a difference may be due to the difference in the molecular weight of PMMA. In fact, the ε′ of the films depends mainly on the orientation of the acrylate group and the polar pendent ester groups in PMMA. The interfacial polarization (IP) that is always present in materials comprising more than one phase is the vital reason for the higher values of ε′ at low f [38]. Such polarization arises from the charge accumulation at the interfaces between the polymeric film and the electrodes which causes the presence of space charges. After that ε′ decreases with increasing f due to the lag of dipole oscillations behind those of the field. In this case, there is no interfacial polarization, and subsequently ε′ appears to be constant, at f ≥20 kHz. which is considered the normal response to dielectric materials [39]. Therefore, it seems that the loading process of the complexes helps in the orientation of the acrylate group in PMMA by applying the electric field. This is because of the complexes loading that decreases the crystallinity, as discussed in the XRD study section, and consequently facilitates the group orientation along with the increase in the film heterogeneity and the interfacial polarization [34]. Figure 12 shows the behavior of ε″ of the films with increasing f. No relaxation peaks were observed in ε″. The values of ε″ are relatively small in comparison with the values of ε′. ε″ describes the energy loss as a result of the micro-Brownian motion of the dipoles and depends on the viscosity, temperature, and composition of the film. At low f, ε″ has maximum values which are due to (1) the mobility of charges within the PMMA matrix, (2) the motion of PMMA polar groups and (3) the interfacial polarization between complexes and PMMA [40] With increasing f, ε″ decreases as a consequence of the decrease in the charge polarization effect [34].

3.5 Optical Measurement Studies of Salophen Complexes/PMMA LSCs

The investigation of optical properties and identification of electronic transitions occurring in LSCs can be achieved using ultraviolet–visible (UV–Vis) spectroscopy. The UV–vis absorption spectra of pure PMMA and salophen complexes/PMMA LSCs films are illustrated in Fig. 13. It can be seen that there is a sharp absorption increase below 224 nm, which corresponds to the π–π* transition of PMMA carbonyl groups. Meanwhile, an absorbance band is displayed by the pure PMMA spectra at about 276 nm, which corresponds to the n–π* electronic transition induced by the non-bonding electrons. Furthermore, in the 200–350 wavelength range, there is a reduction in the absorption spectra of pure PMMA, while at higher wavelengths they become stable, thus indicating the transparent nature of the freestanding PMMA film to the whole visible wavelength over 300 nm [34, 36]. The onset of PMMA absorption shifted to a higher wavelength when complexes were added, Table 4. The formation of microstrain in the salophen/PMMA matrix when complexes are added or the occurrence of extra defects in the energy band gap are potential reasons for such a shift.

3.6 Refractive Index

The refractive index (n) of all investigated samples was calculated using the equation [34, 41]:

The calculated values of n are listed in Table 4. The refractive index of PMMA increases slightly by doping with salophen complexes. As n increased from 2.00 in pure PMMA to 2.15 and 2.12 in Ni(II) complex/PMMA film and Zn(II) complex/PMMA film, respectively. This increase is due to (1) the increase in film density with loading complex molecules and (2) the increase in the amorphicity and devastation of the chain ordering as a result of complex loading which is confirmed above by XRD analysis. Indeed, such amorphous domains cause the light interference phenomenon within the polymer matrix leading to increasing n values [34]. This increase is considered a promising feature for films to be used in the LSCs.

3.7 Determination of Energy Gap

The optical band gap can be calculated from the absorption coefficient by applying the so-called power low. The absorption coefficient (α) can be determined using Lambert’s law [35, 36]:

where A is the optical absorbance and t is the thickness of polymeric thin film. The Tauc model has been applied in the polymeric films to report the optical transition types. According to this model [34, 42]:

where hν is the incident photon energy, Eg is the optical bandgap and B is a constant. The dependence of (αhv)2 and (αhv)1/2 on hν is depicted in Figs. 14 and 15. As usual, the extrapolation of the linear sections of (αhv)1/2 and (αhv)2 to reach the x-axis gives the values of the direct Eg and indirect Eg bandgaps. It is observed from Figs. 14 and 15 that the absorption edge is represented by the linear portion dependence for pure PMMA in one region. Meanwhile, salophen-doped PMMA LSCs give multi-absorption regions representing the multi-optical band gaps. The optical absorption spectra variations reveal the multi-energy gaps that are caused by optical transitions from the HOMO band to the LUMO band. The obtained optical band gap energies are gathered in Table 5. As can be shown in Table 5, there is a decrease in the Eg of salophen-doped PMMA films compared to PMMA. Such a decrease suggests that the PMMA-doped films contain higher densities of localized states and higher amounts of defects in the bandgap structure. Therefore, there are additional energy states induced by the complexes doping. Besides, the complexes loading increases the PMMA amorphicity, as confirmed by XRD, which decreases the optical bandgap and increases charge conduction. According to the density of states model, the optical bandgap decreases as the degree of disorder of the amorphous phase increases, which is consistent with this behavior. The addition of salophen complexes enhanced the presence of multi-energy band gaps that can be used in solar cell harvesting light [34].

The dependence of (αhv)2 and (αhv)1/2 on hυ after exposure to sunlight is depicted in Figs. 16 and 17. The values of direct and indirect band gap are calculated and listed in Table 5. As shown in this table, there is no variation in values of Eg after exposure to sunlight which indicates the highest stability of this system.

3.8 Urbach’s Energy (EU)

In PMMA polymeric systems, the absorption coefficient (α) near the absorption band edge usually shows an exponential dependence on the photon energy (hv) which follows Urbach’s model [34]:

where α0 is a constant and EU is the Urbach tail or Urbach energy, which is the width of the localized states in the optical bandgap. Figure 18 shows the relation between ln(α) and hν for pure PMMA and salophen-doped films. EU is the slope’s reciprocal of these straight lines. The values of EU are lie in the range of 0.45–4.2 eV for the studied films and listed in Table 5. As presented in this table, EU is in reverse proportion to Eg. This is because EU increases with the amorphicity increment found in PMMA polymeric systems which agrees with our XRD results. Besides, the salophen complexes loading increase allowed the number of tail-to-tail and band-to-tail transitions and led to state redistribution from band to tail in the band gap [34].

Figure 19 shows the relation between ln(α) and hν for salophen complexes/PMMA LSCs after exposure to sunlight. The values of EU are listed in Table 5. The obtained data show a variation in the localized band tail width after exposure to sunlight. This may be due to photodegradation of the dye upon exposure to light.

3.9 Transmittance

Figure 20 shows the UV–visible–NIR transmittance spectra (T) of pure PMMA and complexes doped films in the wavelength range 200–800 nm at room temperature. It is well known that PMMA is a good transparent material. Its T reaches a maximum value at 90% at λ > 250 nm. The T of PMMA increases sharply with the wavelength in the UV region and then it reaches the maximum region until 750 nm [43]. Increasing the complexes doping level reduces T in general. As is clear, the Ni(II) and Zn(II) complexes films become totally transparent only at λ > 550 nm. Such a reduction in T is owing to the complex molecules that hinder the light passage through the doped film. Increasing the doping weight of the Zn(II) complex to 0.12 wt% can efficiently block the incident light in the UV and visible region which cut off the transmission in the polymeric films (with zero transmission). Furthermore, the values of T at λ = 650 nm for the different films are depicted in Table 4. It can be seen that pure PMMA shows a T of 91.2% which decreases gradually after loading with 0.06 and 0.12 wt% Zn(II) salophen complex. So the 0.06 wt% concentration is selected for preparation of LSCs from salophen complex. Also, there is no variation in values of T after exposure to sunlight. This indicates the highest stability of salophen complex/PMMA LSCs.

3.10 Photodegradation of Salophen/PMMA LSCs

The photostability of LSCs was investigated after outdoor exposure to sunlight at various times. The results demonstrate that, for all LSCs, the optical intensity of the complexes is decreased by raising exposure time to direct sunlight, Figs. 21 and 22. The reduction obtained in the absorbance intensity can be explained by photochemical degradation of the complexes due to the absorption of the solar radiation.

The study of the kinetics of photodecomposition of LSC specimens during exposure to sunlight was done by following the change in absorption intensity at their absorption maximum. The photodecomposition process was observed to follow the first-order kinetic equation in which [26]:

where k is the first-rate constant, Ao and At are the absorbance intensity at time t = 0 and t = t respectively. The plots of ln(Ao/At) vs. t for photodecomposition of LSCs are illustrated in Fig. 23. The rate constants of the polymeric films were calculated and given in Table 4. The results show that Ni(II) complex LSC has the highest rate of degradation compared with Zn(II) complex LSC with the same concentration. This refers to the Zn(II) complex being more stable than Ni(II) complex. The minor degradation rate of the Zn(II) complex LSC reveals the opportunity to utilize this complex to fabricate some solar collectors.

3.11 Fluorescence Spectra of Salophen/PMMA LSCs

In order to give more information on the efficiency of the solar collectors for our investigated samples, the fluorescence properties of these LSCs were investigated, Figs. 24 and 25. We notice from these figures that Zn(II) complex/PMMA LSC showed broad fluorescence compared with Ni(II) complex/PMMA LSC. This refers to the possibility of using these complexes as fluorescent solar collectors. For all investigated collectors the fluorescence intensity is decreased after exposure to sunlight due to degradation of the complexes.

Fluorescent Quantum yield (ϕf), and Stokes shift (Δλ), before and after exposure to sunlight were calculated. The ϕf of Zn(II) PMMA LSC is higher than Ni(II) complex LSC due to its highest fluorescent intensity. So that this complex can be selected for field performance of solar concentrators.

3.12 I–V Characteristics of the Solar Cell

Figure 26 demonstrates the I–V characteristics of Si PV cells previous and after coupling with a 5.1 × 3.9 cm2 LSC sheet doped with complexes. As observed, The LSC is the main factor that enhances photovoltaic output. The short-circuit current (Isc) and open circuit voltage (Voc) were obtained from the y and x intercepts, respectively. The fill factor was defined by the following relation [44, 45]:

where Vm and Im are voltage and current for maximum output of power, respectively. The overall energy conversion efficiency was calculated by the following relation [46]:

where Pin is the power generated by the incident light. The photovoltaic parameters of the silicon solar cell with and without the LSCs are depicted in Table 6. The enhancement of the photovoltaic parameters can be attributed to the coincidence of the spectral response of the silicon PV cells in the fluorescence spectra of LSC. These results are ascribed to the concentration of the incident light on the top surface of the LSC, collecting and redirecting the photons to the solar cell which are eventually absorbed. Furthermore, as shown in Table 6, the silicon PV cell coupled with LSC shows enhancement in the maximum efficiency by about 50% in comparison with the silicon PV cell without LSC. This enhancement can be ascribed to the energy transfer within the photon harvesting LSC systems that efficiently convert, concentrate, and guide the light throughout the active layer of the silicon PV cells by metal-enhanced fluorescence. The effective energy transfer process overcomes the problem of inefficient absorption of solar spectra [47].

The solar cell should be selected based on the coincidence of the semiconductor’s band gap with the emission wavelengths of the LSC. Furthermore, to achieve the largest possible enhancement, the fluorescence species should be created in a structure that is located in the range of the enhanced localized electromagnetic field of the metal complex.

The efficiency of 13.2% is still too low for the commercial purposes of solar cells. The loss of the concentrated light may be the main cause for the small values of the efficiencies of the LSCs, by refracting out the light of the top surface [48]. These results increased losses from the top surface of the LSC as well as to the complex due to the low value of ϕf of the salophen complex. The second reason is the re-absorption of the reflected light from the solar cell attached to the LSCs, which may be considered the main reason for the losses of the concentrated light. However, it must first travel through the matrix. Therefore, reducing matrix losses is an effective way of reducing efficiency.

4 Conclusion

In this study, we are suggesting a new approach for creating cost-effective, highly efficient LSCs based on coordination complexes. The prepared complexes were characterized by XRD, FTIR, and optical spectroscopy. Both absorption and emission peaks are observant covering most of the visible range which can be explained by the tunable bandgap of the complexes. The photostability of the collectors was carried out under outdoor exposure to the sunlight at different times. The fluorescence properties of the complexes were discussed. Photovoltage parameters were increased after coupling the collector with the silicon solar cell, especially for the Zn(II) salophen/PMMA LSC complex which would be selected for LSCs.

References

X. Gong, W. Ma, Y. Li, L. Zhong, W. Li, X. Zhao, Fabrication of high-performance luminescent solar concentrators using N-doped carbon dots/PMMA mixed matrix slab. Org. Electron. 63, 237–243 (2018). https://doi.org/10.1016/j.orgel.2018.09.028

Y. Zhou, H. Zhao, D. Ma, F. Rosei, Harnessing the properties of colloidal quantum dots in luminescent solar concentrators. Chem. Soc. Rev. 47(15), 5866–5890 (2018). https://doi.org/10.1039/c7cs00701a

J. Wu et al., Solid-state photoluminescent silicone-carbon dots/dendrimer composites for highly efficient luminescent solar concentrators. Chem. Eng. J. 422, 130158 (2021). https://doi.org/10.1016/j.cej.2021.130158

S. Castelletto, A. Boretti, Luminescence solar concentrators: a technology update. Nano Energy 109, 108269 (2023). https://doi.org/10.1016/j.nanoen.2023.108269

S.M. El-Bashir, A.A. Al-Jaghwani, Perylene-doped polycarbonate coatings for acrylic active greenhouse luminescent solar concentrator dryers. Results Phys 16, 102920 (2020). https://doi.org/10.1016/j.rinp.2019.102920

V. Fiorini et al., Colourless luminescent solar concentrators based on Iridium(III)-Phosphors. Dyes Pigm. 193, 109532 (2021). https://doi.org/10.1016/j.dyepig.2021.109532

E. Bagherzadeh-Khajehmarjan, A. Nikniazi, B. Olyaeefar, S. Ahmadi-Kandjani, J.M. Nunzi, Bulk luminescent solar concentrators based on organic-inorganic CH3NH3PbBr3 perovskite fluorophores. Sol. Energy Mater. Sol. Cells 192, 44–51 (2019). https://doi.org/10.1016/j.solmat.2018.12.009

Y. Zhang, W. Zhang, Y. Ye, K. Li, X. Gong, C. Liu, CsPbBr3 nanocrystal-embedded glasses for luminescent solar concentrators. Sol. Energy Mater. Sol. Cells 238, 111619 (2022). https://doi.org/10.1016/j.solmat.2022.111619

O. Moudam et al., Europium complexes with high total photoluminescence quantum yields in solution and in PMMA. Chem. Commun. 43, 6649–6651 (2009). https://doi.org/10.1039/b914978c

G. Katsagounos, E. Stathatos, N.B. Arabatzis, A.D. Keramidas, P. Lianos, Enhanced photon harvesting in silicon multicrystalline solar cells by new lanthanide complexes as light concentrators. J. Lumin. 131(8), 1776–1781 (2011). https://doi.org/10.1016/j.jlumin.2011.04.023

T. Khan, A. Datta, Chemical and Physical Strategies for Modulation of Excited State Dynamics and Consequent Emission Enhancement of Schiff Bases (IIT, Mumbai, 2017)

K.C. Gupta, H.K. Abdulkadir, S. Chand, Synthesis of polymer anchored N,N′-bis(3-allyl salicylidene)o-phenylenediamine cobalt(II) Schiff base complex and its catalytic activity for decomposition of hydrogen peroxide. J Mol Catal A Chem 202(1–2), 253–268 (2003). https://doi.org/10.1016/S1381-1169(03)00209-7

T.A. De Toledo, P.S. Pizani, L.E. Da Silva, A.M.R. Teixeira, P.T.C. Freire, Spectroscopy studies on Schiff base N,N′-bis(salicylidene)-1,2-phenylenediamine by NMR, infrared, Raman and DFT calculations. J. Mol. Struct. 1097, 106–111 (2015). https://doi.org/10.1016/j.molstruc.2015.04.038

A.K. Babaheydari, M. Salavati-Niasari, A. Khansari, Solvent-less synthesis of zinc oxide nanostructures from Zn(salen) as precursor and their optical properties. Particuology 10(6), 759–764 (2012). https://doi.org/10.1016/j.partic.2012.03.006

J.J. Rani et al., Synthesis, characterization, antimicrobial, BSA binding, DFT calculation, molecular docking and cytotoxicity of Ni(II) complexes with Schiff base ligands. J. Mol. Liq. 328, 115457 (2021). https://doi.org/10.1016/j.molliq.2021.115457

D. Banerjee, A.K. Kar, Influence of polaron doping and concentration dependent FRET on luminescence of PAni-PMMA blends for application in PLEDs. Phys. Chem. Chem. Phys. 20(35), 23055–23071 (2018). https://doi.org/10.1039/C8CP02968G

A. Hille et al., [N,N′-Bis(salicylidene)-1,2-phenylenediamine]metal complexes with cell death promoting properties. J. Biol. Inorg. Chem. 14(5), 711–725 (2009). https://doi.org/10.1007/s00775-009-0485-9

J.S. Danilova, S.M. Avdoshenko, M.P. Karushev, A.M. Timonov, E. Dmitrieva, Infrared spectroscopic study of nickel complexes with salen-type ligands and their polymers. J. Mol. Struct. 1241, 130668 (2021). https://doi.org/10.1016/j.molstruc.2021.130668

V.Z. Mota et al., Crystal structure and theoretical studies of the keto-enol isomerism of N,N′-bis(salicylidene)-o-phenylenediamine (salophen). Spectrochim. Acta A Mol. Biomol. Spectrosc. 99, 110–115 (2012). https://doi.org/10.1016/j.saa.2012.09.002

C.R. Bhattacharjee, C. Datta, G. Das, R. Chakrabarty, P. Mondal, Induction of photoluminescence and columnar mesomorphism in hemi-disc salphen type Schiff bases via nickel(II) coordination. Polyhedron 33(1), 417–424 (2012). https://doi.org/10.1016/j.poly.2011.12.001

R.A. Mendes et al., Electronic and magnetic properties of the [Ni(salophen)]: an experimental and DFT study. J. Adv. Res. 9, 27–33 (2018). https://doi.org/10.1016/j.jare.2017.10.004

M. Ellahi, Recent trends in luminescent Zn(II) and Ir(III) complexes bearing a variety of Schiff base ligands enhancing nutritional value of corn silage View project Study the PDLC films (Smart Glass) with different Hardeners and Catalysts. View project Aziza Sarwar [Online]. https://www.researchgate.net/publication/365151063

T. Khan, S. Vaidya, D.S. Mhatre, A. Datta, The prospect of salophen in fluorescence lifetime sensing of Al3+. J. Phys. Chem. B 120(39), 10319–10326 (2016). https://doi.org/10.1021/acs.jpcb.6b05854

J.K.-H. Hui, Z. Yu, M.J. MacLachlan, Supramolecular assembly of zinc salphen complexes: access to metal-containing gels and nanofibers. Angew. Chem. 119(42), 8126–8129 (2007). https://doi.org/10.1002/ange.200702680

J.N. Demasa, G.A. Crosby, The Measurement of Photoluminescence Quantum Yields. A Review (American Chemical Society, 1971)

S.M. Reda, Stability and photodegradation of phthalocyanines and hematoporphyrin doped PMMA as solar concentrators. Sol. Energy 81(6), 755–760 (2007). https://doi.org/10.1016/j.solener.2006.10.004

J.Z. Mbese, P.A. Ajibade, Preparation and characterization of ZnS, CdS and HgS/poly(methyl methacrylate) nanocomposites. Polymers (Basel) 6(9), 2332–2344 (2014). https://doi.org/10.3390/polym6092332

A.A. Elmadani et al., Salt template zirconia reinforcing particles as possible reinforcement for PMMA matrix composite. Adv. Compos. Lett. 28, 0963693519879696 (2019). https://doi.org/10.1177/0963693519879696

S. Sain et al., Synthesis and characterization of PMMA-cellulose nanocomposites by in situ polymerization technique. J. Appl. Polym. Sci. 126(Suppl. 1), 36723 (2012). https://doi.org/10.1002/app.36723

D. Sugumaran, K. Juhanni, A. Karim, Removal of copper(II) ion using chitosan-graft-poly(methyl methacrylate) as adsorbent fabrication and characterization of poly(methyl methacrylate) grafted multiwalled carbon nanotubes reinforced natural rubber nanocomposite. View project. eProc. Chem. (2017). https://doi.org/10.13140/RG.2.2.33911.93601

A. Bahadur, S. Iqbal, H.O. Alsaab, N.S. Awwad, H.A. Ibrahium, Thermal degradation study of polymethylmethacrylate with AlI3 nanoadditive. Microsc. Res. Tech. 85(4), 1494–1501 (2022). https://doi.org/10.1002/jemt.24012

A.D. Berdie, A.A. Berdie, S. Jitian, The degradation of thin poly(methyl methacrylate) films subjected to different destructive treatments. J. Polym. Res. 28(2), 60 (2021). https://doi.org/10.1007/s10965-020-02390-0

K.T.L. Trinh, D.A. Thai, W.R. Chae, N.Y. Lee, Rapid fabrication of poly(methyl methacrylate) devices for lab-on a-chip applications using acetic acid and UV treatment. ACS Omega 5(28), 17396–17404 (2020). https://doi.org/10.1021/acsomega.0c01770

S. El-Gamal, A.M. Ismail, Electrical and optical properties of novel brilliant cresyl blue dye-doped poly(methyl methacrylate) as selective cut-off laser filters. Polym. Int. 69(12), 1308–1318 (2020). https://doi.org/10.1002/pi.6082

M.M. Abutalib, I.S. Yahia, Selective CUT-OFF laser filters using brilliant green-doped PMMA polymeric composite films: sensing approach. J. Mater. Sci. Mater. Electron. 29(23), 19798–19804 (2018). https://doi.org/10.1007/s10854-018-0106-x

S.B. Aziz, O.G. Abdullah, M.A. Brza, A.K. Azawy, D.A. Tahir, Effect of carbon nano-dots (CNDs) on structural and optical properties of PMMA polymer composite. Results Phys. 15, 102776 (2019). https://doi.org/10.1016/j.rinp.2019.102776

M. Gabr, Electric and dielectric properties of some fluorescent dye/PMMA solar concentrators. Int. J. Polym. Mater. Polym. Biomater. 57(6), 569–583 (2008). https://doi.org/10.1080/00914030701818314

M. Hernández, J. Carretero-González, R. Verdejo, T.A. Ezquerra, M.A. López-Manchado, Molecular dynamics of natural rubber/layered silicate nanocomposites as studied by dielectric relaxation spectroscopy. Macromolecules 43(2), 643–651 (2010). https://doi.org/10.1021/ma902379t

M.S. El-Bana, G. Mohammed, A.M. El Sayed, S. El-Gamal, Preparation and characterization of PbO/carboxymethyl cellulose/polyvinylpyrrolidone nanocomposite films. Polym. Compos. 39(10), 3712–3725 (2018). https://doi.org/10.1002/pc.24402

S. Raghu, S. Kilarkaje, G. Sanjeev, H. Devendrappa, Electron beam induced modifications in conductivity and dielectric property of polymer electrolyte film. Radiat. Meas. 53–54, 56–64 (2013). https://doi.org/10.1016/j.radmeas.2013.03.017

M.K. Halimah, M.F. Faznny, M.N. Azlan, H.A.A. Sidek, Optical basicity and electronic polarizability of zinc borotellurite glass doped La3+ ions. Results Phys 7, 581–589 (2017). https://doi.org/10.1016/j.rinp.2017.01.014

Ö.B. Mergen, E. Arda, S. Kara, Ö. Pekcan, Effects of GNP addition on optical properties and band gap energies of PMMA films. Polym. Compos. 40(5), 1862–1869 (2019). https://doi.org/10.1002/pc.24948

W. Zhou, M.C. Wang, X. Zhao, Poly(methyl methacrylate) (PMMA) doped with DCJTB for luminescent solar concentrator applications. Sol. Energy 115, 569–576 (2015). https://doi.org/10.1016/j.solener.2015.03.012

B. Qi, J. Wang, Fill factor in organic solar cells. Phys. Chem. Chem. Phys. 15(23), 8972–8982 (2013). https://doi.org/10.1039/c3cp51383a

G.L. Araujo, E. Sánchez, Analytical expressions for the determination of the maximum power point and the fill factor of a solar cell. Solar Cells 5(4), 377–386 (1982)

F. Mateen, M. Ali, S.Y. Lee, S.H. Jeong, M.J. Ko, S.K. Hong, Tandem structured luminescent solar concentrator based on inorganic carbon quantum dots and organic dyes. Sol. Energy 190, 488–494 (2019). https://doi.org/10.1016/j.solener.2019.08.045

S.M. El-Bashir, F.M. Barakat, M.S. AlSalhi, Double layered plasmonic thin-film luminescent solar concentrators based on polycarbonate supports. Renew. Energy 63, 642–649 (2014). https://doi.org/10.1016/j.renene.2013.10.014

C. Tummeltshammer, A. Taylor, A.J. Kenyon, I. Papakonstantinou, Losses in luminescent solar concentrators unveiled. Sol. Energy Mater. Sol. Cells 144, 40–47 (2016). https://doi.org/10.1016/j.solmat.2015.08.008

Acknowledgements

The authors wish to thank all the staff members and colleagues in the Chemistry Department, Faculty of Science, Benha University, Egypt for their cooperation.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

S. M. Reda is the corresponding authors and wrote the main manuscript text Radwa K. Ahmed prepared figures and tables Naglaa M. Mohamed reviewed the manuscript

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ahmed, R.K., Mohamed, N.M. & Reda, S.M. Enhanced Efficiency of Silicon Solar Cell by New Salophen Complexes Embedded PMMA as Light Concentrators. J Inorg Organomet Polym (2024). https://doi.org/10.1007/s10904-024-03070-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10904-024-03070-y