Abstract

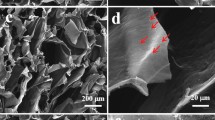

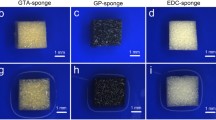

A biodegradable soy protein isolate-based waterborne polyurethane composite sponge (SWPU) was prepared from soy protein isolate (SPI) and polyurethane prepolymer (PUP) by a process involving chemical reaction and freeze-drying. Effects of SPI content (0, 10%, 30%, 50%, 70%) on the micro-structure and physical properties of the composite sponges were characterized by Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM), differential scanning calorimetry (DSC), and thermogravimetric analysis (TGA). The results showed that the reaction between -NCO of PUP and -NH2 of SPI formed porous SPI-based WPU composite sponges. The results of the water absorption ratio measurement, solvent resistance measurement and compressive testing showed that water absorption, hydrophilicity, and tensile strength in the dry state of the composite sponges increased with the increase of SPI content. Especially, the tensile strength ranged from 0.3 MPa to 5.5 MPa with the increase in SPI content. The cytocompatibility and biodegradability of the composite sponges were evaluated by in vitro cell culture and in vivo implantation experiments. The results indicated that a certain SPI content in the sponges could promote the adhesion, growth, and proliferation of cells, enhance the cytocompatibility and accelerate the degradation speed of composite sponges. During the in vivo implanting period within 9 months, SWPU-50 sponge containing 50% of SPI brought out the lowest activated inflammatory reaction, most newly-regenerated blood capillaries, and best histocompatibility. All results indicated that SWPU-50 composite sponges had greatest potential for tissue engineering.

Similar content being viewed by others

References

Cutiongco MF, Anderson DE, Hinds MT, Yim EK. In vitro and ex vivo hemocompatibility of off-the-shelf modified poly(vinyl alcohol) vascular grafts. Acta Biomater. 2015;25:97–108.

Duan X, Mclaughlin C, Griffith M, Sheardown H. Biofunctionalization of collagen for improved biological response: scaffolds for corneal tissue engineering. Biomaterials. 2007;28:78–88.

Chung IM, Enemchukwu NO, Khaja SD, Murthy N, Mantalaris A, Garcia AJ. Bioadhesive hydrogel microenvironments to modulate epithelial morphogenesis. Biomaterials. 2008;29:2637–45.

Cevenini L, Calabretta MM, Tarantino G, Michelini E, Roda A. Smartphone-interfaced 3d printed toxicity biosensor integrating bioluminescent “sentinel cells”. Sens Actuators B. 2016;225:249–57.

Silva BV, Rodríguez BA, Sales GF, Sotomayor MD, Dutra RF. An ultrasensitive human cardiac troponin T graphene screen-printed electrode based on electropolymerized-molecularly imprinted conducting polymer. Biosens Bioelectron. 2016;77:978–85.

Babilotte J, Guduric V, Le Nihouannen D, Naveau A, Fricain JC, Catros S. 3D printed polymer-mineral composite biomaterials for bone tissue engineering: fabrication and characterization. J Biomed Mater Res Part B: Appl Bio-mater. 2019;107:2579–95.

Shao W, He J, Sang F, Ding B, Chen L, Cui S. Coaxial electrospun aligned tussah silk fibroin nanostructured fiber scaffolds embedded with hydroxyapatite-tussah silk fibroin nanoparticles for bone tissue engineering. Mater Sci Eng C. 2016;58:342–51.

Samuelsson K, Andersson D, Ahldén M, Fu FH, Musahl V, Karlsson J. Trends in surgeon preferences on anterior cruciate ligament reconstructive techniques. Clin Sport Med. 2013;32:111–26.

Itani Y, Asamura S, Matsui M, Tabata Y, Isogai N. Evaluation of nanofiber-based polyglycolic acid scaffolds for improved chondrocyte retention and in vivo bioengineered cartilage regeneration. Plast Reconstr Surg. 2014;133:805e–13e.

Salehi M, Naseri-Nosar M, Ebrahimi-Barough S, Nourani M, Khojasteh A, Farzamfar S. Polyurethane/gelatin nanofibrils neural guidance conduit containing platelet-rich plasma and melatonin for transplantation of Schwann cells. Cell Mol Neurobiol. 2018;38:703–13.

Tambe N, Di J, Zhang Z, Bernacki S, El-Shafei A, King MW. Novel genipin-collagen immobilization of polylactic acid (pla) fibers for use as tissue engineering scaffolds. J Biomed mater Res Part B: Appl Bio-mater. 2015;103:1188–97.

Zuo YF, Gu J, Qiao Z, Tan H, Cao J, Zhang Y. Effects of dry method esterification of starch on the degradation characteristics of starch/polylactic acid composites. Int J Biol Macromol. 2015;72:391–402.

Kim MS, Kim GH. Electrohydrodynamic direct printing of PCL/collagen fibrous scaffolds with a core/shell structure for tissue engineering applications. Chem Eng J. 2015;279:317–26.

Jiang X, Wang K, Ding M, Li J, Tan H, Wang Z. Quantitative grafting of peptide onto the nontoxic biodegradable waterborne polyurethanes to fabricate peptide modified scaffold for soft tissue engineering. J Mater Sci: Mater Med. 2011;22:819–27.

Jiang X, Yu F, Wang Z, Li J, Tan H, Ding M Fabrication and characterization of waterborne biodegradable polyurethanes 3-dimensional porous scaffolds for vascular tissue engineering. J Biomater Sci Polym Ed. 2010;21:1637-52.

Shigematsu K, Nishida N, Sakai H, Igawa T, Toriyama K, Nakatani A. Synaptophysin immunoreactivity in adrenocortical adenomas: a correlation between synaptophysin and cyp17a1 expression. Eur J Endocrinol. 2009;161:939–45.

Song NJ, Jiang X, Li JH, Pang Y, Li JS, Tan H, et al. The degradation and biocompatibility of waterborne biodegradable polyurethanes for tissue engineering. Chin J Polym Sci. 2013;31:1451–62.

Du X, Li Y, Liu X, Wang X, Huselstein C, Zhao Y. Fabrication and evaluation of physical properties and cytotoxicity of zein-based polyurethanes. J Mater Sci: Mater Med. 2014;25:823–33.

Gao Z, Peng J, Zhong T, Sun J, Wang X, Yue C. Biocompatible elastomer of waterborne polyurethane based on castor oil and polyethylene glycol with cellulose nanocrystals. Carbohydr Polym. 2012;87:2068–75.

Travinskaya T, Savelyev Y, Mishchuk E. Waterborne polyurethane based starch containing materials: preparation, properties and study of degradability. Polym Degrad Stab. 2014;101:102–08.

Mohamed KR, Beherei HH, El-Rashidy ZM. In vitro study of nano-hydroxyapatite/chitosan-gelatin composites for bio-applications. J Adv Res. 2014;5:201–08.

Zhao SJ, Wen YY, Wang Z, Kang HJ, Li JZ, Zhang SF, et al. Preparation and demonstration of poly(dopamine)-triggered attapulgite-anchored polyurethane as a high-performance rod-like elastomer to reinforce soy protein-isolated composites. Appl Surf Sci. 2018;442:537–46.

Chen Y, Zhang L, Du L. Structure and properties of composites compression-molded from polyurethane prepolymer and various soy products. Ind Eng Chem Res. 2003;42:6786–94.

Santin M, Ambrosio L. Soybean-based biomaterials: preparation, properties and tissue regeneration potential. Expert Rev Med Devices. 2008;5:349–58.

Meikle ST, Standen G, Salvage J, De Santis R, Nicolais L, Ambrosio L, et al. Synthesis and characterization of soybean-based hydrogels with an intrinsic activity on cell differentiation. Tissue Eng Part A. 2012;18:1932–39.

Perut F, Montufar EB, Ciapetti G, Santin M, Salvage J, Traykova T, et al. Novel soybean/gelatine-based bioactive and injectable hydroxyapatite foam: material properties and cell response. Acta Biomater. 2011;7:1780–87.

Merolli A, Nicolais L, Ambrosio L, Santin M. A degradable soybean-based biomaterial used effectively as a bone filler. vivo a rabbit Biomed Mater. 2010;5:15008–15.

Shevchenko RV, Santin M. Pre-clinical evaluation of soybean-based wound dressings and dermal substitute formulations in pig healing and non-healing. Vivo Models Burns Trauma. 2014;2:187–95.

Tian H, Wang Y, Zhang L, Quan CY, Zhang XZ. Improved flexibility and water resistance of soy protein thermoplastics containing waterborne polyurethane. Ind Crops Prod. 2010;32:13–20.

Li MM, Xiao Y, Chen Y, Ni H, Cai J, Wang XM, et al. Soy protein-modified waterborne polyurethane biocomposites with improved functionality. RSC Adv. 2016;6:12837–49.

Bummer PM, Knutson K. Infrared spectroscopic examination of the surfaces of hydrated copoly(ether-urethane-ureas). Macromol. 1990;23:4357–62.

Yang D, Ye F, Rong X, Chen Z, Qiu F. Preparation and properties of waterborne polyurethane containing hyperbranched polyester linkages. Polym-Plast Technol Eng. 2013;52:614–20.

Quadrini F, Bellisario D, Santo L, Gaudio CD, Bianco A. Shape memory foams of microbial polyester for biomedical applications. Polym-Plast Technol Eng. 2013;52:599–602.

Luo N, Wang DN, Ying SK. Crystallinity and hydrogen bonding of hard segments in segmented poly(urethane urea) copolymers. Polym. 1996;37:35–77.

Wang N, Zhang L. Preparation and characterization of soy protein plastics plasticized with waterborne polyurethane. Polym Int. 2005;54:233–39.

Nair BR, Gregoriou VG, Hammond PT. Ft-ir studies of side chain liquid crystalline thermoplastic elastomers. Polym. 2000;41:2961–70.

Zhou X, Fang CQ, Lei WQ, Du J, Huang TY, Li Y, et al. Various nanoparticle morphologies and surface properties of waterborne polyurethane controlled by water. Sci Rep. 2016;6:6472–85.

Wang N, Zhang L, Gu J. Mechanical properties and biodegradability of crosslinked soy protein isolate/waterborne polyurethane composites. J Appl Polym Sci. 2005;95:465–73.

Li YD, Chen SC, Zeng JB, Wang YZ. Novel biodegradable Poly(1,4-dioxan-2-one) grafted soy protein copolymer: synthesis and characterization. Ind Eng Chem Res. 2008;47:8233–8.

Zhang M, Song F, Wang XL, Wang YZ. Development of soy protein isolate/waterborne polyurethane blend films with improved properties. Colloids Surf B. 2012;100:16–21.

Ricci L, Umilta E, Righetti MC, Messina T, Zurlini C, Montanari A, et al. On the thermal behavior of protein isolated from different legumes investigated by DSC and TGA analyses. J Sci Food Agric. 2018;98:5368–77.

Tong XJ, Luo XL, Li YB. Development of blend films from soy meal protein and crude glycerol-based waterborne polyurethane. Ind Crops Prod. 2015;67:11–7.

Chang PR, Zou JW, Shang WL, Yu JH, Xia T, Huang J. Effects of pea protein nanophase on structure and properties of waterborne polyurethane-based composites. J Biobased Mater Bioenergy. 2012;6:108–14.

Jiang L, Wu J, Nedolisa C, Saiani A, Assender HE. Phase separation and crystallization in high hard block content polyurethane thin films. Macromol. 2015;42:386–474.

Dai Z, Li Z, Li L, Xu G. Synthesis and thermal properties of antimony doped tin oxide/waterborne polyurethane nanocomposite films as heat insulating materials. Polym Adv Technol. 2011;22:1905–11.

Yao L, Wu C, Yang Z, Qiu W, Cui P, Xu T. Waterborne polyurethane/poly(vinyl alcohol) membranes: preparation, characterization, and potential application for pervaporation. J Appl Polym Sci. 2012;124:216e–24e.

Liu X, Xu K, Liu H, Cai H, Su J, Fu Z. Preparation and properties of waterborne polyurethanes with natural dimer fatty acids based polyester polyol as soft segment. Prog Org Coat. 2011;72:612–20.

Tien YI, Wei KH. High-tensile-property layered silicates/polyurethane nanocomposites by using reactive silicates as pseudo chain extenders. Macromol. 2011;34:9045–52.

Luo LH, Zhang YF, Wang XM, Wan Y, Chang PR, Anderson DP. Preparation, characterization, and in vitro and in vivo evaluation of cellulose/soy protein isolate composite sponges. J Biomater Appl. 2010;24:503–26.

Ghoniem GM, Elgamasy AN, Elsergany R, Kapoor DS. Grades of intrinsic sphincteric deficiency (isd) associated with female stress urinary incontinence. Int Urogynecol J Pelvic Floor Dysfunct. 2002;13:99–105.

Ju YM, Atala A, Yoo JJ, Lee SJ. In situ regeneration of skeletal muscle tissue through host cell recruitment. Acta Biomaterialia. 2014;10:4332–39.

Li Q, Ma L, Gao C. Biomaterials for in situ tissue regeneration: development and perspectives. J Mater Chem B. 2015;3:8921–38.

Silva SS, Santos MI, Coutinho OP, Mano JF, Reis RL. Physical properties and biocompatibility of chitosan/soy blended membranes. J Mater Sci: Mater Med. 2005;16:575–79.

Tansaz S, Singh R, Cicha I, Boccaccini AR. Soy protein-based composite hydrogels: physico-chemical characterization and in vitro cytocompatibility. Polymers. 2018;10:1159–78.

Lin HH, Hsieh FY, Tseng CS, Hsu SH. Preparation and characterization of a biodegradable polyurethane hydrogel and the hybrid gel with soy protein for 3D cell-laden bioprinting. J Mater Chem B. 2016;4:6694–705.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. NSFC 81871493), the National Natural Science Foundation of Hubei province (Grant No. 2017CFB240), and the Medical Science Advancement Program (Clinical Medicine) of Wuhan University (Grant No. TFLC2018003). Thanks for the technique support from the Experimental Teaching Center of Basic Medical Sciences, Wuhan University.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, M., Dong, Q., Xiao, Y. et al. A biodegradable soy protein isolate-based waterborne polyurethane composite sponge for implantable tissue engineering. J Mater Sci: Mater Med 31, 120 (2020). https://doi.org/10.1007/s10856-020-06451-0

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10856-020-06451-0