Abstract

This study explores the optical and dielectric properties of pure and europium-doped barium titanate ceramics with formula Ba1−3x/2EuxTiO3 (\(x=0,0.005, 0.015\text{ and }0.025\)). The materials were synthesized using the solid-state reaction method. The influence of Eu + 3 ion incorporation on the crystal structure was examined using XRD, which indicated the formation of a cubic phase. Lattice parameter measurements showed excellent agreement with various theoretical models for predicting the lattice constant, with an average error of only 0.20%. UV–visible spectroscopy analysis is utilized to investigate optical characteristics, revealing a decrease in the optical band gap from 2.65 to 2.77 eV post-Eu doping, which is notably lower than the bulk barium titanate value of 3.2 eV. Materials with smaller band gaps are more suited for optoelectronic applications like photodetectors and light-emitting diodes (LEDs). The dielectric response of europium-doped barium titanate was studied across a frequency range of 1 kHz to 2 MHz and a temperature range of 77 to 300 K, showing remarkable stability. The frequency-dependent dielectric analysis revealed that the dielectric constant initially increased with increasing doping concentration, but decreased at higher concentrations. These results suggest that europium-doped barium titanate holds significant promise for future electronic device applications due to its enhanced optical and dielectric properties.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nowadays, there is increasing interest in materials for electronic devices that emit less radiation and pose less threat to human health [1, 2]. Oxide perovskite materials with general formula ABO3-type and related perovskite materials have engrossed much attention due to their excellent dielectric, piezoelectric, and ferroelectric properties [3, 4]. Barium titanate and its derivative enticed researchers over the past decade due to its excellent dielectric and optical properties [5, 6]. Also, these lead-free ceramics cause less damage to the environment during the disposal of material. Barium titanate and its derivative have proved their widespread industrial importance in the production of multilayer ceramic capacitors (MLCC), gas sensors, dynamic random access memory (DRAM), non-volatile ferroelectric random access memory (FRAM), ultrasonic transducers, thermistors, and gate dielectrics [7, 8]. The physical properties of barium titanate can be modified by suitable substitution of A-site ions (Ba+2), B-site ions (Ti+4), and/or amphoteric substitution. These substitutions are generally governed by Hume Rothery rules [9]. The dopant may be a donor or an acceptor type and lies in the alkali/alkaline (s-block), transition metals (d-block), or rare-earth (f-block) group.

Rare-earth elements demonstrate strong stability inside the crystal structure of perovskites with the ABO3 composition. Introducing rare-earth impurities into barium titanate or its derivatives may enhance the material’s performance [10, 11]. Grain growth inhibition, improved temperature response of dielectric constant, and improved reliability in resistance degradation are all qualities needed for MLCC and high dielectric constant capacitors, and donor-type rare-earth elements have shown their usefulness in these areas. Tsur et al. [12] reported that if the ionic radius of the trivalent rare-earth dopant is ≤ 0.087 nm (Lu), then the preferable site will be B-site; if the radius is ≥ 0.094 nm (La, Ce, Pr, Nd, Sm, and Eu), then ion moves in A-sites, whereas if radius lies between 0.087 ≤ r ≤ 0.094 nm (Gd, Dy, Ho, and Er), then ion shows amphoteric nature and can opt for any A-/B-sites. But valency also plays a key role in site occupation and overall defect chemistry. Rare-earth elements generally show + 3 oxidation states but in certain conditions, they can also have + 2 and + 4 oxidation states. It was previously reported that Eu ions can exist in + 3 state and + 2 metastable state [13]. To the best of our knowledge, there is no report that claims the amphoteric nature of Eu supplemented by the change of valency. These two valance states, namely Eu+2 and Eu+3, can co-exist at A-sites. Substituting Ba+2 with Eu+3 will result in a charge imbalance. This charge imbalance must be compensated by either vacancy generation or by electron generation for charge neutrality. The creation of vacancies/electrons may alter the local symmetry or conducting behavior of the barium titanate host matrix. These changes generally reflect in structural, optical, or dielectric properties.

This paper focuses on understanding the mechanisms underlying the introduction of Eu+3 as a dopant in the barium titanate matrix as Ba1−3x/2EuxTiO3. The comprehensive study compares experimentally measured results of lattice constants with theoretical models used for the prediction of lattice constants. A good matching of experimental and theoretical results validate the correlated discussion of structural, optical, and dielectric results of the Eu-doped barium titanate system. Furthermore, the study shows links between these features and the system’s defect chemistry, revealing insights into the way it operates. Thus, this work may be useful to provide more controlled structure of barium titanate-based materials for multifunctional electronic devices application.

2 Experimental details

2.1 Materials

The starting materials were fine powers of Barium Carbonate (BaCO3, purity ≥ 99%), Europium (III) Oxide (Eu2O3, purity ≥ 99.9%), and Titanium (IV) Oxide (TiO2, anatase, purity ≥ 99.8%) purchased from Sigma-Aldrich. Fisher Scientific supplied the ethanol (ACS grade). Before being used, the powers were dried for six hours at 80 °C in an oven.

2.2 Synthesis

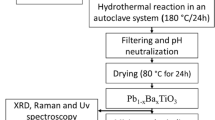

Pure and Europium-doped barium titanate, with formula (Ba1−3x/2Eux)TiO3 where x = 0.000, 0.005, 0.015, and 0.025, powders were prepared by conventional solid-state reaction method. It was reported earlier that the fine barium titanate particles can be synthesized at lower calcination temperatures by using the anatase phase of TiO2. Oven-dried powders of BaCO3, TiO2 and Eu2O3 were mixed stoichiometrically and mixed well using mortar and pestle in the dry state for 15 min. After adding the dry ingredients to the mixture, the mixture was grinded again in ethanol for half an hour. Each sample contained 20 mL of ethanol. The precursors had their ethanol removed by transferring the mixture to a borosilicate glass petri dish and then drying it in an oven set at 40 °C for 6 h. Thermogravimetric and differential thermal analyses were performed on an oven-dried stoichiometric mixture containing TiO2 and BaCO3.The result shows that the weight loss becomes steady around 940 °C (Supplementary Data Fig. S1a). This result was also confirmed by TGA/DTA data of BaTiO3 (Supplementary Data Fig. S1b). The heating rate was kept at 5°/min. Based on these findings, the calcination temperature was set at 1000 °C. Also, three batches of precursors containing TiO2 and BaCO3 were calcinated at 700 °C, 800 °C, and 900 °C for 12 h in a programmable electric furnace in an alumina crucible. The air environment in the furnace is used for every reaction step. The heating and cooling rates were set as 5°/min. After the calcination and cooling process, white lumps were obtained. These lumps were crushed using mortar and pestle, and fine powders of pure and doped BaTiO3 were obtained. The same heating process was repeated two more times to get more homogeneous samples of BaTiO3 with minimum traces of unreacted BaCO3 and TiO2. The XRD investigation demonstrates that a better phase of BaTiO3 requires a temperature of at least 900 °C (Fig. S2, Supplementary Data). Consequently, the same conditions were used to produce all of the doped samples.

2.3 Characterizations

Powder XRD data were collected from RigakuUltima IV X-ray diffractometer using Cu Kα radiation with a scanning rate 2°/min between the 2θ ranges from 20° to 70°. Qualitative analysis of samples was done by software QualX2.0. The crystallite size and cell parameters calculations were done by XRD analysis software EXPO2014. The microstrain was calculated by using a self-made MatLab program [14]. Through the use of a Fourier transform infrared spectrometer (Perkin-Elmer, Spectrum Two), the chemical structure was examined. FTIR spectra were collected in the range of 400–4000 cm−1 with step size of 1 cm−1. Powder morphology and particle size of samples were investigated using a field emission scanning electron microscope (FE-SEM, Zeiss EVO MA10). UV–Vis absorption spectra of pure and Eu+3-doped barium titanate were recorded in the range of 200–800 nm with step size 0.5 nm at room temperature using Shimadzu UV1800 Spectrophotometer. Dielectric measurements were conducted on a precision LCR Meter (Agilent, E4980A) in the frequency range of 1 kHz to 2 MHz and temperature range of 80–320 K. For dielectric measurements, the samples were pressed uniaxially using a hydraulic press by applying pressure of 10 tons. The diameter of all pellets was 10 mm while thickness ranges from 2.5 to 3.5 mm.

3 Theoretical modulations

The different regression methods have been used for lattice parameters prediction, and the results have been compared with the experiment data.

3.1 Lattice parameters

In perfect ABO3-type perovskites, six anions (O) create an octahedral space that is filled by a smaller cation (B-site), resulting in the formation of BO6 octahedra. These eight corners sharing BO6 octahedra make a cuboctahedral cavity which is occupied by a bigger cation (A-site). The BO6 octahedra must be interconnected via vertices, and the A–O to B–O bond ratio should be √2:1 for an undistorted cubic structure, as seen in Fig. 1. Different models were proposed for the relationship between cubic and pseudocubic perovskite lattice constants and the ionic radii of cations and anions at the A- and B-sites [14, 15].

Ye et al. [15] suggested that lattice distortion is influenced by factors such as ionic radii of cations and anions, coordination number, partial covalence, and chemical bonds. The suggested lattice constant is provided as follows:

where \({r}_{A}, {r}_{B}\) are Shannon ionic radii, \({X}_{A, }{ X}_{B}\) are electronegativity, and \({Z}_{A}, {Z}_{B}\) are valency of A- and B-site ions.

Additionally, Jiang et al. [16] put up a model for lattice constant prediction which was further corrected by Moreira and Dias et al. [17] as follows:

Here with coordination numbers 12, 6, and 2, \({r}_{A}^{XII}\) is the Shannon ionic radius of the A-site cation, \({r}_{B}^{VI}\) is that of B-site cation, and \({r}_{O}^{II}\) is that of oxygen anion.

Additionally, Ubic et al. [18] presented a model that uses the linear regression approach to link lattice constant and ionic radii:

Equations 1, 2, and 3 can be rearranged as per stoichiometry, (Ba1−3x/2Eux)TiO3, of the system as follows:

Table 1 summarizes the values of predicted lattice constants for different compositions (x = 0, 0.005, 0.015, and 0.025). Table S1 (Supplementary Data) provides a detailed comparison of lattice constant prediction approaches.

3.2 Tolerance factor

ABO3-type structures’ formability and stability are contingent on A–O and B–O bond length. The Goldschmidt tolerance factor (\({t}_{G}\)) is a geometrical ratio that Goldschmidt first used to propose the idea of perovskite structural stability [19]:

where rA, rB, and rO are the radii of A–cation, B-cation, and O-anion, respectively. If we have a polyatomic hybrid system like [(A1-xAx’)(B1-yBy’)(X1-zXz’)3], Eq. 7 can be rewritten as follows [19]:

The value of tG varies from 0.81 to 1.11 for a stable perovskite structure [19]. The cubic or pseudocubic structures beyond these limits, 0.81 ≤ tG ≤ 1.11, would be distorted or may even be destroyed. For an ideal cubic structure, tG is ~ 1. Reports of tilted corner-sharing octahedra were made when the value of tG was less than 1 [20]. In contrast, ABO3-type perovskites begin to form coupled corner and face-sharing phases when tG was greater than 1. However, if we are concerned about how closely A- and B-site ions are packed, fractional tolerance factors (tl and t2) can be used [21]:

where ‘a’ is the lattice constant and ratio of t1 and t2 gives Goldschmidt tolerance factor (tG = t1/t2) as given in Eq. 7. For polyatomic systems, Eq. 9 and Eq. 10 change accordingly.

It was reported that A-site vacancies can reduce the secondary coordination number of oxygen. This may cause a reduction in the average ionic radius of oxygen ion. Ubic et al. [22] developed empirical modeling approaches to establish a connection between lattice constant and tolerance factor. The modified tolerance factor, as per the revised model, is given by [23]:

where tU is modified tolerance factor, \({r}_{O}^{II}\) and \({r}_{B}^{VI}\) are effective ionic radii of O-anion and B-site cation for coordination number 2 and 6, respectively. The pseudocubic lattice constant, apc, can be determined experimentally or from theoretical approaches [14, 17]. The effective sizes of the oxygen anions (\({r}_{O}\)), oxygen vacancies (\({r}_{V}^{O}\)) at O-site, and cation vacancies (\({r}_{V}^{Ba}\)) at A-site can be calculated as follows [24]:

Table 2 embraces the values of fractional tolerance factor (t1 and t2), Goldschmidt tolerance factor (tG), modified tolerance factor (tU), the effective size of oxygen ion (\({r}_{O}\)), the effective size of A-site vacancies (\({r}_{V}^{Ba}\)) and effective size of oxygen vacancies (\({r}_{V}^{O}\)), for different compositions (x = 0, 0.005, 0.015, and 0.025). All the calculations for Table 1 are based on experimental lattice constant (\({a}^{expt}\)). The same quantities are also recalculated for theoretical lattice constant (based on Eqs. 4–6) and are listed in Table S2 and Table S3 (Supplementary Data).

4 Experimental results and discussion

4.1 X-ray diffraction study

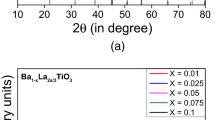

X-ray diffraction patterns for pure and doped samples with formula (Ba1−3x/2EuxTiO3, where x = 0.000, 0.005, 0.015, and 0.025) are shown in Fig. 2. The qualitative and quantitative studies of the samples were done with software QualX and Expo, respectively [24, 25]. The experimental data clearly show that all the peaks of barium titanate and its doped derivatives are crystalline and well defined (Fig. 2). The QualX analysis shows that the peaks of pure and doped samples are in good agreement with previously reported barium titanate structures.

The ICDD (PDF2) database was employed as the reference database in this case for phase identification. Some residues of unreacted BaCO3 (ICDD Card No. 00-045-1471) and TiO2 (ICDD Card No. 00-023-1446) were discovered in pure barium titanate samples calcined at 800 °C and 900 °C (Fig. S2, Supplementary Data). As we increase the calcination temperature from 900 to 1000 °C, the barium titanate phase (ICDD Card No. 00-075-0212) becomes more prominent while BaCO3 (ICDD Card No. 00-045-1471) TiO2 (ICDD Card No. 00-023-1446) phase is reduced significantly at 1000 °C (Fig. S2, Supplementary Data). The careful analysis of doped samples revealed that the impurity phases of Ba2TiO4 (ICDD Card No. 00-070-1377), Eu2O3 (ICDD card no. 00–043-1009), BaCO3 (ICDD Card No. 00-045-1471), and TiO2 (ICDD Card No. 00-023-1446) were detected at higher doping concentrations, particularly for x = 0.025 doping concentration (Fig. 2A). The traces of TiO2 and Eu2O3 were also reported at a higher concentration for SrTiO3 [26]. The formation of BaTiO3 together with the traces of impurity at higher concentrations can be explicated by the chemical reaction [27]:

Figure 2B shows the XRD peaks shifting of (110) peaks of pure and doped samples. A detailed investigation of the (110) peak illustrates a consistent trend towards higher angles for doping concentrations ranging from x = 0.00 to x = 0.015. According to Bragg’s law, this implies a decrease in interplanar spacing, which results in a decrease in cell volume. Furthermore, the same locations of the XRD peaks at x = 0.015 and x = 0.025 indicate that beyond a certain doping level, the lattice parameters and cell volume stabilize, with no further substantial structural changes. This stability at increasing doping concentrations suggests that the initial dopant-induced lattice strain has reached its limit, and the crystal structure has accommodated the highest possible dopant concentration without requiring additional volume reduction. The substitution of dopant depends upon relative ionic radii, crystal structure, and chemical affinity. Replacing Ba+2 with Eu+3 causes a change in vacancy concentration to maintain charge balance. The energy required for dopant substitution onto a lattice site is related to crystal structural deformation and the creation of compensatory defects during the doping process. Therefore, the substitution of dopant into the crystal structure is assertively governed by compensating defect formation energy. It should also be noted that if dopant is deposited on grain boundaries, then there is no such energy requirement [28]. Substituting Eu+3 ions within the crystal structure becomes more energy intensive as the concentration of Eu+3 increases; however, this is not the case when Eu2O3 is present at the grain borders. This is the possible reason for the appearance of traces of impurity at higher concentrations in the present experimental results. Hernández-Lara et al. also reported the traces of Eu2O3 in doped barium titanate at higher concentrations and at 900 °C temperature, which further disappeared when the sample was heated at higher temperature [27].

The crystallite size and the strain induced during the compound formation were calculated by the Williamson–Hall approach [29, 30]:

where β is full width at half maximum (FWHM), θ is the angle of diffraction, ε is strain induced, λ is the wavelength of X-rays, and D is the crystallite size. The values of FWHM are given in Table S4 (Supplementary Data). The strain and crystallite size can be calculated by the MatLab program [21]. The experimental lattice parameters and crystallite size were calculated using Expo and are listed in Table 1. The experimental values of lattice parameters of pure and Eu+3-doped barium titanate samples were found highly consistent with theoretical lattice constant prediction models (Eqs. 4, 5, and 6). The models proposed by Ye et al. [14], Moreira et al. [17], and Ubic et al. [18] are deemed most suitable for this work with average percentage errors 0.236447, 0.24050, and 0.24290, respectively (Table S1, Supplementary Data). In addition, the other theoretical lattice constant prediction models were also checked, and we found that the average percentage error ranged from 0.26283 to 2.70961 for different models (Table S1, Supplementary Data).

The pure barium titanate sample, in the present work, agrees with ICDD Card No. 00-075-0212. The experimental unit cell volume of the pure barium titanate sample, which was found as 64.67 Å3, is a little smaller than the one reported (ICDD Card No. 00-075-0212). This size reduction can be explained based on the size effect. As the size of materials starts to reduce, the ratio of surface area to volume particles starts to increase. The surface particles possess a high value of surface tension and surface energy. To minimize the surface energy, particles start to shrink which causes a reduction in unit cell dimensions. As Eu+3-doping concentration starts to increase, the values of experimental lattice parameters are lowered (Table 1). These values are highly consistent with theoretically found lattice parameters (Eqs. 4–6) reduce continuously (Table 1). This trait could be explained by partial substitution of ionic species inside the unit cell. Ti+4, Ba+2, and Eu+3 ions have respective ionic radii of 0.605 Å (for coordination number 6), 1.61 Å (for coordination number 12), and 1.28 Å (for coordination number 12). Eu+3 ions possess an ionic radius greater than that of Ti+4 ions, yet smaller than the radius of Ba+2 ions. Consequently, it is reasonable to anticipate the substitution of Ba+2 ions with Eu+3 ions at the A-site. The site occupancy is not solely dependent on ionic radii but is also influenced by electronegativity and valence of dopant. The electronegativity (Pauling scale) of Ba, Eu, Ti, and O are 0.89, 1.54, 1.2, and 3.44, respectively. The electronegativity difference in Ba–O, Ti–O, and Eu–O are 2.55, 2.24, and 1.90, respectively. The covalent radius (single bond) of O−2, Ti+4, Eu+3, and Ba+2ions are 0.63 Å, 1.36 Å, 1.68 Å, and 1.96 Å, respectively [31]. The \({r}_{C-O}\) representing bond length computed as follows:

where β (0.09 Å) is a constant, A- or B-site atom’s covalent radius and electronegativity are represented by rC and XC, oxygen’s covalent radius and electronegativity are represented by rO and XO, respectively. The bond lengths of Ba–O, Eu–O, and Ti–O bonds were calculated as 2.360 Å, 2.139 Å, and 1.788 Å, respectively. The Ti–O bond is the shortest, resulting in strong binding between atoms owing to Coulombian interaction. Therefore, a greater amount of energy is required to remove a titanium atom compared to a barium atom. Therefore, it is entirely logical that Eu+3 ions go to the A-site. This migration of Eu+3 enhances the covalent nature of the A-site bond and the A–O bond length starts to decrease. The decrease in lattice parameters in Eu+3-doped samples (x = 0.005 and x = 0.015) is caused by the decrease in ionic size and the rise in electronegativity resulting from europium doping. Substituting Eu+3 ions with Ba+2 ions will alter the charge ordering at the A-site because of the difference in charge. The charge compensation mechanism mainly occurs via vacancy metal formation (A/B-site or both sites) or by electrons formation [12]. Kroger–Vink notation for this substitution can be written as follows:

This equation indicates that one cationic vacancy \((V_{Ba}^{^{\prime\prime}} )\) will be formulated for every two Eu+3 ions migration at A-site for charge neutrality. The charge on Ba-vacancy \((V_{Ba}^{^{\prime\prime}} )\)can be assigned as -2. This vacancy can also be treated as a charged species at A-site. The number of cationic vacancy \((V_{Ba}^{^{\prime\prime}} )\)increases with increasing Eu+3 concentration.

Replacing Ba+2 (1.61 Å) ions with Eu+3 (1.28 Å) ions decreases the Goldschmidt tolerance factor (Eq. 7). Consequently, the effective size of cationic vacancy \((V_{Ba}^{^{\prime\prime}} )\)starts to decrease (Table 2). It is also noteworthy that doping Eu+3 reduces A–O bond length due to the smaller size of the dopant, but there is a simultaneous increase in the number of cationic vacancies \((V_{Ba}^{^{\prime\prime}} )\) too. These vacancies have a significant size in the lattice. These vacancies repel neighboring oxygen ions due to Coulombian force. Therefore, the reduction in A–O bond length is attributed to the smaller radius and higher electronegativity of dopant which reflects as the reduction in lattice parameter. Meanwhile, cationic vacancies try to increase the lattice parameter. These cationic vacancies also affect the oxygen ions nearby. The ionic radius depends upon coordination number. The increase in cationic vacancies decreases the coordination number of oxygen ions. As doping levels rise, there is a corresponding reduction in the ionic radius of oxygen ions (Table 2). The interplay among these mechanisms causes a minute decrease in lattice parameters (Table 1). For doping concentration x = 0.0025, traces of unreacted constituents were found (Fig. 2A). If Eu+3 doping is compensated either by titanium vacancy generation or titanium valency reduction, a significant amount of unreacted TiO2 must be obtained [23]:

Thus, the appearance of unreacted constituents at higher doping levels (Fig. 2A) is a consequence of the charge compensation mechanism at B-sites. The cationic charge reduction at B-site reduces the Coulombic attraction. As a result, lattice relaxation may cause an increase in lattice parameters. Thus, for x = 0.025, lattice constant reduction is minimal. This result is supported by fractional tolerance factor data (Tables 2 and S2; Supplementary Data). When the fractional tolerance factors (t1 or t2) exceed one, the atoms will be tightly packed. Conversely, if the value is below one, the atoms are anticipated to move within their positions (Eqs. 9 and 10). Fractional tolerance factor t2 is directly related to B-site ions. The value of t2 tends to approach unity as the doping level rises, with the exception of x = 0.025 concentration, as seen in Table 2.

This pattern indicates that the B-site ions become more densely arranged after doping. An observed reduction in t2 occurred at x = 0.025, indicating the dangling nature of B-site ions at this composition. Subsequently, a reduction in t1 was seen following doping, suggesting that A-site ions experience decreased proximity after doping. The tolerance factor (Eqs. 8 and 11) gives information about the overall stability of the perovskite structure. The Goldschmidt tolerance factor (Eq. 8) falls as the doping concentration increases and tends towards unity. This implies that the structural distortions start to relax and the material attains a more stable form. Modified tolerance factor (Eq. 11) also shows the same trend but an increase in tU was observed for x = 0.025 concentration (Table 2). Also, the calculations were done for the Goldschmidt and modified tolerance factors (Eqs. 8 and 11) using different lattice constant prediction models (Eqs. 4, 5, and 6). The results given by Eqs. 4 and 5 are in good agreement with experimental data calculations for this system (Table S2; Supplementary Data).

Table 1 summarizes the microstrains and crystallite sizes of both pure and doped samples. Microstrains arise from changes in the lattice structure, confinement of size, and flaws in the crystal. A net force is expected to act on the unit cell due to size confinement which results in terms of microstrain. Also, the size reduction increases the lattice defect which is another cause of strain. Notably, pure barium titanate shows the highest strain while the strain in all doped samples increases with increasing doping concentration (Table 1). It may be assumed that there were no vacancy defects due to foreign impurities in pure barium titanate. The high strain in pure barium titanate may be attributed to the particle size effect. The increase in strain in doped samples might be attributed to vacancy defects due to doping. In addition, the high values of strain for x = 0.015 and 0.025 could be explained by taking the size confinement effect and the presence of the secondary phase into account. It is vital to mention that the sample having concentration x = 0.015 has minimum experimental lattice parameters and crystallite size among all (Table 1). This situation might induce strain due to lattice parameter compression which is a consequence of size confinement. In contrast, the sample having concentration x = 0.025 has the highest experimental lattice parameters and crystallite size among all doped samples (Table 1). Therefore, we could rule out the effect of size confinement. The possible reason for high strain for x = 0.025 sample might be the presence of multiple phases (Fig. 2A). These phases might boost the disorder and persuade the stress and strain inside the unit cell [32].

In addition, the dislocation density (δ) which gives information about the dislocation lines in the unit volume of the crystal is defined by the formula [7]:

where d is the size of the crystallite and n = 1 is the lowest dislocation density. Table 1 displays the dislocation densities for different compositions. When disorder increases, dislocation density goes up, and vice versa. With the exception of x = 0.015, the data reveal that the disorder decreases as the doping concentration increases.

The X-ray density is given by [33]:

where Z is the number of molecules per unit cell, M is molecular weight, and V is lattice volume. There was an increase in x-ray density observed for the doped sample in comparison to the undoped sample. Further, X-ray density starts to decrease with increasing doping concentration (Table 1). In accordance with prior discussions, the incorporation of Eu+3 as a donor at the Ba site induces lattice distortion due to differences in the ionic radii of Eu+3 and Ba+2 ions. The creation of cationic vacancies is another outcome of this replacement. Because of this, densification might be hindered and mass movement could be decreased.

4.2 FTIR study

FTIR spectra of pure and doped samples are shown in Fig. 3A–C. The strong absorption bands were observed in the range 400–800 cm−1, 950–1100 cm−1, and 1350–1800 cm−1 (Fig. 3A). A broad peak, centered on 540 cm−1, is assigned to Ti–OI stretching vibrations of TiO6 octahedra [32]. In addition, two more bands appeared near 440 and 414 cm−1 (Fig. 3B). The frequency band near 440 cm−1 is attributed to Ba–O bond vibrations [34]. The weak band near 414 cm−1 may be assigned to the Ti–OII bending vibrations of TiO6 octahedra [35]. The absorption peaks near 425 cm−1 show a slight increase as x (0, 0.005, and 0.015) starts to increase except for the concentration x = 0.025 (Fig. 3B). The effective size of oxygen ion (rO) starts to decrease with doping concentration x (except for x = 0.025) which causes a reduction in Ba–O bond length and enhances the bond strength. Vacancies also act as a repellent to neighboring oxygen ions, which may lengthen the Ba–O bond and somewhat weaken it.

In order to explain this variation in wavenumber, we must take into account the combined effect of mass and force variation. The wavenumber is given by [36]

where k is force constant and µ is reduced mass. The reduced mass can be written as follows:

where m denotes mass while subscript M stands for metal ion(s) (Ba, Eu, and Ti) and oxygen. If we calculate the reduced mass for A-site in Ba1−3x/2EuxTiO3 samples, Eq. 24 can be rewritten as follows:

Table 3 clearly shows that the reduced mass of A-site ions continuously reduces with increasing doping concentration. At the same time, the bond length is decreased and the Coulombian force is increased when Ba+2 ions are used instead of Eu+3 ions. These two factors increase the force constant with increasing doping concentration. When all of the aforementioned phenomena are considered together, they raise the force constant and lower the reduced mass, leading to a small rise in wavenumber at 425 cm−1 (Fig. 3B). If we compare the shifting of the doped samples peak with respect to the pure barium titanate sample, we can write [37]

where BT is pure BaTiO3, BTEu is Ba1−3x/2EuxTiO3, and other symbols have their usual meaning.

Using Eq. 26, we can conclude that the force constant of doped barium titanate samples increases except for x = 0.0025. An almost similar trend is perceived for the peaks near 540 cm−1. This increase in wavenumber indicates an increase in bond energy. As the concentration of Eu+3 doping increases, more vacancies are produced to compensate for the charge. These vacancies will exert drastic stress on TiO6 octahedra. Consequently, TiO6 octahedra will start to shrink and Ti+4 and O−2 ions will get closer. These results are also supported by Eq. 9 (Table 2). These FTIR results are in good agreement with XRD results.

This reduction in bond length between Ti+4 and O−2 ions boosts the bond strength. Ghosh et al. [38] also reported the same trends for Sm+3 doping in the barium zirconium titanate system. When doping concentration is x = 0.025, a decrease is observed which implies a weakening of bond strength. This behavior can be explained by using XRD data which reveals that there is an increase in experimental lattice constant if doping concentration increases from x = 0.015 to 0.025 (Table 1). Fractional tolerance factor t2 (Eq. 10) also decreases for x = 0.025 which shows the dangling nature of B-site ions and the reduction of bond length at B-site. After doping, the absorbance bands at around 440 and 540 cm−1 become more distinct and refined, suggesting enhanced crystallinity. The absorption bands near 850 cm−1, 1010 cm−1, and 1450 cm−1 confirm the presence of carbonate. The instance peaks centered near 1438 cm−1 correspond to the asymmetric stretching of simple \({\text{CO}}_{3}^{-2}\) ion. The absorption peak centered near 1481 cm−1, for concentrations x = 0.015 and 0.025, is attributed to the asymmetric stretch of the unidentate carbonate ligand. Another small absorption peak that appeared at 1383 cm−1, for concentration x = 0.025, can be assigned to the symmetric stretching of the unidentate carbonate ligand [39].

The small absorption peaks at 501 cm−1, 1014 cm−1, and 1410 cm−1 for x = 0.015 and 0.025 confirm the presence of Eu–O bond. These results confirm the presence of Eu2O3 in samples having concentrations x = 0.015 and 0.025. The presence of Eu2O3 is also confirmed by the XRD data; however, this is limited to a concentration of x = 0.025. The FTIR technique is more sensitive than XRD, so it can detect tiny amounts of substances. The absorption peak located near 2320 cm−1 is attributed to CO2 adsorbed on the surfaces of perovskite [40]. This could be explicated by considering a dipole–dipole interaction between the perovskite crystal and the polar CO2 molecule [39]. The broad absorption bands near 3400 and 1630 cm−1 correspond to stretching vibration (\({\nu }_{OH}\)) and bending vibration (\({\delta }_{OH}\)) of molecularly adsorbed water [34]. It should be noted that these bands were absent in the pure barium titanate sample. The possible reason for the appearance of these bands after doping could be the hygroscopic nature of Eu2O3. Vital information related to uptake mechanism of residual gases can be retrieved by combining the FTIR data with TGA-DTA data. Thermal analysis (TGA-DTA) shows that the water vapor (H2O) and carbon dioxide (CO2) released at different temperatures during reaction (Fig. S1, Supplementary Data). The calcination process was carried out at 1000 °C. At such high temperatures, CO2 may react with barium titanate via a process known as carbonation. According to the carbonation process, the interaction between CO2 and barium titanate may create traces of barium carbonate (BaCO3) and titanium dioxide (TiO2). Here CO2 not only adsorbs onto the surface of barium titanate in this reaction, but it also participates in a chemical process that changes the composition of the material. The newly formed barium carbonate and titanium dioxide may remain on the surface or infuse into the bulk of the substance. In addition, the surface hydroxyl groups, which result due to dissociation of adsorbed water, produce more reactive sites on the surfaces of the perovskite structure. The CO2 reacts with surface hydroxyl groups (OH−) to form bicarbonate or carbonate species which are clearly reflected in FTIR data (1481 cm−1, 1438 cm−1, 1383 cm−1, 2320 cm−1 peaks). At lower doping levels of Eu (x = 0.000 and 0.005), the BaCO3 and TiO2 peaks are not visible. This behavior indicates that the BaCO3 and TiO2 infuse into the bulk substance. At higher doping levels of Eu (x = 0.015 and 0.025), bicarbonate/carbonate and TiO2 peaks are visible. The hygroscopic nature of Eu2O3 provides more OH– active sites which radially interact with CO2 to form bicarbonate/carbonate and TiO2.

4.3 Morphological study

The FE-SEM micrographs of the sintered at 900 °C BaTiO3 ceramic samples (both pure and doped with Eu) are shown in Fig. 4A–D. Each clumped cluster corresponds to either pure or Eu-doped BaTiO3 nanocrystals, as seen clearly in the FE-SEM micrographs. A huge difference between particle and crystallite sizes was observed in pure and Eu-doped BaTiO3 samples (Table 1 and Fig. S4). The data suggest that the particles were formed by many aggregated crystallites. The clumping of crystallites is likely caused by the clamping force [41]. FE-SEM data show that the particle size of the samples was influenced by Eu-doping (Table 1). Particle size reduces initially as the doping percentage increases. However, at 2.5% doping concentration, particle size increased. The findings are compatible with prior research on lanthanide doping in BaTiO3 ceramics [39]. As we discussed above in the XRD study, Eu+3 doping initiates lattice distortion due to the formation of cationic vacancies and consuming energy. In order to minimize this energy, the cationic vacancies gathered at/or near the grain boundaries and hinder the grain growth [42, 43]. Meanwhile, there was an increase in particle size for 2.5% doping concentration. It was reported earlier that a merging process results at a higher doping concentration of Eu [44].

4.4 Optical study

The optical properties of pure and Eu+3-doped barium titanate (Ba1−3x/2EuxTiO3, x = 0.000, 0.005, 0.015, and 0.025) samples were inspected through UV–Vis–NIR spectroscopy between the wavelength range 200–800 nm range at room temperature. Figure 5A shows the pure and doped samples exhibit weak absorption peaks below the 300 nm wavelength range. These peaks are originated by the virtue of charge transfer from O-2p (valance band) to Ti-3d (conduction band) states. This charge transfer results due to the two body collisions of electron and photon in which electron–hole pairs are produced by absorbing photons. The distinct absorption peaks are observed at 261 and 304 nm for Eu+3-doping concentrations x = 0.005 and 0.015, respectively. This red shift may be attributed to reduced crystallite size [45]. The red shift observed in the UV–Vis spectrum for x = 0.005 may also be attributed to several factors related to the structural and electronic changes induced by Eu+3 doping. First, the incorporation of Eu+3 ions into the BaTiO3 lattice can cause lattice distortions, altering the electronic band structure. This can result in a reduction of the optical band gap, which shifts the absorption peaks towards longer wavelengths, hence, a red shift. Additionally, Eu+3 ions can introduce localized states within the band gap, facilitating transitions at lower energies compared to the undoped material. These modifications in the electronic environment due to dopant incorporation effectively lower the energy required for electronic transitions, leading to the observed red shift in the UV–Vis spectrum. Such distinct peaks in this range were not detected for the concentration x = 0.000 and 0.025. In addition, another peak is also observed at 224 nm which may be attributed to TiO2. Nayak et al. also reported such peaks [34].

UV–Vis response for Ba1−3x/2EuxTiO3 ceramics. A Optical absorbance spectra of all the samples (x = 0.000, 0.005, 0.015, and 0.025) at room temperature. B-E Tauc’s plot ((αhυ)2 versus Energy (eV)) and Urbach energy plots (lnα) versus Energy (eV), inset for all samples (x = 0.000–0.025). F Variation in crystallite size, strain, band gap energy, and Urbach energy with Eu-doping concentrations

The optical band gap (Eg) and Urbach energy (EU) of the samples can be deduced by using the absorption spectra datum. The absorption coefficient, α(ν) which depends on frequency, is given by [46]

where A represents absorbance and t is the thickness of the sample. The absorption coefficient is directly related to the optical band gap energy (Eg) by the relationship proposed by Tauc [47], Mott and Davis [48], as follows:

where Eph (Eph = hν) is the energy of the photon, and C and n are constants. The exponent ‘n’ depends upon the nature of the electronic transition whether it is a direct or indirect transition.

For direct allowed and direct-forbidden transitions, the exponent ‘n’ has the numerical values 1/2 and 3/2, respectively. If exponent ‘n’ has the numerical values 2 and 3, the transitions will be indirect allowed and indirect forbidden transitions, respectively. Barium titanate is a direct bandgap material like most of the other perovskite structures [49]. Thus for our present system, only direct transitions (n = 1/2) will be considered for the bandgap determination. Thus, Eq. 29 can be rewritten as follows:

Figure 5B–E shows the plots of [Ephα(ν)]2 against photon energy (hν) for pure and Eu+3-doped samples. The optical band gap (Eg) can be obtained by extrapolating the linear portion of curves to the photon energy axis at [Ephα(ν)]2 = 0 (Fig. 5B–E). The calculated values of optical band gap (Eg) for pure and Eu+3-doped samples, using the Tauc plot, are summarized in Table 4. The datum clearly shows that the Eu+3 doping reduces the optical bandgap energy. In the present work, the optical band gap for the pure barium titanate sample (x = 0.000) is less than its reported bulk value of 3.20 eV [50]. It was reported earlier that the optical band gap energy may be influenced by crystallite size, strain, impurities, lattice constant, and defects [45]. The optical band gap shrinkage (ΔEg) can be correlated to strain as follows [49]:

where (ΔEg)I is the reduction in optical bandgap due to strain and (ΔEg)II comprises the reduction in bandgap due to exchange–correlation and electron-ionized impurity interactions.

This optical band shrinkage of pure barium titanate sample (x = 0.000) might be correlated to residual stresses caused by crystallite size reduction and also electron–phonon interactions. Ramakanth et al. [49] also reported the reduced bandgap energy (2.53 eV) for barium titanate nanoparticles. Furthermore, the pure barium titanate sample (x = 0.000) shows the highest strain among all the samples. This strain can cause a reduction in the optical band gap (Eq. 31). Thus, the possible reason for band gap reduction in pure barium titanate sample might be a combined effect of crystallite size reduction and high strain values. The variation of strain, crystallite size, optical band gap energy, and Urbach energy with respect to doping is shown in Fig. 5F. The Eu+3-doped samples show optical band gap shrinkage in comparison to the pure barium titanate sample (x = 0.000) (Table 4). The optical band gap energy of Eu+3-doped samples first decreases for the concentrations x = 0.005 and 0.015 and then increases for concentration x = 0.025. This decrease in optical band gap energy, with an increase in Eu+3 doping concentration, may be attributed to the formation of Ba vacancies at the A-site. The presence of these vacancies reduces the lattice constant and produces distortion in TiO6 octahedra. The optical band gap is reduced because to the distortion in TiO6 octahedra, which creates sub-electronic defect levels [51].

As doping concentration increases, more and more defect sub-levels will be introduced and a reduction in bandgap will be observed. For doping concentration x = 0.005, the sample shows the least strain among all the samples and relatively bigger crystallite size in comparison to pure barium titanate. The reduction in strain reduces the band shrinkage while lattice distortions try to increase the bandgap shrinkage. The interplay of these processes alters the bandgap. The data show shrinkage in bandgap for x = 0.005 indicating that the lattice distortions effect dominates over strain. The highest shrinkage in the optical band gap is found for doping concentration x = 0.015. For doping concentration x = 0.015, the sample shows the smallest particle size among all samples and increased strain value (Fig. 5F). The optical band gap shrinkage in x = 0.015 might be a combined effect of lattice distortion, strain effect, and also particle size effect. An increase in optical bandgap is observed for the concentration x = 0.025, even the sample shows a high value of strain, highest concentration, and highest particle size among all. The Burstein-Moss (BM) effect allows us to understand this widening of the energy band gap [52]:

where electron’s concentration (ne), Planck’s constant (h), and the electron’s effective mass \((m_{v} c^{*} )\) are all variables in this equation. Bandgap renormalization happens when concentrations rise above the Mott critical density. The lowest energy states are blocked and the conduction band is substantially filled with the increasing number of free electrons. Consequently, an increase in the energy bandgap is observed [45, 53].

The Urbach energy (EU) is linked with the defect bands formed in the bandgap. The polycrystalline and disordered systems show a tailing in absorption spectra. In the tailing portion, the absorption coefficient shows variation with respect to photon energy given by [54]

where the symbols have their usual meaning. The Urbach energy (EU) can be calculated by plotting a curve between ln(α) and photon energy (hv). The slope of this line is equal to the reciprocal of the Urbach energy (EU). The Urbach plots are shown in Fig. 5B–D (inset), and the Urbach energy is tabulated in Table 4. The datum clearly show that there is the Urbach energy and optical band gap are changing inversely after Eu+3 doping (Table 4 and Fig. 5F). It should also be noted that there is a steep difference in Urbach energy between undoped samples and doped samples, but in case of doped samples, this difference in Urbach energy is small (Table 4). The one possible reason for this behavior might be the formation of intermediate states in the optical band gap due to Eu+3 doping, and for higher concentration, it may create subsequent states. The other possibility might be the Urbach energy improved due to the enriched probability of carrier transitions by localized states. Borah et al. reported similar trends for optical band gap and Urbach energy variation for Gd+3-doped BaTiO3 nanostructures [54].

Barium titanate with a 2.72 eV optical band gap has the potential to be used in a variety of optoelectronic devices. An optical band gap of 2.72 eV corresponds to a wavelength of around 456 nm, which falls in the visible light spectrum, specifically in the blue range. Modulators, switches, and couplers that operate in the blue wavelength region might benefit from Eu-doped BaTiO3-based waveguides.

4.5 Dielectric study

The dielectric response of pure and Eu+3-doped barium titanate samples in the frequency range 1 kHz–2 MHz is shown in Fig. 6A, B. All the samples show almost steady dielectric constant in the frequency range 1 kHz–2 MHz at room temperature (Fig. 6A). Dielectric data show two trends. First, all of the samples have a low dielectric constant in comparison to the bulk BaTiO3. Second, all the doped samples (from x = 0.005 to 0.025) have higher dielectric constant in comparison to pure barium titanate which further decreases with doping concentration. The low value of the dielectric constant in samples can be attributed to the co-existence of a non-ferroelectric grain boundary layer or dead layer. These dead layers have a dilution effect on the dielectric constant and can reduce the dielectric constant up to the order of 100 than that of the ferroelectric region. The reason for increased dielectric constant in doped samples might be space charge polarization which can be explained by Maxwell–Wagner interfacial model [55].

The substitution of Eu+3 ions in barium titanate lattice results in metal ion vacancies as discussed in XRD analysis. The Eu+3 ions can migrate towards the outer surface of the grain through hoping with cation vacancies. This migration of Eu+3 continues until the concentration of Eu+3 becomes too high at surfaces. If the cooling rate is slow after calcination, the elimination of Ti+3 and oxygen vacancies could be possible by the re-oxidation process. The re-oxidation process forms an insulating layer on the grain surfaces. On the other hand, grains have relatively high conductivity. This difference in conducting behavior between grain and grain boundary causes charge accumulation at the surface and enhances the space charge polarization. This might be one of the possible reasons for the increased dielectric constant of doped samples.

An infusion of Eu+3 ions will enhance the microstructure of BaTiO3 by increasing the size of grains and decreasing impedance at grain boundaries. Better grain boundary quality allows for smoother polarization processes and reduces the dielectric losses, resulting in a consistent dielectric constant across wide frequency range. The addition of Eu+3 ions to BaTiO3 will also have an effect on interfacial polarization. The strong electric fields created by the highly charged Eu+3ions cause the dipoles to align more effectively even at higher frequencies. This steady dipole alignment delivers a constant dielectric response. As a consequence, we infer that the incorporation of Eu+3ions to BaTiO3 improves grain boundary quality, enhances interfacial polarization, and reduces space charge effects. These factors collectively contribute to the observed almost constant frequency response of the dielectric constant in Eu-doped BaTiO3 samples.

Figure 6A shows that the dielectric constant decreases with increasing doping concentration (x = 0.005 to 0.025). There may be three factors that can influence the reduction in dielectric constant: the existence of Eu+2 ions, the presence of other phases, and porosity. It has been reported earlier that Eu+3 co-exists with Eu+2 ions at the A-site and Ti+4 also co-exists with Ti+3 ions at the B-site at higher doping levels [56, 57]. The Kröger–Vink notation for point defects at the A-site and B-site can be written as follows [58]:

It is clear from Eq. 38 that the Eu+3 ions may be BaCO3 and Eu2O3) and barium orthotitanate (Ba2TiO4) are present at higher concentrations (Figs. 2A, 3 and S3, Supplementary Data). These low dielectric constant compounds may be the second possible cause of reduced dielectric constant at higher concentrations. The decrease in the dielectric constant in doped samples with increasing doping concentration (x = 0.015–0.025) can also be attributed to microstructural changes. The density of Eu+3-doped barium titanate starts to alter to metastable Eu+2 ions by trapping 3d electrons from Ti+3 ions. This partial conversion of Eu+3 ions (donor type) to metastable Eu+2 ions (acceptor type) will change the defect from electronic to vacancy type. This change may be one of the possible causes of a decrease in the dielectric constant (for x = 0.015 and 0.025).

The XRD, FTIR, and EDX-elemental mapping data reveal that the traces of unreacted compounds (TiO2, BaCO3, and Eu2O3) and barium orthotitanate (Ba2TiO4) are present at higher concentrations (Figs. 2A, 3 and S3, Supplementary Data). These low dielectric constant compounds may be the second possible cause of reduced dielectric constant at higher concentrations. The decrease in the dielectric constant in doped samples with increasing doping concentration (x = 0.015–0.025) can also be attributed to microstructural changes. The density of Eu+3-doped barium titanate starts to diminish as doping concentration increases from x = 0 to 0.025 (Table 1). As a result, there is an augmentation in material porosity, potentially constituting the third contributing factor responsible for the decline in dielectric constant as the doping concentration rises.

The variation of dissipation factor (tanδ) with frequency is depicted in Fig. 6B for Ba1−3x/2EuxTiO3 ceramics. The dielectric loss shows higher values at lower frequencies and starts to fall gradually up to 800 kHz. Further, there is an increase observed in the frequency range 800–1300 kHz, and after 1300 kHz, the dielectric loss starts falling with the increase in frequency. The fluctuation of the dissipation factor with frequency in the current work is found to be less than that reported by other researchers [53, 56]. The dielectric loss behavior of pure and doped samples can be explained by the relaxation mechanism. The relaxation polarization includes orientational polarization and space charge polarization. The polarization time of these polarizations is of the order of 10–5 s [59]. All polarizations, which include electronic, ionic, orientation, and space charge polarization, contribute to the dielectric constant at lower frequencies. As frequency increases and reaches ~ 102–106 Hz value, only orientation and space charge polarization contribute to dielectric behavior. The charge carriers that are accumulated at grain boundaries in polycrystalline materials behave like a dipole under the action of the alternating field [60]. At higher frequencies, there is a mismatch between the orientation of these dipoles and the applied alternating field. This match causes a loss. In addition, domain wall relaxations also lead the losses at this frequency range.

Figure 7A, B shows the variation of dielectric constant with the temperature at different frequencies for pure and Eu+3-doped barium titanate samples. The dielectric response with respect to temperature is the same for all the samples. The dielectric constant of all samples decreases with increasing frequencies (Fig. 7A). This decrease in the dielectric constant is a consequence of reduced space charge polarization. A steady dielectric constant with an increase in temperature is observed for pure and Eu+3-doped samples (Fig. 7B). Figure 7C illustrates the variation of dissipation factor (tanδ) with the temperature at 1 kHz frequency for pure and Eu+3-doped barium titanate samples. The curves clearly show that the dissipation factor increases with a doping concentration in the temperature range ~ 125–250 K. After 250 K temperature, there is an increase in dissipation factor for x = 0.015 while the samples having concentration x = 0.005 and 0.025 continue to fall with increasing temperature. The increase in dissipation factor with increasing doping concentration might be a consequence of the electrical conductivity phenomenon. As doping increases, more charge carriers are in the picture which can alter the conductivity of the samples. The other factor which may influence the losses is the porosity of the samples. Here the density decreases with an increase in doping concentration which increases the porosity (Table 1). This increase in porosity with the increase in doping concentration may be the other factor that upsurges the dissipation factor with doping concentration [61]. The results are in good agreement with the previous reports [13, 56]. An increase in dissipation factor with temperature is observed for concentration levels x = 0 and 0.015 (Fig. 7C). This behavior might be attributed to the size effect. These two concentration levels have small crystallite sizes (Table 1). The small size samples may have surface imperfections which may contribute to conduction and raise the losses. In contrast, for the concentration level x = 0.005 and 0.025, a decreasing trend with temperature is observed. This behavior might be due to the ferroelectric domain’s ease of switching when subjected to alternating fields via the introduction of heat energy [62].

Temperature-dependent dielectric behavior of Ba1−3x/2EuxTiO3 ceramics, A Variation of the dielectric constant of different samples with temperature at 1 kHz, 100 kHz, and 1000 kHz frequencies. B Variation in the dielectric constant of all Eu-doped samples with the temperature at 100 kHz frequency. C Dielectric loss behavior at 100 kHz frequency

5 Conclusions

Eu+3-doped barium titanate ceramics, formulated as (Ba1−3x/2Eux)TiO3, were successfully synthesized through the conventional solid-state reaction approach. Examination of XRD and FTIR data unveiled the substitution of Ba+2 ions by Eu+3 ions at the A-site, leading to a contraction in lattice parameters. The dielectric analysis indicated the co-existence of both Eu+2 and Eu+3 at A-sites in a metastable state. The determined lattice parameters from experimentation harmonized well with previously established lattice constant prediction models. The optical band gap energy spanned from 2.77 to 2.65 eV, attributable to the interplay of strain effects and cation vacancies, which introduced intermediary energy levels within the bandgap. The shift in Urbach energy was ascribed to the heightened likelihood of carrier transitions and the emergence of intermediary states within the optical bandgap. The relatively subdued value of the ceramics’ dielectric constant could be attributed to the concurrent existence of a non-ferroelectric grain boundary layer or an inert layer. Notably, the frequency and temperature-dependent dielectric constants of the doped samples exceeded those of pure barium titanate, likely influenced by the Maxwell–Wagner interfacial model. Furthermore, the frequency-dependent dissipation factor displayed low values due to relaxation polarization phenomena. Hence, the findings indicate that employing Eu-doped BaTiO3 nanoparticles in optoelectronic devices is viable due to their narrow band gap and minimal dissipation losses.

Data availability

The data of the paper are available with the corresponding authors based on request.

References

D. Lan, H. Li, M. Wang, Y. Ren, J. Zhang, M. Zhang, L. Ouyang, J. Tang, Y. Wang, Recent advances in construction strategies and multifunctional properties of flexible electromagnetic wave absorbing materials. Mater. Res. Bull. 171, 112630 (2024). https://doi.org/10.1016/j.materresbull.2023.112630

D. Lan, Y. Wang, Y. Wang, X. Zhu, H. Li, X. Guo, J. Ren, Z. Guo, G. Wu, Impact mechanisms of aggregation state regulation strategies on the microwave absorption properties of flexible polyaniline. J. Colloid Interface Sci. 651, 494–503 (2023). https://doi.org/10.1016/j.jcis.2023.08.019

P. Thakur, N. Sharma, D. Pathak, P. Sharma, K. Kishore, S. Dhar, M. Lal, State-of-art review on smart perovskites materials: properties and applications. Emergent Mater. 7, 667–694 (2024). https://doi.org/10.1007/s42247-024-00645-w

S. Paul, S. Barman, A. Datta, Zn-based oxide perovskite nanocomposites for energy and sensing applications. J. Mater. Sci. (2024). https://doi.org/10.1007/s10853-024-09765-4

Y.B. Adediji, A.M. Adeyinka, D.I. Yahya, O.V. Mbelu, A review of energy storage applications of lead-free BaTiO3-based dielectric ceramic capacitors. Energ. Ecol. Environ. 8, 401–419 (2023). https://doi.org/10.1007/s40974-023-00286-5

J. Su, J. Zhang, Recent development on modification of synthesized barium titanate (BaTiO3) and polymer/BaTiO3 dielectric composites. J. Mater. Sci. Mater. Electron. 30(3), 1957–1975 (2019). https://doi.org/10.1007/s10854-018-0494-y

A. Kumari, K. Kumari, F. Ahmed, A. Alshoaibi, P.A. Alvi, S. Dalela, M.M. Ahmad, R.N. Aljawfi, P. Dua, A. Vij, S. Kumar, Influence of Sm doping on structural, ferroelectric, electrical, optical and magnetic properties of BaTiO3. Vacuum 184, 109872 (2021). https://doi.org/10.1016/j.vacuum.2020.109872

R. Kumari, S. Kumari, E. Sharma, S. Kumari, J. Dalal, D. Padalia, Structural and optical properties of gadolinium doped barium titanate nano-crystal for multifunctional nanodevices. Opt. Mater. (Amst). (2023). https://doi.org/10.1016/j.optmat.2023.114244

D. William, J.R. Callister, Fundamentals of Materials Science and Engineering, 5th edn. (Wiley, New York, 2001)

C. Pithan, H. Katsu, R. Waser, Defect chemistry of donor-doped BaTiO3 with BaO-excess for reduction resistant PTCR thermistor applications-redox-behaviour. Phys. Chem. Chem. Phys. 22, 8219–8232 (2020). https://doi.org/10.1039/c9cp06793k

J.P. Hernández-Lara, M. Pérez-Labra, F.R. Barrientos-Hernández, J.A. Romero-Serrano, A. Hernández-Ramírez, M. Reyes-Pérez, J.C. Juárez-Tapia, A.M. Teja-Ruiz, V.E. Reyes-Cruz, J.C. Ramírez-Castellanos, Synthesis and characterization of BaTiO3 doped with Eu3+ by the reaction solid-state method. Miner. Met. Mater. Ser. Part F1, 723–729 (2020). https://doi.org/10.1007/978-3-030-36628-5_71

Y. Tsur, T.D. Dunbar, C.A. Randall, Crystal and defect chemistry of rare earth cations in BaTiO3. J. Electroceramics 7, 25–34 (2001). https://doi.org/10.1023/A:1012218826733

D.Y. Lu, T. Ogata, H. Unuma, X.C. Li, N.N. Li, X.Y. Sun, Self-compensation characteristics of Eu ions in BaTiO3. Solid State Ionics 201, 6–10 (2011). https://doi.org/10.1016/j.ssi.2011.07.021

C.Z. Ye, J. Yang, L.X. Yao, N.Y. Chen, Regularities of formation and lattice distortion of perovskite-type compounds. Chinese Sci. Bull. 47(6), 458–460 (2002)

A.S. Verma, V.K. Jindal, Lattice constant of cubic perovskites. J. Alloys Compd. 485, 514–518 (2009). https://doi.org/10.1016/j.jallcom.2009.06.001

L.Q. Jiang, J.K. Guo, H.B. Lin, M. Zhu, X. Zhou, P. Wu, C.H. Li, Prediction of lattice constant in cubic perovskites. J. Phys. Chem. Solids 67, 1531–1536 (2006). https://doi.org/10.1016/j.jpcs.2006.02.004

R.L. Moreira, A. Dias, Comment on “Prediction of lattice constant in cubic perovskites.” J. Phys. Chem. Solids 68, 1617–1622 (2007). https://doi.org/10.1016/j.jpcs.2007.03.050

R. Ubic, Revised method for the prediction of lattice constants in cubic and pseudocubic perovskites. J. Am. Ceram. Soc. 90, 3326–3330 (2007). https://doi.org/10.1111/j.1551-2916.2007.01881.x

Z. Zeng, Y. Xu, Z. Zhang, Z. Gao, M. Luo, Z. Yin, C. Zhang, J. Xu, B. Huang, F. Luo, Y. Du, C. Yan, Rare-earth-containing perovskite nanomaterials: design, synthesis, properties and applications. Chem. Soc. Rev. 49, 1109–1143 (2020). https://doi.org/10.1039/c9cs00330d

I.M. Reaney, E.L. Colla, N. Setter, Dielectric and structural characteristics of Ba- and Sr-based complex perovskites as a function of tolerance factor. Jpn. J. Appl. Phys. 33, 3984 (1994). https://doi.org/10.1143/JJAP.33.3984

D. Padalia, G. Bisht, U.C. Johri, K. Asokan, Fabrication and characterization of cerium doped barium titanate/PMMA nanocomposites. Solid State Sci. 19, 122–129 (2013). https://doi.org/10.1016/j.solidstatesciences.2013.02.002

R. Ubic, K. Tolman, K. Chan, N. Lundy, S. Letourneau, W.M. Kriven, Effective size of vacancies in aliovalently doped SrTiO3 perovskites. J. Alloys Compd. 575, 239–245 (2013). https://doi.org/10.1016/j.jallcom.2013.04.091

R. Ubic, K. Tolman, K. Talley, B. Joshi, J. Schmidt, E. Faulkner, J. Owens, M. Papac, A. Garland, C. Rumrill, K. Chan, N. Lundy, H. Kungl, Lattice-constant prediction and effect of vacancies in aliovalently doped perovskites. J. Alloys Compd. 644, 982–995 (2015). https://doi.org/10.1016/j.jallcom.2015.04.213

A. Altomare, N. Corriero, C. Cuocci, A. Falcicchio, A. Moliterni, R. Rizzi, QUALX2.0: a qualitative phase analysis software using the freely available database POW-COD. J. Appl. Crystallogr. 48, 598–603 (2015). https://doi.org/10.1107/S1600576715002319

A. Altomare, C. Cuocci, C. Giacovazzo, A. Moliterni, R. Rizzi, N. Corriero, A. Falcicchio, EXPO2013: a kit of tools for phasing crystal structures from powder data. J. Appl. Crystallogr. 46, 1231–1235 (2013). https://doi.org/10.1107/S0021889813013113

C.R. García, J. Oliva, M.T. Romero, R. Ochoa-Valiente, L.A.G. Trujillo, Effect of Eu3+ concentration on the luminescent properties of SrTiO3 phosphors prepared by pressure-assisted combustion synthesis. Adv. Mater. Sci. Eng. (2015). https://doi.org/10.1155/2015/291230

J.P. Hernández-Lara, M. Pérez-Labra, J.A. Romero-Serrano, A. Hernández-Ramírez, F.R. Barrientos-Hernández, R. Martínez-López, V.E. Reyes-Cruz, J.A. Cobos-Murcia, Phase evolution of Ba1-xEuxTi1-x/4O3 during the sintering process in air with high temperature in situ X-ray diffraction. Rev. Metal. 56, 1–10 (2020). https://doi.org/10.3989/REVMETALM.167

D. Makovec, Z. Samardžija, M. Drofenik, Solid solubility of holmium, yttrium, and dysprosium in BaTiO3. J. Am. Ceram. Soc. 87, 1324–1329 (2004). https://doi.org/10.1111/j.1151-2916.2004.tb07729.x

N. Kadian, R. Kumari, A. Panchal, J. Dalal, D. Padalia, Structural and optical properties of gadolinium doped-magnetite nano-crystal for photocatalytic application. J. Alloys Compd. (2023). https://doi.org/10.1016/j.jallcom.2023.170811

S. Kumari, E. Sharma, J. Verma, J. Dalal, A. Kumar, Structural and photoluminescence properties of Dy-doped nanocrystalline ZrO2 for optoelectronics application. Ceram. Int. 49, 20185–20192 (2023). https://doi.org/10.1016/j.ceramint.2023.03.142

P. Pyykkö, M. Atsumi, Molecular single-bond covalent radii for elements 1–118. Chem. A Eur. J. 15, 186–197 (2009). https://doi.org/10.1002/chem.200800987

Y. Li, Z. Zhang, Y. Chen, D.A. Hall, Electric field-induced strain in core-shell structured BiFeO3K0.5Bi0.5TiO3PbTiO3 ceramics. Acta Mater. 160, 199–210 (2018). https://doi.org/10.1016/J.ACTAMAT.2018.08.033

M.V. Zdorovets, A.L. Kozlovskiy, Study of the effect of La3+ doping on the properties of ceramics based on BaTiOx. Vacuum (2019). https://doi.org/10.1016/j.vacuum.2019.108838

S. Nayak, B. Sahoo, T.K. Chaki, D. Khastgir, Facile preparation of uniform barium titanate (BaTiO3) multipods with high permittivity: impedance and temperature dependent dielectric behavior. RSC Adv. 4, 1212–1224 (2014)

X. Jin, D. Sun, M. Zhang, Y. Zhu, J. Qian, Investigation on FTIR spectra of barium calcium titanate ceramics. J. Electroceramics 22, 285–290 (2009). https://doi.org/10.1007/s10832-007-9402-1

C.N.R. Rao, Chemical Applications of Infrared Spectroscopy (Academic Press, New York, 1963)

C. Ostos, L. Mestres, M.L. Martínez-Sarrión, J.E. García, A. Albareda, R. Perez, Synthesis and characterization of A-site deficient rare-earth doped BaZrxTi1−xO3 perovskite-type compounds. Solid State Sci. 11, 1016–1022 (2009). https://doi.org/10.1016/j.solidstatesciences.2009.01.006

S.K. Ghosh, M. Ganguly, S.K. Rout, T.P. Sinha, Structural and dielectric relax or properties of A-site deficient samarium-doped (Ba1−xSm2x/3)(Zr0.3Ti0.7O3) ceramics. J. Mater. Sci. 49(15), 5441–5453 (2014)

M.D.C. Blanco López, G. Fourlaris, B. Rand, F.L. Riley, Characterization of barium titanate powders: barium carbonate identification. J. Am. Ceram. Soc. 82, 1777–1786 (1999). https://doi.org/10.1111/j.1151-2916.1999.tb01999.x

C. Proust, E. Husson, G. Blondiaux, J.P. Coutures, Residual carbon detection in barium titanate ceramics by nuclear reaction technique. J. Eur. Ceram. Soc. 14, 215–219 (1994). https://doi.org/10.1016/0955-2219(94)90089-2

G. Panomsuwan, H. Manuspiya, Correlation between size and phase structure of crystalline BaTiO3 particles synthesized by sol-gel method. Mater. Res. Express. 6, 065062 (2019). https://doi.org/10.1088/2053-1591/AB101B

Y. Wang, K. Miao, W. Wang, Y. Qin, Fabrication of lanthanum doped BaTiO3 fine-grained ceramics with a high dielectric constant and temperature-stable dielectric properties using hydro-phase method at atmospheric pressure. J. Eur. Ceram. Soc. 37, 2385–2390 (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.01.035

S.K. Jo, J.S. Park, Y.H. Han, Effects of multi-doping of rare-earth oxides on the microstructure and dielectric properties of BaTiO3. J. Alloys Compd. 501, 259–264 (2010). https://doi.org/10.1016/j.jallcom.2010.04.085

L.V. Maneeshya, S.S. Lekshmy, P.V. Thomas, K. Joy, Europium incorporated barium titanate thin films for optical applications. J. Mater. Sci. Mater. Electron. 25, 2507–2515 (2014). https://doi.org/10.1007/s10854-014-1903-5

S. Soni, S. Kumar, B. Dalela, S. Kumar, P.A. Alvi, S. Dalela, Defects and oxygen vacancies tailored structural and optical properties in CeO2 nanoparticles doped with Sm3+ cation. J. Alloys Compd. 752, 520–531 (2018). https://doi.org/10.1016/J.JALLCOM.2018.04.157

S.F. Ismail, M.R. Sahar, S.K. Ghoshal, Physical and absorption properties of titanium nanoparticles incorporated into zinc magnesium phosphate glass. Mater Charact 111, 177–182 (2016). https://doi.org/10.1016/j.matchar.2015.11.030

J. Tauc, Optical properties of amorphous semiconductors, in Amorphous and liquid semiconductors. (Springer, Boston, 1974), pp.159–220. https://doi.org/10.1007/978-1-4615-8705-7_4

N.F. Mott, E.A. Davis, Conduction in non-crystalline systems V conductivity, optical absorption and photoconductivity in amorphous semiconductors. Philos. Mag. 22, 903–922 (1970)

S. Ramakanth, K.C. James Raju, Band gap narrowing in BaTiO3 nanoparticles facilitated by multiple mechanisms. J. Appl. Phys. (2014). https://doi.org/10.1063/14871776

A. Karvounis, F. Timpu, V.V. Vogler-Neuling, R. Savo, R. Grange, Barium titanate nanostructures and thin films for photonics. Adv. Opt. Mater. 8, 1–23 (2020). https://doi.org/10.1002/adom.202001249

A. Mahapatra, S. Parida, S. Sarangi, T. Badapanda, Dielectric and ferroelectric behavior of bismuth-doped barium titanate ceramic prepared by microwave sintering. JOM 67(8), 1896–1904 (2014). https://doi.org/10.1007/S11837-014-1266-7

B. Choudhury, A. Choudhury, Lattice distortion and corresponding changes in optical properties of CeO2 nanoparticles on Nd doping. Curr. Appl. Phys. 13, 217–223 (2013). https://doi.org/10.1016/j.cap.2012.07.014

G.N. Bhargavi, A. Khare, T. Badapanda, P.K. Ray, N. Brahme, Influence of Eu doping on the structural, electrical and optical behavior of barium zirconium titanate ceramic. Ceram. Int. 44, 1817–1825 (2018). https://doi.org/10.1016/J.CERAMINT.2017.10.116

M. Borah, D. Mohanta, Effect of Gd3+ doping on structural, optical and frequency-dependent dielectric response properties of pseudo-cubic BaTiO3 nanostructures. Appl. Phys. A Mater. Sci. Process. 115, 1057–1067 (2014). https://doi.org/10.1007/s00339-013-7941-7

J.C. Maxwell, A treatise on electricity and magnetism (Macmillan and Co., London, 1873)

D.Y. Lu, Y. Liang, Valence states and dielectric properties of fine-grained BaTiO3 ceramics co-doped with double valence-variable europium and chromium. Ceram. Int. 44, 14717–14727 (2018). https://doi.org/10.1016/j.ceramint.2018.05.100

S.P. Culver, V. Stepanov, M. Mecklenburg, S. Takahashi, R.L. Brutchey, Low temperature synthesis and characterization of lanthanide-doped BaTiO3 nanocrystals. Chem. Commun. 50, 3480–3483 (2014). https://doi.org/10.1039/c3cc49575b

M.T. Da-Yong Lu, T. Koda, H. Suzuki, Structure and dielectric properties of Eu-doped barium titanate ceramics. J. Ceram. Soc. Japan. 113, 721–727 (2005). https://doi.org/10.2109/jcersj.113.721

R. Gao, X. Qin, H. Wu, R. Xu, L. Liu, Z. Wang, C. Fu, W. Cai, G. Chen, X. Deng, Effect of Ti doping on the dielectric, ferroelectric and magnetic properties of Bi0.86La0.08Sm0.14FeO3 ceramics. Mater. Res. Express. (2019). https://doi.org/10.1088/2053-1591/ab3fee

C. Elissalde, J. Ravez, Ferroelectric ceramics: defects and dielectric relaxations. J. Mater. Chem. 11, 1957–1967 (2001). https://doi.org/10.1039/b010117f

M.M.V. Petrović, J.D. Bobić, T. Ramoška, J. Banys, B.D. Stojanović, Electrical properties of lanthanum doped barium titanate ceramics. Mater Charact 62, 1000–1006 (2011). https://doi.org/10.1016/j.matchar.2011.07.013

W. Cai, C. Fu, J. Gao, X. Deng, G. Chen, Z. Lin, Effect of samarium on the microstructure, dielectric and ferroelectric properties of barium titanate ceramics. Integr. Ferroelectr. (2012). https://doi.org/10.1080/10584587.2012.741466

Acknowledgements

Authors are thankful to Central Instrumentation Facility, K.R. Mangalam University, Gurugram, Haryana (India) for providing the facility and support to carry out research work.

Funding

Open access funding provided by Eötvös Loránd University. This work was supported by the K. R. Mangalam University, Gurugram, Haryana (India) through a research grant [KRMU/SeedGrant/FY21/001SBAS01].

Author information

Authors and Affiliations

Contributions

Diwakar Padalia: Conceptualization, Formal analysis, Methodology, Resources, Visualization, Validation, Writing—original draft, Writing—review & editing. Umesh Kumar: Data curation, Formal analysis, Investigation, Writing—review & editing. Prabhakar Bhandari: Formal analysis, Visualization, Writing—review & editing. Jasvir Dalal: Formal analysis, Visualization, Writing—review & editing. Lalit Ranakoti: Data curation, Formal analysis, Writing—review & editing. Tej Singh: Conceptualization, Formal analysis, Visualization, Validation, Writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors do not have any conflicting interests that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Padalia, D., Kumar, U., Bhandari, P. et al. Tuning the structural, optical, and dielectric properties of europium-doped barium titanate ceramics. J Mater Sci: Mater Electron 35, 1375 (2024). https://doi.org/10.1007/s10854-024-12984-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10854-024-12984-9