Abstract

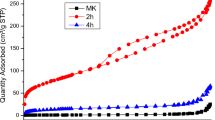

In the present study the spherically granulated micro- and mesoporous zirconium silicates were prepared and thermally treated in the wide region of temperatures 110–700 °C. Physico-chemical properties of materials obtained were investigated by powder X-ray diffraction, low-temperature nitrogen adsorption/desorption method and scanning electron microscopic studies. It was found that calcination leads to significant decreasing the surface area and total pore volumes of zirconium silicates. After hydrothermal treatment of spherically granulated material previously dried at room temperature the positive changes of porous structure with significant increasing the total surface area and volume of mesopores it was fixed. Adsorption properties of as-prepared samples and obtained after thermal and hydrothermal treatments in the process of removing Cu2+, Ni2+ and Co2+ cations from water solution were examined. It was determined that zirconium silicate hydrothermally treated at 300 °C during 5 h hours has the biggest surface area and shows the lowest decreasing adsorption capacity among sorbents calcined toward cobalt and nickel ions and could be used as perspective material for effective removing the d-metal ions at high temperatures.

Similar content being viewed by others

References

K.A. Kydralieva, G.I. Dzhardimalieva, A.A. Yurishcheva, S.J. Jorobekova, J. Inorg. Organomet. Polym. 26, 1212 (2016). https://doi.org/10.1007/s10904-016-0436-1

R. Kumar, M.A. Laskar, I.F. Hewaidy, M.A. Barakat, Earth. Syst. Environ. 3, 83 (2019). https://doi.org/10.1007/s41748-018-0085-3

I. Ihsanullah, M. Sajid, S. Khan, M. Bilal, Sep. Purif. Technol. 291, 120923 (2022). https://doi.org/10.1016/j.seppur.2022.120923

M.E. Mahmoud, G.M. Nabil, S.M.E. Mahmoud, J. Environ. Chem. Eng. 3(2), 1320 (2015). https://doi.org/10.1016/j.jece.2014.11.027

B. Zhang, Y. Wu, Y. Fan, J. Inorg. Organomet. Polym. 29, 290 (2019). https://doi.org/10.1007/s10904-018-0987-4

J. Qu, X. Tian, Zh. Jiang, B. Cao, M.S. Akindolie, Q. Hu, Ch. Fenga, Y. Fenga, X. Meng, Y. Zhang, J. Hazard. Mater. 387, 121718 (2020). https://doi.org/10.1016/j.jhazmat.2019.121718

P. Shende, N.P. Devlekar, Curr. Nanosci. 17(6), 819 (2021). https://doi.org/10.2174/1573413716999201209105819

S. Gupta, S. Sireesha, I. Sreedhar, Ch.M. Patel, K.L. Anitha, J. Water Process Eng. 38, 101561 (2020). https://doi.org/10.1016/j.jwpe.2020.101561

C. Hood, E. Pensini, Water Air Soil Pollut. 233, 137 (2022). https://doi.org/10.1007/s11270-022-05609-6

R.S. Hassan, M.R. Abass, M.A. Eid, E.A. Abdel-Galil, Appl. Radiat. 178, 109985 (2021). https://doi.org/10.1016/j.apradiso.2021.109985

M. Nasrollahzadeh, M. Sajjadi, S. Iravani, R.S. Varmac, Chemosphere 263, 128005 (2021). https://doi.org/10.1016/j.chemosphere.2020.128005

D.V. Tarnovsky, M.M. Tsyba, L.S. Kuznetsova, T.A. Khodakovska, I.V. Romanova, J. Chem. Technol. 29(2), 192 (2021). https://doi.org/10.15421/jchemtech.v29i2.232199

D. Bhatt, N. Gururani, A. Srivastava, PCh. Srivastav, Environ. Earth. Sci. 80, 273 (2021). https://doi.org/10.1007/s12665-021-09566-x

S. Safari, B.G. Lottermoser, D.S. Alessi, Appl. Mater. Today 19, 100638 (2020). https://doi.org/10.1016/j.apmt.2020.100638

I.Z. Zhuravlev, M.F. Kovtun, A.V. Botsman, Sep. Sci. Technol. (2021). https://doi.org/10.1080/01496395.2021.1934024

P. Vassileva, P. Tzvetkova, L. Lakov, O. Peshev, J. Porous Mater. 15, 593 (2008). https://doi.org/10.1007/s10934-007-9138-y

H. Li, Y. Huang, J. Liu, H. Duan, Chemosphere 282, 131046 (2021). https://doi.org/10.1016/j.chemosphere.2021.131046

M. Maslova, N. Mudruk, A. Ivanets, I. Shashkova, N. Kitikova, Environ. Sci. Pollut. Res. 27, 3933 (2020). https://doi.org/10.1007/s11356-019-06949-3

D.V. Tarnovsky, I.K. Chepurna, S.I. Meleshevych, V.I. Davydov, I.V. Romanova, Res. Chem. Intermed. 48, 2253 (2022). https://doi.org/10.1007/s11164-022-04691-z

Zh. Dinga, M. Ridley, J. Deijkers, N. Liu, Sh. Bin Hoque, J. Gaskins, M. Zebarjadi, P. Hopkins, H.Wadley, E. Opila, K. Esfarjani, Materialia 12, 100793 (2020). https://doi.org/10.1016/j.mtla.2020.100793.

A.I. Bortun, L.N. Bortun, A. Clearfield, Chem. Mater. 9, 1854 (1997). https://doi.org/10.1021/cm9701419

A. Clearfield, A.I. Bortun, L.N. Bortun, D.M. Poojary, S.A. Khainakov, J. Mol. Struct. 470, 207 (1998). https://doi.org/10.1016/S0022-2860(98)00482-7

Ch.S. Fewox, Sh.R. Kirumakki, A. Clearfield, Chem. Mater. 19, 384 (2007). https://doi.org/10.1021/cm061835x

Ch.S. Fewox, A. Clearfield, J. Phys. Chem. A 112, 2589 (2008). https://doi.org/10.1021/jp709592x

I.M. El-Naggar, E.A. Mowafy, Y.F. El-Aryan, M.G. Abd El-Wahed, Solid State Ionics 178, 741 (2007). https://doi.org/10.1016/j.ssi.2007.03.009

M.E. Mahmoud, G.M. Nabil, S.M.E. Mahmoudet, J. Environ. Chem. Eng. 3, 1320 (2015). https://doi.org/10.1016/j.jece.2014.11.027

D. Skoda, A. Styskalik, Z. Moravec, P. Bezdicka, J. Pinkas, J. Mater. Sci. 50, 3371 (2015). https://doi.org/10.1007/s10853-015-8888-1

S. Nazer, A.N. Chermahini, B.H. Monjezi, H.A. Dabbagh, J. Taiwan Inst. Chem. Eng. 114, 168 (2020). https://doi.org/10.1016/j.jtice.2020.09.007

B. El-Gammal, S.A. Shady, Colloids. Surf. 287, 132 (2006). https://doi.org/10.1016/j.colsurfa.2006.02.068

J.M. Palomino, D.T. Tran, A.R. Kareh, Ch.A. Miller, J.M.V. Gardner, H. Dong, S.R.J. Oliver, J. Power Sources 278, 141 (2015). https://doi.org/10.1016/j.jpowsour.2014.12.043

Ch. Yue, P.C.M.M. Magusin, B. Mezari, M. Rigutto, E.J.M. Hensen, Microporous Mesoporous Mater. 180, 48–55 (2013). https://doi.org/10.1016/j.micromeso.2013.06.032

T.M.B. Campos, N.C. Ramos, J.D.M. Matos, G.P. Thim, R.O.A. Souza, M.A. Bottino, L.F. Valandro, R.M. Melo, J. Mech. Behav. Biomed. Mater. 109, 103774 (2020). https://doi.org/10.1016/j.jmbbm.2020.103774.

V.V. Baghramyan, A.A. Sargsyan, A.S. Sargsyan, N.B. Knyayan, V.V. Harutyunyan, E.M. Aleksanyan, N.E. Grigoryan, A.H. Badalyan, Arm. J. Phys. 10(1), 56 (2017)

V.I. Yakovlev, V.V. Strelko, M.V. Kravchenko, Sol–gel method of obtaining spherically granular highly porous zirconium silicate. UA Patent 105,999 (2016) (in Ukrainian)

A. Clearfield, A.I. Bortun, S.A. Khainakov, L.N. Bortun, V.V. Strelko, V.N. Khryaschevskii, Waste Manag. 18, 203 (1998)

I.Z. Zhuravlev, V.A. Kanibolotsky, V.V. Strelko, G.P. Gallios, Sep. Sci. Technol. 39, 287 (2004). https://doi.org/10.1081/SS-120027559

V.V. Strelko, J. Sol-Gel Sci. Technol. 68, 438 (2013). https://doi.org/10.1007/s10971-013-2990-0

F. Mahmood, H. Hu, L. Cao, G. Lu, S. Ni, J. Yuan, Ann. Nucl. Energy 125, 138 (2019). https://doi.org/10.1016/j.anucene.2018.10.031

M. Khalil, Y.F. El-Aryan, I.M. Ali, J. Inorg. Organomet. Polym. 26, 359 (2016). https://doi.org/10.1007/s10904-015-0318-y

A. Patterson, Phys Rev. 56, 972 (1939)

K.Y. Foo, B.H. Hameed, Chem. Eng. J. 156, 2 (2010). https://doi.org/10.1016/j.cej.2009.09.013

A. Kaiser, M. Lobert, R. Telle, J. Eur. Ceram. Soc. 28, 2199 (2008). https://doi.org/10.1016/j.jeurceramsoc.2007.12.040

A.M. Neris, J.M. Ferreira, M.G. Fonseca, I.M. Garcia dos Santos, J. Therm. Anal. Calorim. 143, 3307 (2021). https://doi.org/10.1007/s10973-020-09286-7

I. Romanova, S. Kirillov, J. Therm. Anal. Calorim. 132, 503 (2018). https://doi.org/10.1007/s10973-017-6880-5

S. Tong, Sh. Zhang, H. Yin, J. Wang, M. Chen, J. Anal. Appl. Pyrol. 155, 105074 (2021). https://doi.org/10.1016/j.jaap.2021.105074

V. Raju, S. Jaenicke, G.-K. Chuah, Appl. Catal. B 91(1–2), 92 (2009). https://doi.org/10.1016/j.apcatb.2009.05.010

A.V. Redkina, N.V. Kravchenko, N.D. Konovalova, V.V. Strelko, Vopr. Khimii i Khimicheskoi Tekhnologii 2, 117 (2021). http://udhtu.edu.ua/public/userfiles/file/VHHT/2021/2/Redkina.pdf

Acknowledgements

Financial support for this study has been provided by National Academy of Sciences of Ukraine within the framework of the target research program “Synthesis and physicochemical studies of composite materials for environmental purposes based on natural and synthetic silicates”, 2022-2024. The authors thank O. I. V’yunov for his help in carrying out XRD measurements and M. M. Tsyba for supporting the porous investigations the materials.

Funding

The authors have not disclosed any funding.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation and morphology investigation were performed by MVK and IZZ, adsorption data collection and analysis were performed by SIM. OAD was carrying out all SEM measurements.The first draft of the manuscript was written by IR and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kravchenko, M.V., Diyuk, O.A., Zhuravlev, I.Z. et al. Impact of Hydrothermal Treatment on the Porous Structure and Adsorption Properties of Spherically Granulated Zirconium Silicate. J Inorg Organomet Polym 33, 2346–2353 (2023). https://doi.org/10.1007/s10904-023-02663-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10904-023-02663-3